Antifriction modified thermoplastic polyurethane elastomer formula as well as preparation method and application thereof

A technology of thermoplastic polyurethane and elastomer, which is applied in the formulation and preparation of friction-reducing modified thermoplastic polyurethane elastomer, which can solve the problems of increased heat, large frictional resistance, and high frictional heat generation, etc., and achieves improved tensile strength and wear rate. The effect of reducing and reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

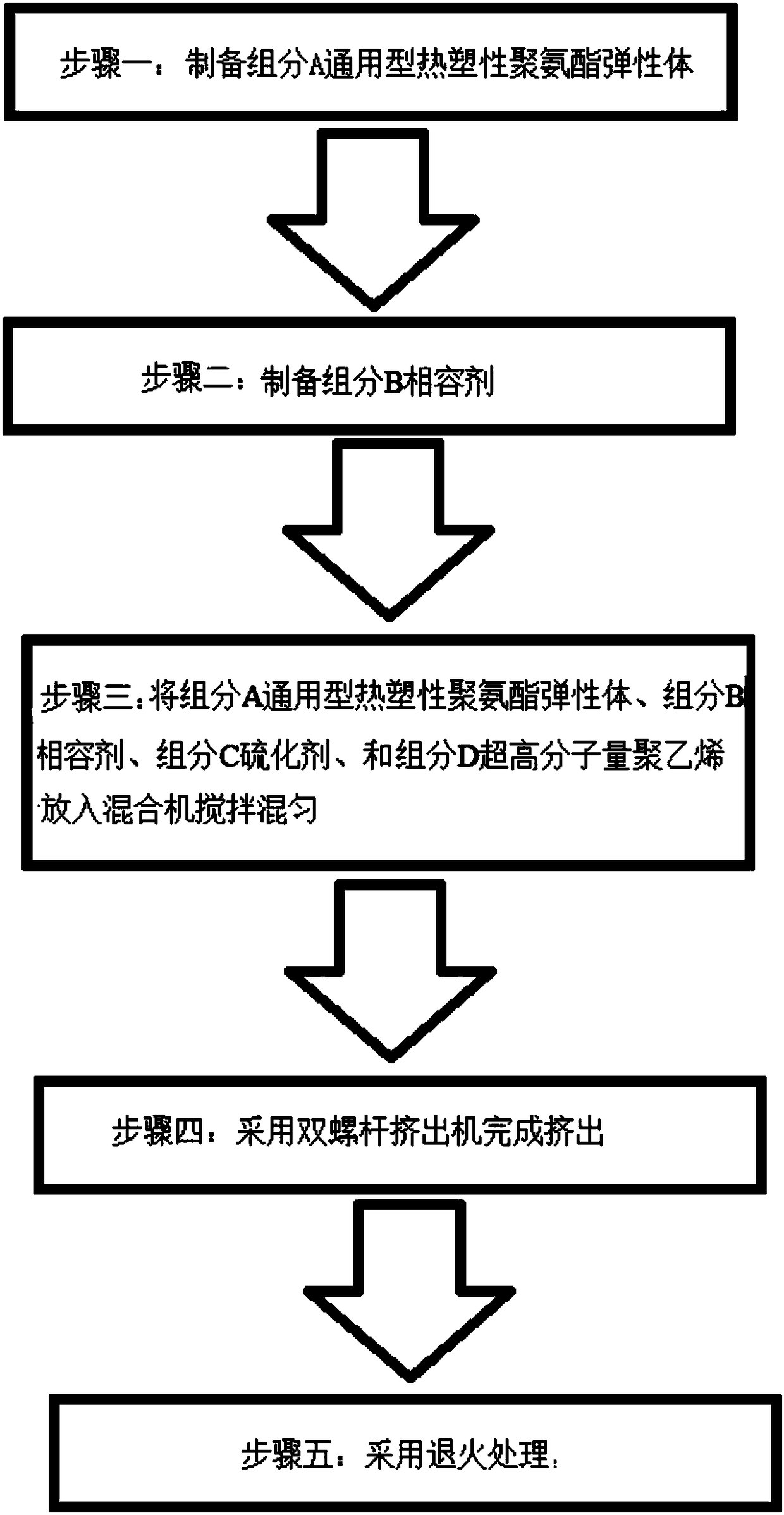

Method used

Image

Examples

Embodiment 1

[0059] Anti-friction modified thermoplastic polyurethane elastomer formula, including component A, component B, component C, and component D, prepared according to the ratio of parts by mass: 95-105: 7-9: 0.04-0.06: 14-16 ;

[0060] Among them, component A is a general-purpose thermoplastic polyurethane elastomer (TPU), prepared from the following raw materials in parts by mass:

[0061] Including 1,4-butylene adipate, 4,4-diphenylmethane diisocyanate, 1,4-butanediol (BDO, chain extender), parts by mass of each component: polyhexamethylene 385-415 parts of 1,4-butanediol acid ester, 105-145 parts of diphenylmethane diisocyanate, 26-29 parts of 1,4-butanediol;

[0062] Poly 1,4-butylene adipate is a polyester polyol, and the polyester polyol in the TPU elastomer constitutes the soft segment structure of the TPU elastomer.

[0063] 4,4-Diphenylmethane diisocyanate (MDI) is used as a coupling agent to connect polyester polyols to form urethane sparse soft segments, and at the s...

Embodiment 2

[0085] Anti-friction modified thermoplastic polyurethane elastomer formula, including component A, component B, component C, and component D, prepared according to the ratio of parts by mass of 100:8:0.05:15;

[0086] Among them, component A is a general-purpose thermoplastic polyurethane elastomer (TPU), prepared from the following raw materials in parts by mass:

[0087] Including 1,4-butylene adipate, 4,4-diphenylmethane diisocyanate, 1,4-butanediol (BDO, chain extender), parts by mass of each component: polyhexamethylene 400 parts of 1,4-butanediol acid ester, 125 parts of diphenylmethane diisocyanate, 28 parts of 1,4-butanediol;

[0088] Poly 1,4-butylene adipate is a polyester polyol, and the polyester polyol in the TPU elastomer constitutes the soft segment structure of the TPU elastomer. The poly-1,4-butylene adipate is the poly-1,4-butylene adipate with a molecular weight of 2000.

[0089] 4,4-Diphenylmethane diisocyanate (MDI) is used as a coupling agent to connect...

Embodiment 3

[0108] Anti-friction modified thermoplastic polyurethane elastomer formula, including component A, component B, component C, and component D, prepared according to the ratio of parts by mass of 95:7:0.04:14;

[0109] Among them, component A is a general-purpose thermoplastic polyurethane elastomer (TPU), prepared from the following raw materials in parts by mass:

[0110] Including 1,4-butylene adipate, 4,4-diphenylmethane diisocyanate, 1,4-butanediol (BDO, chain extender), parts by mass of each component: polyhexamethylene 400 parts of 1,4-butanediol acid ester, 125 parts of diphenylmethane diisocyanate, 28 parts of 1,4-butanediol;

[0111] Poly 1,4-butylene adipate is a polyester polyol, and the polyester polyol in the TPU elastomer constitutes the soft segment structure of the TPU elastomer. The poly-1,4-butylene adipate is the poly-1,4-butylene adipate with a molecular weight of 2000.

[0112] 4,4-Diphenylmethane diisocyanate (MDI) is used as a coupling agent to connect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com