A fully extinction light-weight moisture-absorbing quick-drying polyester fiber and its preparation method

A polyester fiber, moisture-absorbing and quick-drying technology, which is applied in the field of chemical fibers, can solve the problems of difficult cleaning of the filter element of the melt filter, low titanium dioxide content, and difficulty in continuous and stable production, so as to ensure the stability of the melt and improve the capillary Function, the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The present invention provides a kind of preparation method of full-dull lightweight moisture-absorbing quick-drying polyester fiber, comprising the following steps:

[0022] 1) Install a screw extrusion device on the melt direct spinning semi-dull polyester fiber production line, put the matte polyester masterbatch into the screw extrusion device, and obtain the matte polyester masterbatch melt through melt extrusion;

[0023] 2) The semi-dull polyester melt and the matte polyester masterbatch melt obtained in step 1) are respectively metered by a metering pump and injected into a mixer to mix evenly to obtain a mixed melt;

[0024] 3) The mixed melt obtained in step 2) is transported to the spinning box through the melt distribution pipe, and extruded from the special-shaped hollow spinneret, and then cooled by ring blowing, oiling nozzle, hot roller drafting, network device Add network and take-up machine to wind up, obtain a kind of complete extinction lightweight m...

Embodiment 1

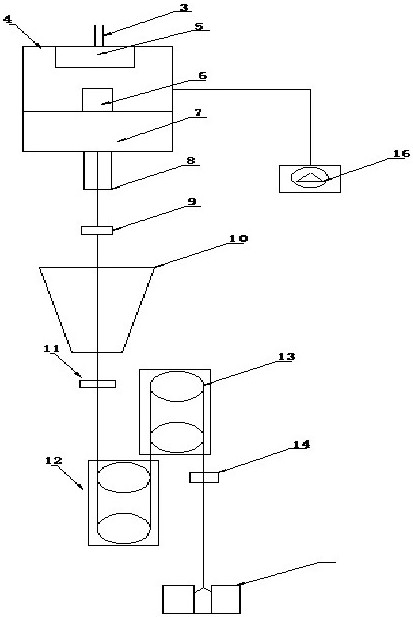

[0030] according to figure 1 The production process flow chart of the full-dull lightweight moisture-absorbing and quick-drying polyester fiber is shown, and the fully-dull lightweight moisture-absorbing and quick-drying polyester fiber is prepared:

[0031] (1) Install a screw extrusion device 1 in front of the mixer 2, put the matte polyester masterbatch with a titanium dioxide content of 50wt% into the screw extrusion device 1, and obtain a matte polyester masterbatch melt by melt extrusion .

[0032] (2) The semi-dull polyester melt with a titanium dioxide content of 0.3wt% and the matte polyester masterbatch melt are measured at a flow rate of 1:17, respectively, and then injected into the mixer 2 and mixed evenly by a metering pump to obtain a mixed melt body.

[0033] (3) Transport the mixed melt to the spinning box 4 at 290°C (the spinning box 4 is heated by the biphenyl evaporator 16), distribute it through the melt distribution pipe 3 and then measure it with the m...

Embodiment 2

[0036] according to figure 1 The production process flow chart of the full-dull lightweight moisture-absorbing and quick-drying polyester fiber is shown, and the fully-dull lightweight moisture-absorbing and quick-drying polyester fiber is prepared:

[0037] (1) Install a screw extrusion device 1 before the mixer 2, put the matte polyester masterbatch with a titanium dioxide content of 45wt% into the screw extrusion device 1, and obtain a matte polyester masterbatch melt by melt extrusion .

[0038] (2) The semi-dull polyester melt with a titanium dioxide content of 0.4wt% and the matte polyester masterbatch melt are measured at a flow rate of 1:15, respectively, and then injected into the mixer 2 and mixed evenly by a metering pump to obtain a mixed melt body.

[0039] (3) Transport the mixed melt to the spinning box 4 at 285°C (the spinning box 4 is heated by the biphenyl evaporator 16), distribute it through the melt distribution pipe 3 and then measure it with the meteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| Evaporation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com