Bendable protective film for folding screen and preparation method thereof

A protective film, bending technology, applied in the direction of film/sheet release liner, film/sheet release coating, film/sheet adhesive, etc., can solve the problem of insufficient bending resistance and scratch resistance , The bending resistance performance is difficult to meet the needs of the folding screen, so as to achieve the effect of good anti-fingerprint, anti-oil pollution, improved light transmission performance, and excellent scratch resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Wherein, the preparation method of the bendable protective film for the folding screen includes the following steps:

[0043] 1) Preparation of anti-rebound OCA optical glue: mix polyacrylate, polyisoprene, diluent, modifier, photoinitiator, crosslinking agent, and antioxidant evenly, heat to 50-120°C, and stir for 2.0 ~4 hours, vacuumize to remove air bubbles, cool to obtain anti-rebound OCA optical glue;

[0044] 2) On the surface and the bottom surface of the bendable substrate layer 2, the first flexible HC treatment layer 1 and the second flexible HC treatment layer 3 are respectively coated, and the prepared anti-bounce layer is coated on the second flexible HC treatment layer 3. OCA optical glue, after curing, an anti-rebound OCA optical glue layer 4 is obtained;

[0045] 3) drying in an oven, and pasting the release isolation layer 5 on the anti-rebound OCA optical adhesive layer 4 .

Embodiment 1

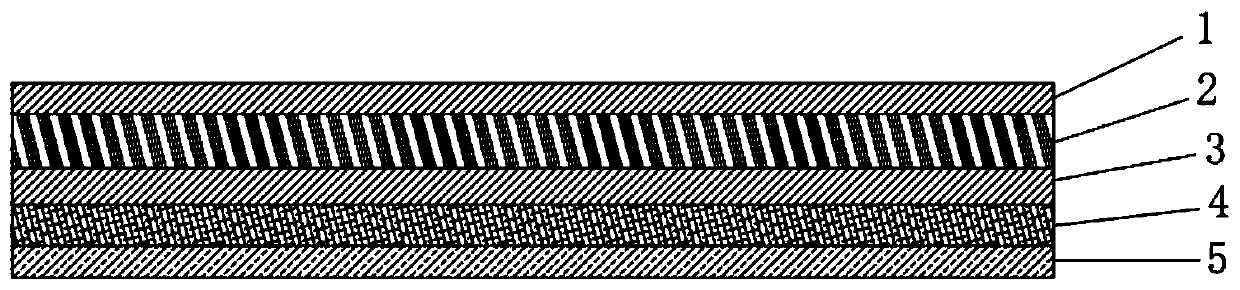

[0048] A bendable protective film for a folding screen, comprising a first flexible HC treatment layer 1 (15 μm), a bendable substrate layer 2 (25 μm), a second flexible HC treatment layer 3 (10 μm), and an anti- Rebound OCA optical adhesive layer 4 (15 μm) and release isolation layer 5 (20 μm);

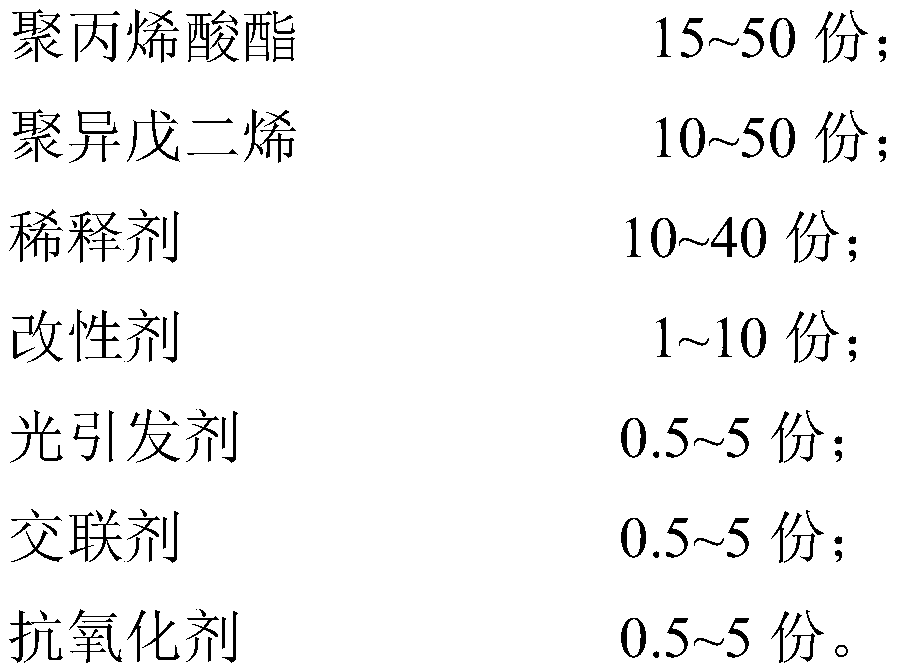

[0049] Among them, the anti-rebound OCA optical glue includes the following raw materials by weight:

[0050]

[0051] The modifying agent comprises the following raw materials in parts by weight:

[0052]

[0053] The preparation method of the bendable protective film for the folding screen comprises the following steps:

[0054] 1) Preparation of anti-rebound OCA optical glue: mix polyacrylate, polyisoprene, diluent, modifier, photoinitiator, crosslinking agent, and antioxidant evenly, heat to 50-120°C, and stir for 2.0 ~4 hours, vacuumize to remove air bubbles, cool to obtain anti-rebound OCA optical glue;

[0055] 2) On the surface and the bottom surface of the bendable ...

Embodiment 2

[0058]A bendable protective film for a folding screen, comprising a first flexible HC treatment layer 1 (15 μm), a bendable substrate layer 2 (25 μm), a second flexible HC treatment layer 3 (10 μm), and an anti- Rebound OCA optical adhesive layer 4 (15 μm) and release isolation layer 5 (20 μm);

[0059] Among them, the anti-rebound OCA optical glue includes the following raw materials by weight:

[0060]

[0061] The modifying agent comprises the following raw materials in parts by weight:

[0062]

[0063] The preparation method of the bendable protective film for the folding screen is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com