Transparent rubber modified styrene resins

A technology of styrene-based resin and transparent rubber, which is applied in the field of transparent rubber-modified polystyrene-based resin, which can solve the problems that the molding of transparent products cannot be used, and the environmental stress cracking resistance of the resin cannot be met.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

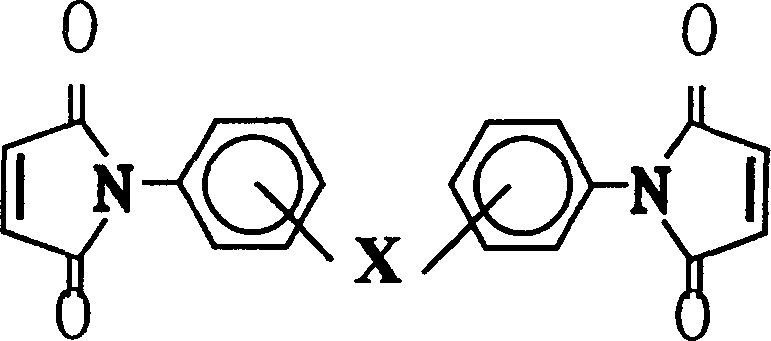

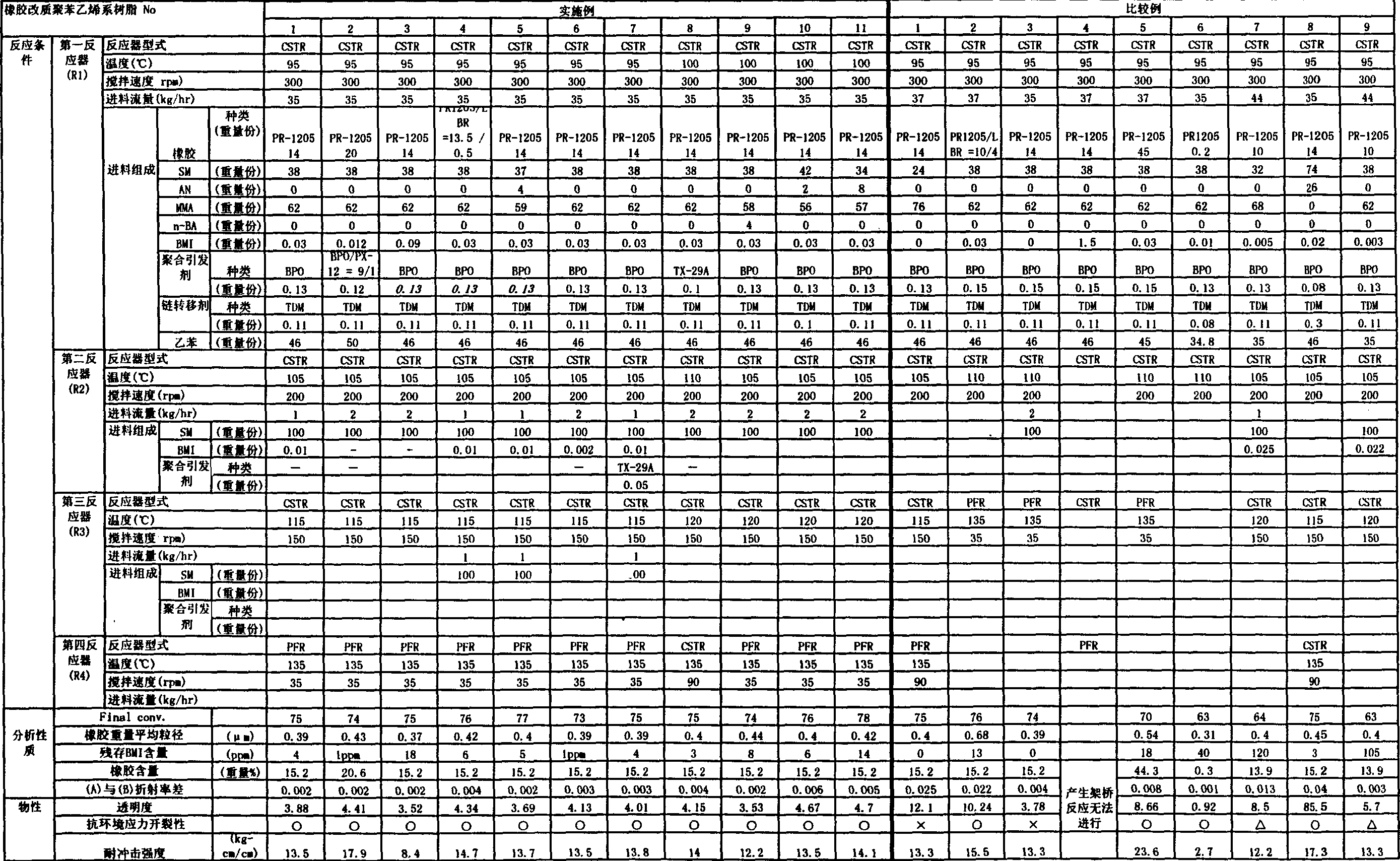

[0079]14.0 parts by weight of a rubbery polymer (PR-1205 manufactured by Chimei Corporation, styrene / butadiene content=25 / 75, 1,2-vinyl content=15.4 wt%, solution viscosity 10, taper block copolymer, Mw=130,000), with 38 parts by weight of styrene, 62 parts by weight of methyl methacrylate, 46 parts by weight of ethylbenzene, 0.03 parts by weight of N,N'-4,4'-diphenylmethane bismaleimide part, with 0.11 parts by weight of dodecyl mercaptan, the feed solution formed by 0.13 parts by weight of dibenzoyl peroxide is continuously supplied to the first reactor continuous polymerization device with a pump flow rate of 35kg / hour reaction, the reacted polymer solution enters the second reactor; in addition, 100 parts by weight of styrene and 0.01 parts by weight of N,N'-4,4'-diphenylmethane bismaleimide form the feed Solution, with the flow rate of pump 1kg / hour, is continuously supplied in the second reactor and reacts, and the polymer solution that the second reactor has reacted ent...

Embodiment 2

[0081] Feed solution is as table 1, with the flow rate of pump 35kg / hour, is supplied continuously in the first reactor continuous polymerization device and reacts, and the polymer solution that has reacted enters the second reactor; In addition, styrene 100 weight The feed solution that forms in 10 parts is continuously supplied to the second reactor continuous polymerization device with the flow rate of pump 2kg / hour and reacts; As shown in Table 1, the final polymerization conversion rate was 74%. After the reaction is completed, the transparent rubber-modified styrenic resin of the present invention can be obtained by the same post-treatment method as in Example 1. Analysis of its rubber content is 20.6% by weight; the weight average particle diameter of rubber particles is 0.43 μm; the refractive index difference between the copolymer continuous phase (B) and the rubber particle dispersed phase (A) is 0.002; remaining N, N '-4, 4'-diphenylmethane bismaleimide is less th...

Embodiment 3

[0083] Feed solution is as table 1, with the flow rate of pump 35kg / hour, is supplied continuously in the first reactor continuous polymerization device and reacts, and the polymer solution that has reacted enters the second reactor; In addition, styrene 100 weight The feed solution that forms in part, with the flow rate of pump 2kg / hour, continuously supply to react in the continuous polymerization device of the second reactor; The rotational speed is shown in Table 1, and the final polymerization conversion rate is 75%. After the reaction is completed, the same post-treatment method is implemented to obtain the transparent rubber-modified styrene resin of the present invention. Analysis of its rubber content is 15.2% by weight; the rubber particle weight average particle diameter is 0.37 μ m; the refractive index difference between the copolymer continuous phase (B) and the rubber particle dispersed phase (A) is 0.002; remaining N, N '-4, The content of 4'-diphenylmethane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com