Portable automatic discharge rod

An automatic discharge, portable technology, applied in the direction of measuring electricity, measuring electrical variables, instruments, etc., can solve the problems of no clear discharge time, long discharge time, and inability to judge, so as to save discharge time, speed up discharge speed, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

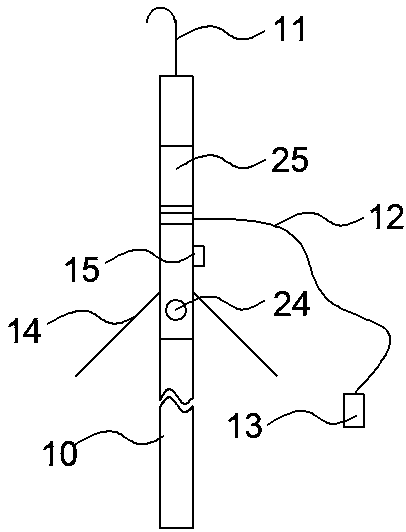

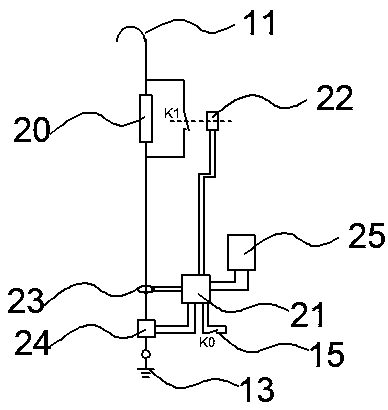

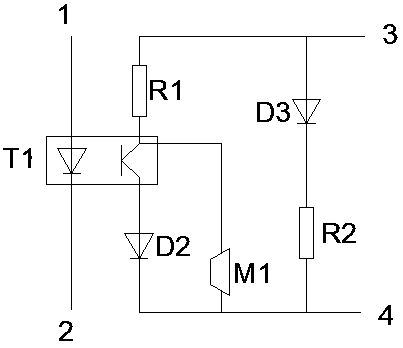

[0024] like figure 1 , 2 As shown in , 3 and 4, the present embodiment is a portable automatic discharge rod. Its body is an insulating rod 10 made of glass fiber material. A metal contact 11 and a discharge end connected to the metal contact 11 are provided. One end of the flexible wire 12 is fixedly or detachably connected to the discharge end, and the other end is connected to the grounding clamp 13 . After the metal contact 11 is connected to the high voltage resistor 20, it first passes through the current measuring device 23 and then connects the sound and light alarm 24 to connect with the grounding chuck 13. The current measuring device 23 is an active Hall current sensor, and the output terminal of the current measuring device 23 It is connected with the first input end of the control module 21 . The first output end of the control module 21 is connected to the control end of the short circuit switch 22 , the output end of the short circuit switch 22 is a normally o...

Embodiment 2

[0037] like Figure 4 , 5 As shown in , 6, this embodiment is a portable automatic discharge stick. The difference from Embodiment 1 is that this embodiment does not set a separate battery, so as to realize the safety of storage and use, and reduce the time cost of use at the same time. Therefore, the control module 21 is provided with a supercapacitor as a power supply; and is additionally provided with a discharge switching circuit formed by multiple sets of high-voltage resistors 20 and a short-circuit switch 22. When the discharge circuits R21 and R22 are connected in series, the total discharge resistance is the largest. When K1, K2 When both are in the conduction state, the discharge resistance is the smallest. When R21>R22, there can be four total discharge resistances from large to small R21+R22, R21, R22, and 0. The sound and light alarm 24 is the low power consumption OLED of the surrounding insulating rod 10 and the built-in buzzer of the insulating rod 10 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com