A purple sand ceramic brick made from vanadium and titanium industrial waste slag and its preparation method

A technology of industrial waste slag and ceramic bricks, which is applied in the field of ceramic bricks, can solve the problems of unrealized vanadium titanium slag and extensive utilization methods, and achieve the effect of shortening the firing cycle and lowering the firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

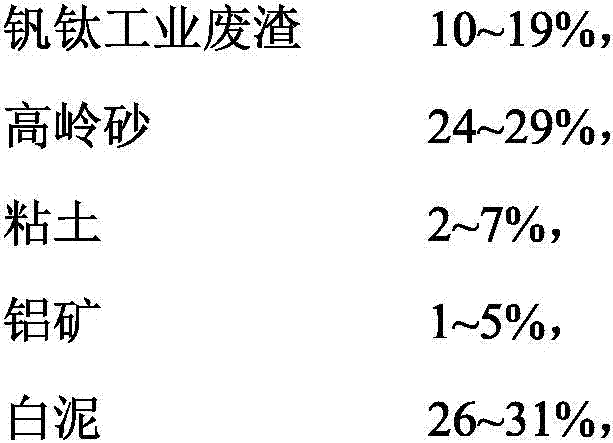

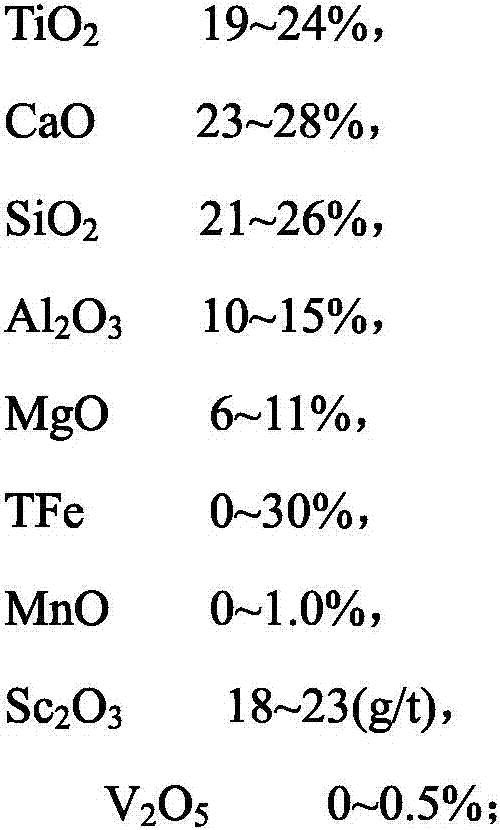

[0060]A kind of preparation method of the purple sand ceramic tile that utilizes vanadium-titanium industrial waste slag to make, taking the formula composition of 1000kg as an example, comprises the following steps:

[0061] A. Raw material detection: Mixing homogenization treatment and component analysis of vanadium and titanium industrial waste slag raw materials;

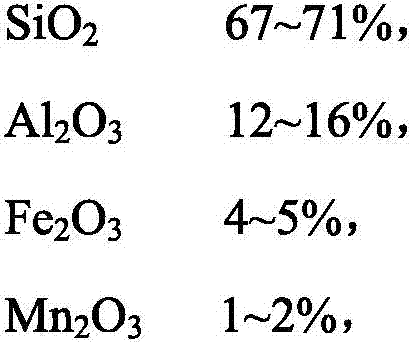

[0062] B. Ingredients: Weigh raw materials by weight percentage: 100kg of vanadium-titanium industrial waste slag analyzed and processed in step A, 290kg of kaolin sand, 20kg of clay, 50g of aluminum ore, 260kg of white mud, 100kg of shale, 40kg of recovered mud for floor tiles, polished Recycled mud 110kg, waste billet 30kg;

[0063] C. Pulping: Mix and stir the materials in step B evenly, and ball mill the mixed raw materials according to the ratio of material: ball: water = 1:2:0.5; after ball milling, pass through a 250-mesh sieve to form a sieve residue of 2~2.5% slurry;

[0064] D. Flour making: Dry the ...

Embodiment 2

[0073] Taking the formula composition of 1000kg of raw materials as an example, the raw materials are composed of: 170kg of vanadium and titanium industrial waste residue, 240kg of kaolin sand, 60kg of clay, 10kg of aluminum ore, 280g of white mud, 50kg of shale, 70kg of floor tile recycling mud, 60kg of polishing recycling mud, waste Blank 60kg. The preparation method is the same as in Example 1.

Embodiment 3

[0075] Taking the formula composition of 1000kg of raw materials as an example, the raw materials are composed of: 140kg of vanadium and titanium industrial waste residue, 250kg of kaolin sand, 40kg of clay, 30kg of aluminum ore, 280g of white mud, 80kg of shale, 60kg of floor tile recycling mud, 80kg of polishing recycling mud, waste Blank 40kg. The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com