Modified small hollow high-density polyethylene resin for blow molding and preparation method thereof

A high-density polyethylene and small hollow technology, which is applied in the field of modified high-density polyethylene resin for small hollow blow molding and its preparation, can solve problems such as failure of normal blow molding, sticking of parisons, difference in taste of drinks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

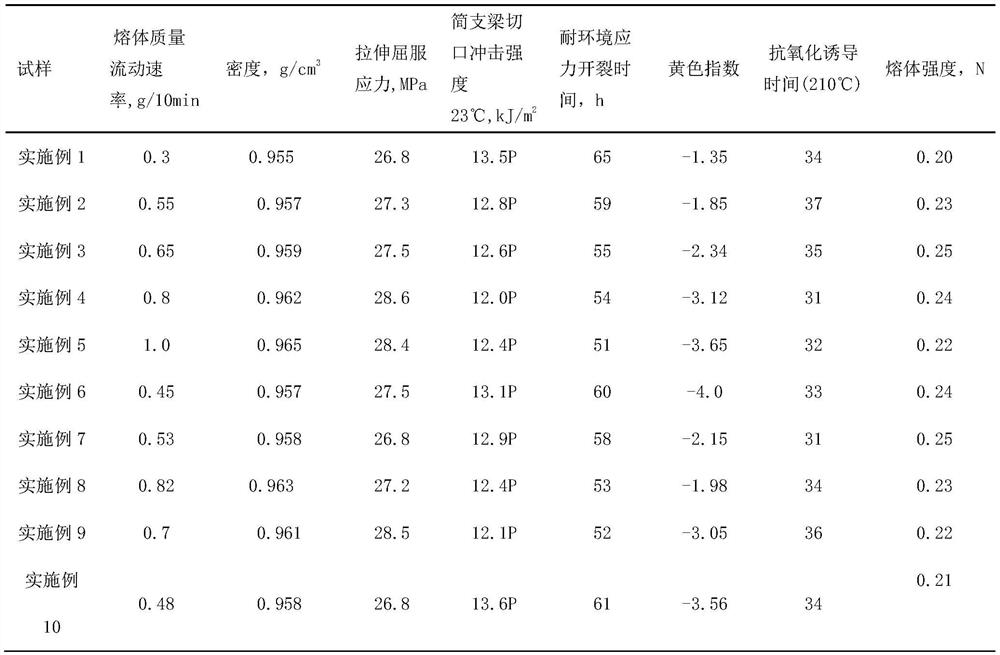

Examples

Embodiment 1

[0037] 1) Add ethylene monomer, 1-hexene and EP30X chromium-based catalyst into the first reactor of the slurry double-loop tube, control the pressure of the reactor at 3.6MPa, and control the reaction temperature at 101°C to carry out the polymerization reaction;

[0038] 2) Add ethylene monomer, 1-hexene and the polymerization product of the first reactor into the second reactor of the slurry double-loop pipe. The pressure of the reactor is controlled at 3.5MPa, the reaction temperature is controlled at 100°C, and a small amount of hydrogen is added at the same time. Control the mass ratio of hydrogen to ethylene to 0.003:1, and continue the polymerization reaction; through polymerization, the melt index is 0.3g / 10min and the density is 0.955g / cm 3 The ethylene-1-hexene copolymer powder;

[0039] 3) Mix 100 parts of ethylene-1-hexene copolymer powder with 0.05 parts of main antioxidant 1076 or 3114, 0.1 part of auxiliary antioxidant 168 or 626, 0.15 parts of light stabilizer 6...

Embodiment 2

[0043] 1) Add ethylene monomer, 1-hexene and EP30X chromium-based catalyst into the first reactor of the slurry double-loop tube. The reactor pressure is controlled at 3.7MPa, and the reaction temperature is controlled at 102°C to carry out the polymerization reaction;

[0044] 2) Add ethylene monomer, 1-hexene and the polymerization product of the first reactor into the second reactor of the slurry double-loop pipe. The pressure of the reactor is controlled at 3.6MPa, the reaction temperature is controlled at 101°C, and a small amount of hydrogen is added at the same time. Control the mass ratio of hydrogen to ethylene to 0.005:1, and continue the polymerization reaction; through polymerization, the melt index is 0.55g / 10min and the density is 0.957g / cm 3 The ethylene-1-hexene copolymer powder;

[0045] 3) Combine 100 parts of ethylene-1-hexene copolymer powder with 0.06 parts of main antioxidant 1076 or 3114 of composite auxiliary agent, 0.12 part of auxiliary antioxidant 16...

Embodiment 3

[0049] 1) Add ethylene monomer, 1-hexene and EP30X chromium-based catalyst into the first reactor of the slurry double-loop tube. The reactor pressure is controlled at 3.8MPa, and the reaction temperature is controlled at 103°C to carry out the polymerization reaction;

[0050] 2) Add ethylene monomer, 1-hexene and the polymerization product of the first reactor into the second reactor of the slurry double-loop pipe. The pressure of the reactor is controlled at 3.7MPa, the reaction temperature is controlled at 102°C, and a small amount of hydrogen is added at the same time. Control the mass ratio of hydrogen to ethylene to 0.006:1, and continue the polymerization reaction; through polymerization, the melt index is 0.65g / 10min, and the density is 0.959g / cm 3 The ethylene-1-hexene copolymer powder;

[0051] 3) Mix 100 parts of ethylene-1-hexene copolymer powder with 0.07 parts of main antioxidant 1076 or 3114, 0.14 parts of auxiliary antioxidant 168 or 626, 0.17 parts of light s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com