Silane cross-linked and directionally stretched high-strength polymer film

A cross-linked polymer and silane cross-linked technology, which can be used in flat products, household appliances, and other household appliances, can solve the problems of insufficient anti-aging performance, and achieve good environmental stress cracking resistance, low cost, and high tensile strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

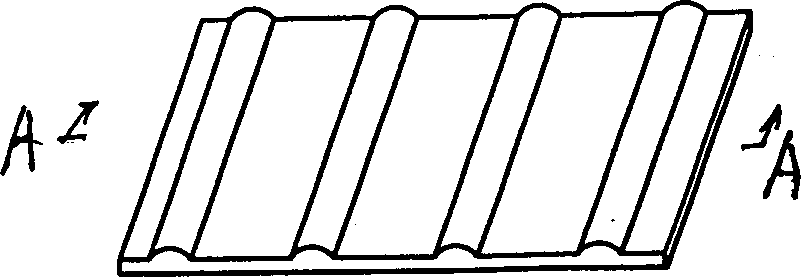

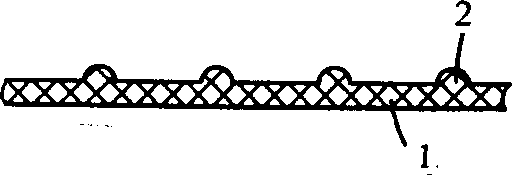

[0026] figure 1 , figure 2 Figure 1 is given for Example 1. Polyethylene (PE) undergoes uniaxial stretching and orientation, and undergoes hydrolysis, condensation, and crosslinking reactions under humid heat conditions to form a silane crosslinked stretching orientation film 1 with concave and convex ribs 2 .

Embodiment 2

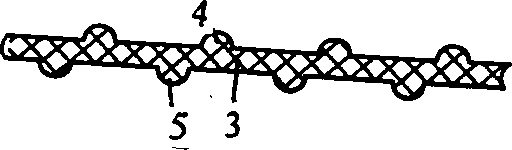

[0028] image 3 Figure 2 is given for Example 2. On the top and bottom of the silane cross-linked stretched oriented film 3 there are concavo-convex ribs 4 and 5 respectively.

Embodiment 3

[0030] Figure 4 Figure 3 of Example is given. There is the silane cross-linking of the silane cross-linked tensile oriented polypropylene film 6 with heat-welding (or adhesive performance) and the degree of molecular orientation and tensile strength are higher than that of the polypropylene film 6 by heat-melting (or bonding). Stretch oriented polypropylene (PP) and polyethylene (PE) copolymer film 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com