High-flexible environment-friendly shrink film

An environmentally friendly, shrinkable film technology, applied in the direction of lamination, layered products, synthetic resin layered products, etc., can solve problems such as environmental pollution, and achieve the effects of high transparency, improved stability, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

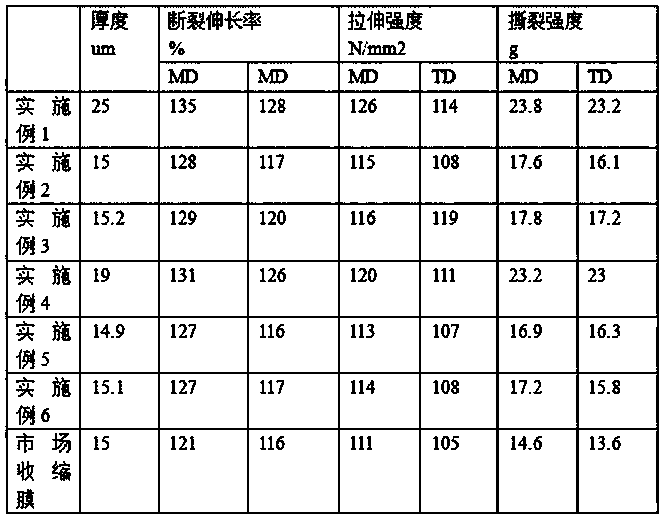

Examples

Embodiment 1

[0013] 5 parts of propylene, 15 parts of polyethylene, 30 parts of linear low density polyethylene, 1 part of high density polyethylene, 60 parts of thermoplastic starch, 5 parts of dibutyl phthalate, 1 part of polyethylene wax, antioxidant 168 1 part, 2 parts hydrogenated castor oil.

[0014] Extrusion compounding is carried out on the film prepared by the ratio of Example 1, and the number of compound layers is 5 layers.

Embodiment 2

[0016] 15 parts of propylene, 20 parts of polyethylene, 40 parts of linear low density polyethylene, 5 parts of high density polyethylene, 60 parts of thermoplastic starch, 10 parts of dibutyl phthalate, 5 parts of polyethylene wax, antioxidant 168 1 part, 2 parts hydrogenated castor oil.

[0017] The membrane prepared by the formulation of Example 2 was not compounded.

Embodiment 3

[0019] 10 parts of propylene, 18 parts of polyethylene, 32 parts of linear low density polyethylene, 4 parts of high density polyethylene, 70 parts of thermoplastic starch, 5 parts of dibutyl phthalate, 5 parts of polyethylene wax, 168 parts of antioxidant 0.5 parts, hydrogenated castor oil 1.5 parts.

[0020] The membrane prepared by the formulation of Example 3 was not compounded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com