Polyester spandex super-quick-drying knitted fabric and processing method thereof

An ultra-fast-drying knitting and processing method technology, applied in the field of knitted fabrics, can solve the problems of unsatisfactory moisture absorption and quick-drying effect, poor wearing comfort, and few hydrophilic groups, so as to improve the smoothness and anti-pilling performance , Improve the ability of water diffusion, the effect of soft luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present invention is a polyester and spandex ultra-quick-drying knitted fabric, which is made of full-dull superfine polyester fiber and spandex fiber with a monofilament fineness of 1.1 to 1.7D as raw materials, and is woven by the following special weaving method. The next-to-body surface of the fabric has dotted jacquard protrusions that can wick moisture in one direction.

[0037] The processing method of the above-mentioned polyester spandex super fast-drying knitted fabric is as follows:

[0038] 1. Raw materials: mainly use 75D / 72F DTY full-dull superfine polyester + 30D spandex;

[0039] 75dtex / 72F (ie 75D / 72F) DTY full-dull superfine polyester (coil length 12cm / 50N, yarn ratio 83.73%) covered with 30D spandex (coil length 5.1cm / 50N, yarn ratio 16.27%)

[0040] 2. Weaving process:

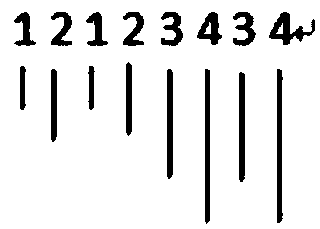

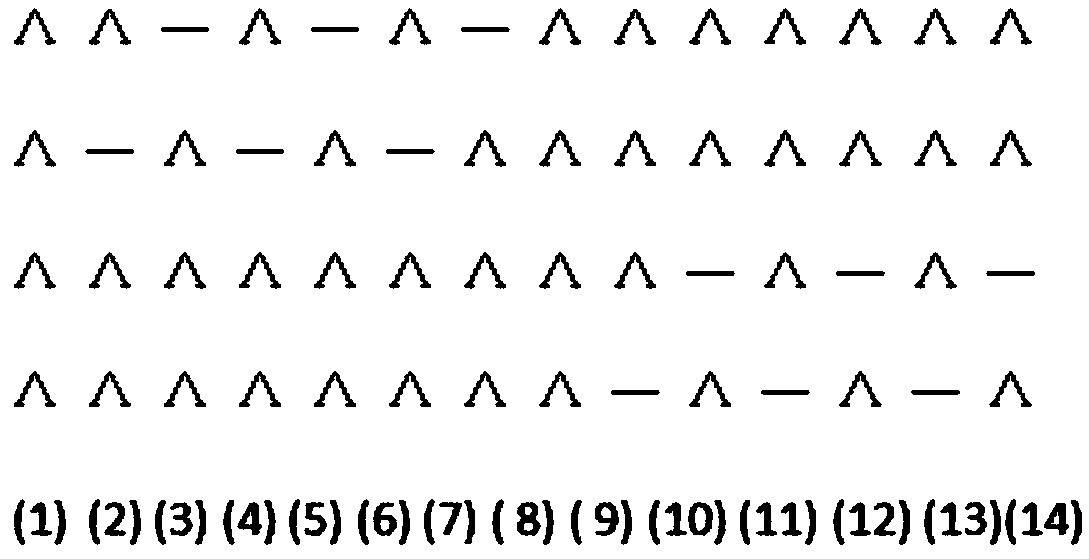

[0041] Weaving with a four-track single jersey knitting machine, only the lower needle, the order of the needle arrangement is 1, 2, 3, 4 four needles; the knitting process is ...

Embodiment 2

[0061] The present invention is a polyester and spandex ultra-quick-drying knitted fabric, which is made of full-dull superfine polyester fiber and spandex fiber with a monofilament fineness of 1.1 to 1.7D as raw materials, and is woven by the following special weaving method. The next-to-body surface of the fabric has dotted jacquard protrusions that can wick moisture in one direction.

[0062] The processing method of the above-mentioned polyester spandex super fast-drying knitted fabric is as follows:

[0063] 1. Raw materials: 75D / 96F DTY full extinction superfine polyester + 30D spandex

[0064] 75D / 96F DTY full-dull superfine polyester (coil length 11.5cm / 50N, yarn ratio 80%) covered with 30D spandex (coil length 5cm / 50N, yarn ratio 15%)

[0065] 2. Weaving process:

[0066] Weaving with a four-track single jersey knitting machine, only the lower needle, the order of the needle arrangement is 1, 2, 3, 4 four needles; the knitting process is fourteen ways and one cycle;...

Embodiment 3

[0086] The present invention is a polyester and spandex ultra-quick-drying knitted fabric, which is made of full-dull superfine polyester fiber and spandex fiber with a monofilament fineness of 1.1 to 1.7D as raw materials, and is woven by the following special weaving method. The next-to-body surface of the fabric has dotted jacquard protrusions that can wick moisture in one direction.

[0087] The processing method of the above-mentioned polyester spandex super fast-drying knitted fabric is as follows:

[0088] 1. Raw materials: 100D / 144F DTY full extinction superfine polyester + 30D spandex

[0089] 100D / 144F DTY full-dull superfine polyester (coil length 13cm / 50N, yarn ratio 85%) covered with 30D spandex (coil length 5.5cm / 50N, yarn ratio 18%)

[0090] 2. Weaving process:

[0091] Weaving with a four-track single jersey knitting machine, only the lower needle, the order of the needle arrangement is 1, 2, 3, 4 four needles; the knitting process is fourteen ways and one cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com