Electric contact material for connector, and method for producing same

A manufacturing method and technology of electrical contacts, applied in conductive materials, conductive materials, circuits, etc., to achieve the effects of stabilizing contact resistance, maintaining contact resistance for a long time, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

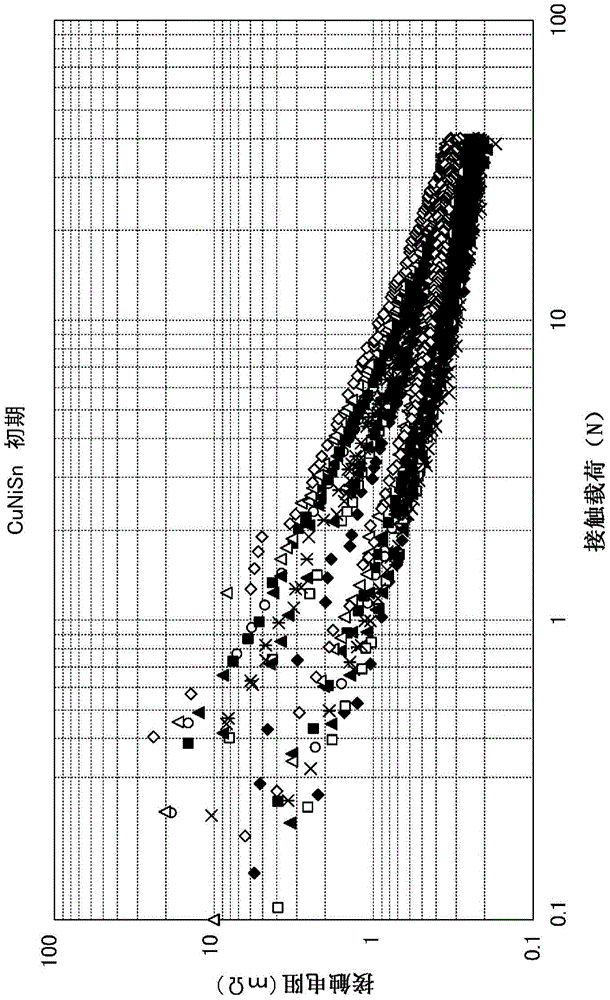

Embodiment 1

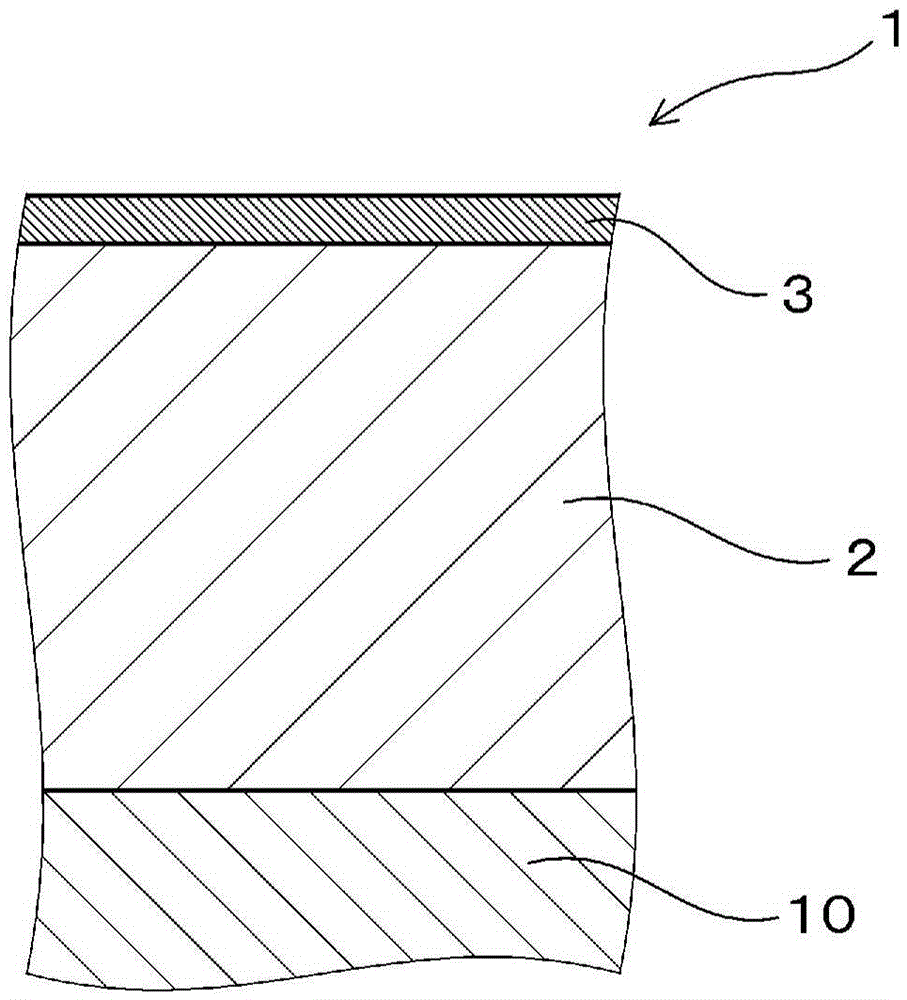

[0057] The electrical contact material for connectors mentioned above and its manufacturing method are demonstrated using drawings.

[0058] Such as figure 2 As shown, the electrical contact material 1 of this example has: a base material 10 made of a metal material, a ternary alloy layer 2 containing Sn and Cu and also containing Ni formed on the base material 10, and a ternary alloy layer 2 formed on the surface of the alloy layer 2 The formed conductive coating layer 3 . Alloy layer 2 contains Cu 6 sn 5 (Cu,Ni) obtained by substituting a part of Cu in Ni 6 sn 5 intermetallic compound. Hereinafter, the manufacturing method and more detailed structure of the electrical contact material 1 are demonstrated.

[0059]

[0060] First, a plate-shaped material made of brass was prepared as the base material 10 . In addition, the material and form of the base material 10 can be changed variously according to a use. In addition, in this example, a diffusion barrier layer wa...

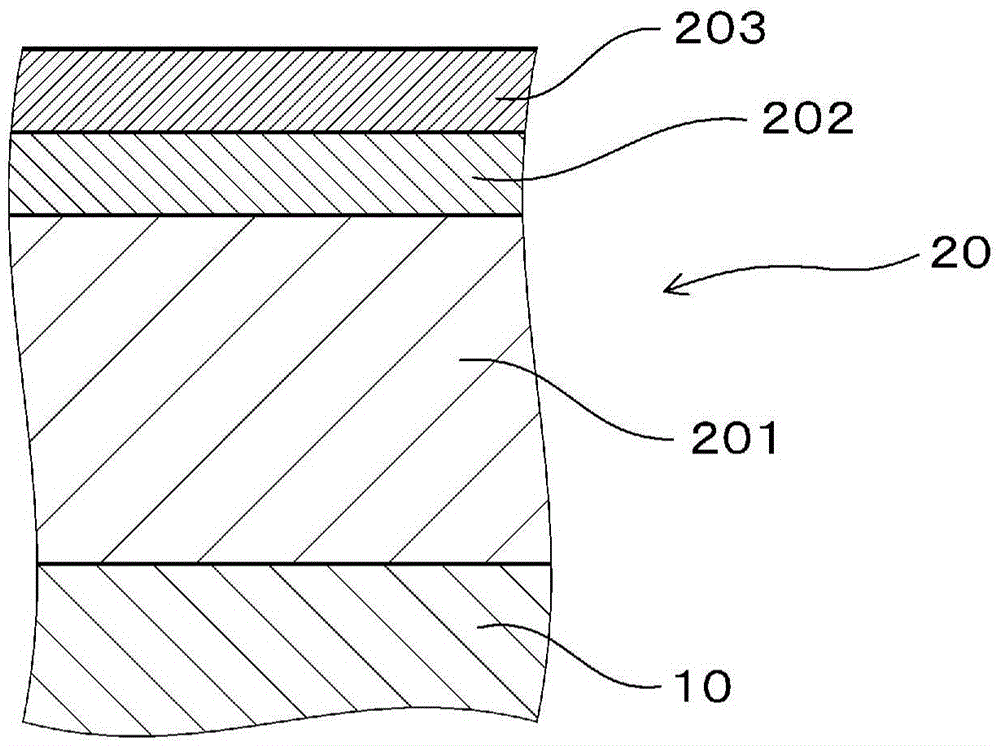

Embodiment 2

[0095] In the electrical contact material for connectors of this example, the alloy layer 2 in Example 1 is changed to a ternary alloy layer containing Sn and Cu and Zn, and accordingly, the composition of the conductive coating layer 3 is also changed. example of .

[0096]

[0097] It manufactured similarly to Example 1 except having performed formation of a Zn layer instead of forming a Ni layer in Example 1.

[0098] (Formation of Zn layer)

[0099] · Liquid composition of the plating bath

[0100] · Zinc chloride [ZnCl 2 ]: 60g / L

[0101] Sodium chloride [NaCl]: 35g / L

[0102] Sodium hydroxide [NaOH]: 80g / L

[0103] Liquid temperature: 25°C

[0104] ·Current density: 1A / dm 2

[0105]

[0106] The composition of the alloy layer obtained in this example was analyzed by EDX. As a result, it was found that (Cu, Zn) 6 sn 5 metal compounds. In addition, the composition analysis of the obtained conductive coating layer of this example was carried out by XPS. As a ...

Embodiment 3

[0111] In the electrical contact material for connectors of this example, the alloy layer 2 in Example 1 is changed to a ternary alloy layer containing Sn and Cu and Co, and accordingly, the composition of the conductive coating layer 3 is also changed. example of .

[0112]

[0113] It manufactured in the same manner as in Example 1 except having performed formation of a Co layer instead of forming a Ni layer in Example 1.

[0114] (Formation of Co layer)

[0115] · Liquid composition of the plating bath

[0116] Cobalt chloride [CoCl 2 ]: 250g / L

[0117] Hydrochloric acid [HCl]: 50g / L

[0118] Liquid temperature: 40°C

[0119] ·Current density: 2A / dm 2

[0120]

[0121] The composition of the alloy layer obtained in this example was analyzed by EDX. As a result, it was found that (Cu, Co) 6 sn 5 metal compounds. In addition, composition analysis of the obtained conductive coating layer of this example by XPS revealed that a mixed oxide of Sn oxide, Cu oxide, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com