Compound sound insulation material and preparation method thereof

A technology of sound insulation materials and raw materials, applied in the field of sound insulation materials, can solve the problems of lack of market competitiveness, poor quality of sound insulation materials, poor sound insulation effect, etc., and achieve the effect of enhancing market competitiveness, improving sound insulation effect, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

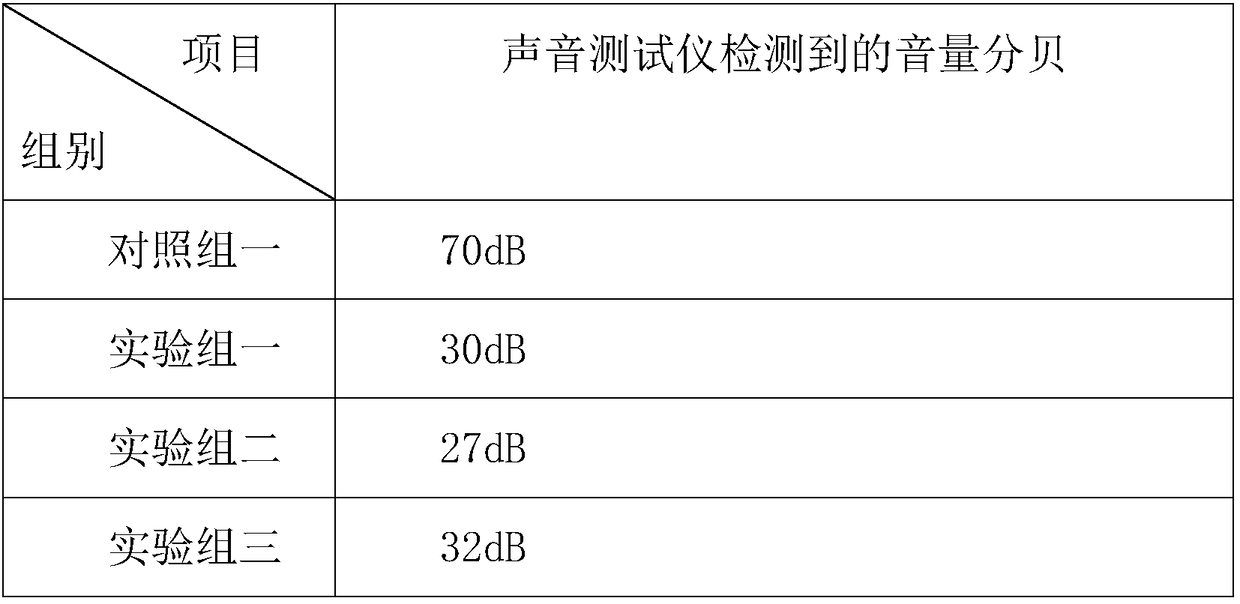

Image

Examples

Embodiment 1

[0033] A composite sound insulation material proposed by the present invention comprises the following raw materials in weight percent: 40% vinyl chloride vinyl acetate resin, 10%-20% low-density polyethylene, 20%-30% methyl vinyl silicone rubber, polymer 5%-10% compatibilizer, 2%-3% diluent, 1%-5% superfine fiber and 1%-2% antioxidant.

[0034] The preparation method of composite sound insulation material comprises the following steps:

[0035] S1, weighing and preparing materials: weigh each raw material according to the weight percentage, mark and save;

[0036] S2, feeding and stirring: put vinyl chloride vinyl acetate resin, low-density polyethylene, methyl vinyl silicone rubber, and polymer compatibilizer into the high-speed mixer in sequence, and stir and mix for 6-10 minutes, then Then add diluent and antioxidant, and stir for 5-10min;

[0037] S3, plasticizing: import the mixture in S2 into an internal mixer for internal mixing for 10 minutes, and the internal mixin...

Embodiment 2

[0041] A composite sound-insulating material proposed by the present invention comprises the following raw materials in percentage by weight: 40% vinyl chloride vinyl acetate resin, 15% low-density polyethylene, 25% methyl vinyl silicone rubber, 10% polymer compatibilizer, Thinner 3%, Microfiber 5% and Antioxidant 2%.

[0042] The preparation method of composite sound insulation material comprises the following steps:

[0043] S1, weighing and preparing materials: weigh each raw material according to the weight percentage, mark and save;

[0044] S2, feeding and stirring: put vinyl chloride vinyl acetate resin, low-density polyethylene, methyl vinyl silicone rubber, and polymer compatibilizer into the high-speed mixer in sequence, and stir and mix for 6-10 minutes, then Then add diluent and antioxidant, and stir for 5-10min;

[0045] S3, plasticizing: import the mixture in S2 into an internal mixer for internal mixing for 10 minutes, and the internal mixing temperature is 12...

Embodiment 3

[0049] A composite sound-insulating material proposed by the present invention comprises the following raw materials in weight percent: 40% vinyl chloride vinyl acetate resin, 30% low-density polyethylene, 20% methyl vinyl silicone rubber, 5% polymer compatibilizer, Thinner 3%, Microfiber 1% and Antioxidant 1%.

[0050] The preparation method of composite sound insulation material comprises the following steps:

[0051] S1, weighing and preparing materials: weigh each raw material according to the weight percentage, mark and save;

[0052] S2, feeding and stirring: put vinyl chloride vinyl acetate resin, low-density polyethylene, methyl vinyl silicone rubber, and polymer compatibilizer into the high-speed mixer in sequence, and stir and mix for 6-10 minutes, then Then add diluent and antioxidant, and stir for 5-10min;

[0053] S3, plasticizing: import the mixture in S2 into an internal mixer for internal mixing for 10 minutes, and the internal mixing temperature is 120°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com