High-performance barrier environmental-friendly package material of inner bag of flexible freight bag and preparation method of package material

A packaging material and high-performance technology, applied in packaging, wrapping paper, transportation and packaging, etc., to achieve good heat sealing performance, good thickness deviation, and good film transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

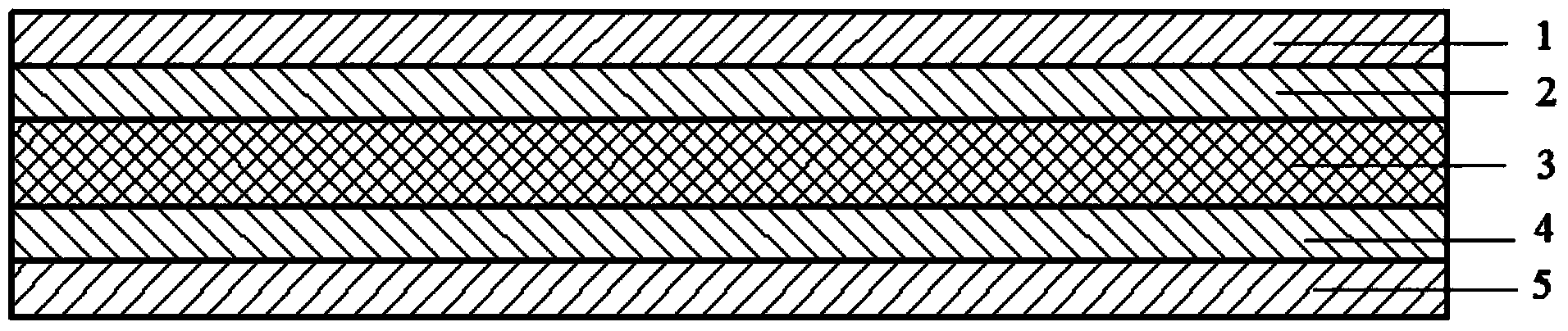

[0022] Such as figure 1 As shown, a high-performance barrier environmental protection packaging material for the inner bag of the container bag, its structure from top to bottom is the first surface layer 1, the first adhesive layer 2, the ethylene-vinyl alcohol layer 3, and the second adhesive layer 4 and the second skin 5;

[0023] Both the first surface layer 1 and the second surface layer 5 are low-density polyethylene (LDPE) or linear low-density polyethylene layer (LLDPE); or any layer of the first surface layer 1 and the second surface layer 5 is ethylene-ethylene Alcohol layer (EVOH), another layer is low density polyethylene (LDPE) or linear low density polyethylene (LLDPE) layer;

[0024] Both the first adhesive layer 2 and the second adhesive layer 4 are chitosan cellulose layers. The thickness of the ethylene-vinyl alcohol layer 3 is 12-16 μm.

[0025] The first and second low-density polyethylene (LDPE) or linear low-density polyethylene (LLDPE) layers make the...

Embodiment 2

[0029] The inner bag of the container bag uses a high-performance barrier environmental protection packaging material. Because the high-barrier multi-layer co-extrusion composite material has a multi-layer structure, it needs special multi-layer co-extrusion extrusion equipment to form, and the appropriate material is selected according to the material characteristics of each layer. screw type. The present invention adopts a special five-layer co-extrusion extruder produced in Taiwan. The diameters of three sets of extruder screw rods are: 45mm, 75mm, and 100mm respectively. Bit winder for winding. Other ancillary equipment includes: dryer, material conveying system, online scrap recycling system.

[0030] The specific steps are: the high-performance barrier environmental protection packaging material used for the inner bag of the container bag is divided into 5 layers from the inside to the outside, and the middle layer is ethylene-vinyl alcohol layer (3), which can be direc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com