Wet brake for forklift drive axle

A wet brake and drive axle technology, applied in hydraulic brakes, brake types, brake components, etc., can solve the problems of brake steel disc warpage, friction material burning, failure, etc., to reduce manufacturing costs and reduce oil temperature. The effect of improving the utilization rate and reducing the vibration amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

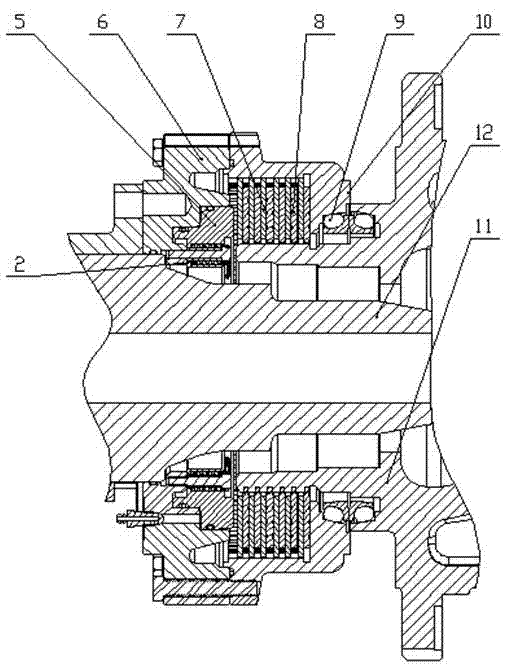

[0017] see figure 1 , A wet brake for a forklift drive axle, including a left housing 6, a right housing 10, a piston assembly 5, staggered spacers 7 and friction plates 8. The left housing 6 is fixedly connected with the axle housing shaft head assembly 11 by bolts to form a rigid body, and the piston assembly 5, the spacers 7 and the friction plates 8 arranged in a staggered manner are installed in the space formed after the left housing 6 and the right housing 10 are connected. In the cavity, the friction plate 8 is connected with the hub assembly 12 through splines, and the spacer 7 is connected with the right housing 10 through splines.

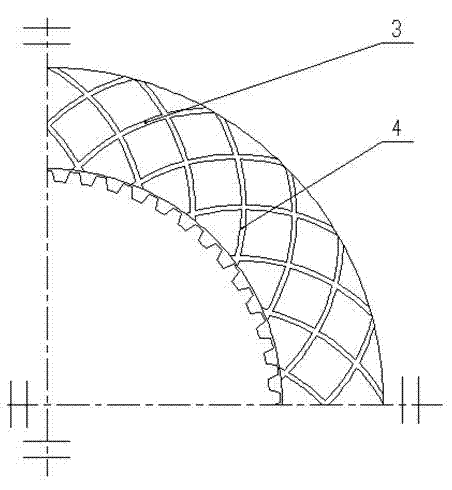

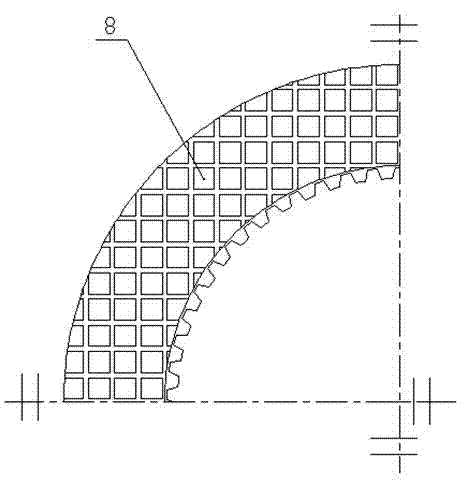

[0018] Both sides of the friction plate 8 are evenly distributed with a first arc-shaped oil groove 3 in the clockwise direction and a second arc-shaped oil groove 4 in the counterclockwise direction, the first arc-shaped oil groove 3 and the second arc-shaped oil groove 4 interlaced to form a grid. The intersection of the first arc-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com