Flexible printed circuit board element and grounding steel sheet connecting device and method

A technology of flexible circuit boards and connecting devices, which is applied in the direction of printed circuit grounding devices, circuit devices, electrical components, etc., can solve problems such as instability, large contact resistance, and high production costs, and achieve improved efficiency, stable contact resistance, and reduced production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

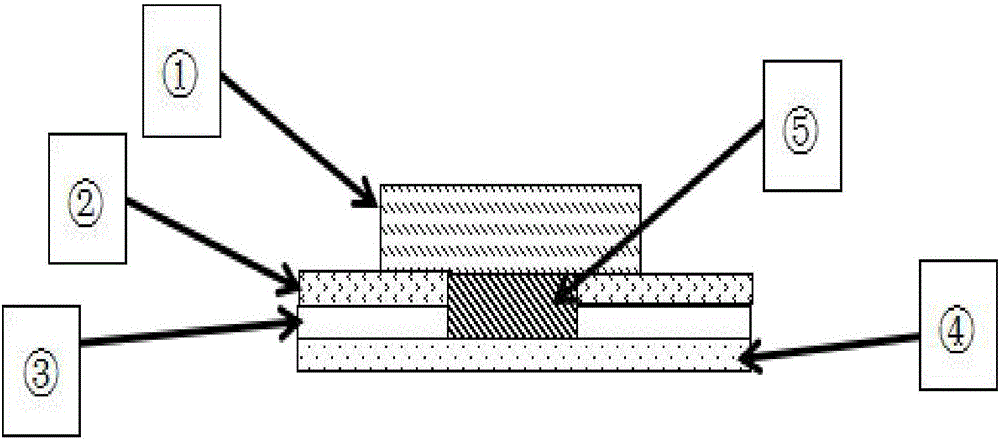

[0023] A device for connecting flexible circuit board components and grounding steel sheets, including: FPC electronic components 1, flexible circuit board layers 2, thermosetting conductive adhesive 3, grounding steel sheets 4 and solder paste 5, such as figure 2 As shown, the thermosetting conductive adhesive 3 is bonded to the flexible circuit board layer 2, and a square connecting the upper and lower layers is punched out, and solder paste 5 is placed in the square, and the grounding steel sheet 4 is connected to the thermosetting conductive layer 2. The remaining part of the glue 2 is attached, and the FPC electronic component 1 is attached to the flexible circuit board layer 2 and is in contact with the solder paste 5 .

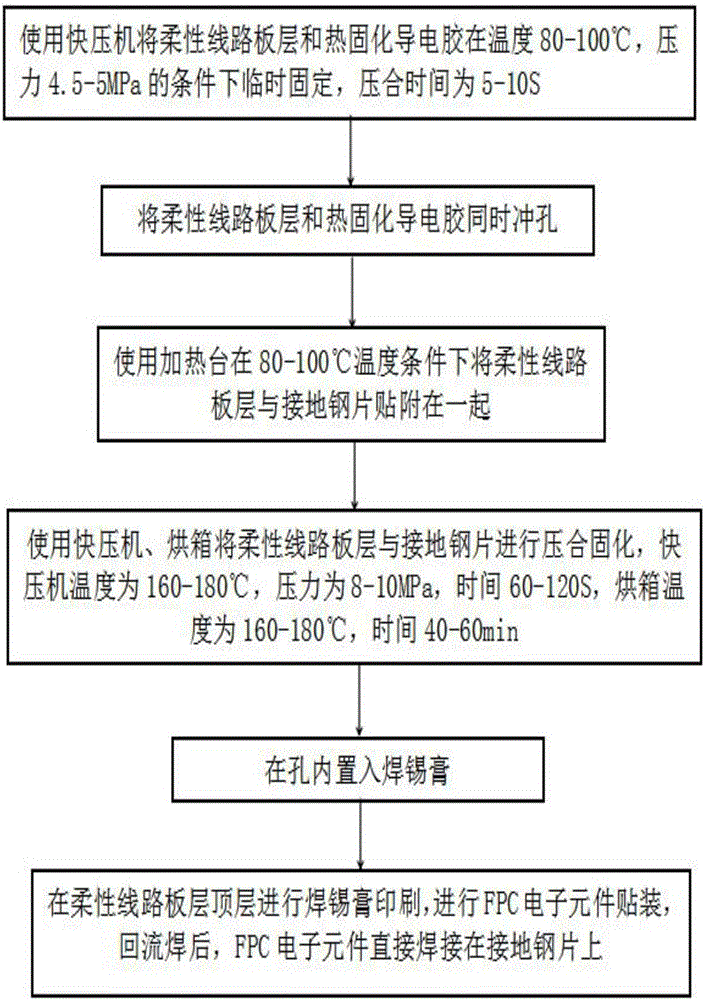

[0024] Firstly, the heat-curing conductive adhesive 3 and the flexible circuit board layer 2 are pasted together, and temporarily fixed by false pressure, and then the flexible circuit board layer 2 where the components on the flexible circuit board lay...

Embodiment 2

[0026] A device for connecting a flexible circuit board element to a grounding steel sheet, comprising: a motor, a flexible circuit board layer, a thermosetting conductive adhesive, a grounding steel sheet and solder paste, the thickness of the thermosetting conductive adhesive is 30 μm, and the thermosetting conductive adhesive Glue and the flexible circuit board layer are bonded together, and a circle connecting the upper and lower layers is punched in it, and solder paste is placed in the circle. Attached to the flex circuit layer and in contact with the solder paste.

[0027] Firstly, the heat-curing conductive adhesive and the flexible circuit board layer are bonded together, temporarily fixed by false pressure, and then the flexible circuit board layer where the components on the flexible circuit board layer need to be grounded is punched out together with the heat-curing conductive adhesive with a punching die , forming a circle with the upper and lower layers connected...

Embodiment 3

[0029] A connection device of a flexible circuit board element and a grounding steel sheet, comprising: a chip, a flexible circuit board layer, thermosetting conductive glue, a grounding steel sheet and solder paste.

[0030] Use a fast press to temporarily fix the flexible circuit board layer and heat-curing conductive adhesive at a temperature of 80-100°C and a pressure of 4.5-5MPa, and the pressing time is 5-10S; then the flexible circuit board layer and heat-curing conductive adhesive Punch holes at the same time; then use a heating table to attach the flexible circuit board layer and the grounding steel sheet together at a temperature of 80-100°C; then use a fast press and an oven to press and cure the flexible circuit board layer and the grounding steel sheet , the temperature of the fast press is 160-180°C, the pressure is 8-10MPa, and the time is 60-120S; the temperature of the oven is 160-180°C, and the time is 40-60min; the solder paste is printed on the top layer of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com