Friction damper with gap for additional stiffness

A friction damper and gap technology, applied in the field of friction dampers with gaps, can solve the problems that the friction damper cannot provide additional stiffness, the thickness of the laminated friction damper is large, and the overall performance is poor, so as to achieve enhanced stiffness and in-board pull The effect of uniform compressive stress and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

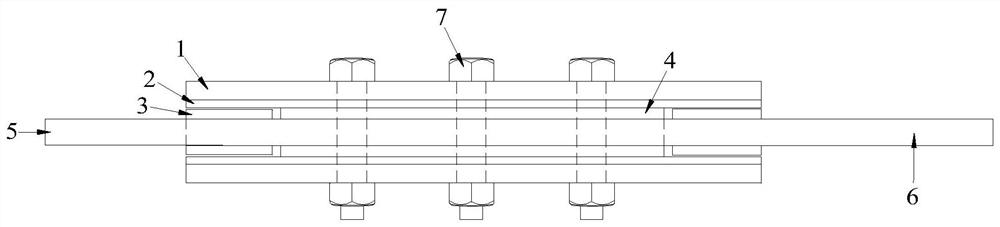

[0046] Such as Figure 1-8 Shown: a friction damper with gap with additional stiffness, including outer cover steel plate 1, friction plate 2, I-shaped plate 3, rectangular steel plate 4, one-shaped plate 5, U-shaped plate 6, high-strength friction bolt 7 .

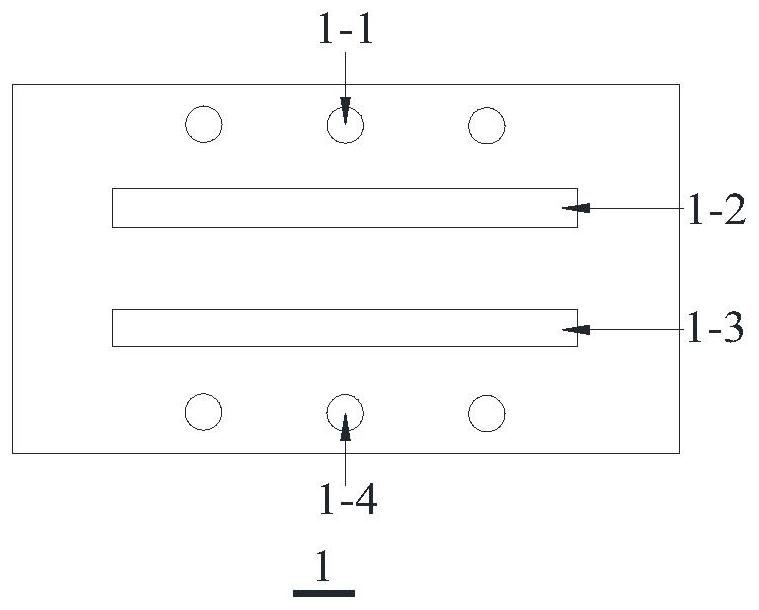

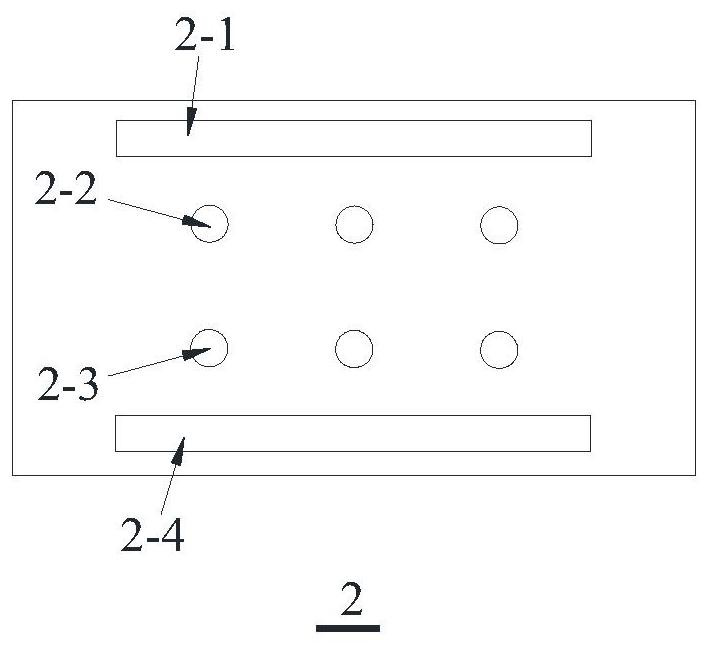

[0047] The outer cover steel plate 1 includes a circular hole C11-1, a rectangular hole R11-2, a rectangular hole R21-3 and a circular hole C21-4. Round hole C11-1, rectangular hole R11-2, rectangular hole R21-3 and round hole C21-4 are arranged symmetrically about the axis of symmetry in the length direction of outer cover steel plate 1, and round hole C11-1 and round hole C21-4 are arranged along the outer cover steel plate The length direction of 1 is evenly arranged, and the distance between the centers of adjacent circular holes is equal. The friction plate 2 includes a rectangular hole R32-1, a circular hole C32-2, a circular hole C42-3 and a rectangular hole R42-4. The rectangular hole R32-1, the circular hole C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com