PCB turnover frame and production equipment

A technology of material frame and guide rail, which is applied in the field of PCB turnover frame and production equipment, can solve the problems of low PCB production efficiency, and achieve the effects of improving production efficiency, optimizing precision, and smooth adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

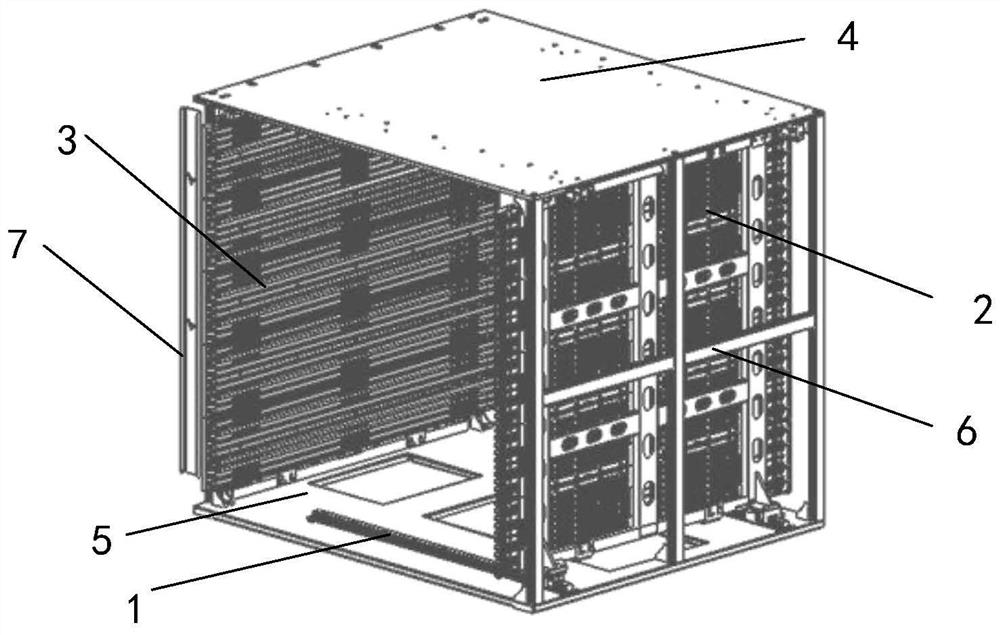

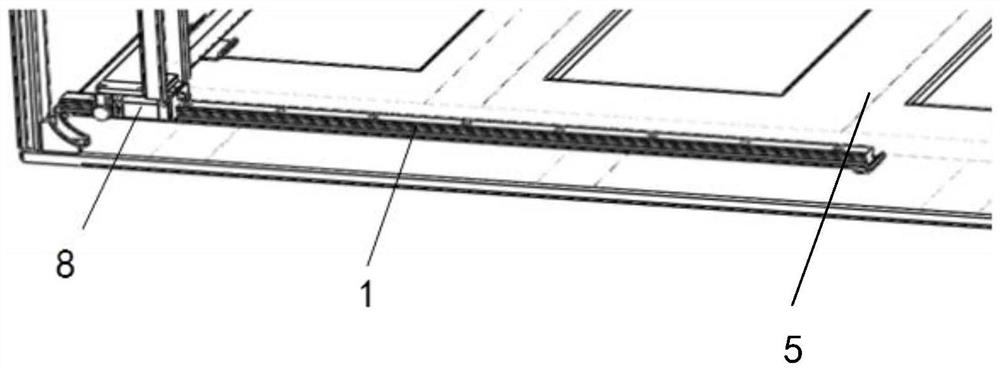

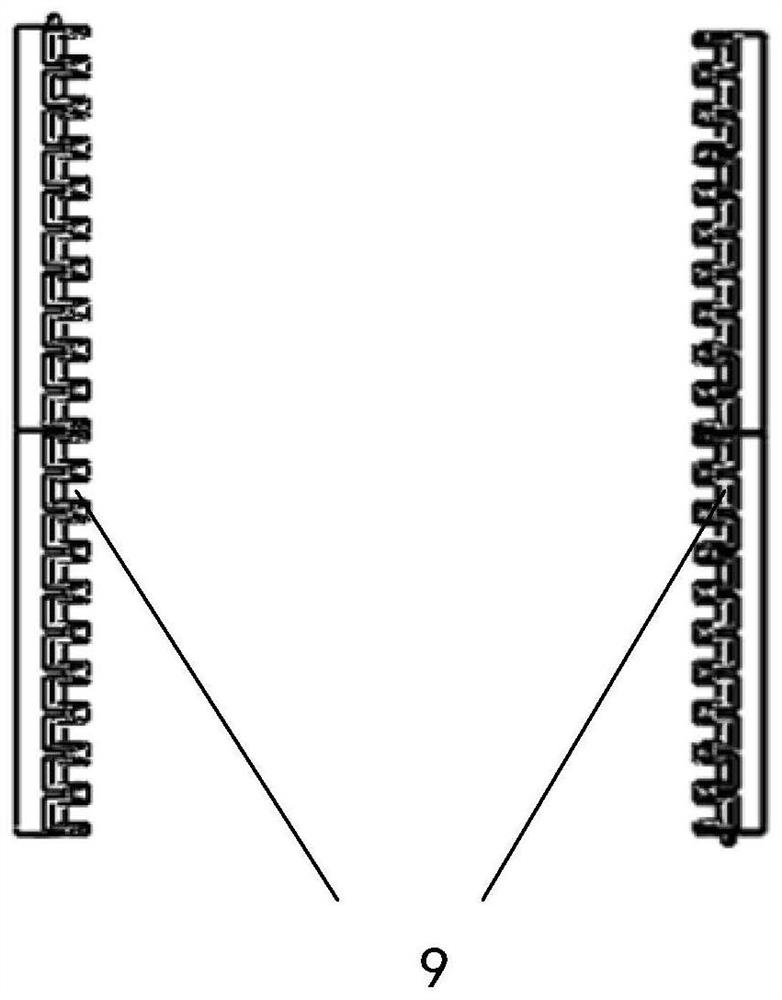

[0036] Such as figure 1 , figure 2 with image 3 As shown, the PCB turnover frame provided by the embodiment of the present invention includes a guide rail 1, a moving side plate 2 and a fixed side plate 3. The positions of the grooves 9 on the fixed side plate 3 are opposite to each other, so that the PCB board can be placed in parallel. The movable side plate 2 is provided with a slider 8 matched with the guide rail 1 , and the movable side plate 2 can slide along the guide rail 1 to change the distance between the movable side plate 2 and the fixed side plate 3 . Using the PCB turnover frame provided by the embodiment of the present invention, the slider 8 provided on the movable side plate 2 corresponding to the guide rail 1 can be used, so that the movable side plate 2 can slide along the guide rail 1, so that the PCB can be adjusted easily and smoothly The width of the turnover frame, and under the action of the guide rail 1, the verticality of the moving side plate ...

Embodiment 2

[0045] The embodiment of the present invention also provides a production equipment, including the PCB turnover frame provided by the above-mentioned embodiment 1. After the PCB board completes a production and processing process, the PCB turnover frame is adjusted to the required width, and the PCB turnover frame undertakes PCB board on the assembly line. The production equipment adopting the PCB turnover box increases the convenience in the production process and further improves the production efficiency.

[0046]The production equipment provided by the embodiments of the present invention has the same technical features as the PCB turnover frame provided by the above embodiments, so it can solve the same technical problems and achieve the same technical effects.

[0047] It should be noted that like numerals and letters denote similar items in the following figures, therefore, once an item is defined in one figure, it does not require further definition and explanation in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com