Patents

Literature

32results about How to "Less gas consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

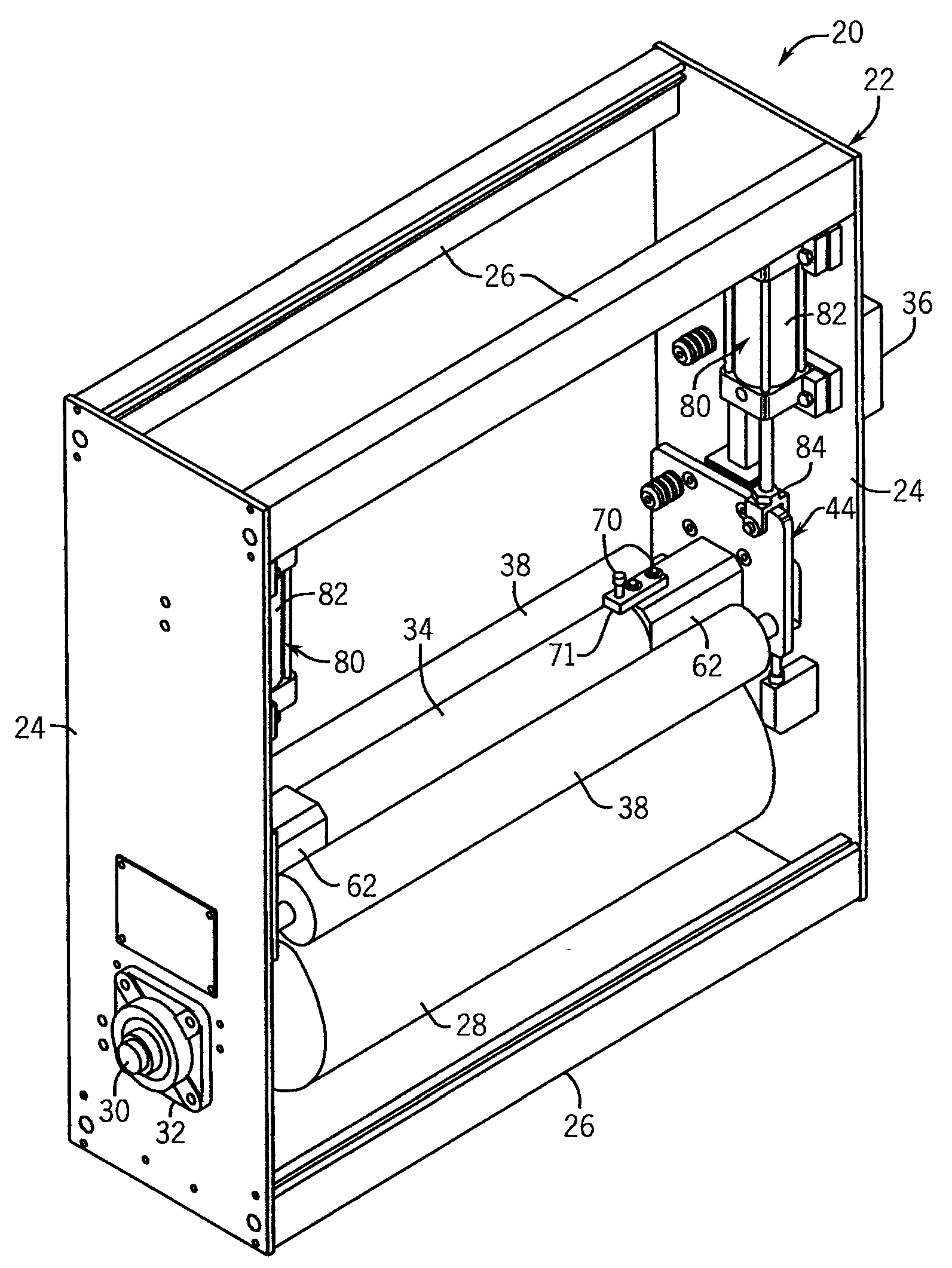

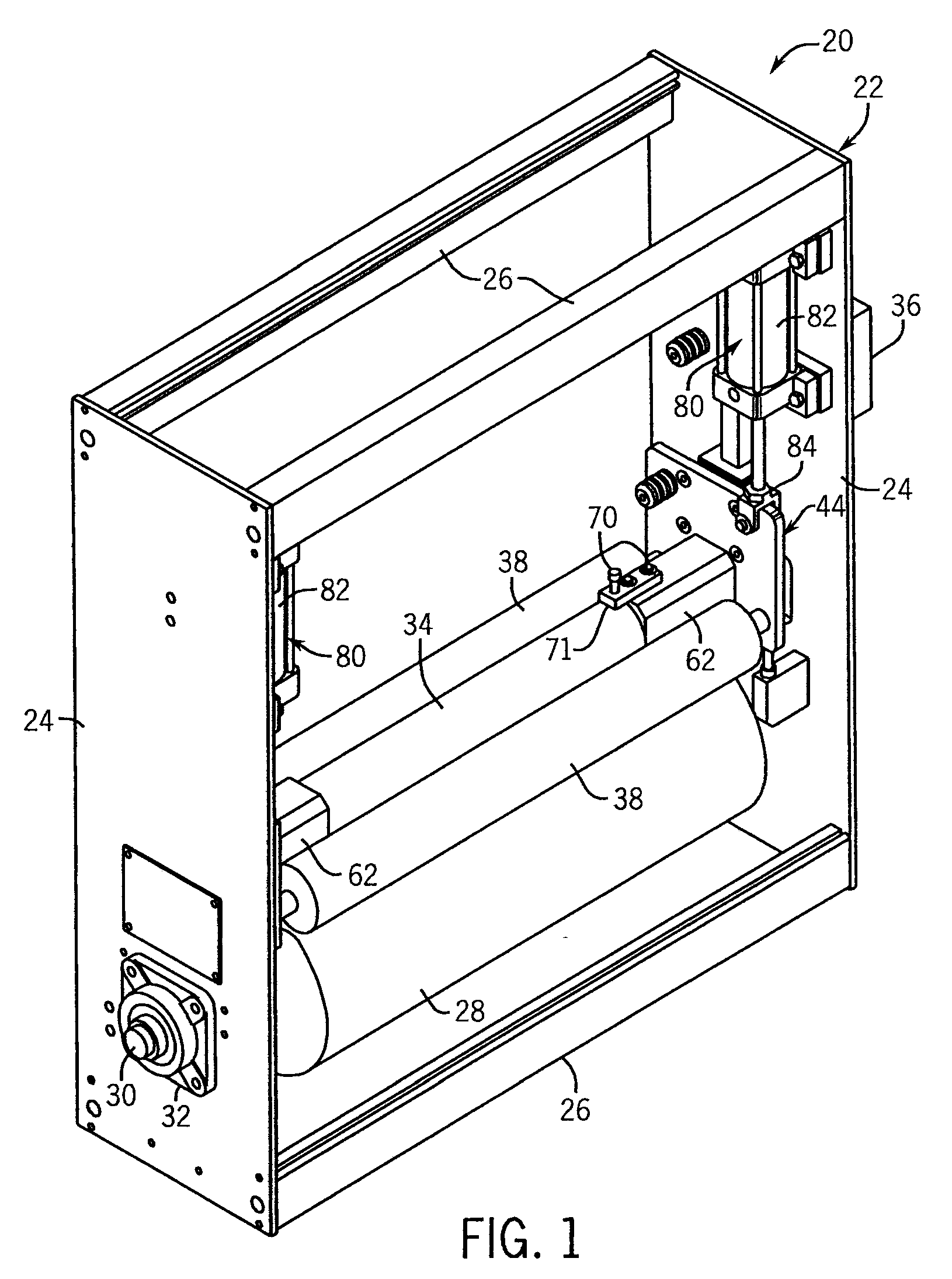

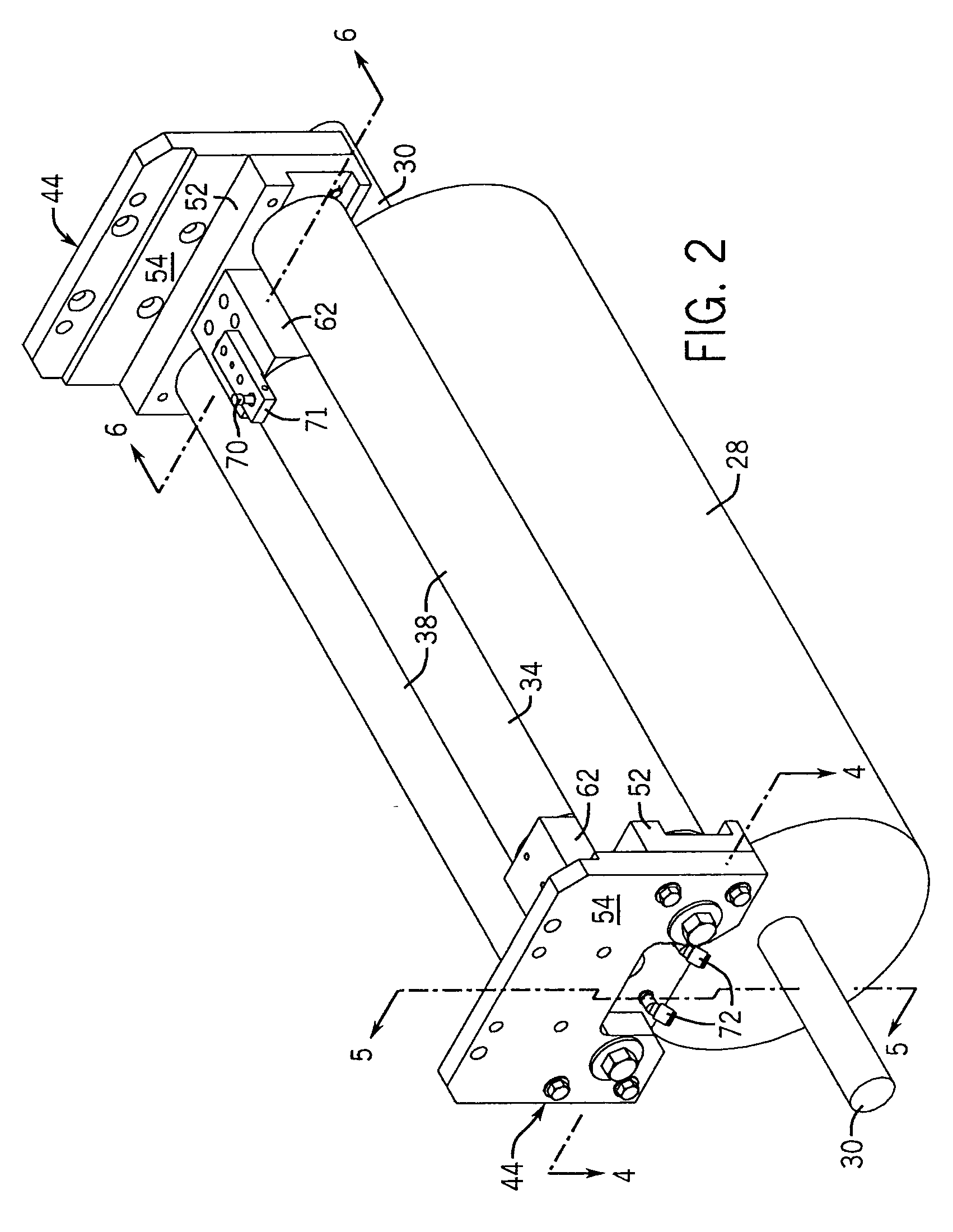

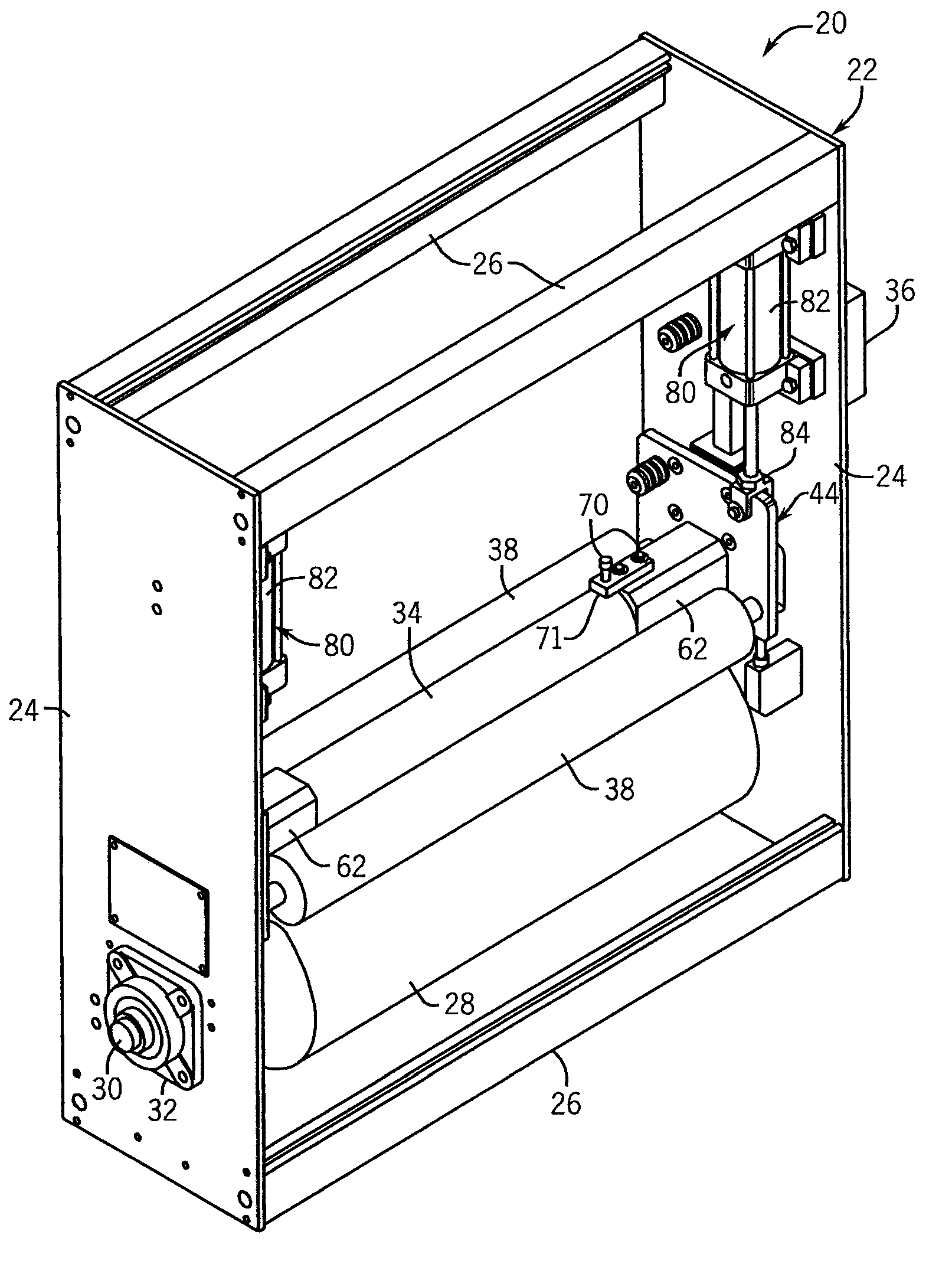

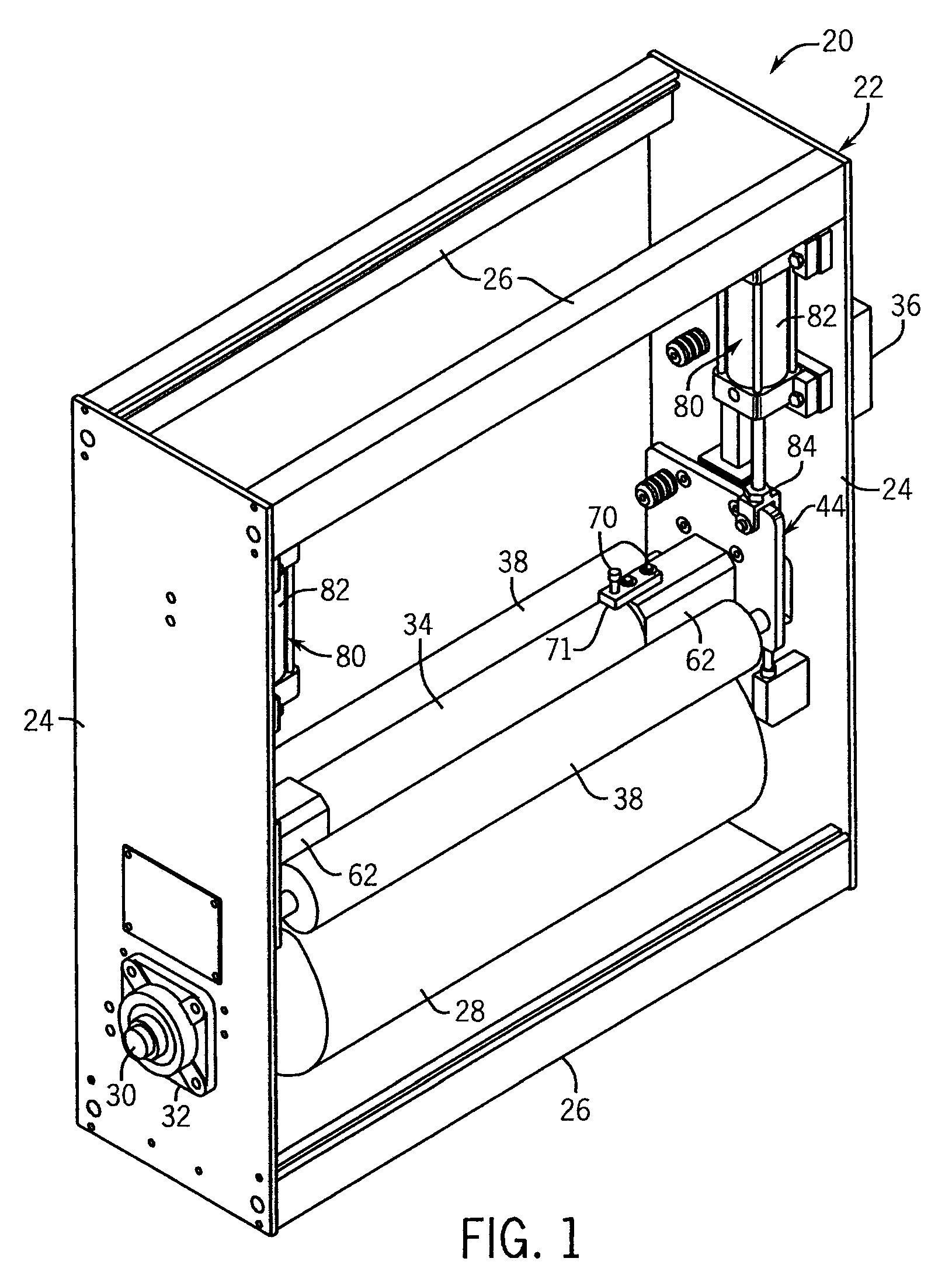

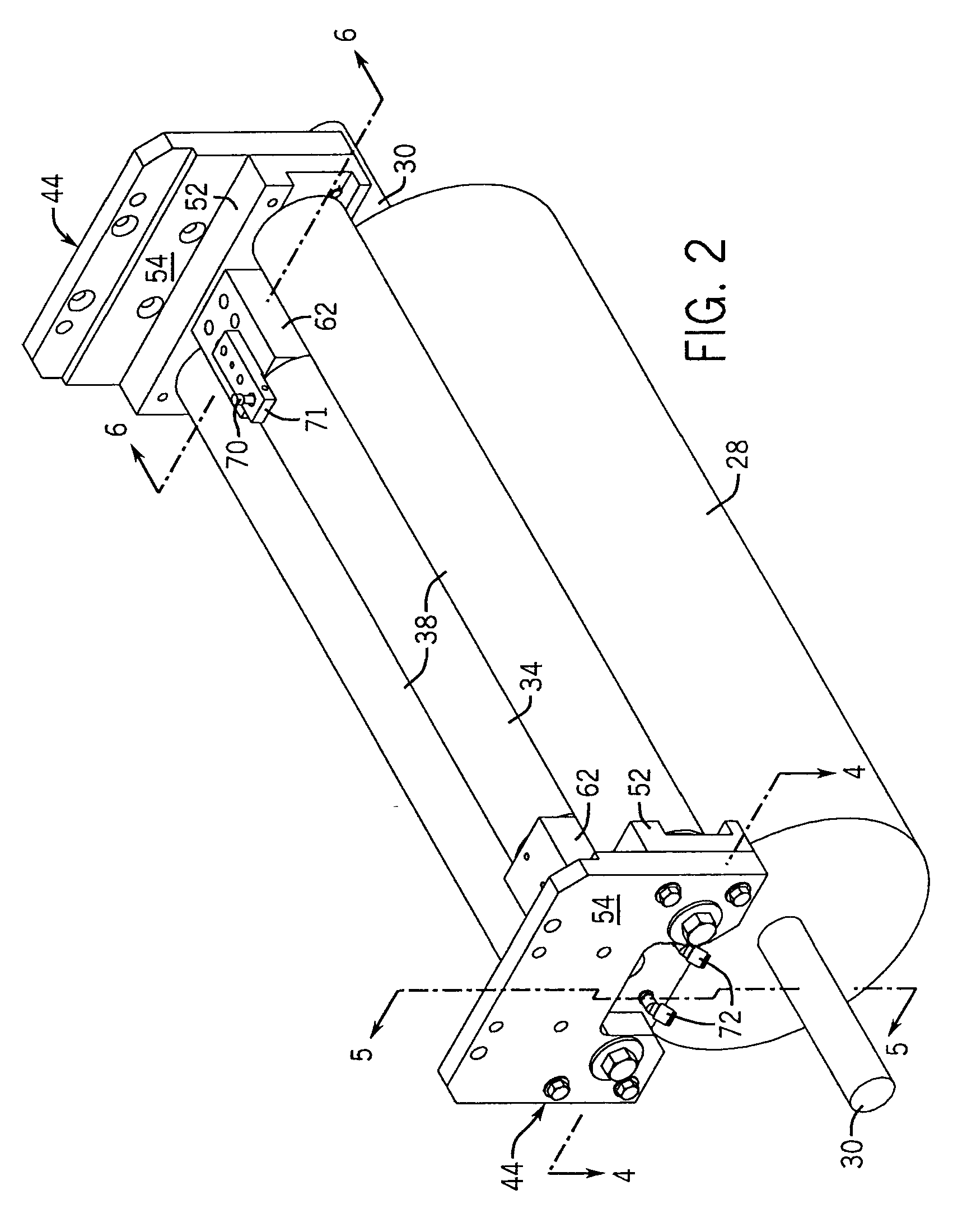

Atmospheric Treater With Roller Confined Discharge Chamber

ActiveUS20090120782A1Good surface treatmentQuality improvementDuplicating/marking methodsPhysical paper treatmentEngineeringAtmospherics

A continuous feed discharge surface treater for treating web materials has a discharge chamber where ionization of a process gas occurs defined and contained by one or more rollers. Enhanced chemical coronas and plasmas are achieved by limiting depletion of the gas chemistry from the discharge chamber and dilution or contamination from mixing with drawn in ambient air. Atmospheric coronas can also be achieved in which minimal or no ozone is exhausted from the treater. Various roller and electrode assemblies, including both fixed and rolling electrodes, can be employed.

Owner:ENERCON INDS

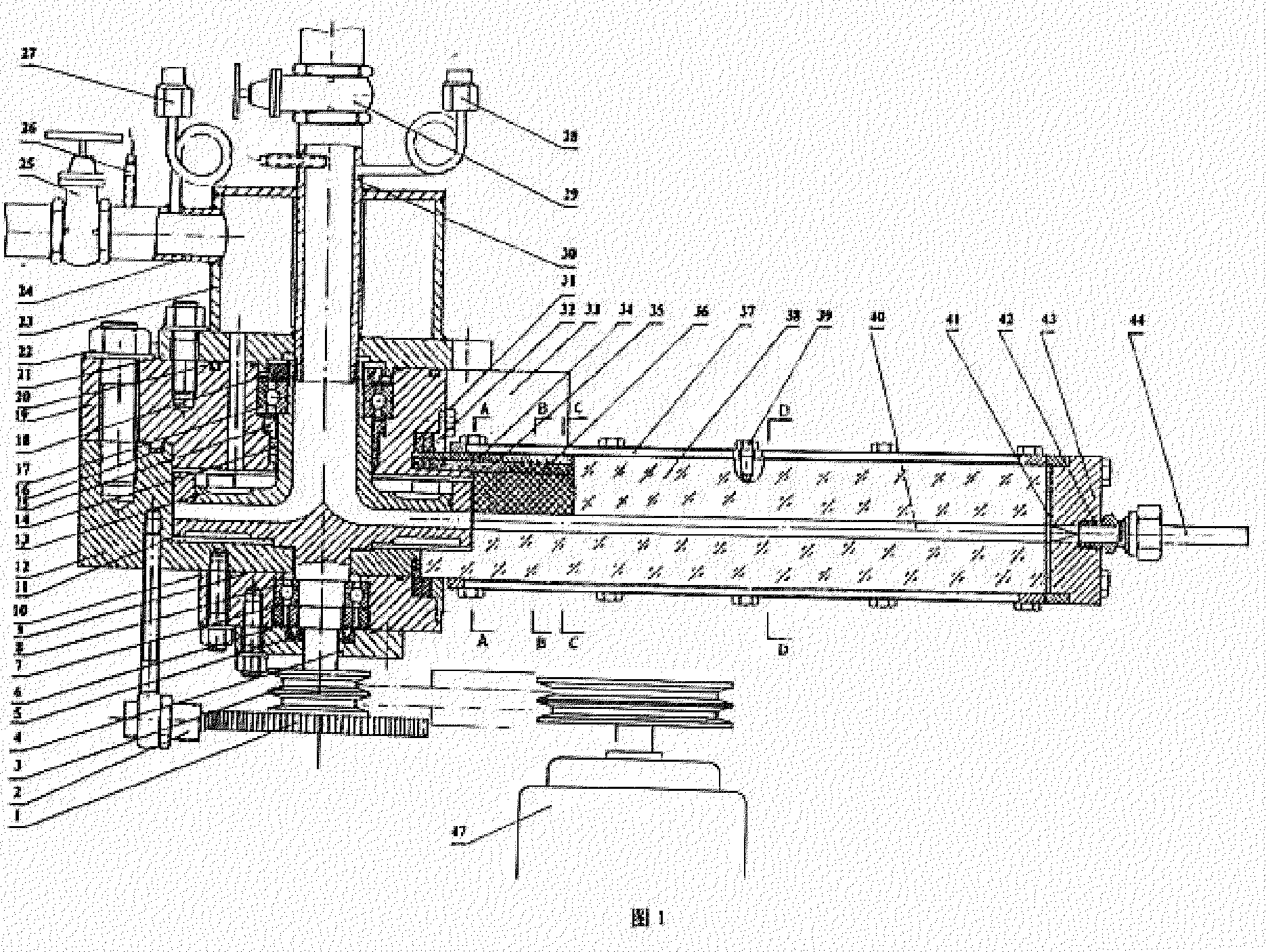

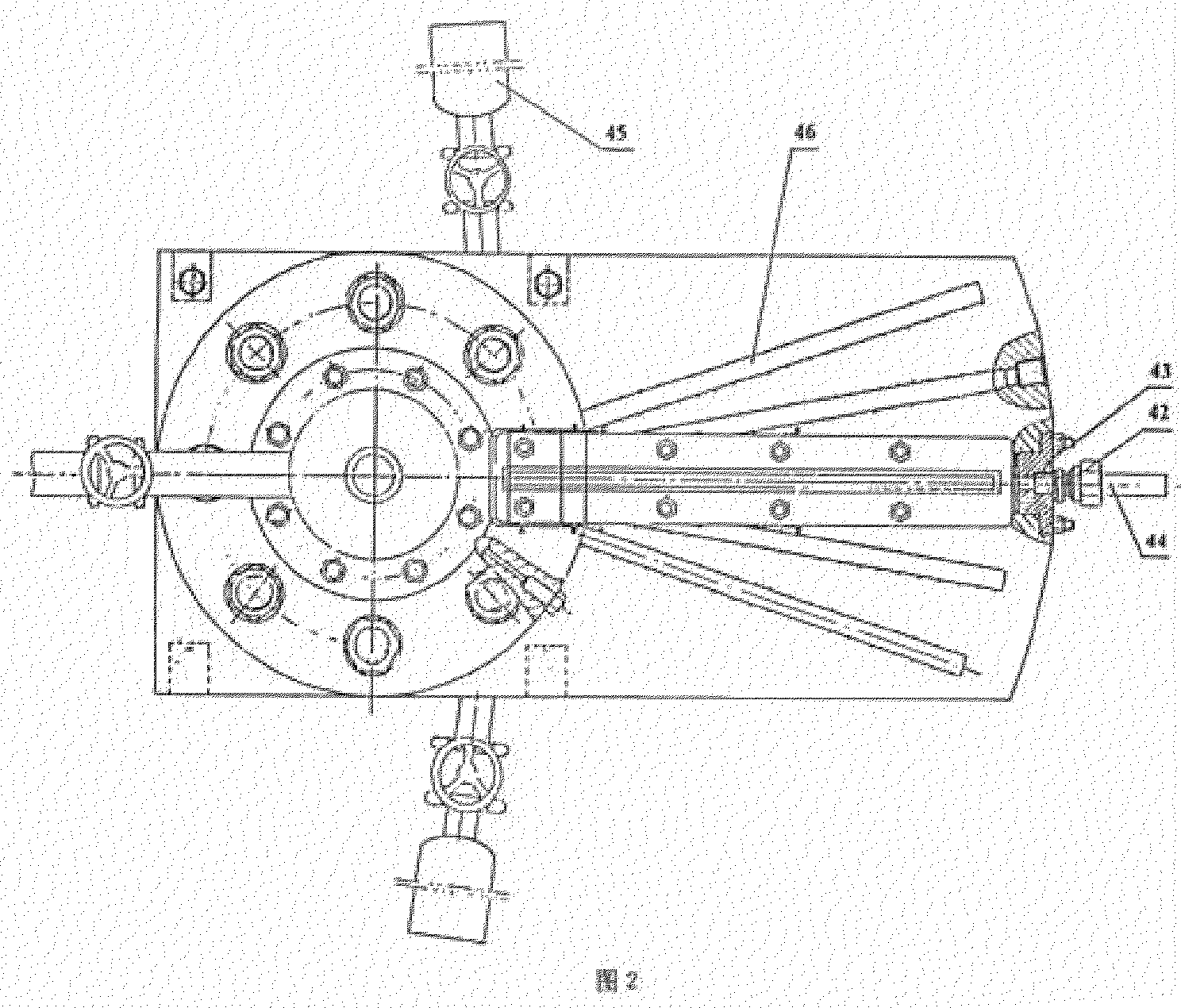

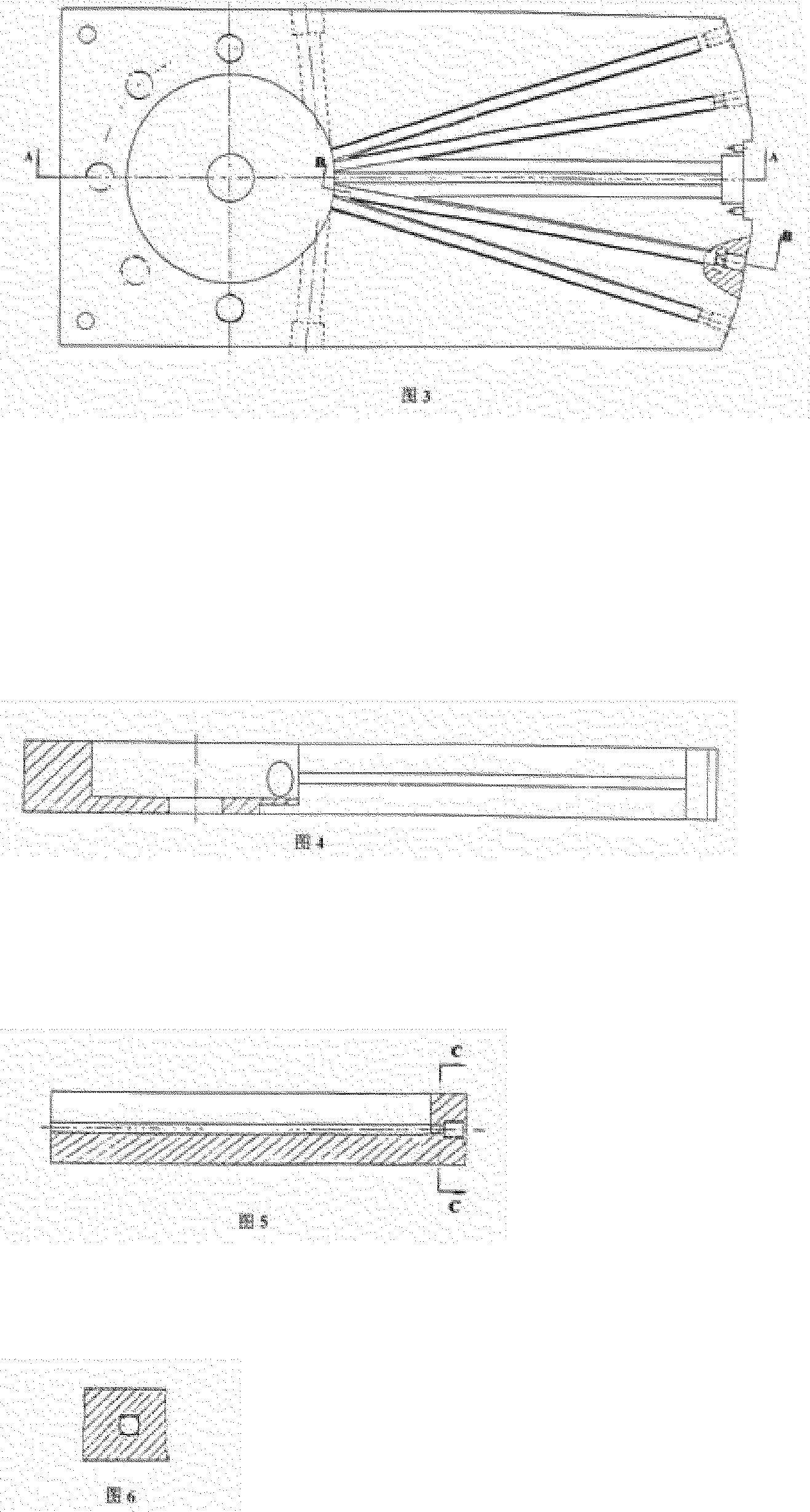

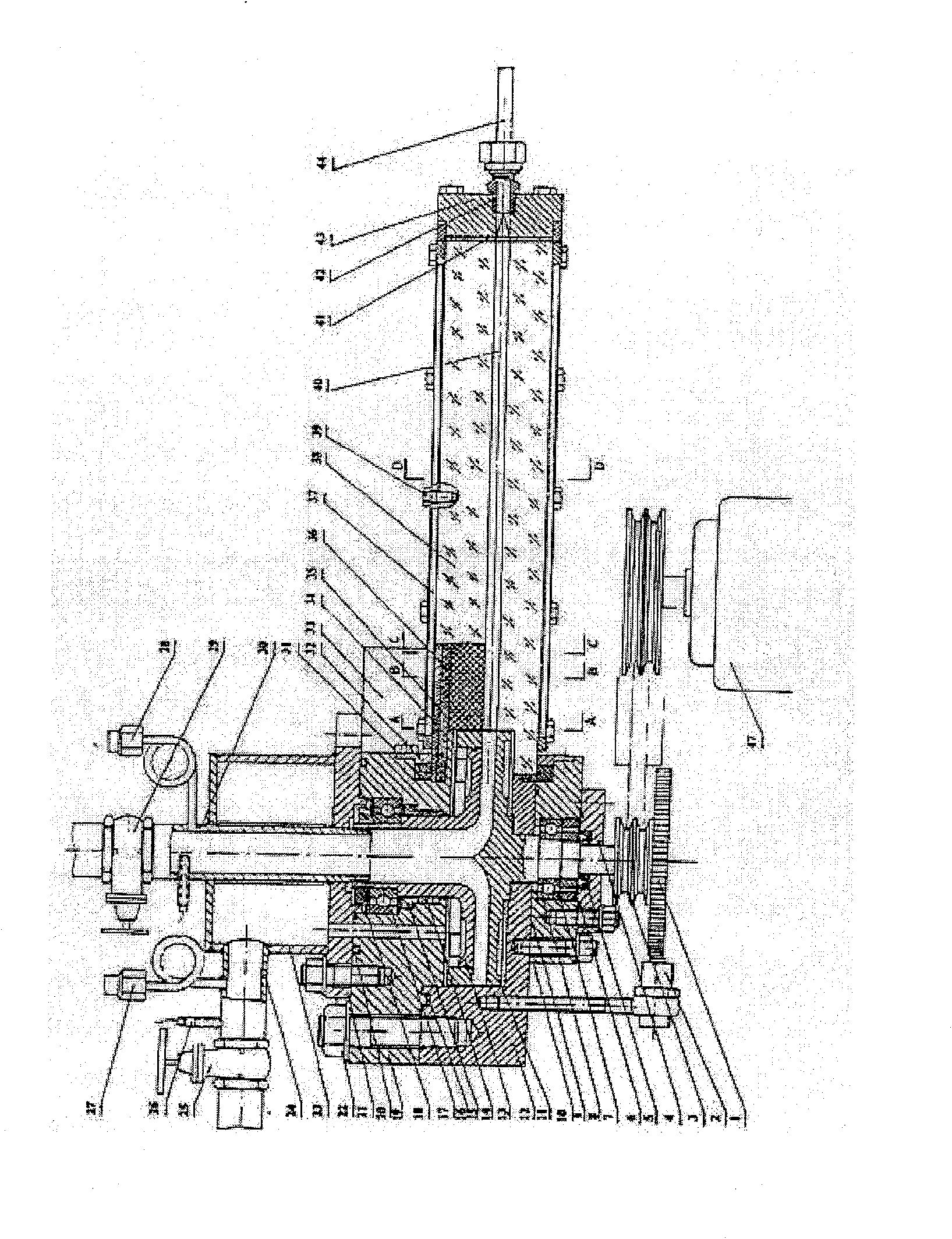

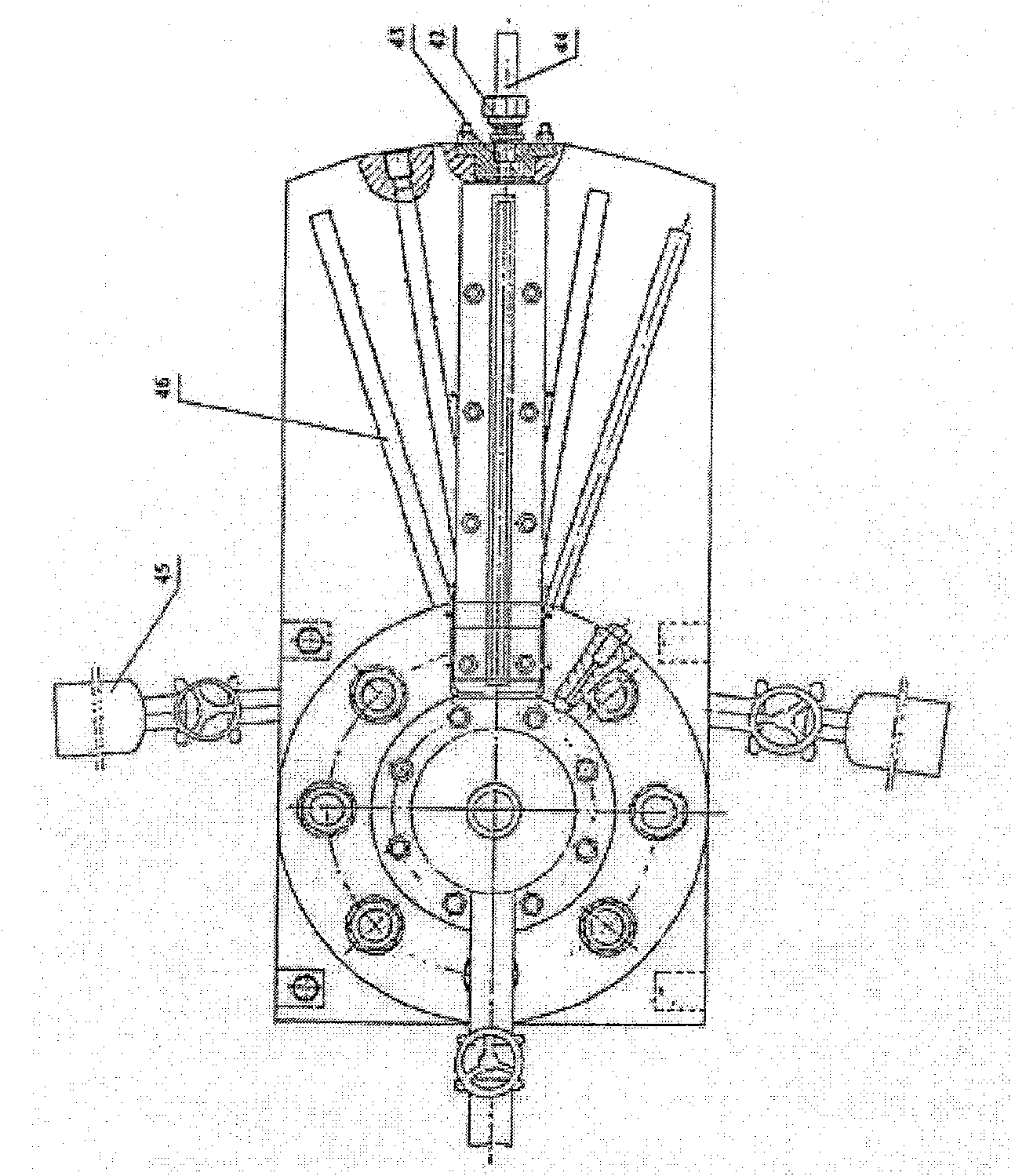

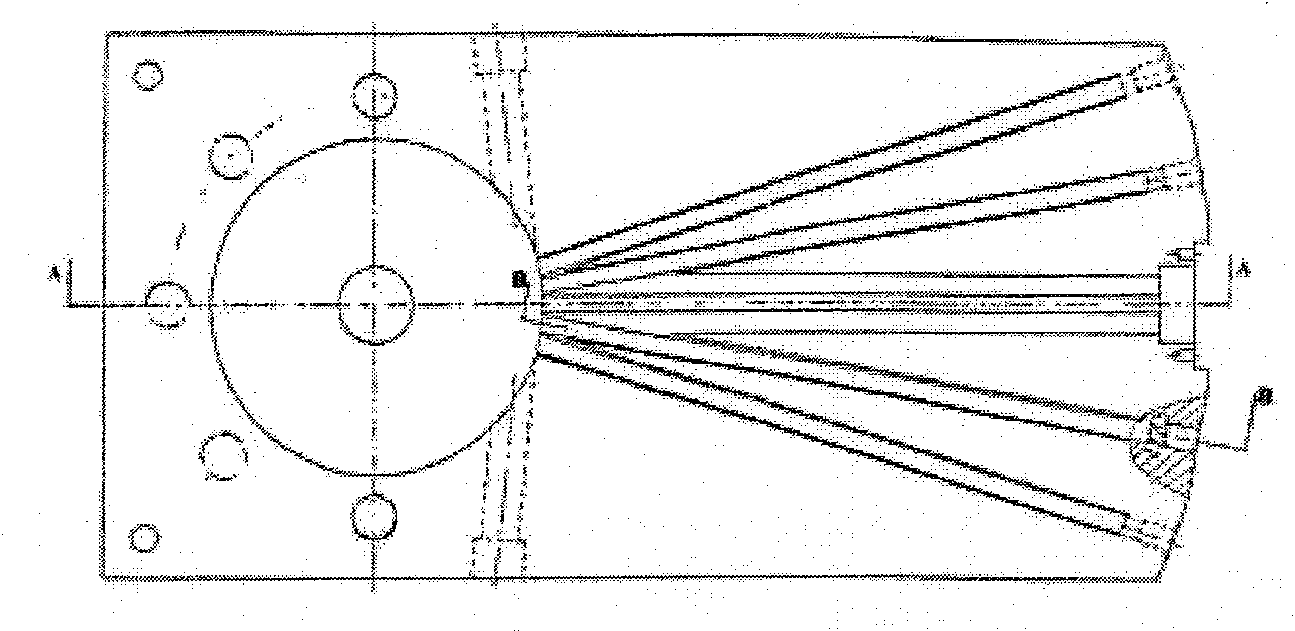

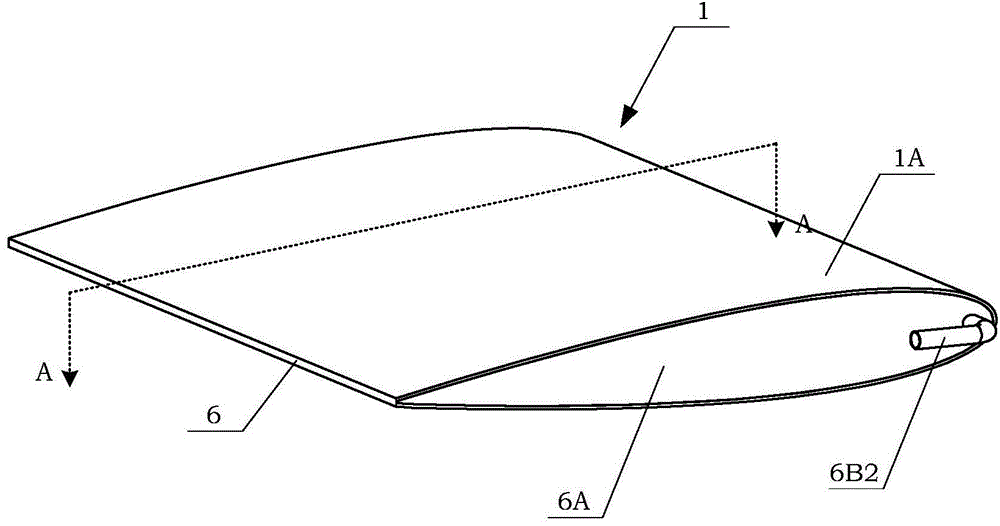

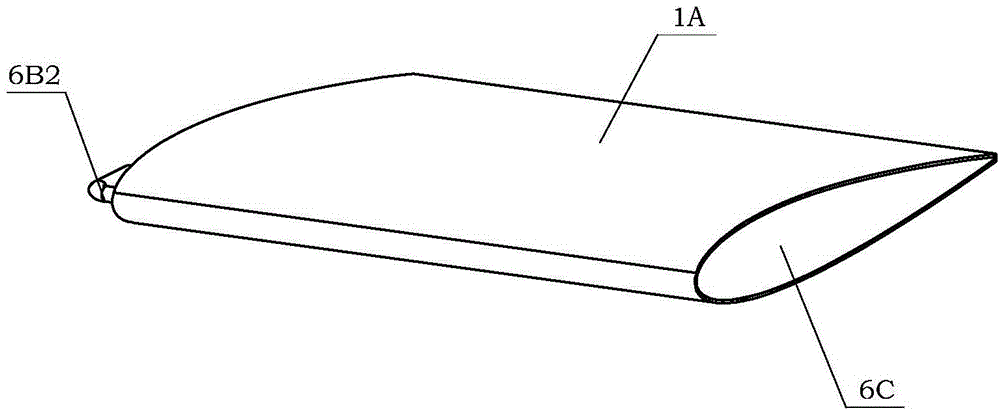

Multifunctional gas wave refrigerating jet stream field displaying apparatus and method for measuring

InactiveCN101097167ASimple structureEasy to processAerodynamic testingHydrodynamic testingExperimental researchJet flow

A kind of multiple functions gas wave cooling effluxion flow filed display device and measuring method which belongs to technique field of effluxion of pressure gas and expanded cooling and measuring control. The invention adopts integrated structure and works when running and static and possesses window for view and shooting image, it can analogue working mechanism and performance of multiple types of gas, and provides platform for leading high-precision PIV to wave mechanical flow filed measurement, and measures important parameters in-phase, and fulfills requirement of experiment, and accomplishes research content of changing condition, experiment component, rotate speed, two phases of gas and liquid, and accomplishes important experiment of best matching of structure and parameter. The structure is reasonable and easy, operation is convenient, and performance is stable and reliable. It fits for multiple functions gas wave cooling measuring filed of changing condition and research content.

Owner:DALIAN UNIV OF TECH

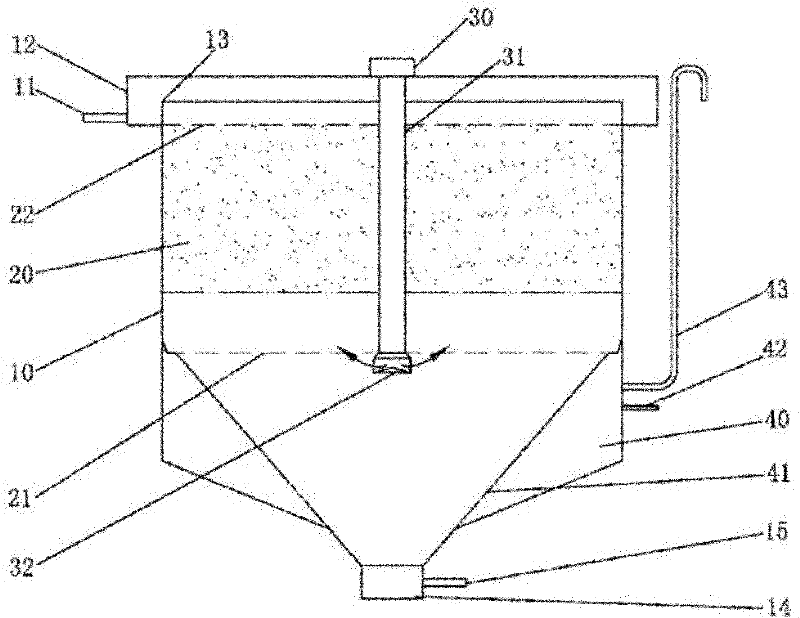

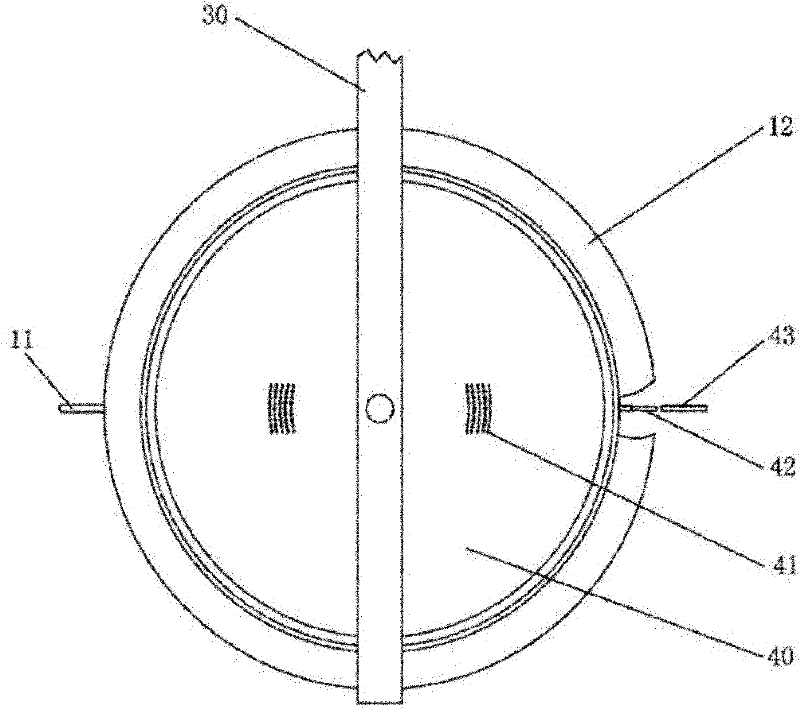

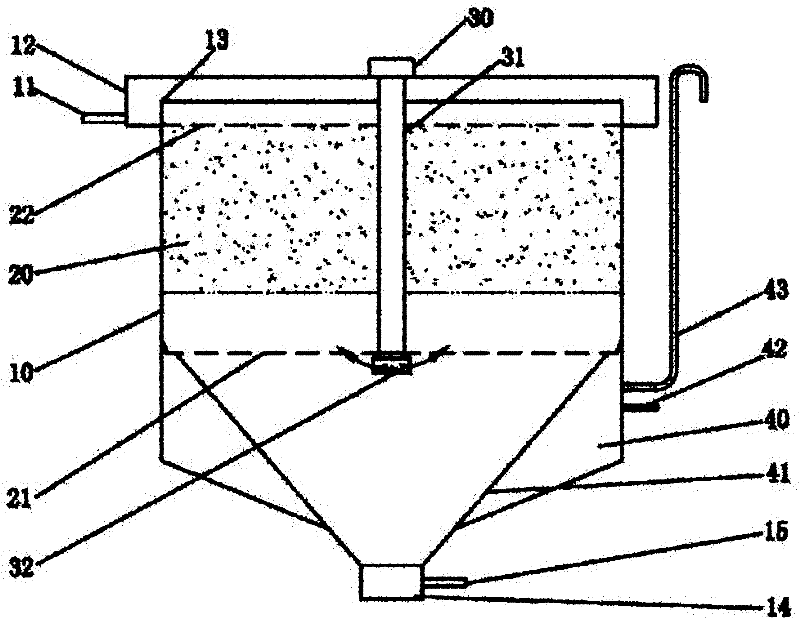

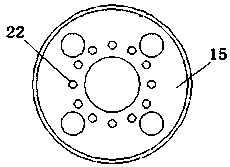

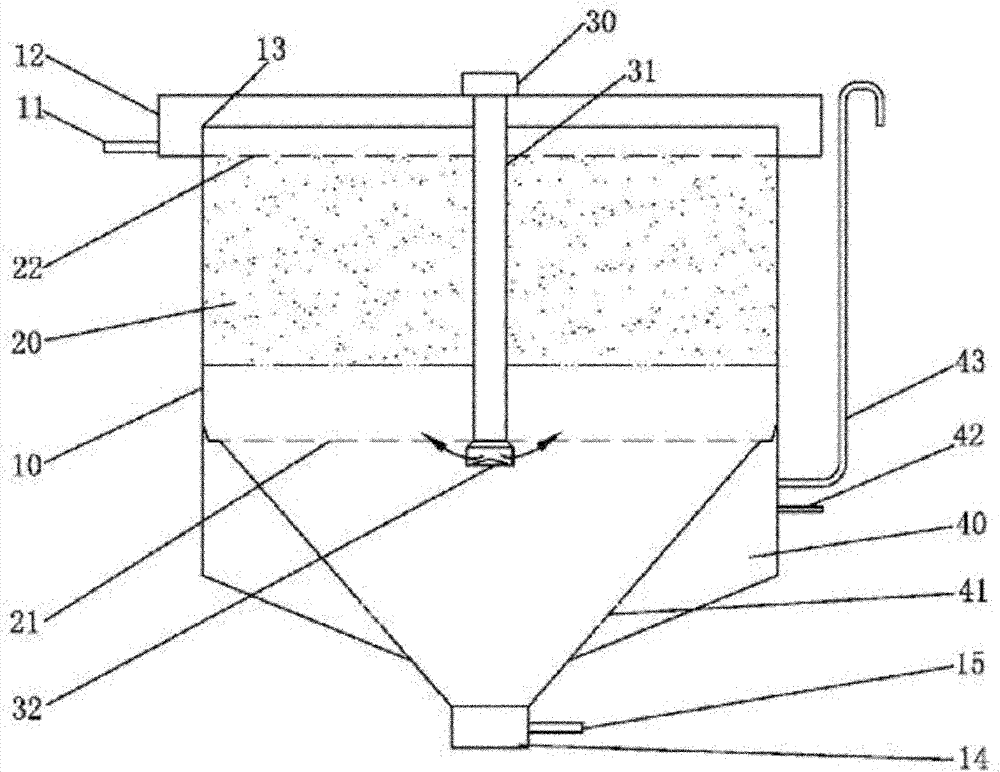

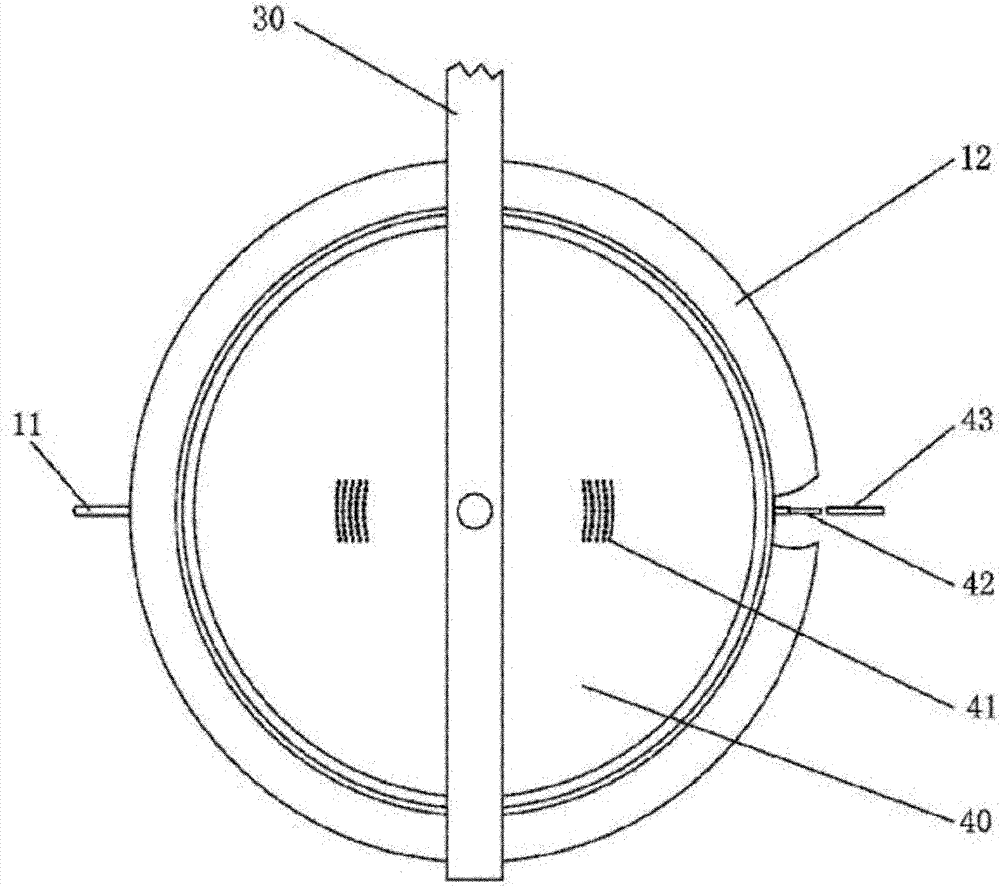

Aquiculture integrated water processing unit and flushing method thereof

InactiveCN102218236ALarge specific surface areaSmall particle sizeLoose filtering material filtersGravity filtersProduct gasWater processing

The invention relates to the technical field of aquiculture water processing and discloses an aquiculture integrated water processing unit, which comprises a hopper-shaped pool body (10); a hole plate (22) is arranged at the upper part of the pool body (10); a filter material (20) for light weight foaming grains is arranged on the lower part of the hole plate (22); a communicating hole (41) and aback-flushing air chamber (40) are arranged at the lower part of the conical surface of the pool body (10); an intake pipe (42) and an exhaust pipe (43) are respectively arranged above the pool body;and a screen (21) is arranged at the lower part of the cylinder of the pool body (10). A flushing method for the aquiculture integrated water processing unit is as follows: a discharge pipe (15) is opened and then is closed; the intake pipe (42) is opened for charging air; the water in the back-flushing air chamber (40) is pressed into the pool body (10); when the back-flushing air chamber (40) is filled with air, the intake pipe (42) is closed and the exhaust pipe (43) is opened instantly; then the air is exhausted and the water in the pool body (10) quickly enters the back-flushing air chamber (40); then the filter material (20) downwards expands and looses; and the intercepted suspension solids and aged biomembrane fall into the water and the filter material (20) is flushed. The filtermaterial has high water processing efficiency, good back-flushing effect and low energy consumption.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

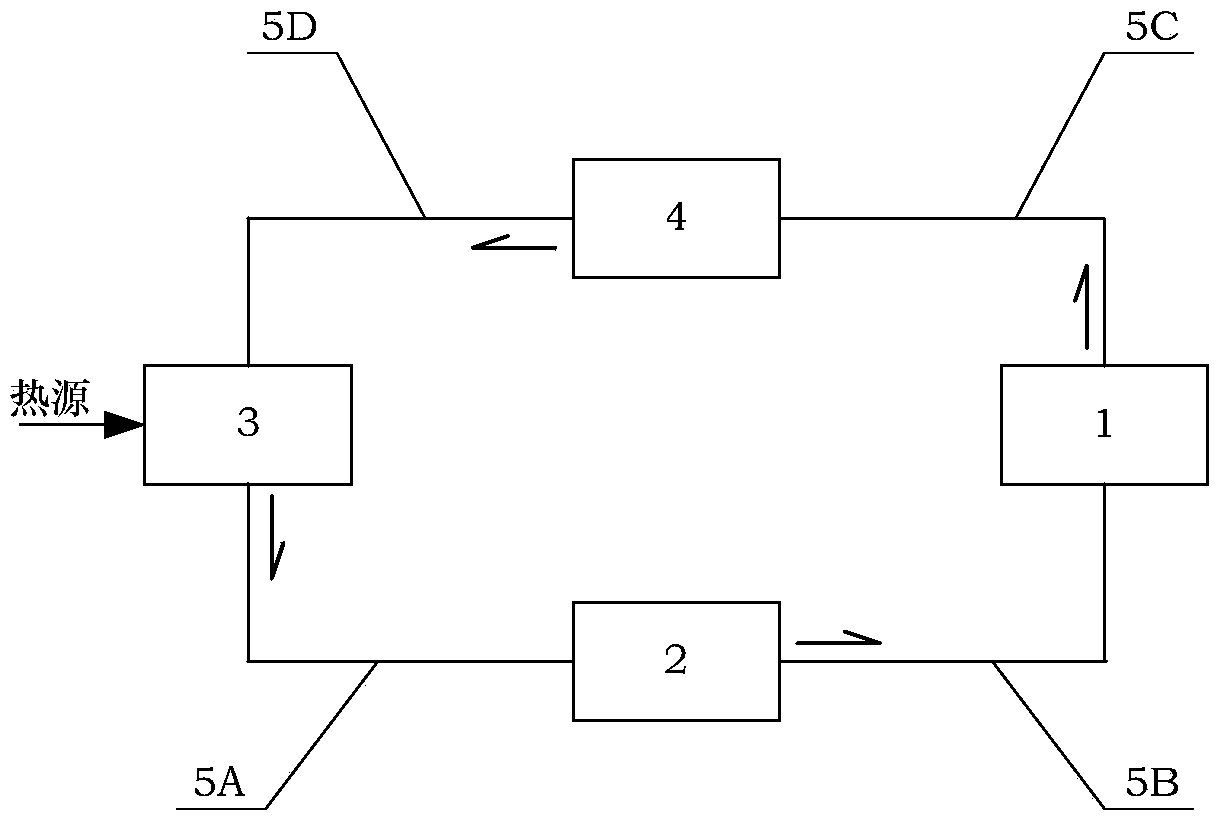

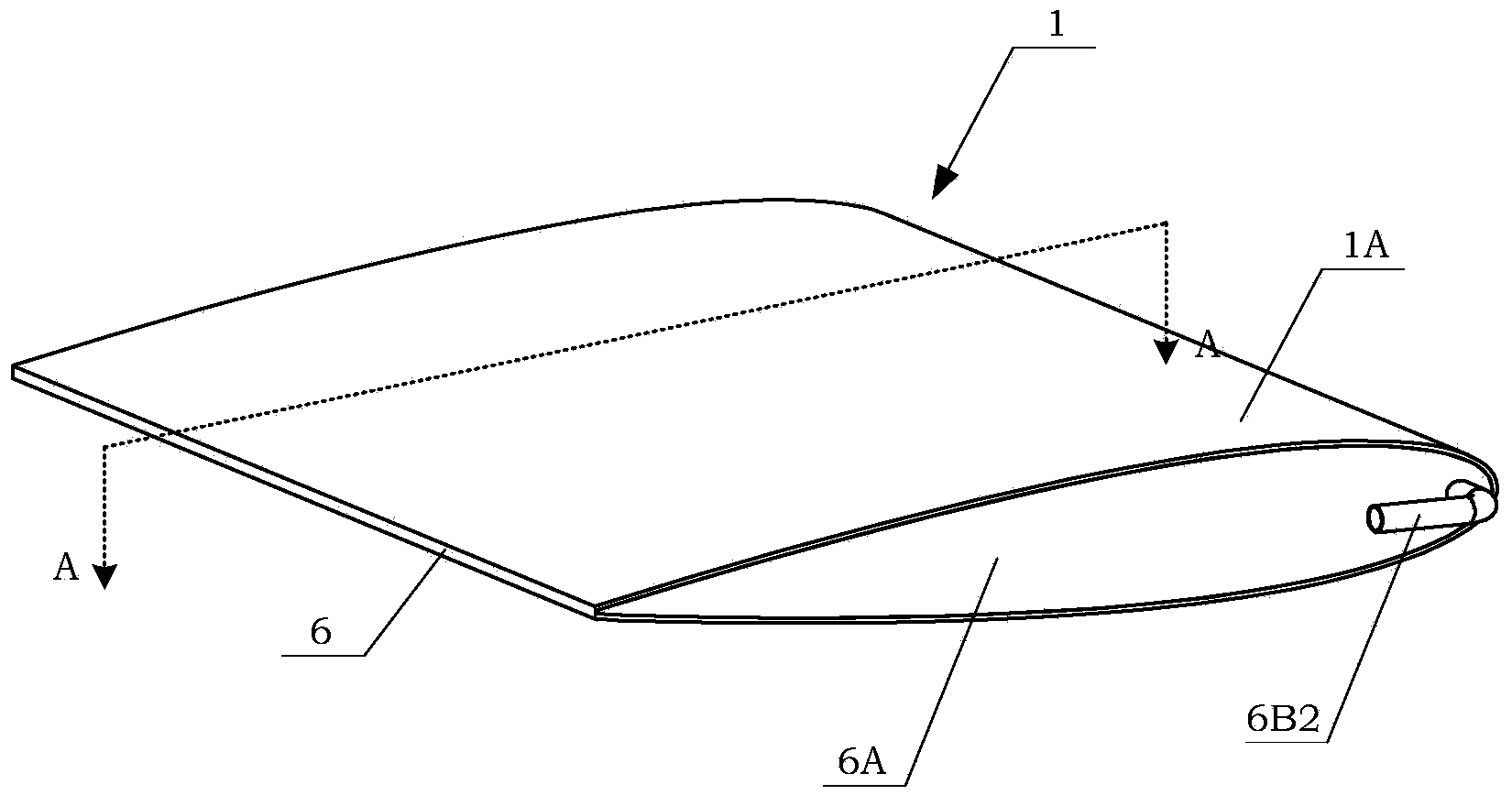

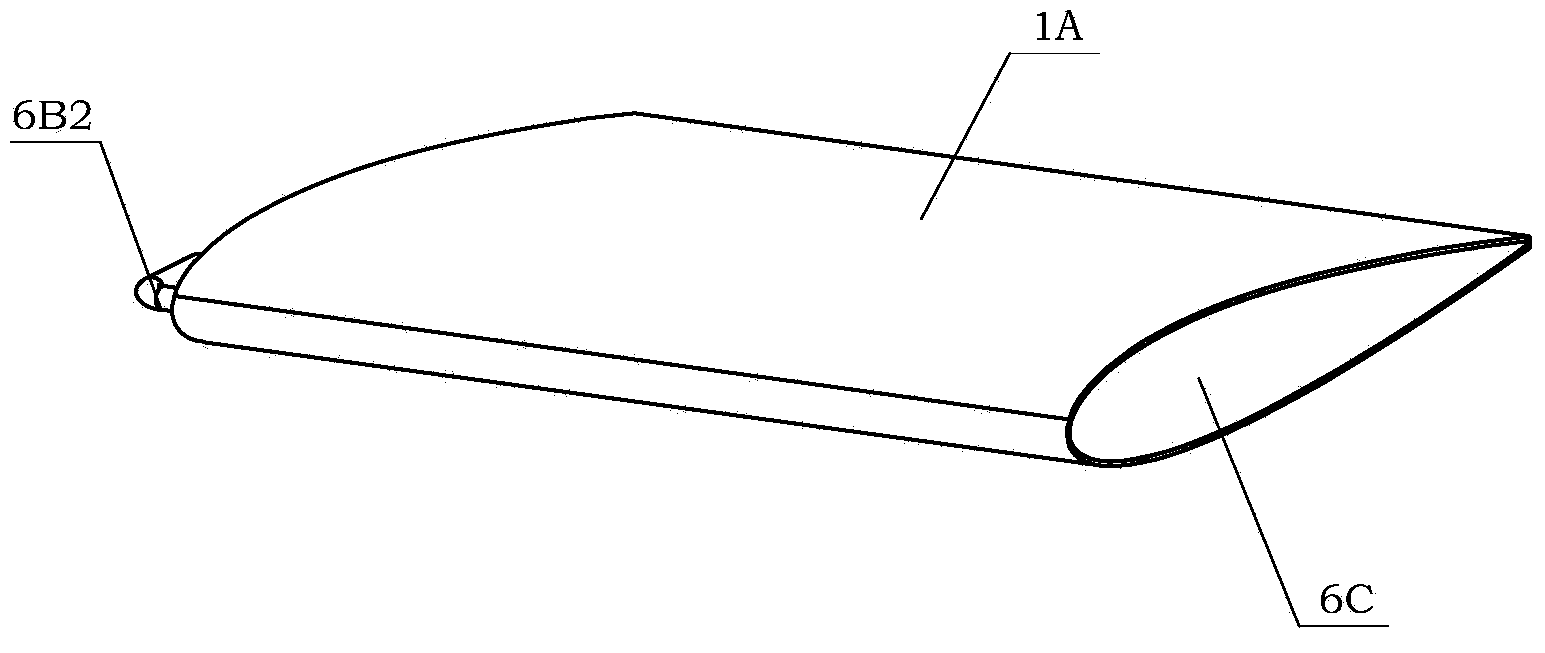

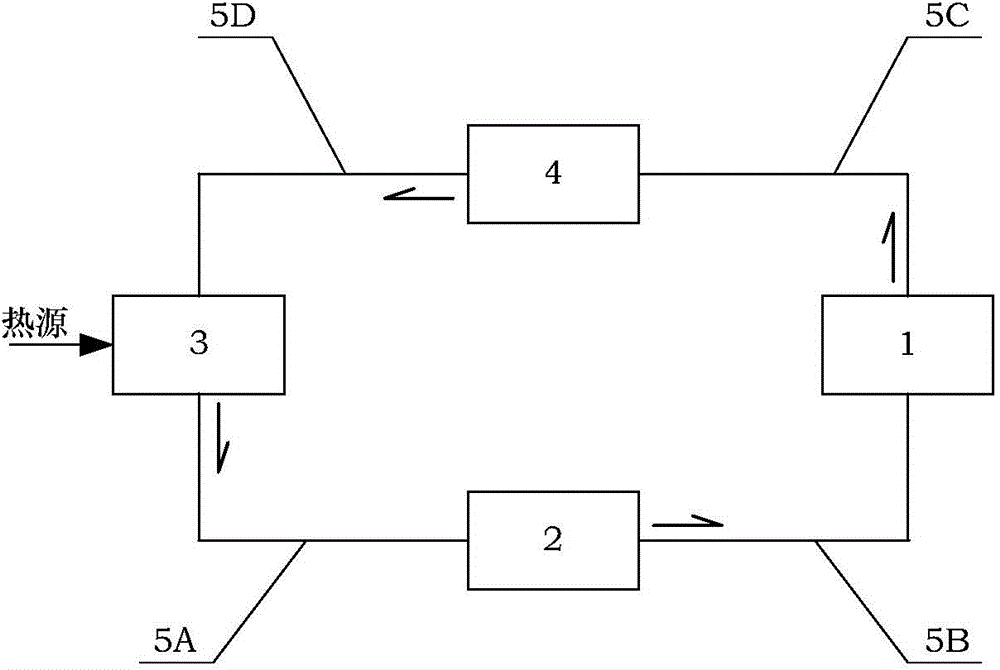

Novel wing icing prevention system using airborne waste heat

The invention discloses a novel wing icing prevention system using airborne waste heat. According to the system, the connection among a skin heat exchanger, a rotary compressor, an evaporator and an electronic expansion valve is realized through a pipeline; a liquid storage device is additionally arranged in an anti-icing cavity of each wing, and a double-skin structure is changed. According to the system disclosed by the invention, an evaporative-cycle anti-icing manner is adopted to an unmanned aerial vehicle, heat source heat of airborne electronic equipment is sufficiently absorbed by using the evaporator and the heat exchanger, is transferred to skin in a flute-shaped tube impact jet flow manner and is subjected to heat exchange with outside supercooling wet air, and the temperature of the skin is increased to the minimum anti-icing temperature, so as to reach the anti-icing effect.

Owner:BEIHANG UNIV

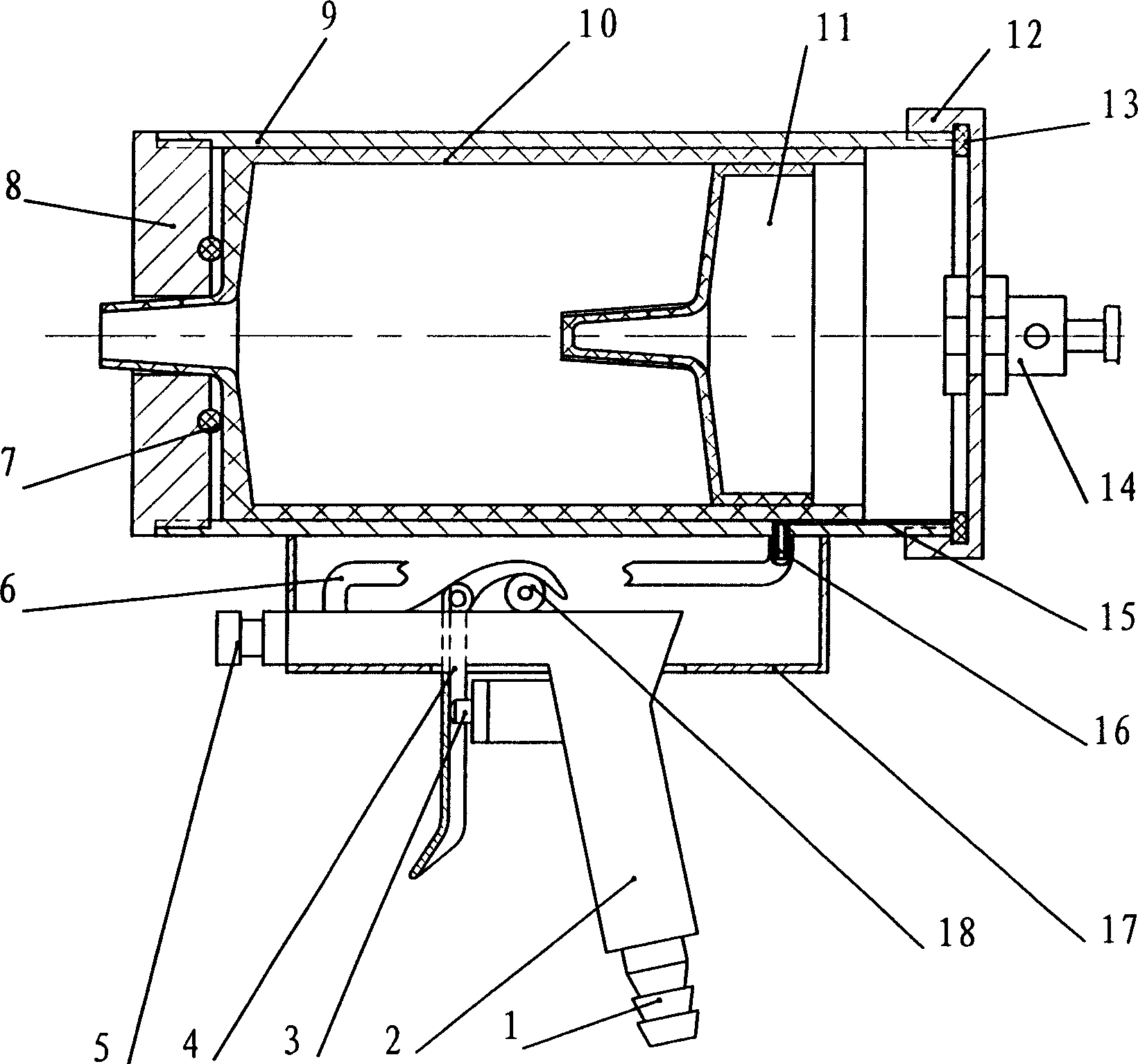

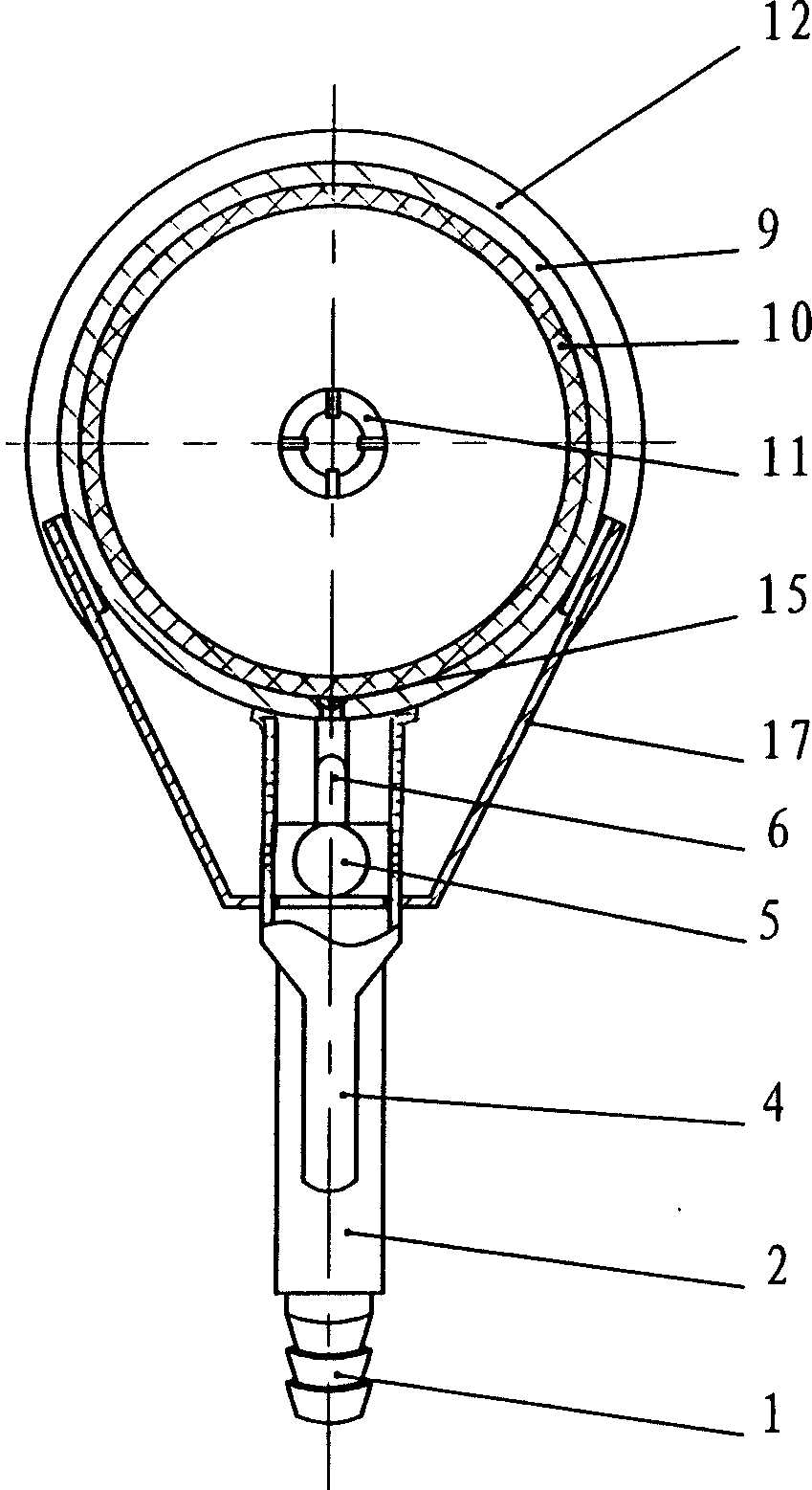

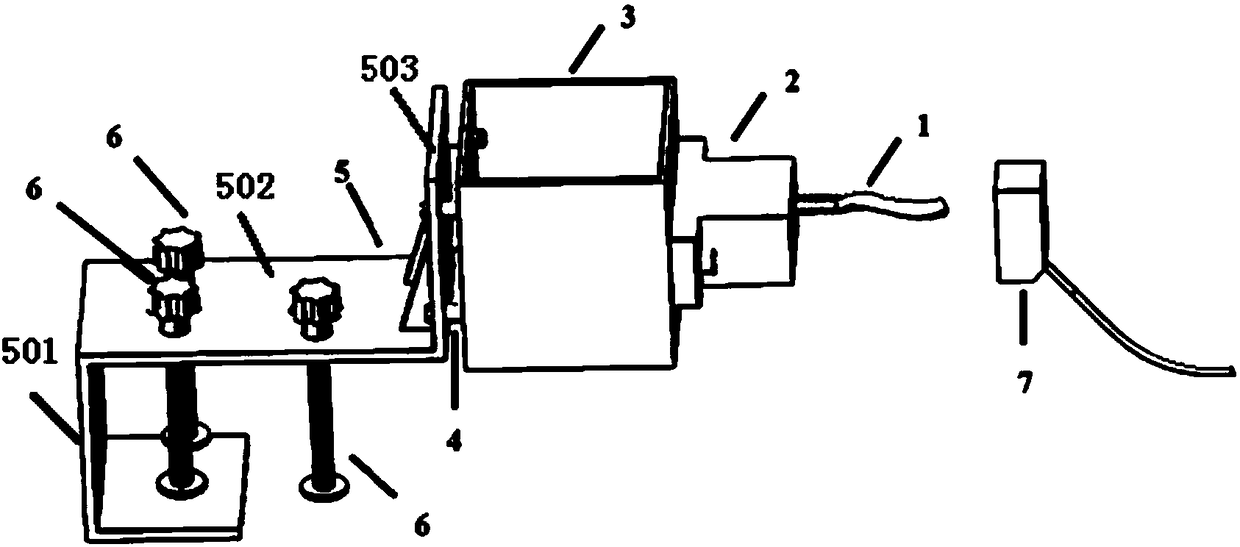

Pneumatic hand control ink supply device

The pneumatic hand control ink supplying device includes barrel for installing the ink container, pneumatic control unit on the barrel, air pipe in the outlet of the pneumatic control unit and connected to the air inlet hole on the barrel, back cap on one end of the barrel to cover the installed ink container, and top cap on the one end. The pneumatic hand control ink supplying device is simple, reliable, fast in ink feeding speed of 1.2 kg / min, high in production efficiency and low cost.

Owner:谭慈源

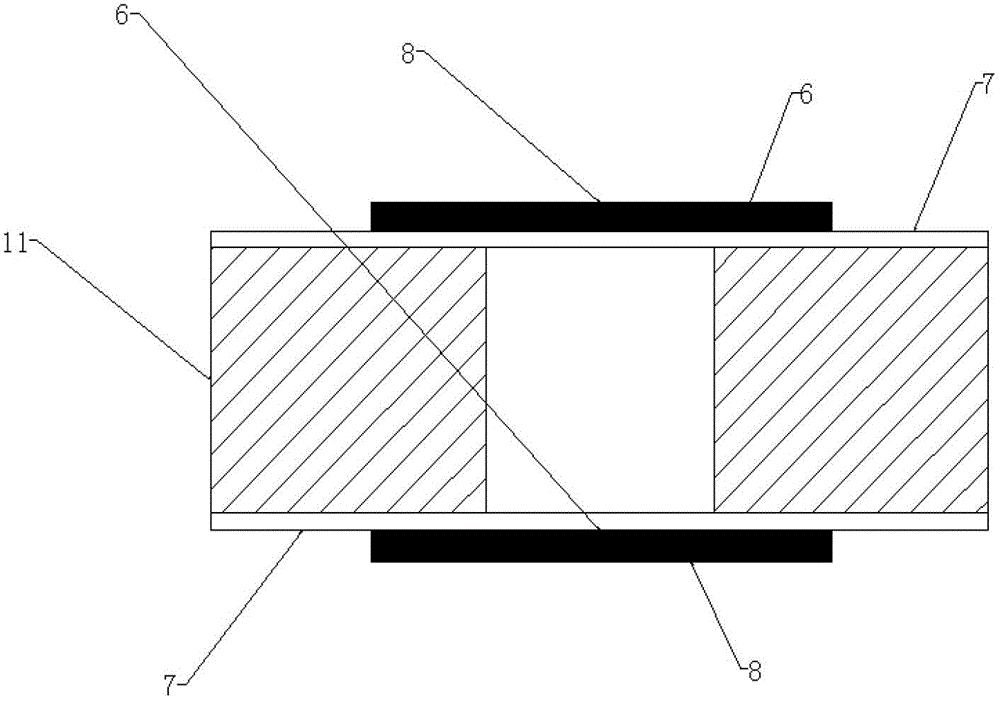

Spectrum detection method and device for dielectric barrier discharge

InactiveCN103149195AMiniaturizationSimple structureAnalysis by electrical excitationAngle of incidenceMiniaturization

The invention provides a spectrum detection method and a spectrum detection device for dielectric barrier discharge. The detection method comprises the following steps that after the dielectric barrier discharge generates plasma, the incident light enters from an inclined angle, is repeatedly reflected in a reflection layer in a dielectric barrier discharge cavity and is emitted from the carrier gas outlet at the inclined angle, the emitted light is received by the detector, and the signal is detected. The light path length can be adjusted by adjusting the incident angle according to the needs, and because the incident light is emitted in an angle, the backlight light interference generated by discharge is effectively avoided. Compared with the conventional detection method, the method has the advantages that the sensitivity and stability are effectively improved, the method is simple in structure, small in size and low in gas consumption, and miniaturization of the instrument is easily realized.

Owner:HOHAI UNIV

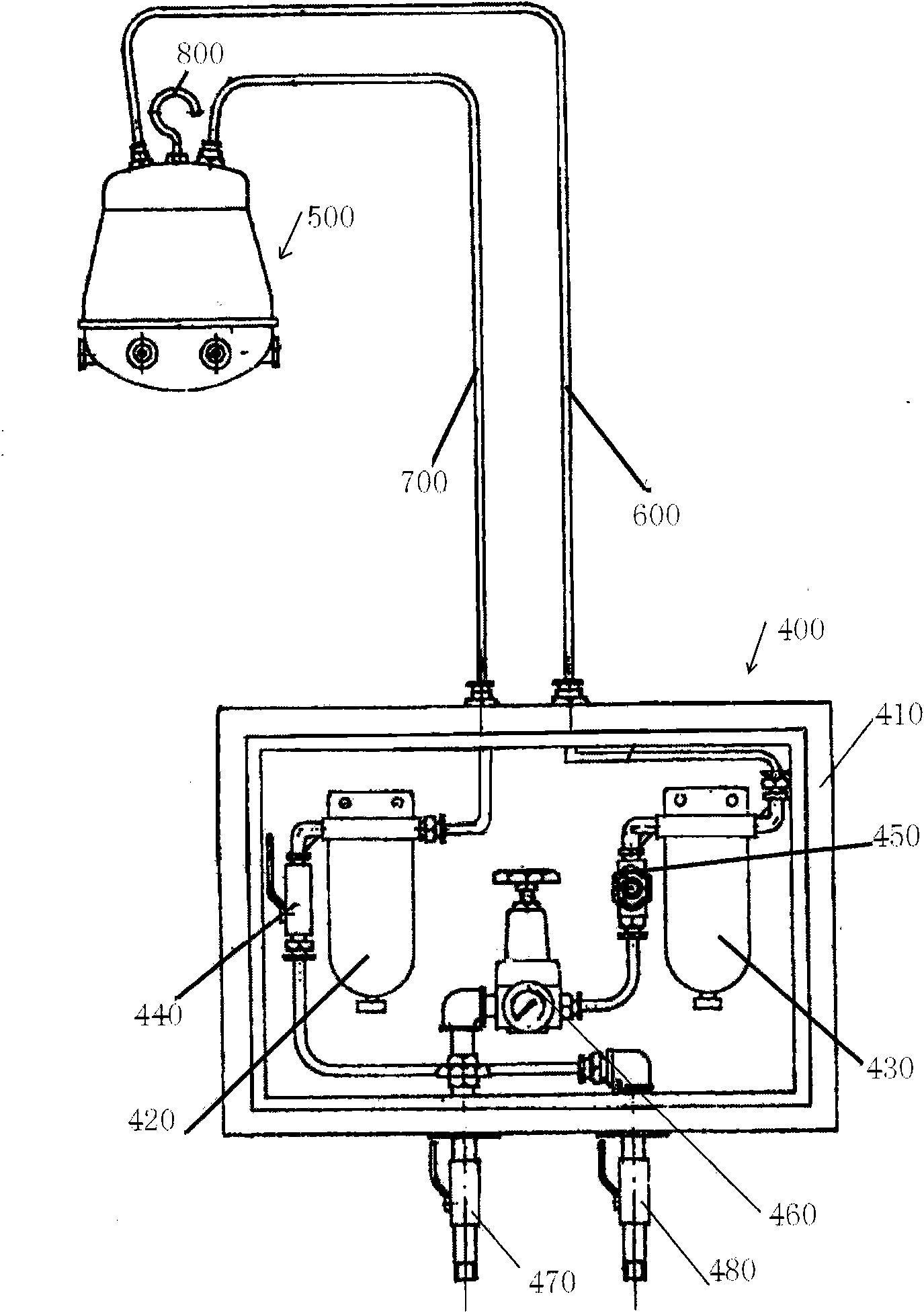

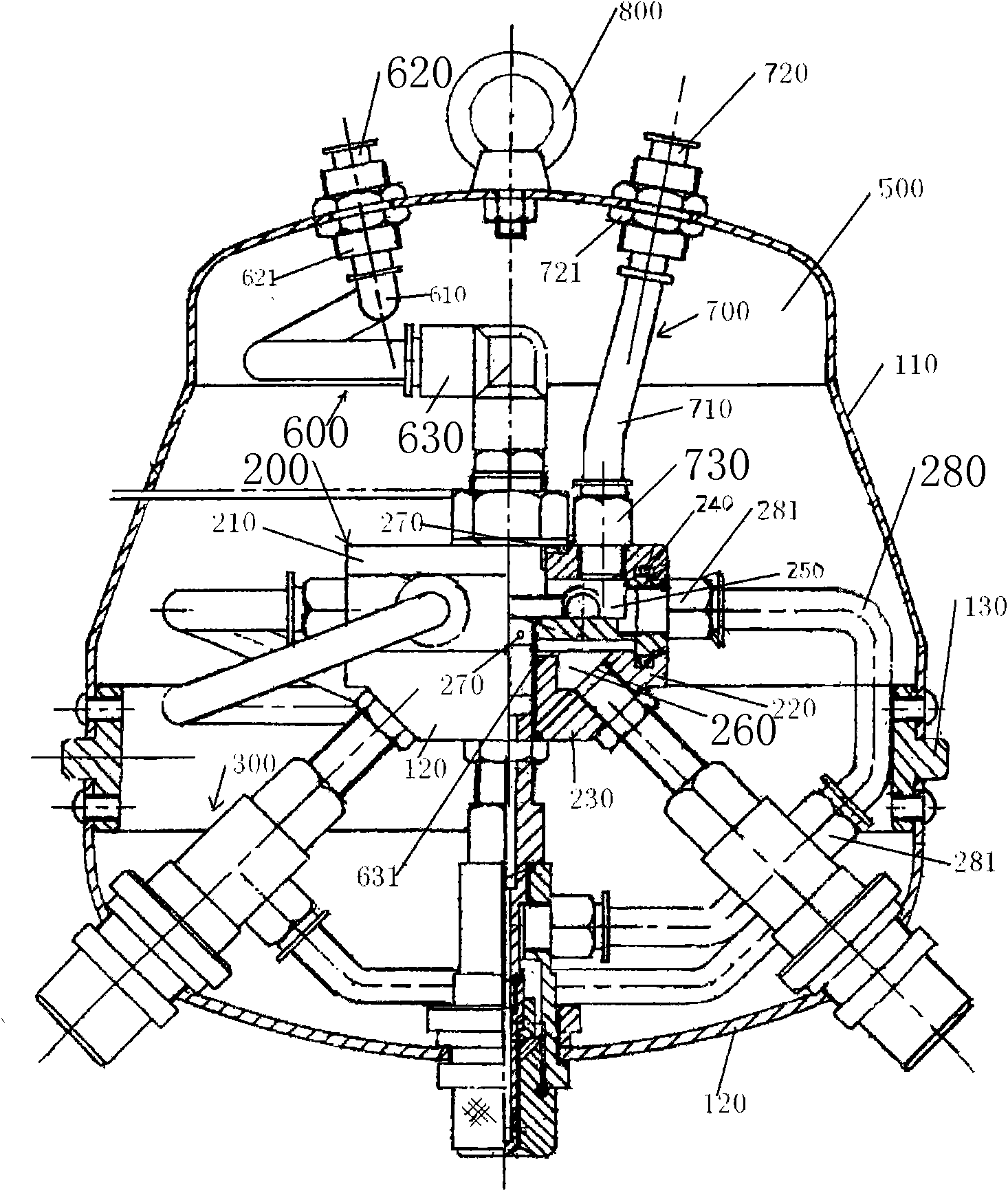

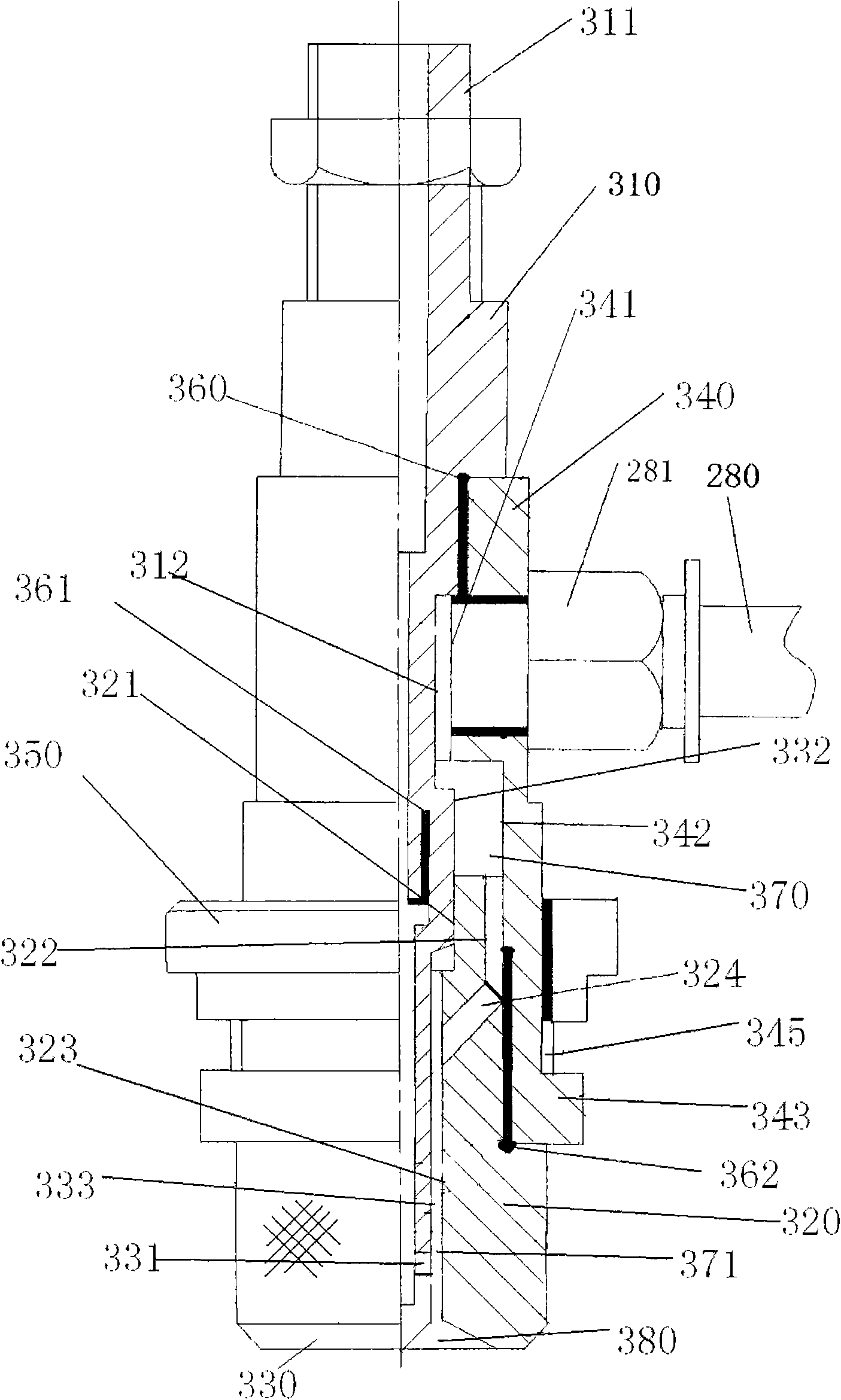

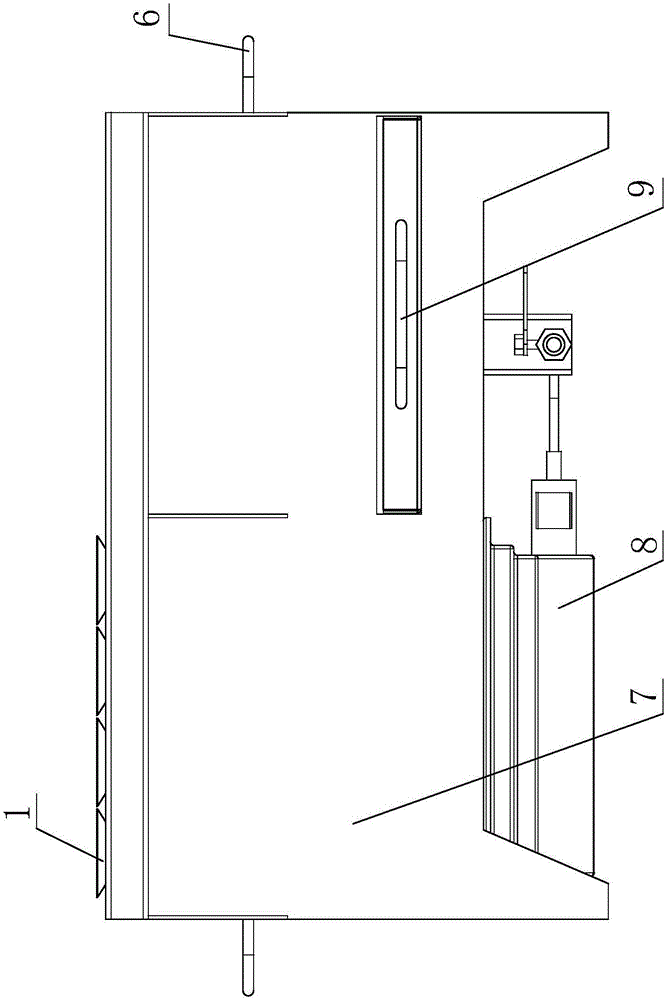

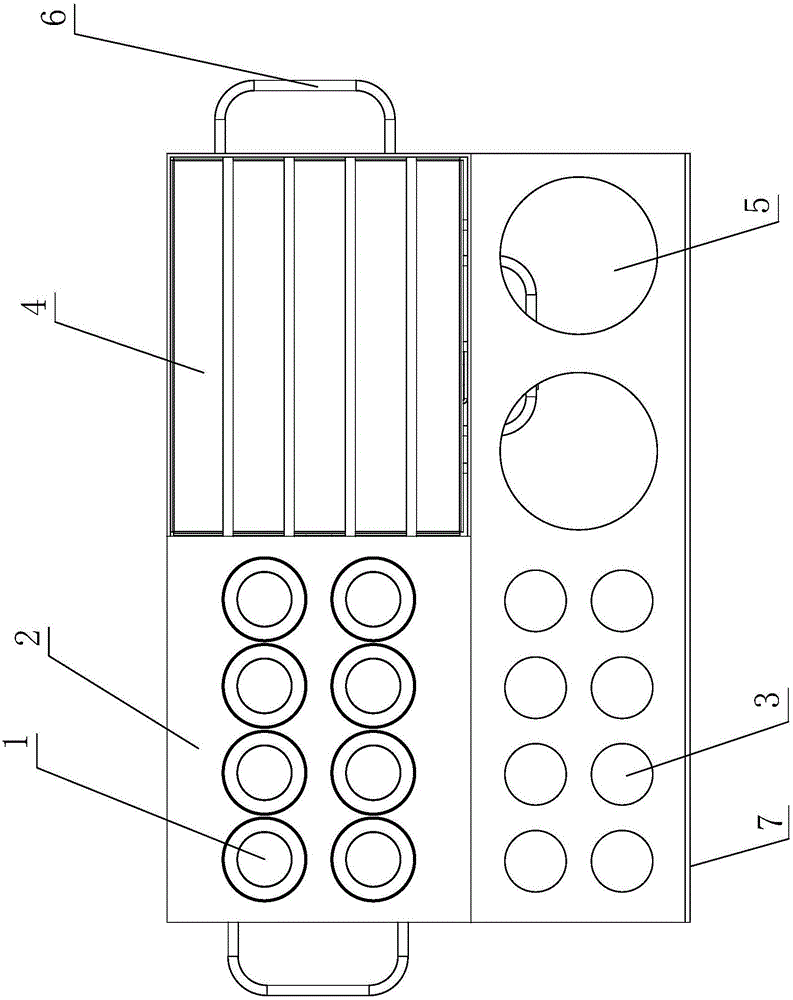

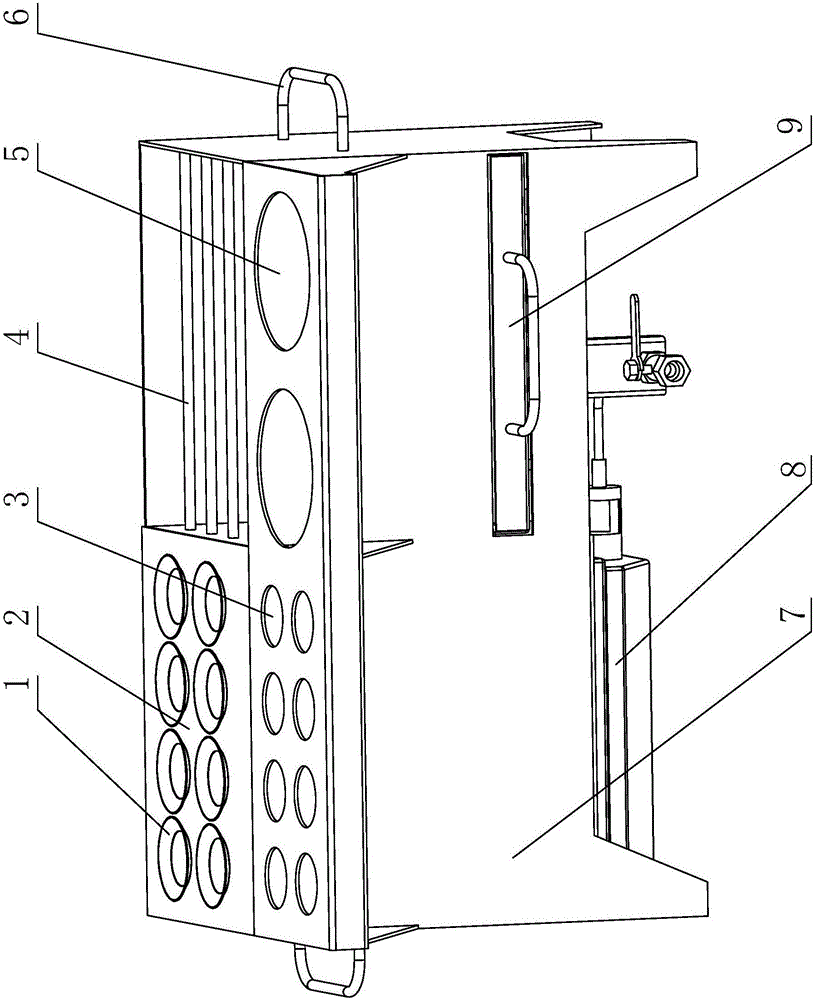

Dust removing sprayer for mine

InactiveCN101649748AGood application of dust suppression works wellLess gas consumptionDust removalFire preventionWater sourceSprayer

The invention discloses a dust removing sprayer for a mine, which comprises a shell. The shell is provided with a suspender used for suspending the whole dust removing sprayer for the mine; a distributor is arranged in the shell; one end of a header water inlet pipe is connected with a water inlet end of a water flow distribution passage in the distributor, and the other end of the header water inlet pipe is extended out of the shell and connected with a water source; one end of the header water inlet pipe is communicated with an air inlet end of a compressed air distribution passage in the distributor, and the other end of the header water inlet pipe is extended out of the shell and connected with a compressed air source; a plurality of ends are communicated with a water distribution endof the water flow distribution passage in the distributor, and the other ends are extended to a nozzle outside the shell; and the nozzle is provided with an air inlet connector which is communicated with the compressed air distribution passage of the distributor through an air distribution pipe. The sprayer can achieve good application effect of reducing the dust by adopting the mass transfer of fog droplets under high-speed airflow acceleration, has the advantages of gas consumption economization, little used water, fine and even fog droplets, large diffusion area, no spraying dead angle, safety, and explosion prevention, and is suitable for continuous operation under severe environment.

Owner:SHANGHAI GORO CONVEYOR EQUIP CO LTD

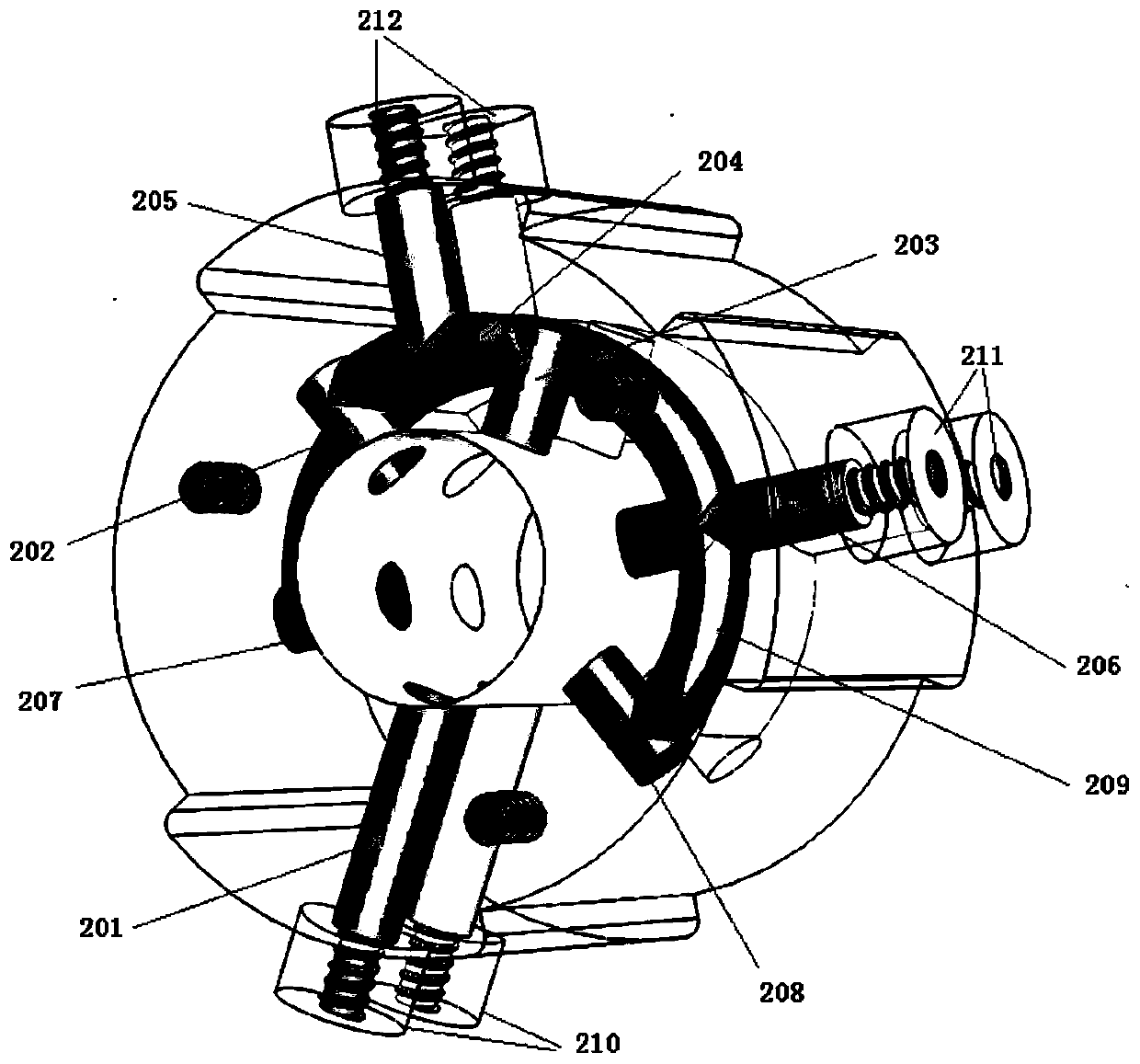

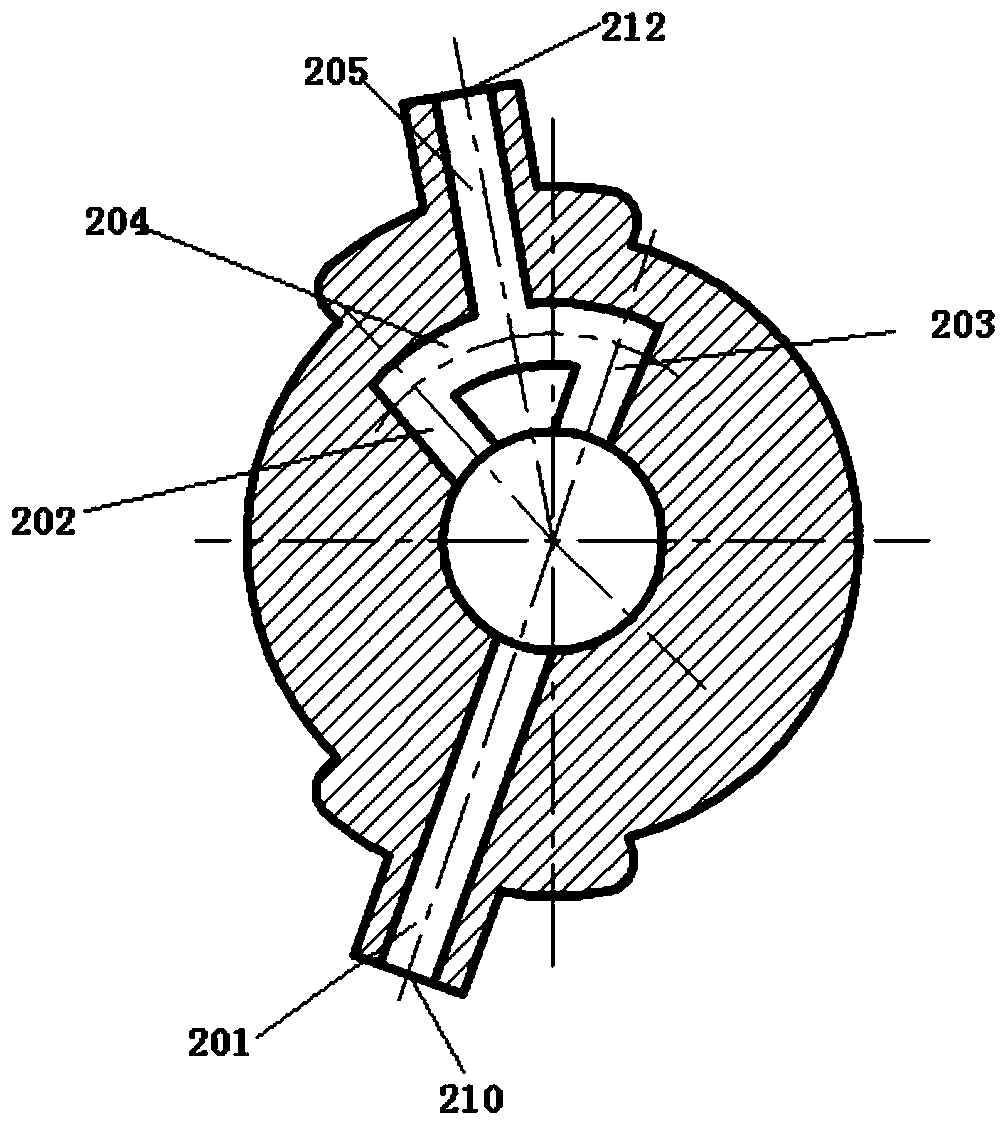

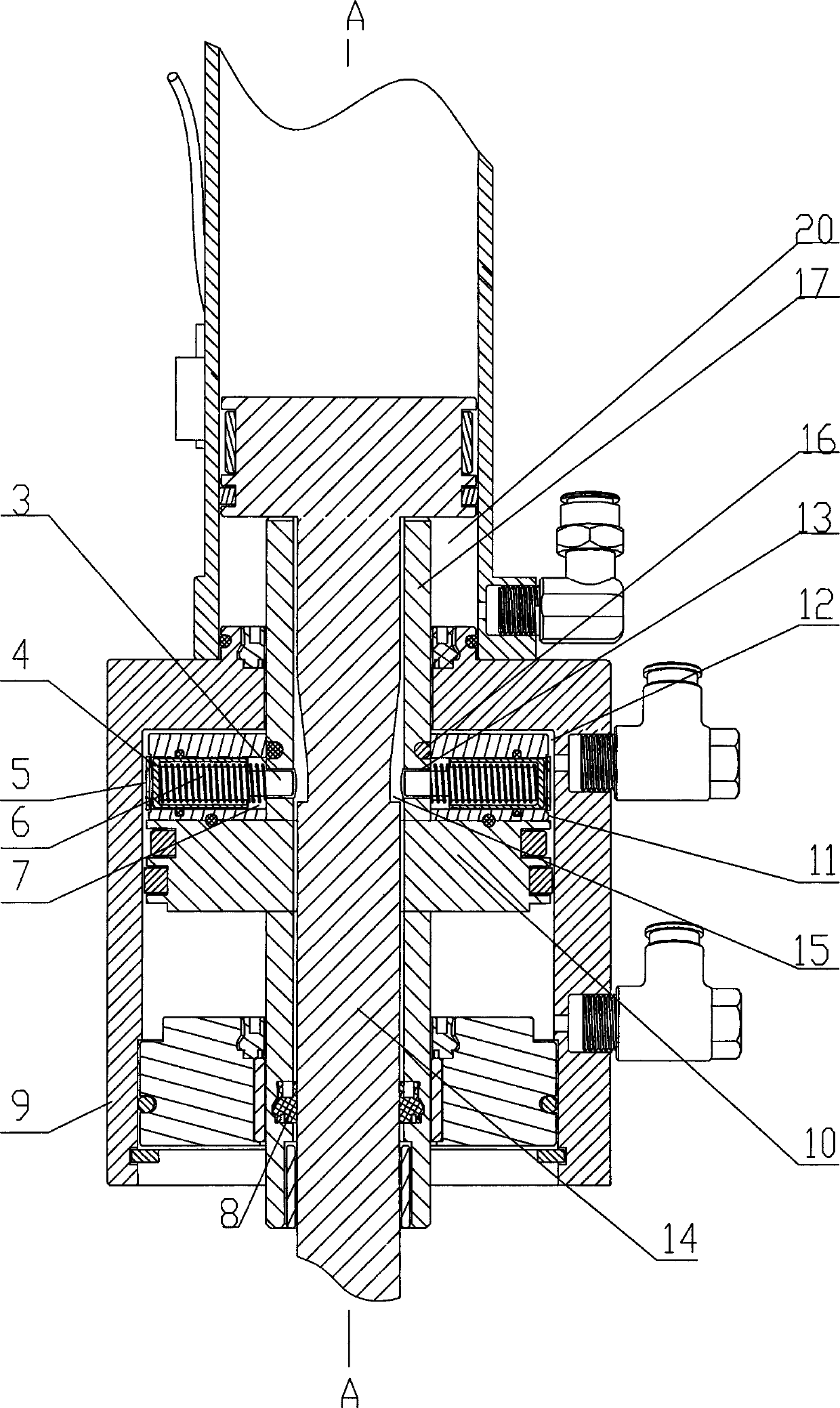

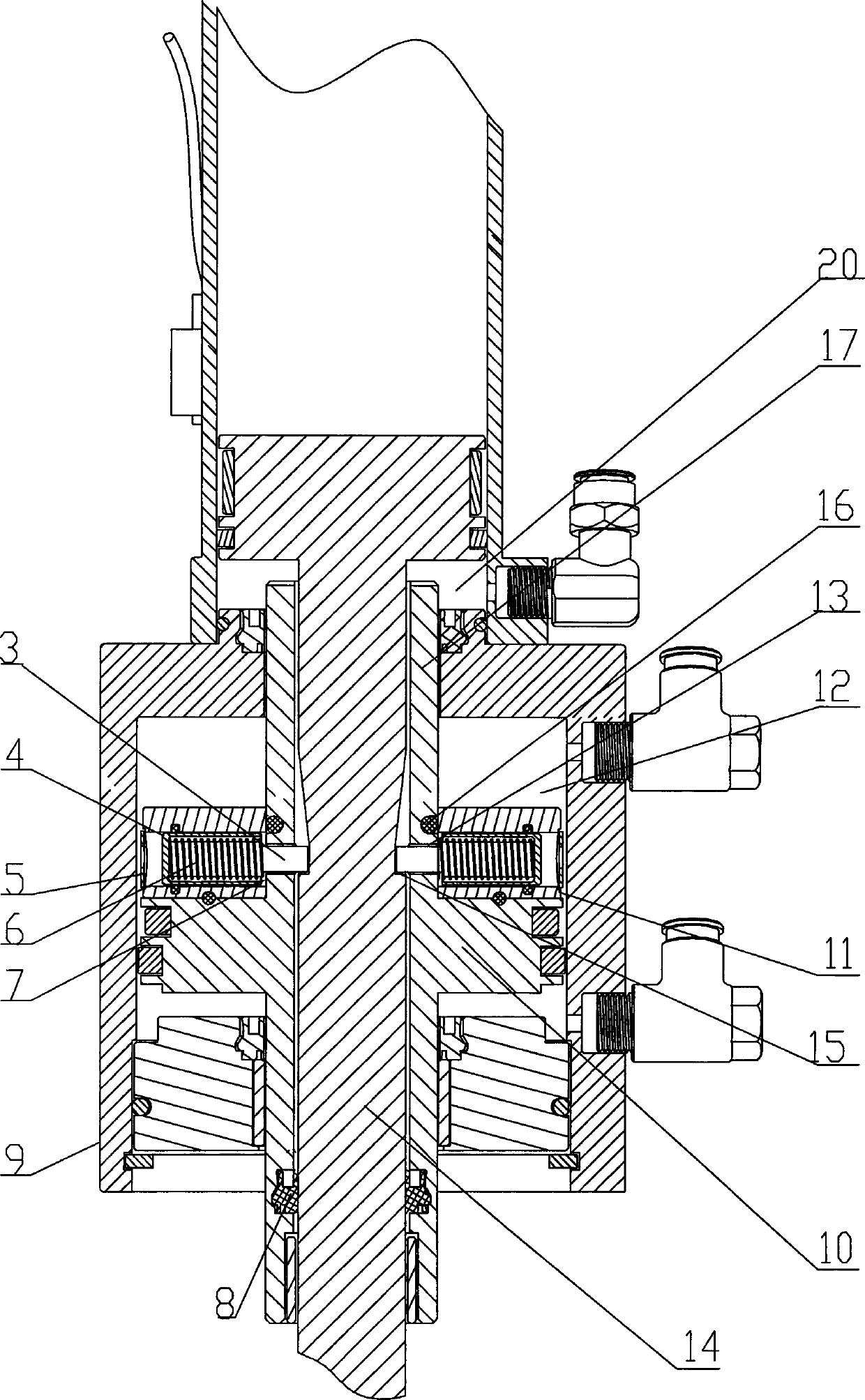

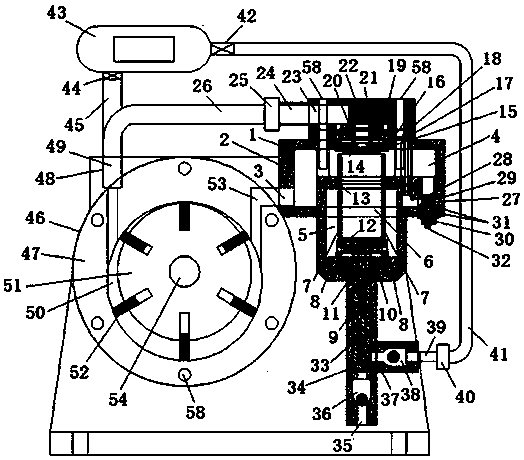

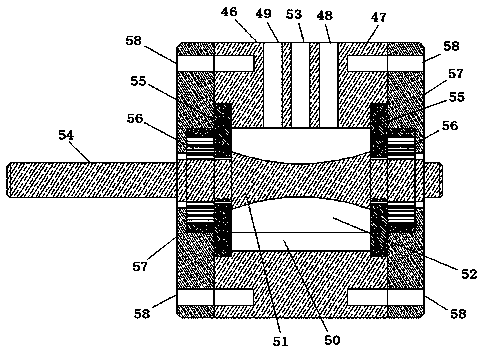

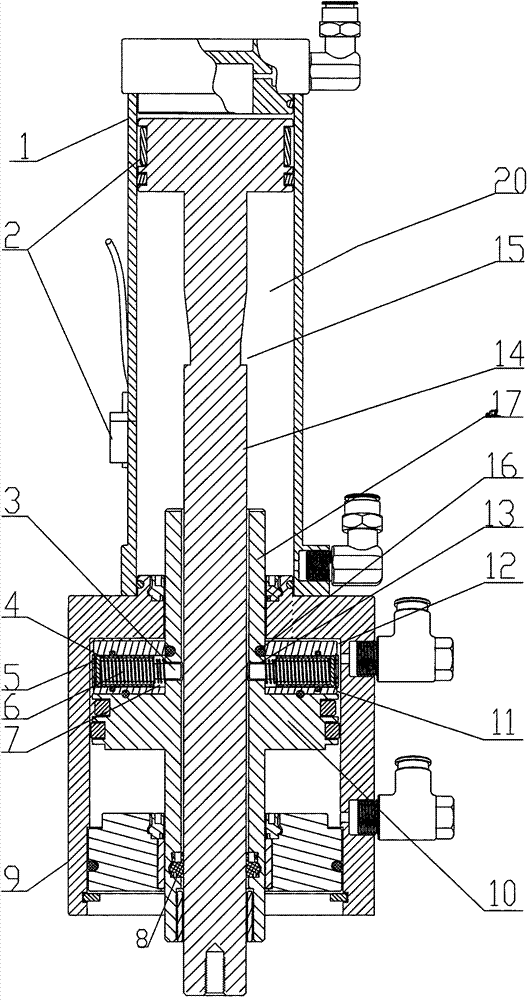

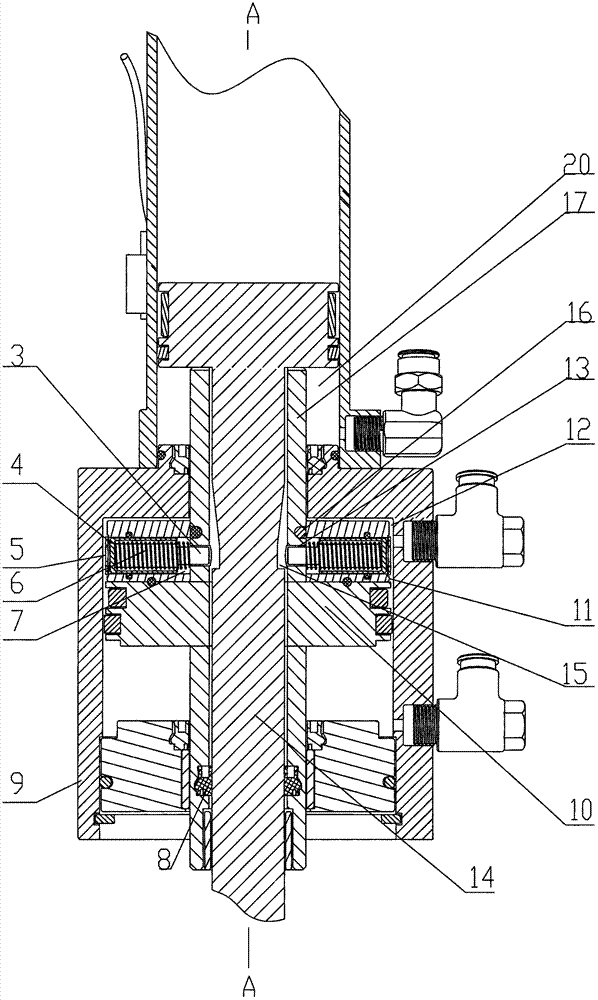

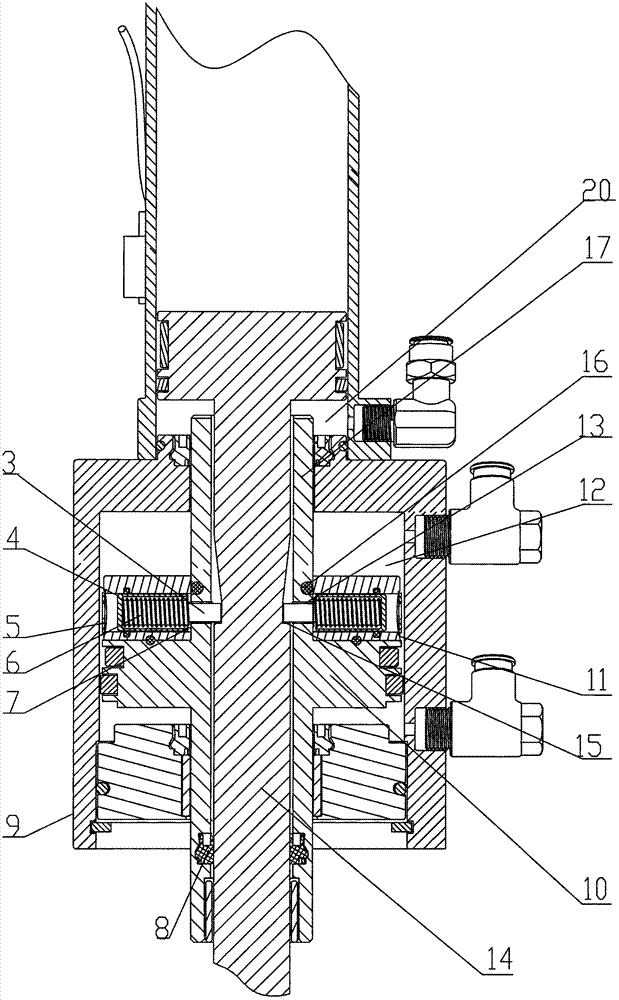

Multi-station pneumatic reversing valve

PendingCN110440032AFast responseAccurate locationPlug valvesMultiple way valvesEnergy lossEngineering

The invention provides a multi-station pneumatic reversing valve. The multi-station pneumatic reversing valve comprises a valve seat, a valve core, a shaft coupling and a power driving system, whereinthe power driving system is used for driving the valve core to rotate in the inner cavity of the valve seat through the shaft coupling; the valve seat is provided with an air source supply hole, a cylinder air supply and exhaust hole and an external atmospheric air vent hole; the air source supply hole, the cylinder air supply and exhaust hole and the external atmospheric air vent hole are connected with a through loop inside the valve seat; and the valve core is matched with the through loop after rotation to realize switching of the given working state of the reversing valve. Through adoption of the multi-station pneumatic reversing valve, the technical problem of energy loss since exhausting needs to be performed at the other end when the pneumatic reversing valve switches to supply air to one side of the cylinder at a valve core station is solved.

Owner:DALIAN MARITIME UNIVERSITY

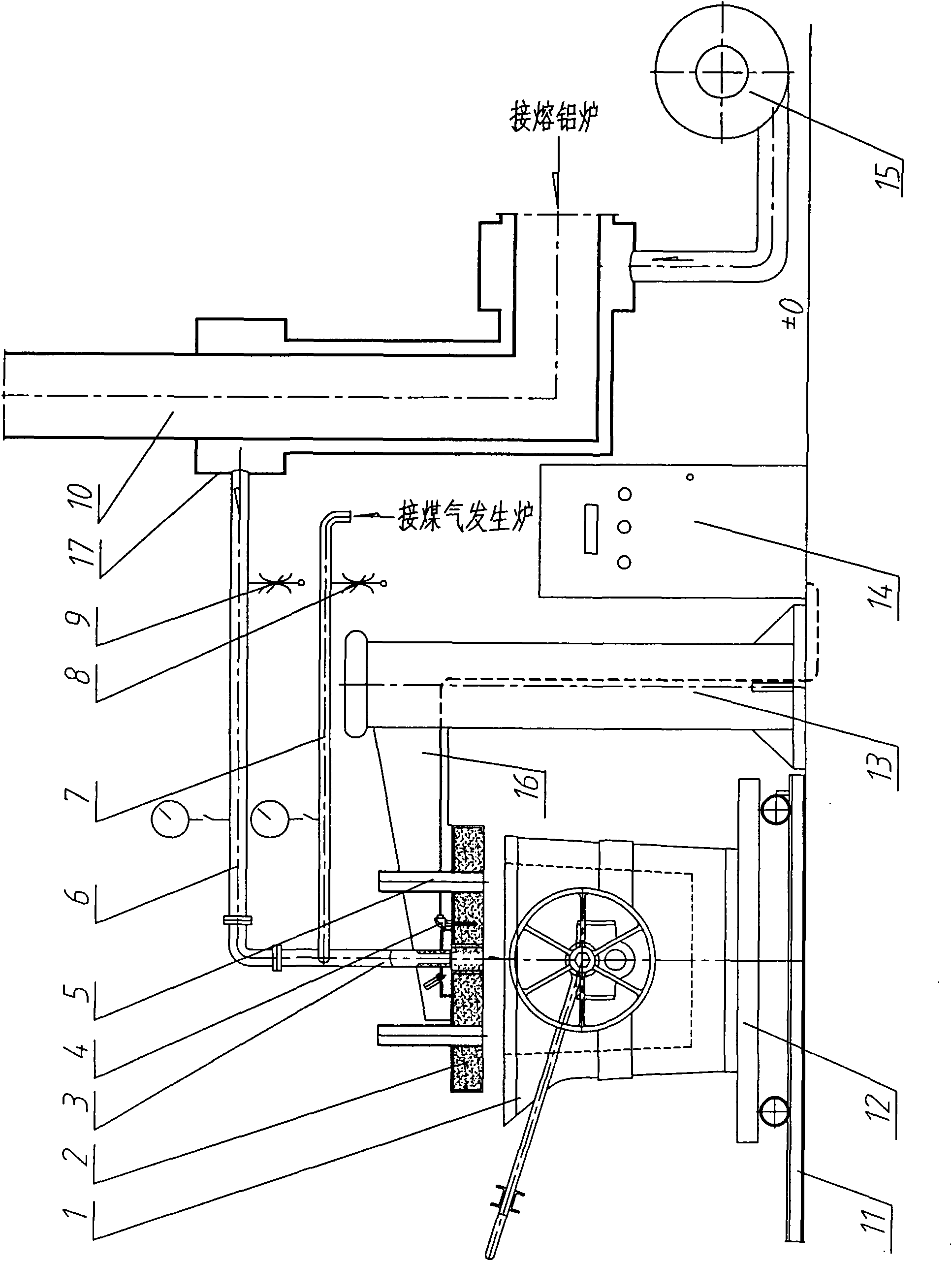

Aluminum liquid turning bag hot air energy-saving heating device and heating method thereof

InactiveCN101554659AAchieve recyclingReduce pollutionMelt-holding vesselsThermal energyThermal insulation

The invention relates to an aluminum liquid turning bag hot air energy-saving heating device which is characterized in that a hot air flue container is communicated and connected with a smoke exhaust opening of an aluminum melting furnace, a blower which can send compressed air into a separation layer of the hot air flue container is connected at the junction thereof; a fire banking cover is connected with a vertical column which performs the support effect through a crossbeam, a flame jetting pipe is arranged on the fire banking cover; a hot air pipe is connected on an air tank of the hot air flue container, the other end of the hot air pipe is connected with the top end of the flame jetting pipe, a lateral opening is arranged at the middle part of the flame jetting pipe, a coal gas pipe is connected thereon, the other end of the coal gas pipe is connected with a gas outlet of a coal gas producer; and a turning bag which can contain molten aluminum liquid is arranged below the fire banking cover. The preheating and the thermal insulation processes are integrated with the aluminum melting process, the three processes can be carried out simultaneously, and the invention can complete the preheating and the thermal insulation of the turning bag while melting aluminum, thereby realizing the recycling of heat energy to the maximum extent, which can not be achieved by the prior art.

Owner:JIANGSU JIANGXU CASTING GROUP

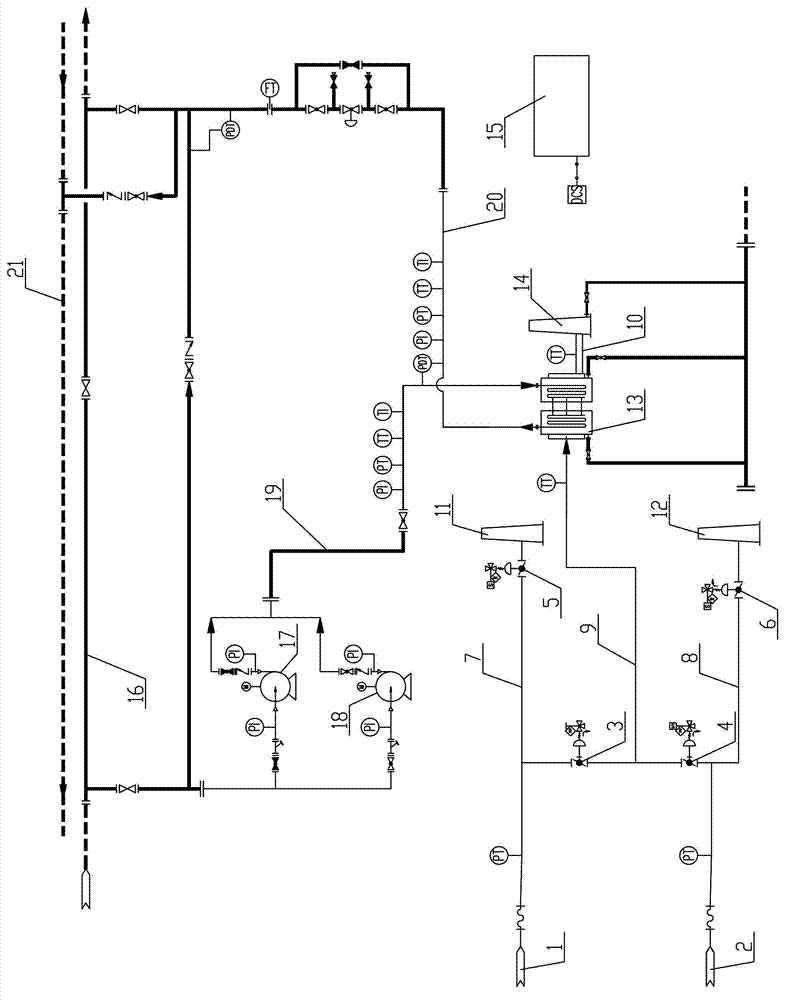

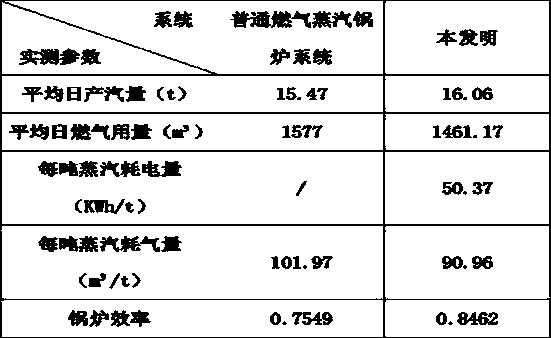

Turbine residual heat recycling and utilizing system

InactiveCN102758703AIncrease temperatureLower fuel consumptionInternal combustion piston enginesPipeline systemsProcess engineeringAtmospheric pollutants

The invention discloses a turbine residual heat recycling and utilizing system which mainly comprises a residual heat boiler, a hot oil circulating pump, a smoke valve and a field control disc. High-temperature smoke discharged by a turbine motor is used as a heat source and the residual heat of smoke is recycled; heat-conducting oil is introduced to a residual heat boiler heat exchanging disc through a hot oil circulating pump and the heat-conducting oil in a residual heat boiler heat exchanging coiled pipe is heated by utilizing the high-temperature smoke; and after the heat-conducting oil is heated, the heat-conducting oil is returned to a heat-conducting oil system. According to the turbine residual heat recycling and utilizing system disclosed by the invention, the heat energy in turbine smoke can be recycled and the heat-conducting oil can be heated by effectively utilizing the residual heat of the smoke, so that the temperature of the heat-conducting oil is improved, the consumption of fuel is reduced, the load of a previous heat medium boiler is reduced, and the normal maintenance of the heat medium boiler and the normal operation of a hot oil system are guaranteed; and therefore, the risk of safely operating the previous heat medium boiler is reduced, the safety operating factor of equipment is improved and the pressure of outputting crude oil is relieved. Meanwhile, the emission of atmospheric pollutants is further reduced, and energy conservation and emission reduction are realized.

Owner:CHINA NAT OFFSHORE OIL CORP +1

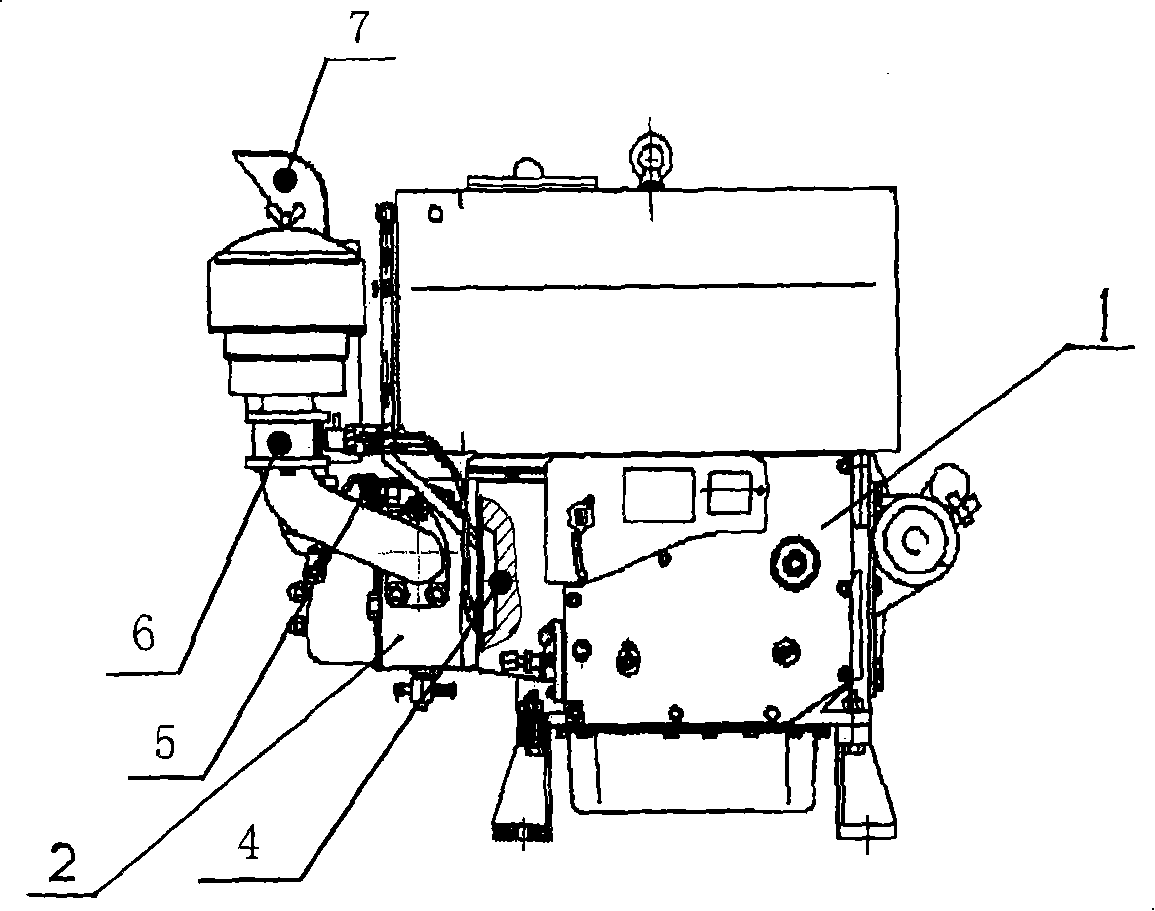

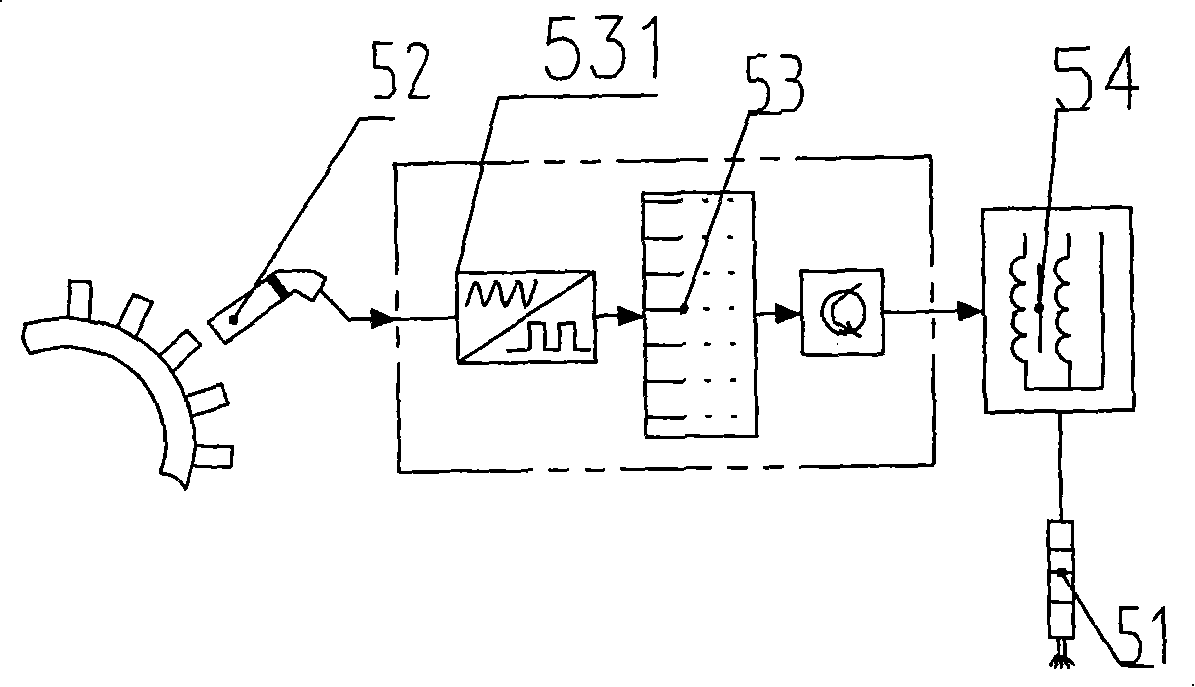

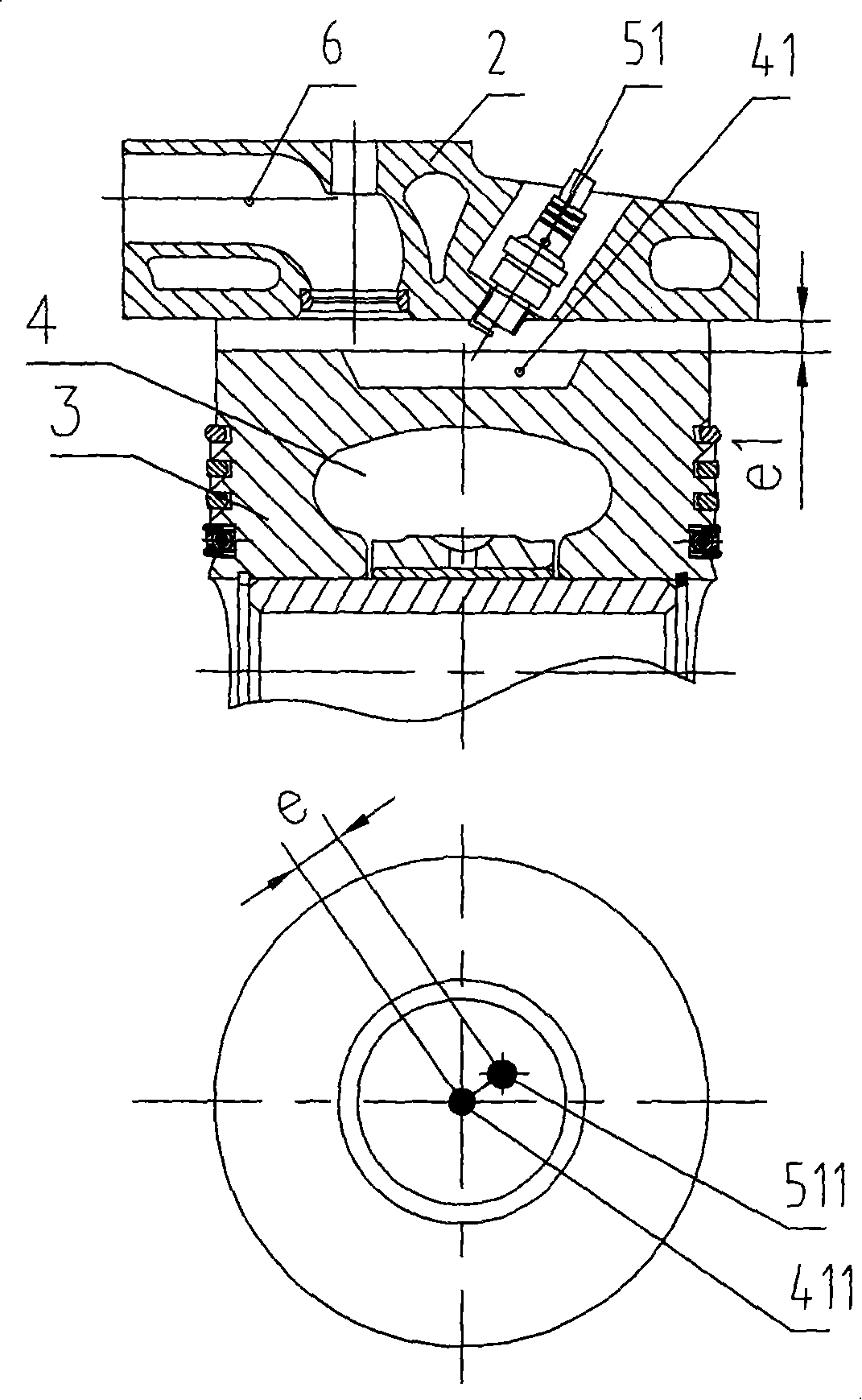

Single-cylinder four-stroke gaseous propellant engine

InactiveCN101245755ANo abnormal combustion problems such as knockingIncrease the calibration powerInternal combustion piston enginesIgnition automatic controlCombustion chamberInlet channel

The invention relates to a motor, in particular to a single cylinder four-stroke motor using gas fuel. The motor is provided with a body that is provided with a cylinder head and a piston, the cylinder head is provided with a spark plug and an inlet channel, and the piston is under the inlet channel; a combustion chamber is arranged between the bottom surface of the cylinder head of the body and the top surface of the piston of the body, under the spark plug and the inlet channel and is linked with an ignition device which is respectively communicated with the inlet channel and an exhaust device. The single cylinder four-stroke motor improves the power of the generator, saves energy ( less gas consumption), has low emission and cost and is safe and reliable by improving the ignition device and the combustion chamber, etc.

Owner:JIANGSU UNIV +1

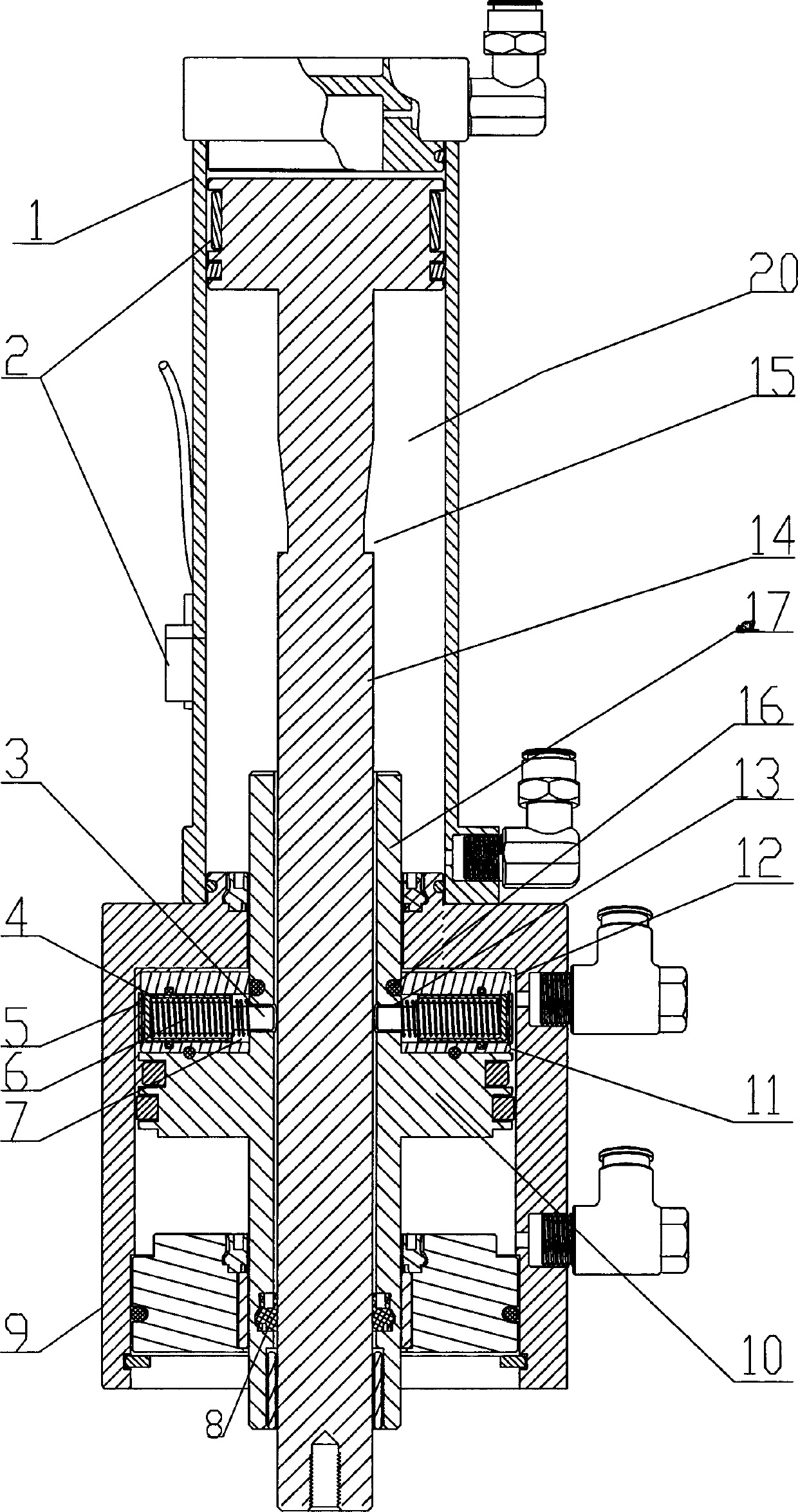

Energy-saving combined air cylinder

ActiveCN104196820ASave direction positioning deviceOrientation to ensureFluid-pressure actuatorsRam-air intakeEngineering

The invention relates to an air cylinder, in particular to an energy-saving combined air cylinder special for punching equipment. The energy-saving combined air cylinder comprises a large air cylinder, a small air cylinder and a piston rod clutch connection device. A large piston rod in the large air cylinder is a large hollow piston rod. A small piston rod in the small air cylinder penetrates through the large hollow piston rod. The piston rod clutch connection device comprises a built-in air cylinder, a radial groove formed in the small piston rod and a pin hole formed in the large hollow piston rod. The built-in air cylinder is arranged on a punching air inlet cavity of the large air cylinder, an air inlet cavity of the built-in air cylinder is communicated with the punching air inlet cavity of the large air cylinder, an air exhaust cavity of the built-in air cylinder is communicated with a center hole in the large hollow piston rod, and a piston pin rod in the built-in air cylinder is in sliding fit with the pin hole. By the adoption of the energy-saving combined air cylinder, set pressure is ensured, and air consumption amount is reduced. Compared with the prior art, the energy-saving combined air cylinder has the advantages of reducing air consumption amount exponentially, and being high in working speed.

Owner:余理翔

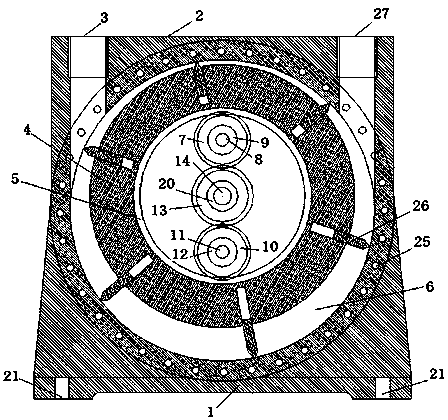

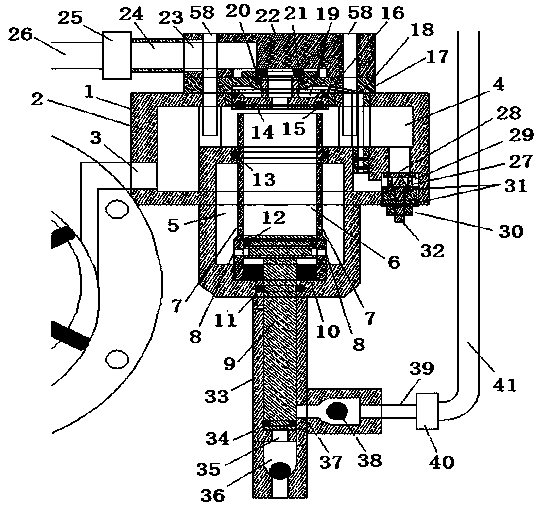

Blade gear ring rotor air engine and circulating system

InactiveCN108825308AImprove efficiencyLess gas consumptionEngine componentsRotary piston enginesPower stationAerospace engineering

The invention discloses a blade gear ring rotor air engine and a circulating system. The blade gear ring rotor air engine comprises an engine shell, an engine air inlet, an air cylinder, engine exhaust outlets, a blade gear ring rotor, a gear ring rotor inner gear, a transmission gear I, a transmission gear shaft I, a bearing I, a transmission gear II, a transmission gear shaft II, a bearing II, an output shaft gear, an output shaft, a transmission gear support I, a transmission gear support II, a bracket bearing I, a bracket bearing II, an output shaft bearing I, an output shaft bearing II, an engine cover plate I, an engine cover plate II and blades. The invention further provides a circulating system comprising the blade gear ring rotor air engine. The blade gear ring rotor air engine and the circulating system have the characteristics of being high in efficiency, low in air consumption, large in power, high in rotating speed and the like, and capable of being widely applied to agriculture and industrial engineering such as the power fields of transportation automobiles, ships, air-driven generators and air driven power stations.

Owner:张谭伟

Gas egg-sausage machine

InactiveCN106037461AFast processingEasy accessMultiple-unit cooking vesselsWarming devicesFlavorHeating effect

The invention discloses a gas egg-sausage machine which comprises a tank and a collecting disc. A layer of heat-insulation materials is arranged on the inner side wall of the tank, the upper surface of the tank is divided into an egg-sausage processing area, an egg-sausage reservation accommodating area, an egg-sausage heat-insulation area and a flavor cup accommodating area, the egg-sausage processing area is provided with egg-sausage heating pipes, a gas stove which is positioned in the tank is arranged at the egg-sausage heating pipes, a gas stove connecting piece is arranged at the outer end of the gas stove, the withdrawable collecting disc is arranged in the tank and is positioned below the egg-sausage heat-insulation area, and handles are further respectively arranged on two sides of the tank. The gas egg-sausage machine has the advantages that Teflon coatings are arranged inside the egg-sausage heating pipes of the gas egg-sausage machine, and accordingly eggs and sausages can be prevented from being stuck in the inner wall of the gas egg-sausage machine; the heat-insulation materials are arranged inside the tank, accordingly, the temperatures of heating areas of the tank can be effectively kept, heat loss can be prevented, and gas can be saved; a gas cooking range is an energy-saving gas cooking range with honeycomb ceramic plates, accordingly, uniform heating effects can be realized, the temperatures can be increased quickly, and the gas egg-sausage machine is low in gas consumption.

Owner:SHANDONG HUIFA FOODS

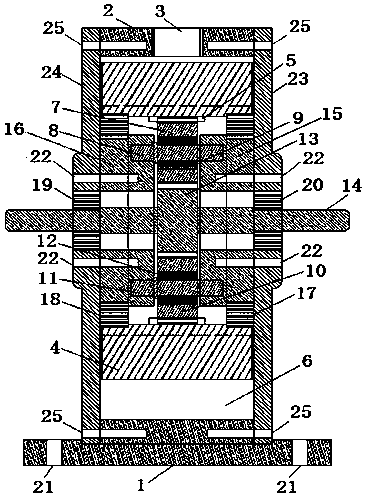

Pneumatic circulation air compression pump and air engine combined body

InactiveCN109854306AImprove efficiencyLess gas consumptionPiston pumpsPositive-displacement liquid enginesAir compressionAir cycle

A pneumatic circulation air compression pump and air engine combined body comprises a pneumatic circulation air compression pump and a blade type air engine. The pneumatic circulation air compressionpump comprises a pneumatic circulation air compression pump shell, a pneumatic circulation air compression pump air inlet, an air inlet air storage cavity, a piston air return cavity, an air cylinderI, an air outlet of an air cylinder inlet piston air return cavity, a piston air return port, a piston I, a seal pad I, a seal ring I, a seal ring II, a seal ring III, an air cylinder cover piston, aseal ring IV, a seal ring V, an air cylinder cover, an air cylinder cover air inlet, an air cylinder cover air storage cavity, a seal ring VI, a seal pad II, an air cylinder exhaust cover, an exhaustcover air outlet, a connector I, a check valve I, an air return pipe, a switch, a switch locking nut, a seal ring VII, a switch gas rod, a compressed air cylinder and a seal ring VIII. The pneumatic circulation air compression pump and air engine combined body can cyclically utilize compressed air and has the characteristics of being high in efficiency, low in air consumption and the like.

Owner:张谭伟

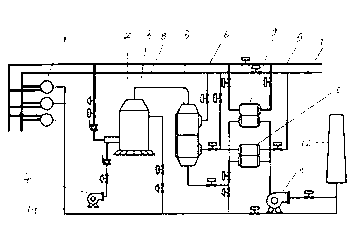

High-blast-temperature combinative heat exchange system of blast furnace

InactiveCN103045786AReduce consumptionReduce volumeBlast furnace detailsHeating stovesCold airCombustion

The invention provides a high-blast-temperature combinative heat exchange system of a blast furnace, which comprises a hot-blast furnace, a front combustion furnace, an air turbolator heat exchanger, a blast blower, a cold coal gas header pipe, a hot coal gas header pipe, a cold air header pipe, a hot air header pipe, a coal gas heat pipe exchanger, an air heat pipe exchanger, a draught fan and a chimney, wherein the blast blower and the hot coal gas header pipe are respectively communicated with the front combustion furnace by control valves; a control valve is arranged between the cold coal gas header pipe and the hot coal gas header pipe; a control valve is arranged between the cold air header pipe and the hot air header pipe; the cold coal gas header pipe is connected with one end of the coal gas heat pipe exchanger by a control valve; the other end of the coal gas heat pipe exchanger is connected with the hot coal gas header pipe by a control valve; the cold air header pipe is connected with one end of the air heat pipe exchanger by a control valve; and the other end of the air heat pipe exchanger is respectively connected with the hot air header pipe and the air turbolator heat exchanger by control valves. The high-blast-temperature combinative heat exchange system of the blast furnace has the advantages of small equipment size, few metal consumption, low manufacturing cost, low running cost and the like.

Owner:JIANGXI KAISITONG ENVIRONMENTAL PROTECTION EQUIP

Multifunctional gas wave refrigerating jet stream field displaying apparatus and method for measuring

InactiveCN100575900CSimple structureEasy to processAerodynamic testingHydrodynamic testingExperimental researchJet flow

A kind of multiple functions gas wave cooling effluxion flow filed display device and measuring method which belongs to technique field of effluxion of pressure gas and expanded cooling and measuring control. The invention adopts integrated structure and works when running and static and possesses window for view and shooting image, it can analogue working mechanism and performance of multiple types of gas, and provides platform for leading high-precision PIV to wave mechanical flow filed measurement, and measures important parameters in-phase, and fulfills requirement of experiment, and accomplishes research content of changing condition, experiment component, rotate speed, two phases of gas and liquid, and accomplishes important experiment of best matching of structure and parameter. The structure is reasonable and easy, operation is convenient, and performance is stable and reliable. It fits for multiple functions gas wave cooling measuring filed of changing condition and research content.

Owner:DALIAN UNIV OF TECH

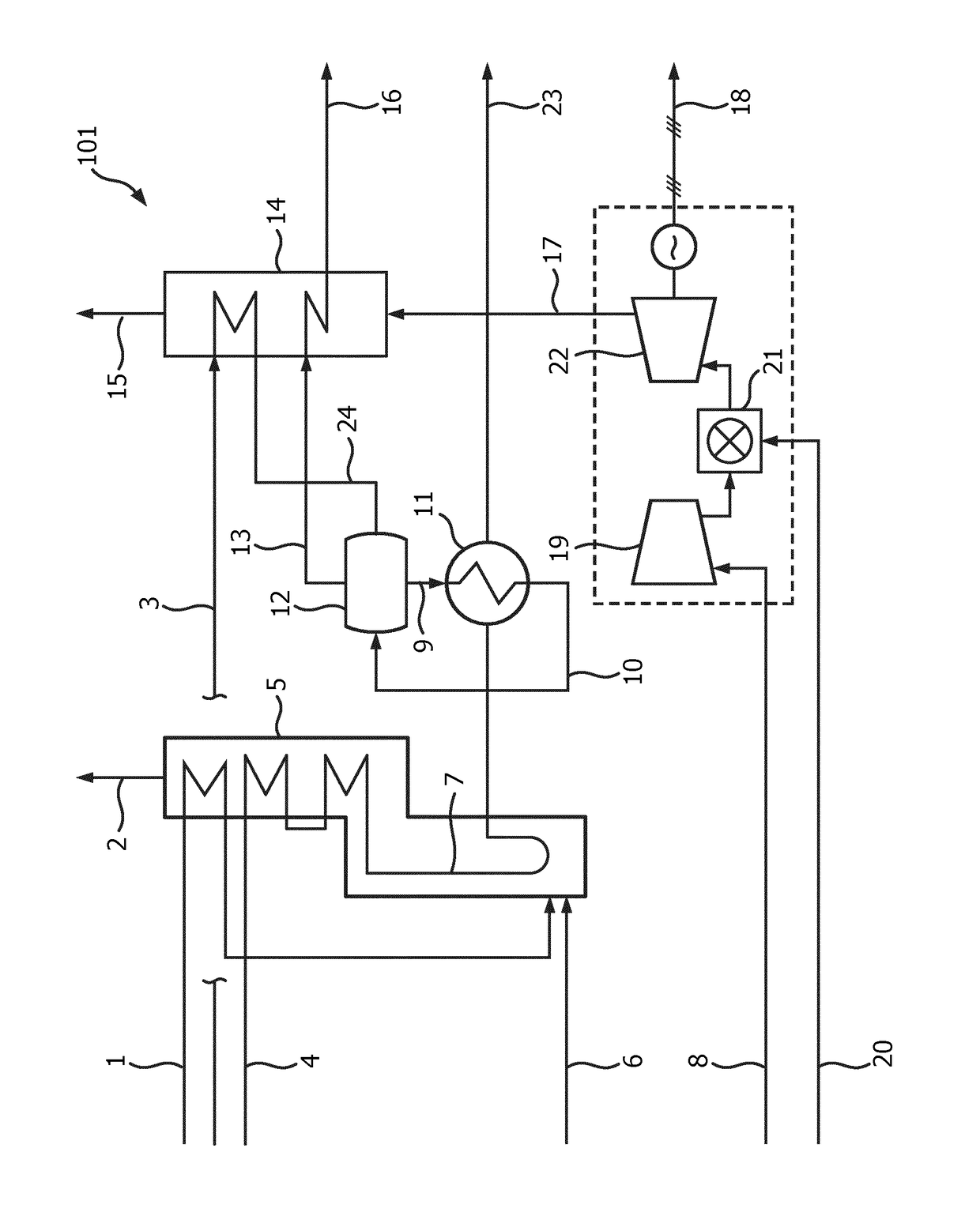

Process for increasing process furnaces energy efficiency

ActiveUS10190060B2Increasing steam cracker energy efficiencyNegative effectThermal non-catalytic crackingGas turbine plantsProcess engineeringGas turbines

A process for increasing furnace energy efficiency through gas turbine integration by using turbine exhaust gas, wherein a hydrocarbon feed is heated in a furnace.

Owner:SAUDI BASIC IND CORP SA +1

Atmospheric treater with roller confined discharge chamber

ActiveUS8709351B2Good surface treatmentQuality improvementMaterial analysis by optical meansTextile treatment by spraying/projectingEngineeringAtmospherics

A continuous feed discharge surface treater for treating web materials has a discharge chamber where ionization of a process gas occurs defined and contained by one or more rollers. Enhanced chemical coronas and plasmas are achieved by limiting depletion of the gas chemistry from the discharge chamber and dilution or contamination from mixing with drawn in ambient air. Atmospheric coronas can also be achieved in which minimal or no ozone is exhausted from the treater. Various roller and electrode assemblies, including both fixed and rolling electrodes, can be employed.

Owner:ENERCON INDS

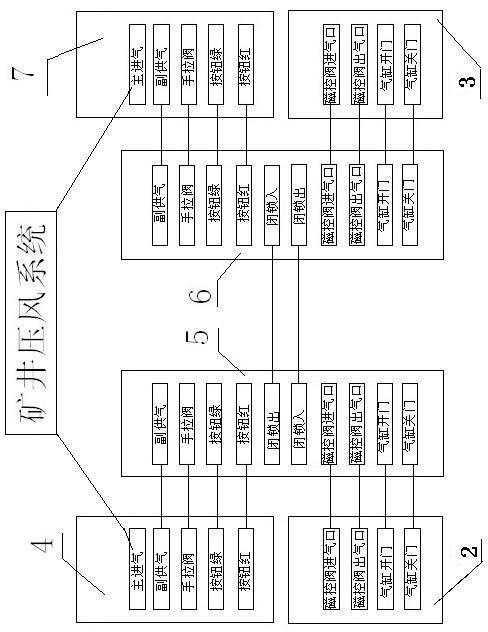

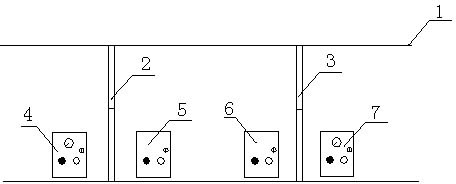

Pneumatic control device for throttle control

InactiveCN102661100AFlexible opening and closingSimple and fast operationPower-operated mechanismTunnel/mines ventillationThrottle controlEngineering

The invention discloses a pneumatic control device for throttle control. The pneumatic control device comprises an air source box arranged on one side of a door A, a control box arranged on the other side of the door A, an air source box arranged on one side of a door B and a control box arranged on the other side of the door B, and also comprises air cylinders and locking detection magnetic control valves respectively arranged on the door bodies of the door A and the door B, wherein each air source box and each control box are respectively provided with a door opening button, a door closing button and an emergency pressure-relief hand pull valve; the main air inlet of the air source box is connected with a mine underground compressed-air pipeline, and is connected with the control box through an auxiliary air supply pipe and the filtering treatment of the air source box; the door opening button, the door closing button and the emergency pressure-relief hand pull valve of the air source box are connected with the corresponding positions of the control box, the air cylinders and the locking detection magnetic control valves on the door bodies are connected with the corresponding interfaces of the control boxes, and the locking control inlets and the locking control outlets of the control boxes of the door A and the door B are connected in an intersected manner. The pneumatic control device has the beneficial effects that no circuit devices are adopted, the potential safety hazards in high-gas mines are completely avoided, the cost is low, the operation is simple, and the maintenance is simple.

Owner:济南嘉宏科技有限责任公司

Method for producing desulfurized denitrated carbon

PendingCN110606484AReduce energy consumptionEmission reductionGas treatmentOther chemical processesWear resistantCarbonization

The invention discloses a method for producing desulfurized denitrated carbon. An external heating type carbonization and activation integrated furnace is adopted; in a carbonization section, materials are gradually heated in a certain low-temperature range and under the condition of air isolation, the materials are slowly heated so that colloid in the materials is pyrolyzed in order, and effective pores of a desulfurization process are achieved to the maximum extent by controlling the pyrolysis speed and controlling the size of molecules overflowing during pyrolysis; in an activation section,the materials continue to be heated to 650 DEG C or above to start polycondensation, part of components of the materials start coking to form high-strength carbon, at the moment, the materials form developed pores along with a water gas reaction in an activating agent atmosphere, and the pore structure and the abrasion resistance of the active coke are kept or improved while the compressive strength and the ignition point are improved. The method has the advantages of low energy consumption, less emission, automatic production, low working intensity, high equipment safety and reliability, andlow maintenance cost and personnel cost; the raw material consumption is reduced by 20-40%, the wear-resistant and compression-resistant strength is high, and the regeneration cycle frequency is high.

Owner:淮北中清环保科技有限公司

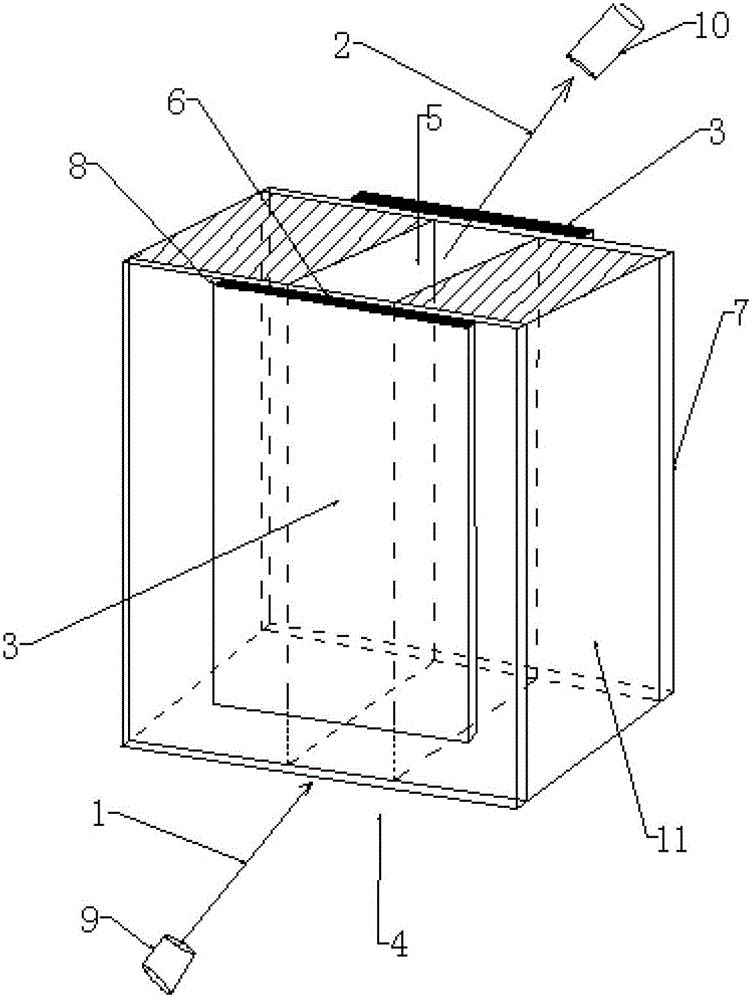

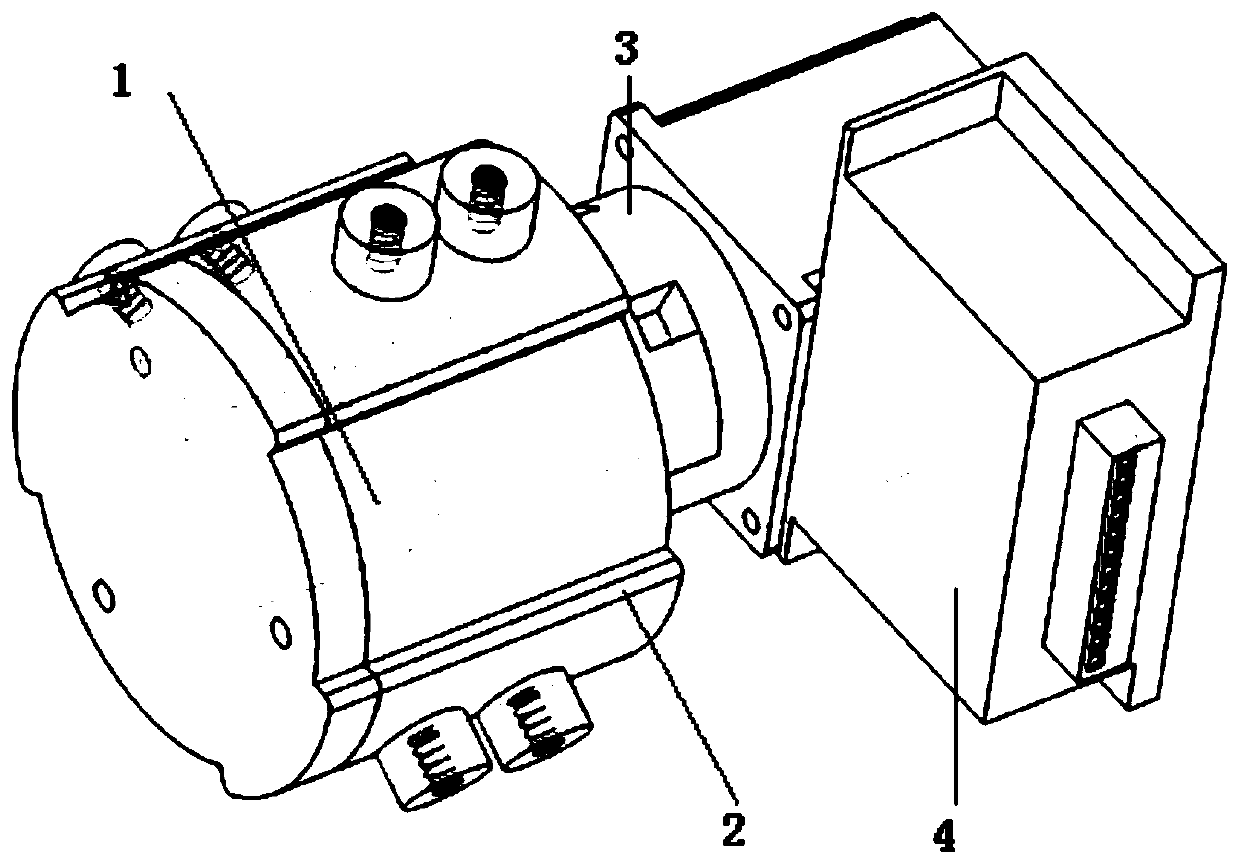

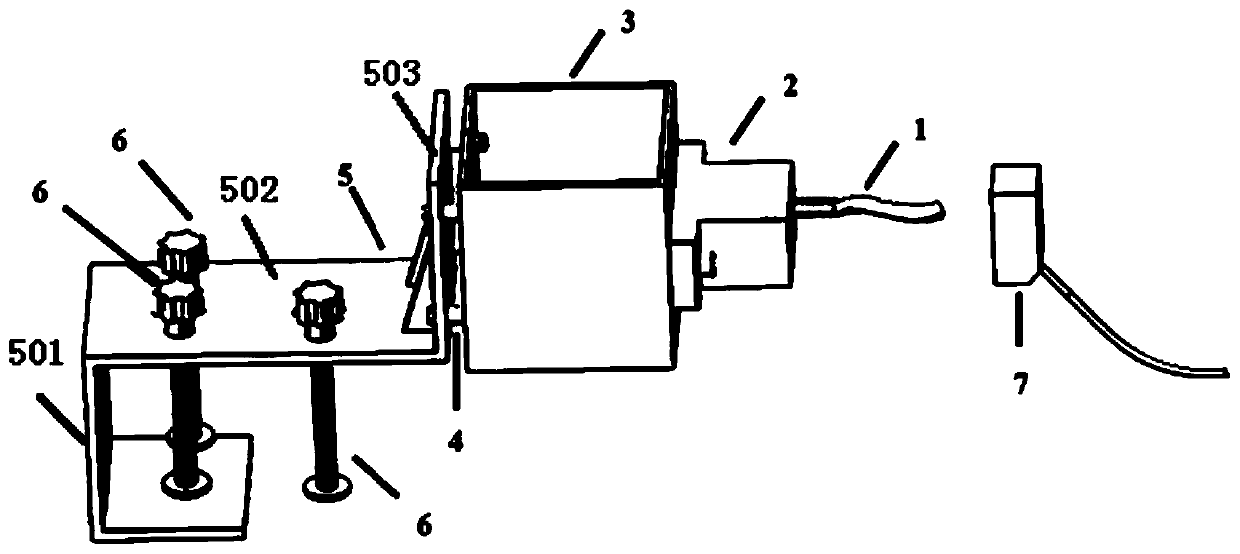

A kind of pneumatic vibration test device and method

The invention provides a pneumatic vibration test device and method; the test device comprises a pneumatic vibrator used for providing a vibration air pressure for the test; the pneumatic vibrator hasan air inlet part connected with an air supply device; the test device also comprises a vibration table used for containing a to-be-detected member; the vibration table is fixedly connected with thepneumatic vibrator; the vibrations of the pneumatic vibrator are transferred to the vibration table, and the vibration table drives the to-be-detected member to vibrate; the test device also comprisesa mount base used for mounting and fixing the vibration table. The pneumatic vibration test device is easy to mount and dismount, large in a controllable scope of the vibration frequency (0.1Hz to 400Hz) and amplitude (0-5mm), can be repeatedly used, and is low in cost.

Owner:SHANGHAI JIAOTONG UNIV

Firing method of electric porcelain blank

The invention discloses an electrical porcelain blank firing method which includes oxygenolysis, oxidation temperature preservation, strong reduction, weak reduction, heat preservation through strong fire and cooling sequentially performed in a kiln, wherein the atmosphere in the kiln in steps of the strong reduction and the weak reduction is neutral flame. By means of the electrical porcelain blank firing method, the neutral flame replaces the existing reduction flame, and the electrical porcelain blank firing method has the advantages of being high in product strength, less in gas consumption and the like.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

Energy-saving combined cylinder

ActiveCN104196820BSave direction positioning deviceOrientation to ensureFluid-pressure actuatorsRam-air intakePunching

The invention relates to an air cylinder, in particular to an energy-saving combined air cylinder special for punching equipment. The energy-saving combined air cylinder comprises a large air cylinder, a small air cylinder and a piston rod clutch connection device. A large piston rod in the large air cylinder is a large hollow piston rod. A small piston rod in the small air cylinder penetrates through the large hollow piston rod. The piston rod clutch connection device comprises a built-in air cylinder, a radial groove formed in the small piston rod and a pin hole formed in the large hollow piston rod. The built-in air cylinder is arranged on a punching air inlet cavity of the large air cylinder, an air inlet cavity of the built-in air cylinder is communicated with the punching air inlet cavity of the large air cylinder, an air exhaust cavity of the built-in air cylinder is communicated with a center hole in the large hollow piston rod, and a piston pin rod in the built-in air cylinder is in sliding fit with the pin hole. By the adoption of the energy-saving combined air cylinder, set pressure is ensured, and air consumption amount is reduced. Compared with the prior art, the energy-saving combined air cylinder has the advantages of reducing air consumption amount exponentially, and being high in working speed.

Owner:余理翔

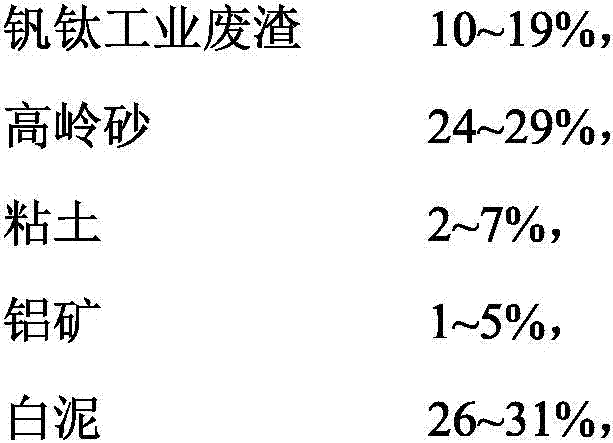

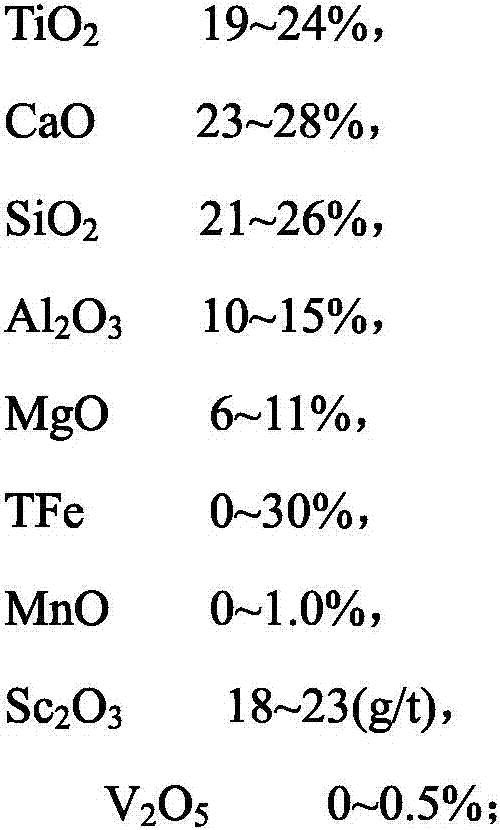

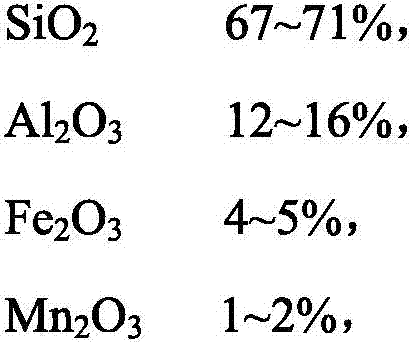

A purple sand ceramic brick made from vanadium and titanium industrial waste slag and its preparation method

InactiveCN105254277BConforms to radioactivityPromote healthy and sustainable developmentCeramic materials productionClaywaresCinnabarBrick

The invention provides a purple sand ceramic tile prepared from vanadium-titanium industrial waste residue and a preparation method thereof. The purple sand ceramic tile comprises, by weight, 10-19% of vanadium-titanium industrial waste residue, 24-29% of kaolin sand, 2-7% of clay, 1-5% of aluminum ore, 26-31% of white mud, 5-10% of shale and 13-27% of recovered mud. Through raw material detection, blending, pulping, pulverizing, molding and drying, glazing and printing, sintering, and refinement and packaging, the purple sand ceramic tile with a cinnabar purple sand color is obtained. The preparation method fully utilizes coloring and sintering characteristics of vanadium-titanium industrial waste residue, realizes resource recycle, reduces a production cost and energy consumption, and reduces exhaust gas discharge. The purple sand ceramic tile has product quality completely satisfying building decorative material performance requirements.

Owner:SICHUAN BAITA XINLIANXING CERAMIC GROUP

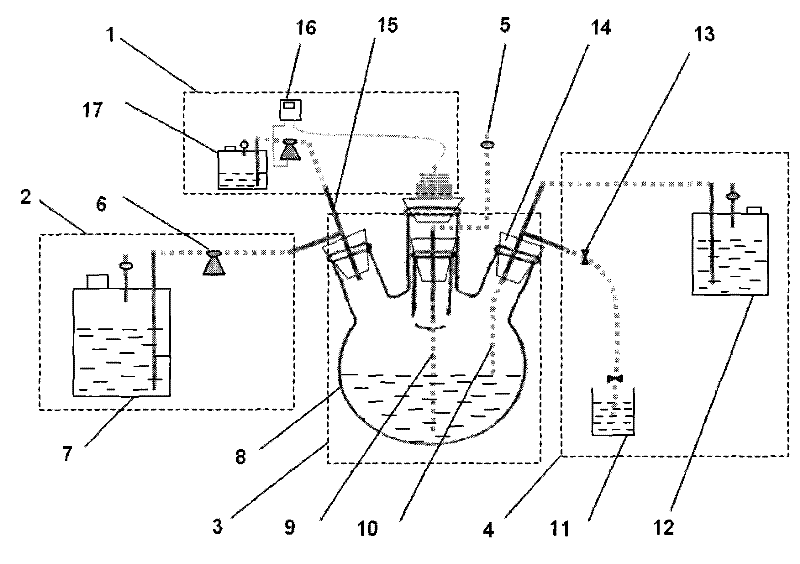

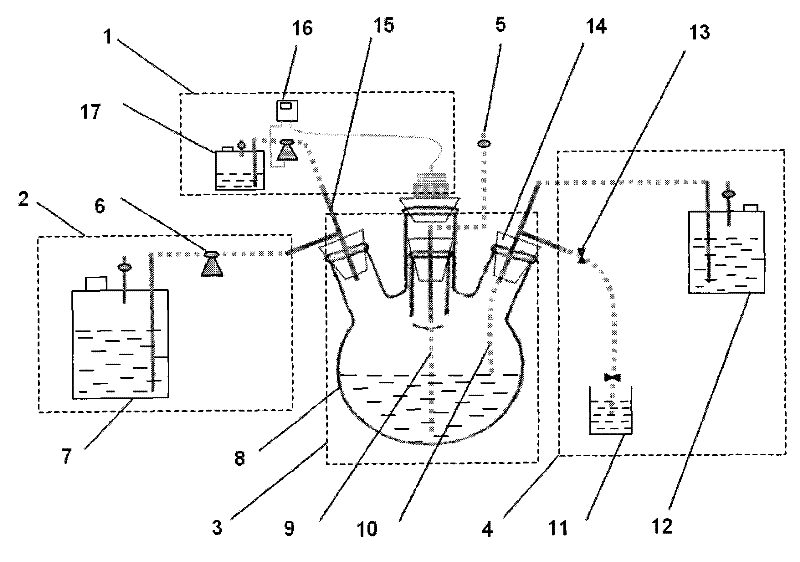

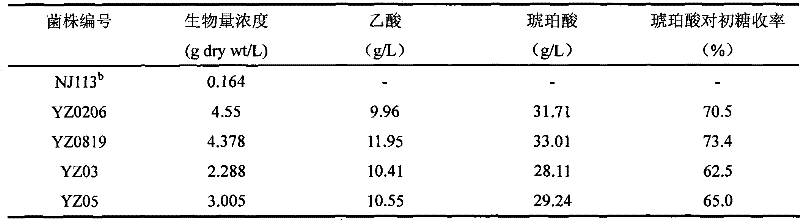

Chemostat continuous cultivation device

InactiveCN101709263BEasy to assembleEasy to operateBioreactor/fermenter combinationsBiological substance pretreatmentsControl systemSuccinic acid

The invention relates to a chemostat continuous cultivation device which is characterized by comprising an acid-alkali pH adjusting and controlling system, a supplementing system, a reaction system, a discharging and sampling system and a gas inlet system, wherein the reaction system comprises a reaction tank which is respectively communicated with the acid-alkali pH adjusting and controlling system, the supplementing system, the discharging and sampling system and the gas inlet system through connecting pipes, and a sealing member is arranged at a bottle opening of the reaction tank. The invention also relates to a method for screening a succinic acid mutant strain by using the chemostat continuous cultivation device of the invention. The device of the invention has simple materials, needs no additional special equipment, no stirring device, and features easy assembly, convenient use, small equipment, little power consumption, little gas consumption, good sealing property and difficult microbiological contamination; and the method of the invention not only features simple operation, durability and stability, but also can realize continuous cultivation on a long-term basis.

Owner:NANJING TECH UNIV

Pneumatic vibration test device and method

ActiveCN108548645AEasy to install and disassembleHigh frequencyVibration testingAtmospheric pressurePneumatic pressure

The invention provides a pneumatic vibration test device and method; the test device comprises a pneumatic vibrator used for providing a vibration air pressure for the test; the pneumatic vibrator hasan air inlet part connected with an air supply device; the test device also comprises a vibration table used for containing a to-be-detected member; the vibration table is fixedly connected with thepneumatic vibrator; the vibrations of the pneumatic vibrator are transferred to the vibration table, and the vibration table drives the to-be-detected member to vibrate; the test device also comprisesa mount base used for mounting and fixing the vibration table. The pneumatic vibration test device is easy to mount and dismount, large in a controllable scope of the vibration frequency (0.1Hz to 400Hz) and amplitude (0-5mm), can be repeatedly used, and is low in cost.

Owner:SHANGHAI JIAO TONG UNIV

A Novel Wing Anti-Icing System Using Airborne Waste Heat

The invention discloses a novel wing icing prevention system using airborne waste heat. According to the system, the connection among a skin heat exchanger, a rotary compressor, an evaporator and an electronic expansion valve is realized through a pipeline; a liquid storage device is additionally arranged in an anti-icing cavity of each wing, and a double-skin structure is changed. According to the system disclosed by the invention, an evaporative-cycle anti-icing manner is adopted to an unmanned aerial vehicle, heat source heat of airborne electronic equipment is sufficiently absorbed by using the evaporator and the heat exchanger, is transferred to skin in a flute-shaped tube impact jet flow manner and is subjected to heat exchange with outside supercooling wet air, and the temperature of the skin is increased to the minimum anti-icing temperature, so as to reach the anti-icing effect.

Owner:BEIHANG UNIV

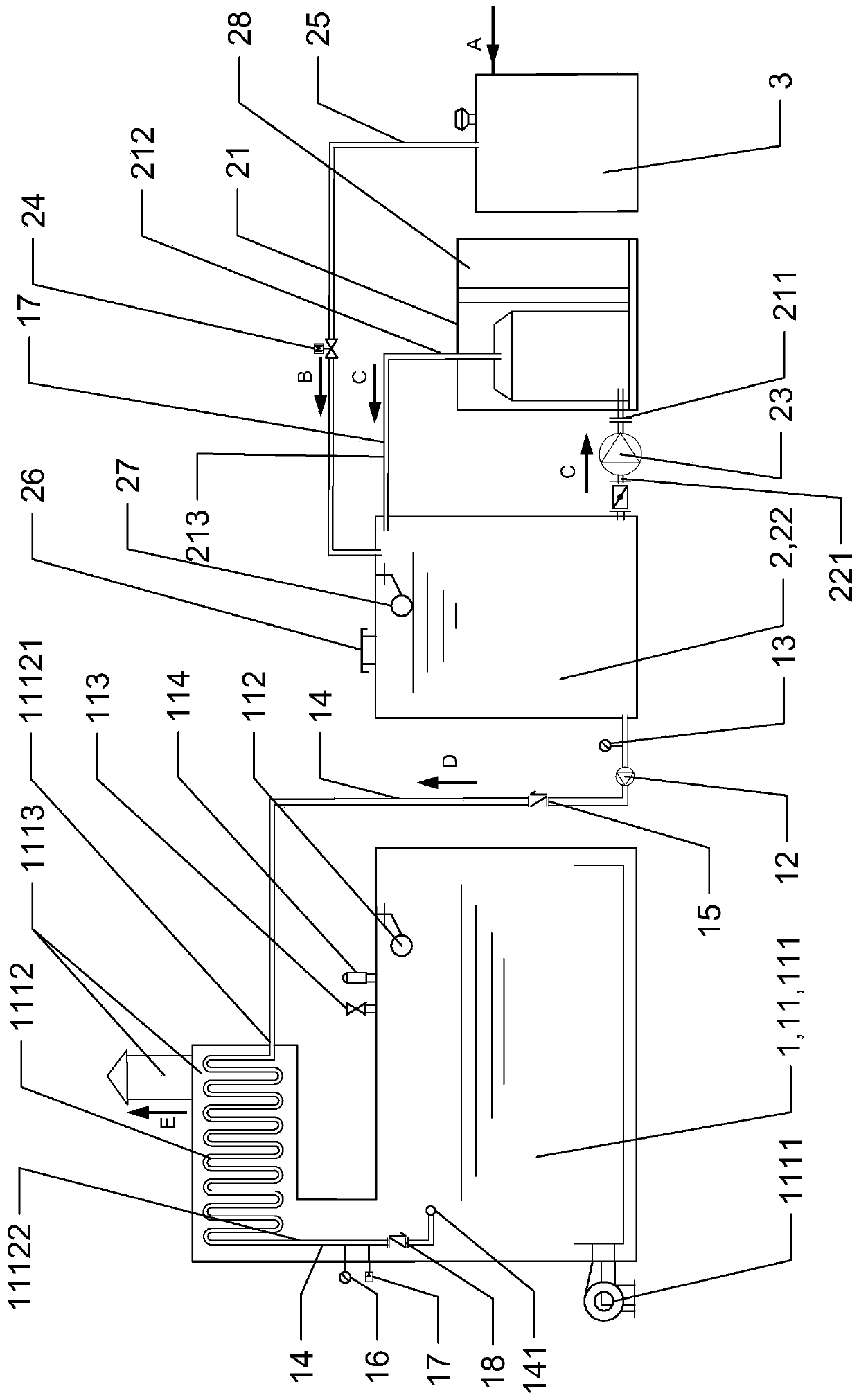

Combined steam generation device with preheating water tank and method for generating steam

PendingCN111457340ALess gas consumptionLow gas consumptionFluid heatersSteam generation heating methodsSolenoid valveWater circulation

The invention relates to a combined steam generation device with a preheating water tank. The device comprises a soft water treater, a normal-pressure water heating system and a steam production system which are sequentially connected in series through pipelines in a communicating mode, wherein the steam production system comprises a steam boiler, a variable-frequency water feeding pump, a check valve and a preheating water inlet pipeline, the normal-pressure water heating system comprises a preheating electromagnetic boiler, a preheating water tank, a circulating water pump, an electromagnetic valve and a cold water pipeline, and an outlet of the soft water treater communicates with the upper part of the preheating water tank through the cold water pipeline. During work, incoming water isinput into the preheating water tank, the preheating electromagnetic boiler is started at night, the circulating water pump circularly inputs water in the preheating water tank into the preheating electromagnetic boiler for heating, in the daytime, a combustor of a gas-steam boiler is started, hot water in a waste heat recovery device is further heated through flue gas, the hot water enters the gas-steam boiler, and steam is generated.

Owner:常州金坛金能电力有限公司

Aquiculture integrated water processing unit and flushing method thereof

InactiveCN102218236BLarge specific surface areaSmall particle sizeLoose filtering material filtersGravity filtersBiological membraneWater processing

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com