Graphene modified paper-based friction material and preparation method

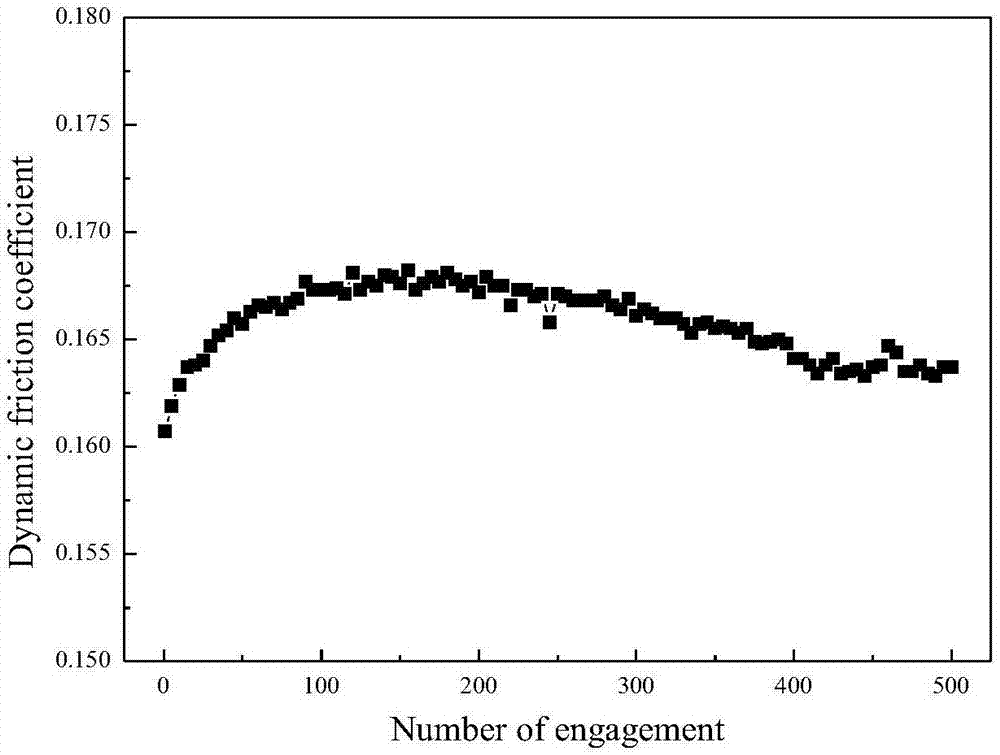

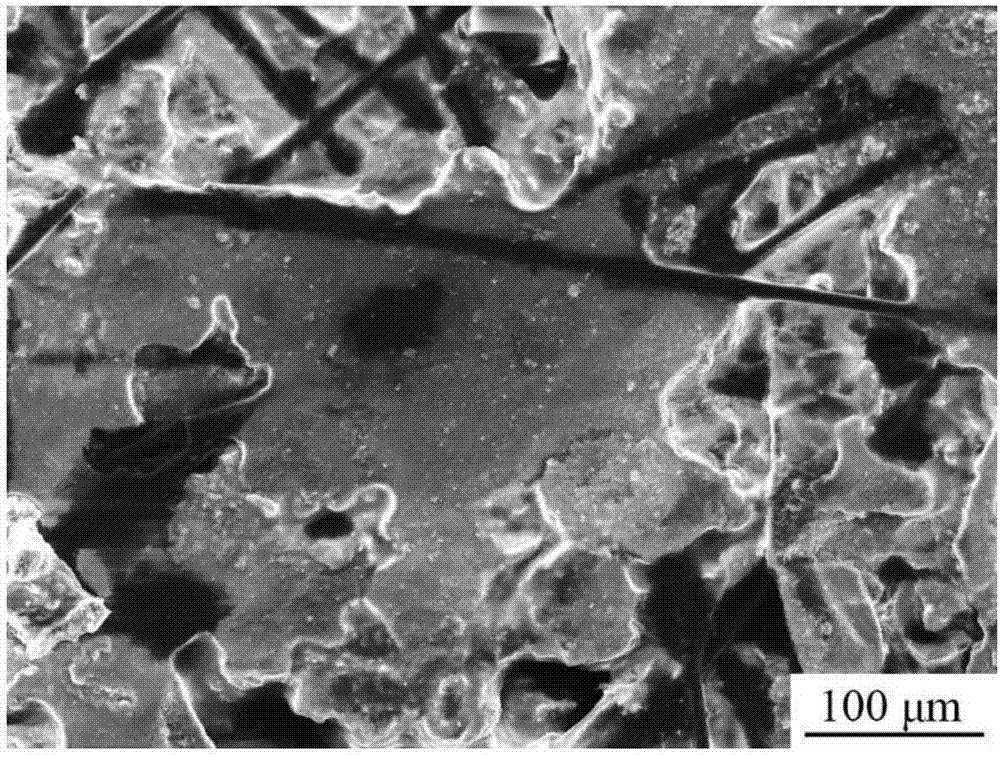

A paper-based friction material and graphene modification technology, which is applied in the process of adding pulp raw materials, synthetic cellulose/non-cellulose material pulp/paper, paper, etc., can solve the problems of reducing the friction coefficient of materials, and achieve the improvement of dynamic friction coefficient , Avoid fiber breakage or pulling out and matrix peeling, friction and wear properties synchronously improve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1: dissolving the resin in absolute ethanol to prepare a resin solution with a mass fraction of 25%, then letting the resin solution stand for 24 hours to fully dissolve it, and sealing it for storage to obtain solution A.

[0031] Step 2, take by weighing filler altogether 12.9g, be respectively mineral powder 3.25g, chromite powder 3.97g, fluorite powder 0.72g, barium sulfate 0.72g, aluminum oxide 2.17g, phenolic resin particle 2g, carbon black 0.07g; The weighed powdery raw materials were sequentially added into the high-speed mixer, and the mixture was mixed for 3-5 minutes to obtain a uniformly mixed mixture B.

[0032] Step 3: Weigh 0.89g of graphene; weigh a total of 22.9g of reinforcing fibers, which are respectively carbon fiber 6.5g, aramid fiber 6.5g, and wood fiber 9.9g; weigh a total of 16.5g of friction performance regulators, which are respectively stearic acid Zinc 0.5g, black rubber powder 16g; graphene, reinforcing fiber, friction modifier and com...

Embodiment 2

[0037] Step 1: dissolving the resin in absolute ethanol to prepare a resin solution with a mass fraction of 25%, then letting the resin solution stand for 24 hours to fully dissolve it, and sealing it for storage to obtain solution A.

[0038] Step 2, take by weighing filler altogether 12.9g, be respectively mineral powder 3.25g, chromite powder 3.97g, fluorite powder 0.72g, barium sulfate 0.72g, aluminum oxide 2.17g, phenolic resin particle 2g, carbon black 0.07g; The weighed powdery raw materials were sequentially added into the high-speed mixer, and the mixture was mixed for 3-5 minutes to obtain a uniformly mixed mixture B.

[0039] Step 3: Weigh 1.8g of graphene; weigh a total of 22.9g of reinforcing fibers, which are respectively carbon fiber 6.5g, aramid fiber 6.5g, and wood fiber 9.9g; weigh a total of 16.5g of friction performance regulators, which are respectively stearic acid Zinc 0.5g, black rubber powder 16g; graphene, reinforcing fiber, friction modifier and comp...

Embodiment 3

[0044] Step 1: dissolving the resin in absolute ethanol to prepare a resin solution with a mass fraction of 25%, then letting the resin solution stand for 24 hours to fully dissolve it, and sealing it for storage to obtain solution A.

[0045] Step 2, take by weighing filler altogether 12.9g, be respectively mineral powder 3.25g, chromite powder 3.97g, fluorite powder 0.72g, barium sulfate 0.72g, aluminum oxide 2.17g, phenolic resin particle 2g, carbon black 0.07g; The weighed powdery raw materials were sequentially added into the high-speed mixer, and the mixture was mixed for 3-5 minutes to obtain a uniformly mixed mixture B.

[0046] Step 3: Weigh 2.75g of graphene; weigh a total of 22.9g of reinforcing fibers, which are respectively carbon fiber 6.5g, aramid fiber 6.5g, and wood fiber 9.9g; weigh a total of 16.5g of friction performance regulators, which are respectively stearic acid Zinc 0.5g, black rubber powder 16g; graphene, reinforcing fiber, friction modifier and com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com