Polyethylene composition for rotomoulding and its preparation method

A technology of polyethylene and composition, which is applied in the field of polyethylene composition for rotational molding and its preparation, to achieve the effects of good plasticization, simple process, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The preparation method of the titanium-containing catalyst comprises the following steps:

[0050] (a) 100kg of carrier silica gel was activated, the activation temperature was 500°C, the activation time was 10h, and the specific surface area of the carrier silica gel was 300m 2 / g;

[0051] (b) in step (a), put 1000 mol of alkyl aluminum into the treatment, the treatment temperature is 80 ° C, the treatment is carried out for 6 hours, and the powder is dried;

[0052] (c) adding premixed 5000mol tetrahydrofuran, 500mol magnesium chloride and 1mol titanium trichloride to the powder prepared in step (b), stirring, drying, and the ratio of magnesium to titanium is 2~4;

[0053] (d) adding 0.1 mol of monochloroethylaluminum and 10 mol of di-n-hexylaluminum, stirring for 20 min, and drying to obtain a titanium-containing catalyst a.

[0054] The preparation method of the described polyethylene composition for rotational molding, comprises the following steps:

[0055] ...

Embodiment 2

[0059] The preparation method of the titanium-containing catalyst comprises the following steps:

[0060] (a) 100kg of carrier silica gel was activated, the activation temperature was 800°C, the activation time was 5h, and the specific surface area of the carrier silica gel was 600m 2 / g;

[0061] (b) In step (a), 10 mol of alkyl aluminum is put into the treatment, the treatment temperature is 60 ° C, the treatment is carried out for 10 h, and the powder is dried;

[0062] (c) adding premixed 100mol tetrahydrofuran, 1mol magnesium chloride and 500mol titanium trichloride to the powder prepared in step (b), stirring and drying, and the ratio of magnesium to titanium is 2~4;

[0063] (d) adding 10 mol of monochloroethylaluminum and 0.1 mol of di-n-hexylaluminum, stirring for 50 min, and drying to obtain titanium-containing catalyst b.

[0064] The preparation method of the described polyethylene composition for rotational molding, comprises the following steps:

[0065] (1)...

Embodiment 3-5

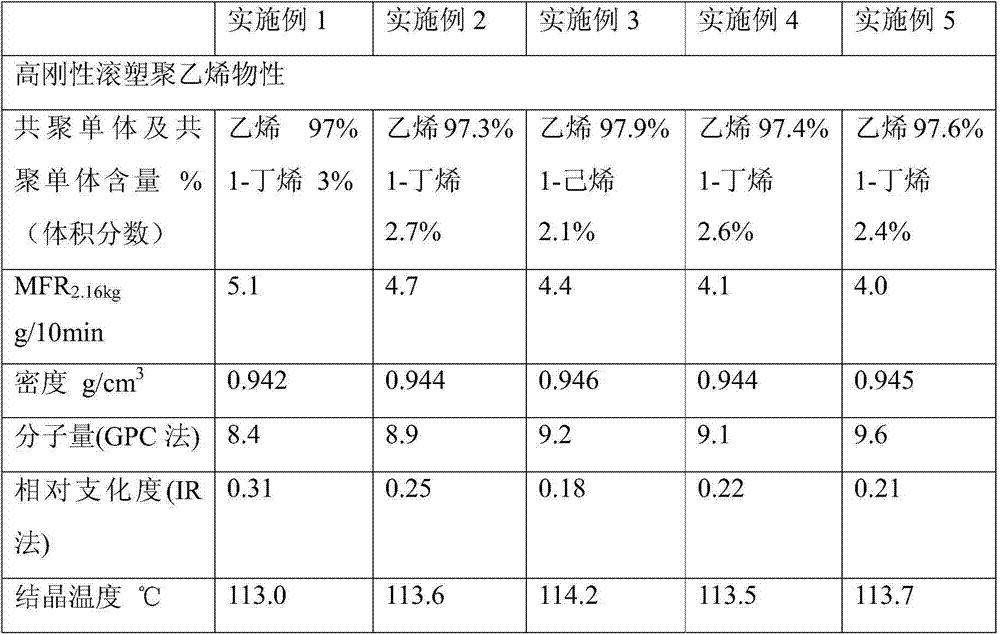

[0069] Examples 3-5 were all prepared using the same catalyst and preparation process as in Example 1, the only difference being that the used polymerization monomers were different, as shown in Table 1 for details.

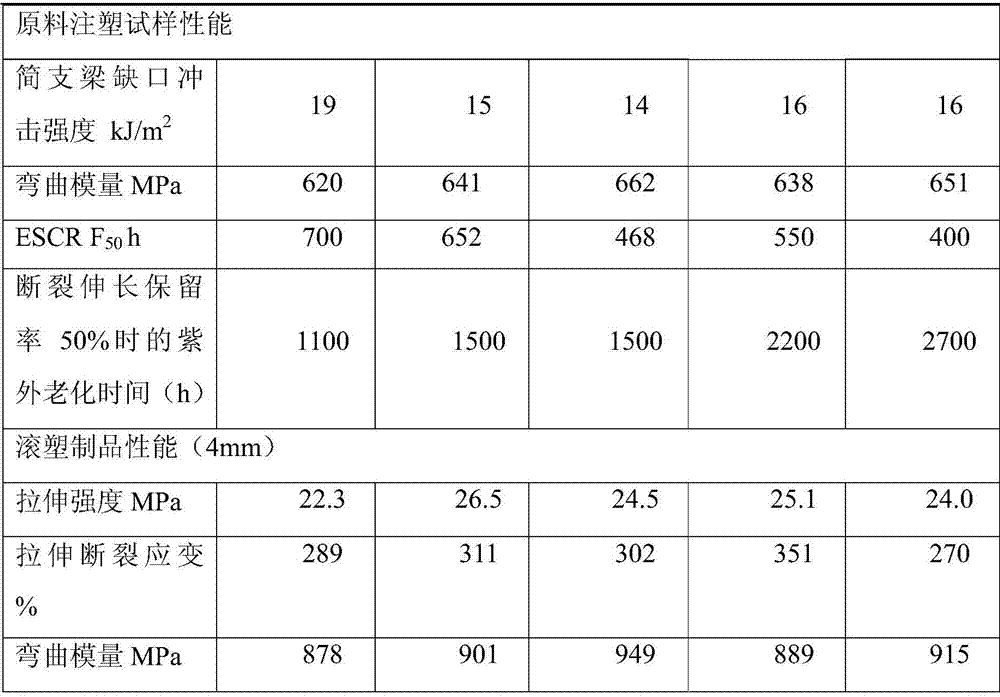

[0070] The properties of the polyethylene resin compositions prepared in Examples 1-5 are shown in Table 1.

[0071] Test method for retention rate of elongation at break: UV aging test is carried out with injection-molded tensile specimen, UV lamp is 313B type, and the irradiation intensity is 0.71W / m 2 / nm, illuminated at 60°C for 4 hours, and condensed at 50°C for 4 hours, and so on.

[0072] Table 1 Properties of the polyethylene resin compositions prepared in Examples 1-5

[0073]

[0074]

[0075] Note: The rotomolding equipment is electric heating, the process of rotomolding products is heating chamber temperature 260℃, heating time 30min, cooling time 25min, product size 500mm×500mm×250mm, product thickness 4mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com