Manufacture method of halogen-free semiconductive shielding cable material

A semi-conductive and cable technology, applied in the direction of power cables with shielding layer/conductive layer, etc., can solve the problems that restrict the popularization and application of high-voltage power cables, and achieve the effects of low production cost, good tensile strength and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

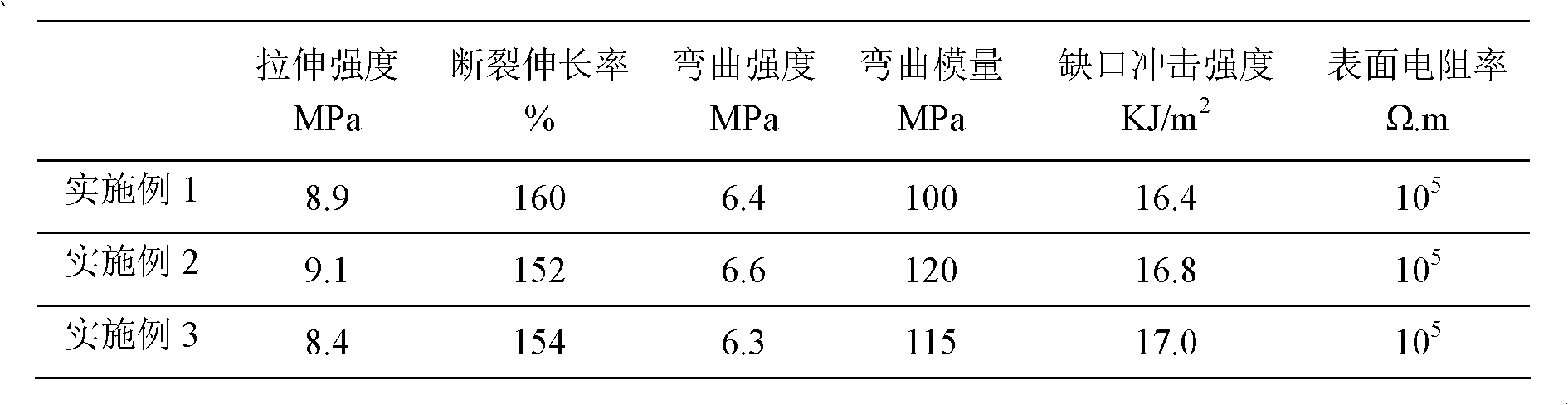

Embodiment 1

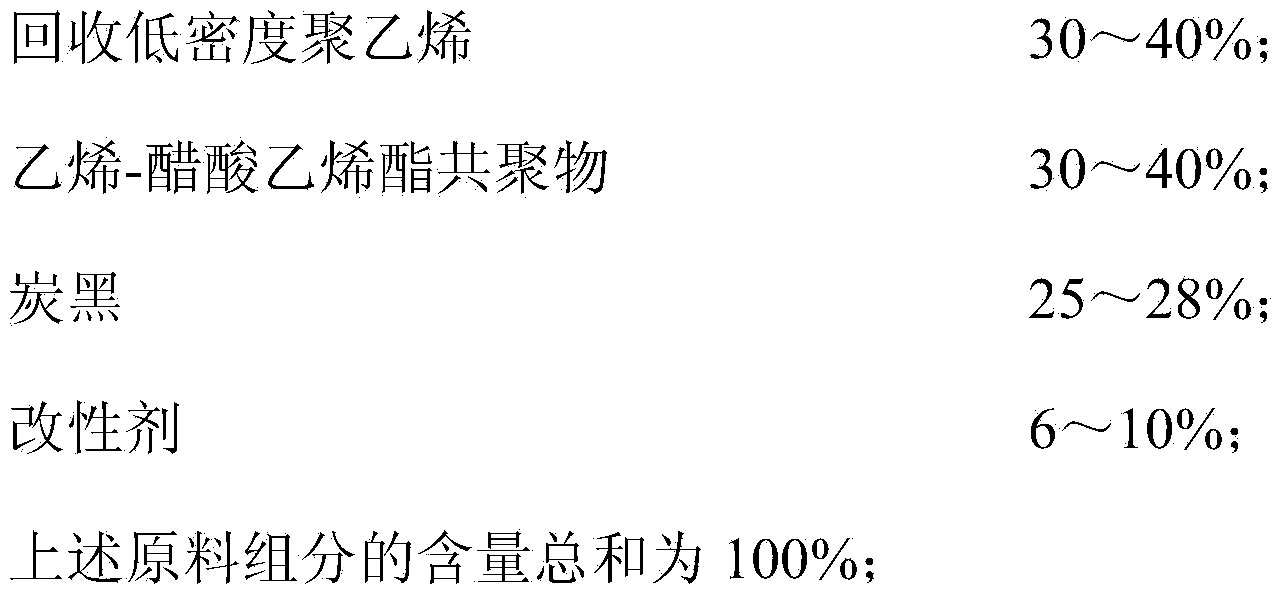

[0026] Raw material components: recycled low-density polyethylene (LDPE) 37kg (melt flow rate at 190°C 2.8g / 10min), ethylene-vinyl acetate copolymer (EVA) 35.5kg (melt flow rate at 190°C 3.2g / 10min) 10min, vinyl acetate content 18%), conductive carbon black 20kg (particle size 20-30nm, specific surface area 1000-1100m 2 / g);

[0027] Modifier: polyethylene wax 1kg, magnesium stearate 1kg, distearyloxy isopropoxy aluminate coupling agent 0.5kg, white mineral oil (3# white oil, molecular weight 250-450, flash point 90 ℃) 5kg. In addition, additives such as antioxidants and pigments can also be added.

[0028] (1) Carbon black was vacuum-dried at 105°C for 2 hours; carbon black and modifier were added to a high-speed mixer, and mixed with a stirrer at a speed of 200rpm for 15min at 80°C;

[0029] (2) Recover LDPE and EVA and dry them under vacuum at 80°C for 2 hours, then stir them evenly with carbon black and modifier; extrude, granulate, and inject the mixed materials;

[0...

Embodiment 2

[0033] Raw material components: 34.5kg of low-density polyethylene (LDPE) (melt flow rate at 190°C is 2.8g / 10min), ethylene-vinyl acetate copolymer (EVA) 33kg (melt flow rate at 190°C is 3.2g / 10min , mass content of vinyl acetate 18%), conductive carbon black 25kg (particle diameter 20-30nm, specific surface area 1000-1100m 2 / g);

[0034] Modifier: polyethylene wax 1kg, trimethyl aluminate 0.5kg, magnesium stearate 1kg, white mineral oil (5# white oil, molecular weight 250-450, flash point 110°C) 5kg. In addition, additives such as antioxidants and pigments can also be added.

[0035] (1) Carbon black was vacuum-dried at 105°C for 2 hours; carbon black and modifier were added to a high-speed mixer, and mixed with a stirrer at a speed of 200rpm for 15min at 80°C;

[0036] (2) reclaim LDPE and EVA and vacuum-dry at 80 DEG C for 2 hours, then stir evenly with carbon black and modifier; extrude, granulate, and inject the mixed material; the process of extrusion, granulation, an...

Embodiment 3

[0038] Raw material components: Low-density polyethylene (LDPE) 34.5kg (melt flow rate at 190°C 2.8g / 10min), ethylene-vinyl acetate copolymer (EVA) 33kg (melt flow rate at 190°C 3.2g / 10min , vinyl acetate content 18%), conductive carbon black 25kg (particle size 20-30nm, specific surface area 1000-1100m 2 / g);

[0039] Modifier: polyethylene wax 1kg, trimethyl aluminate 0.5kg, magnesium stearate 1kg, white mineral oil (5# white oil, molecular weight 250-450, flash point 110°C) 5kg. In addition, additives such as antioxidants and pigments can also be added.

[0040] (1) Carbon black was vacuum-dried at 105°C for 2 hours; carbon black and modifier were added to a high-speed mixer, and mixed with a stirrer at a speed of 200rpm for 15min at 80°C;

[0041] (2) Recover LDPE and EVA and dry in vacuum at 80°C for 2 hours, stir the dried EVA, carbon black and modifier evenly; extrude and granulate the mixed materials;

[0042] The obtained particles are mixed with recycled LDPE, ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com