Flexible pipe for water purifying equipment

A technology for water purification equipment and hoses, applied in the field of hoses, can solve the problems of pipe bursting at the connection between the pipe and the connector, insufficient toughness of the PVC pipe, and low service life, and achieves low water flow resistance and resistance to environmental stress cracking. Excellent performance and enhanced protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

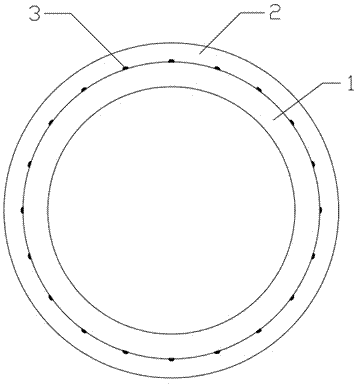

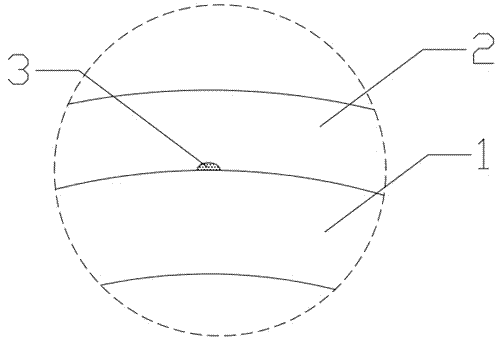

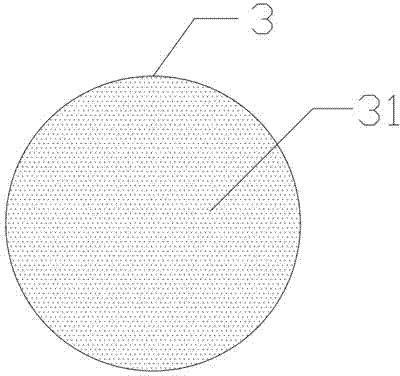

[0079] Example 1: Please refer to the attached Figure 1 to Figure 5 ,and also Figure 7 , a hose for water purification equipment of the present invention, the hose includes a tubular outer layer 2, and also includes a tubular inner layer 1, a braided reinforcement layer 3 arranged between the tubular inner layer 1 and the tubular outer layer 2, The braided reinforcing layer 3 is formed by intersecting linear bodies 31 interspersed in a net shape, and the tubular inner layer 1 is made of materials selected from the following weight ratios:

[0080] Polyolefin 30~50%;

[0081] Polyamide such as polyamideimide 5~10%;

[0082] Polyamide-11 (PA-11) 3~5%;

[0083] Polyamide-12(PA-12) or polyamide-6(PA-6) 10~20%;

[0084] Polysulfide such as polyphenylene sulfide (PPS) 2~10%;

[0085] Polysulfone such as polysulfone (PAS) 2~10%;

[0086] Polyacrylate 5~10%;

[0087] Polyethylene terephthalate (T) 5~15%;

[0088] Polyetheretherketone (EK) 8~20%;

[0089] Polyethylene compou...

Embodiment 2

[0093] Embodiment 2: Please refer to the attached Figure 1 to Figure 5 ,and also Figure 7 , the tubular inner layer 1 can also be made of materials selected from the following weight ratios:

[0094] Polyolefin 30~50%;

[0095] Polyamide such as polyamideimide 5~10%;

[0096] Polyamide-11 (PA-11) 3~5%;

[0097] Polyamide-12(PA-12) or polyamide-6(PA-6) 10~20%;

[0098] Polyimide (PI) 2~10%;

[0099] Polysulfide such as polyphenylene sulfide (PPS) 2~10%;

[0100] Polyurethane 2~10%;

[0101] Polyurea 2~10%;

[0102] Polyester 1~5%;

[0103] Polyethylene terephthalate (T) 5~15%;

[0104] Polyetheretherketone (EK) 8~20%;

[0105] Polyethylene compound 10~20%;

[0106] Polyacrylonitrile 10~20%;

[0107] Polyether ketone ketone (KK) 10~20%.

[0108] The material ratio in Example 2 of the present invention adopts the production scheme in the prior art, and can refer to the patent 201210493812.5, the production process of the hose braiding and winding machine, and the t...

Embodiment 3

[0109] Embodiment 3: Please refer to the attached Figure 1 to Figure 5 ,and also Figure 7 , the tubular inner layer 1 can also be made of materials selected from the following weight ratios:

[0110] Polyolefin 30~50%;

[0111] Polyamide such as polyamideimide 5~10%;

[0112] Polyamide-11 (PA-11) 3~5%;

[0113] Polyamide-12(PA-12) or polyamide-6(PA-6) 10~20%;

[0114] Polyimide (PI) 2~10%;

[0115] Polysulfide such as polyphenylene sulfide (PPS) 2~10%;

[0116] Polyurethane 2~10%;

[0117] Polyurea 2~10%;

[0118] Polyester 1~5%;

[0119] Polyacetal 5~15%;

[0120] Polyether such as polyethersulfone (S) 8~20%

[0121] Polyethylene compound 10~20%;

[0122] Polyacrylonitrile 10~20%;

[0123] Polyether ketone ketone (KK) 10~20%.

[0124]The material ratio in Example 3 of the present invention adopts the production scheme in the prior art, and can refer to the patent 201210493812.5, the production process of the hose braiding and winding machine, and the tubular in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com