Resin composition and molded article

A technology for resin compositions and molded products, which is applied in the field of resin compositions and molded products, can solve problems such as reducing the coefficient of dynamic friction, and achieve the effects of excellent sliding properties and low coefficient of dynamic friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

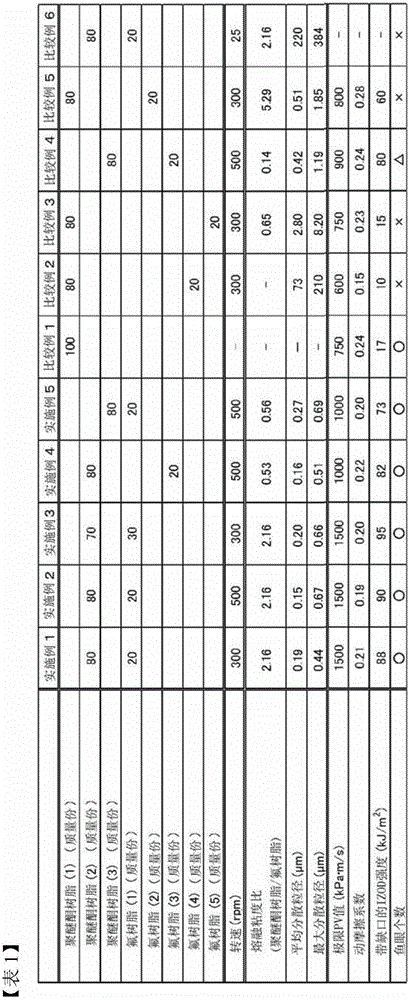

[0123] Carry out pre-mixing of aromatic polyetherketone resin (2) and fluororesin (1) according to the ratio (parts by mass) shown in Table 1, using a twin-screw extruder (φ15mm, L / D=60), in the barrel Melt-kneading was carried out under conditions of a temperature of 390° C. and a screw rotation speed of 300 rpm to produce a resin composition. Using the obtained resin composition, a test piece was produced by the above-mentioned method, and the measurement of the limit PV value, the coefficient of dynamic friction, and the notched IZOD impact strength was performed. And using this test piece, the average dispersed particle diameter and the maximum dispersed particle diameter of the fluororesin (II) were calculated.

Embodiment 2

[0125] Carry out pre-mixing of aromatic polyetherketone resin (2) and fluororesin (1) according to the ratio (parts by mass) shown in Table 1, using a twin-screw extruder (φ15mm, L / D=60), in the barrel Melt-kneading was carried out under conditions of a temperature of 390° C. and a screw rotation speed of 500 rpm to manufacture a resin composition. Using the obtained resin composition, a test piece was produced by the above-mentioned method, and the measurement of the limit PV value, the coefficient of dynamic friction, and the notched IZOD impact strength was performed. And using this test piece, the average dispersed particle diameter and the maximum dispersed particle diameter of the fluororesin (1) were calculated.

Embodiment 3

[0127] Carry out the premixing of aromatic polyetherketone resin (2) and fluororesin (1) according to the ratio (mass part) shown in Table 1, use twin-screw extruder (φ15mm, L / D=60), in barrel Melt-kneading was carried out under conditions of a temperature of 390° C. and a screw rotation speed of 300 rpm to produce a resin composition. Using the obtained resin composition, a test piece was produced by the above-mentioned method, and the measurement of the limit PV value, the coefficient of dynamic friction, and the notched IZOD impact strength was performed. And using this test piece, the average dispersed particle diameter and the maximum dispersed particle diameter of the fluororesin (1) were calculated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com