Aquiculture integrated water processing unit and flushing method thereof

A water treatment device and aquaculture technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of poor working conditions, inability to clean and remove, long time, etc., and achieve good comprehensive treatment effect and intercept solid pollutants. The effect of strong physical ability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

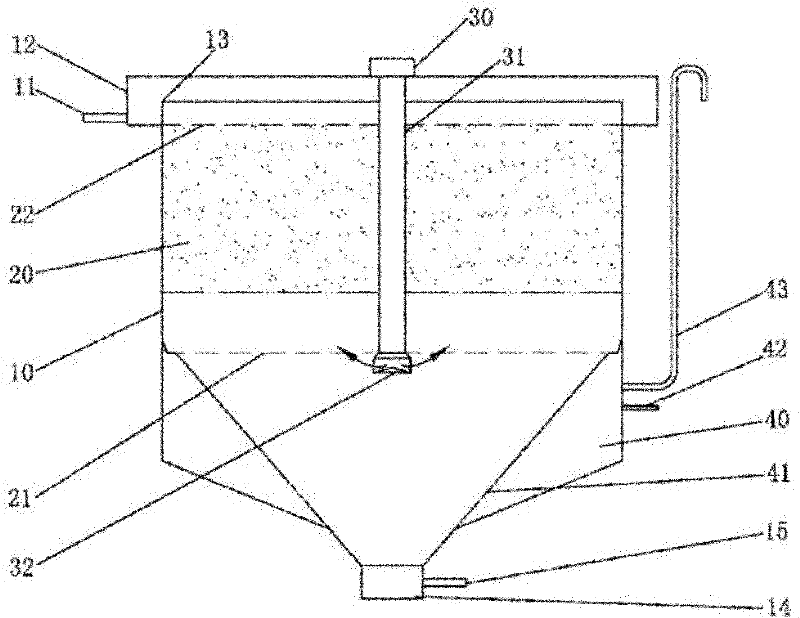

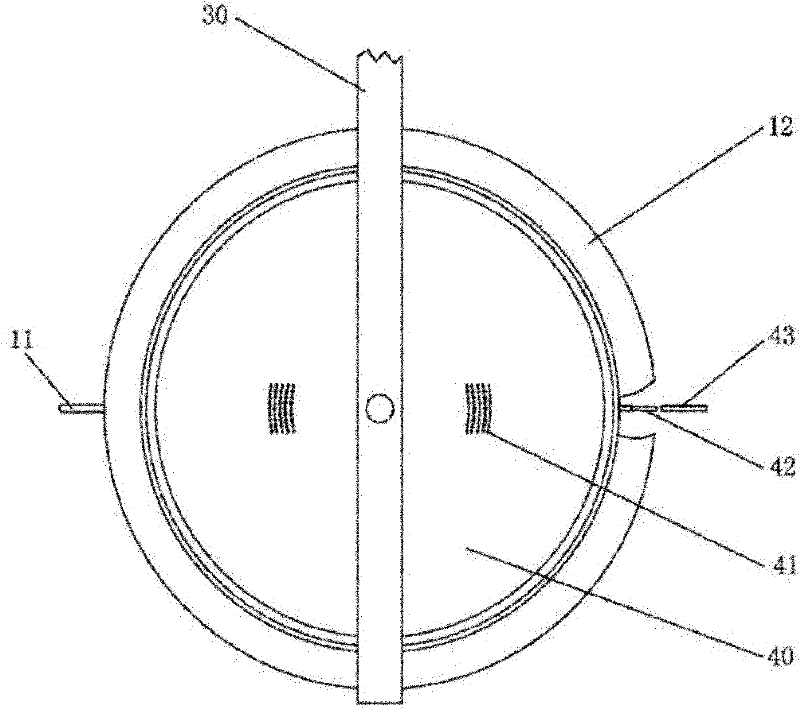

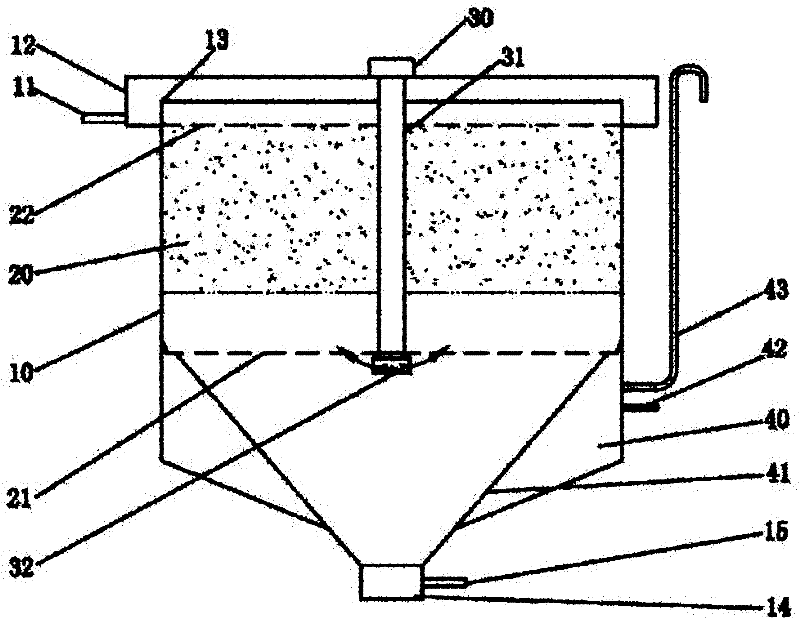

[0036]Below in conjunction with accompanying drawing, the present invention is introduced and described in more detail.

[0037] An integrated water treatment device for aquaculture, comprising a funnel-shaped tank body 10 with a cylindrical upper part and a conical lower part. The upper side of the pool body 10 is a circle of weir plates 13, and the outer side is an annular water collection tank 12. The water in the sump 12 is discharged from the outlet pipe 11; the center of the pool body 10 is a vertical center pipe 31; the conical bottom of the pool body 10 is a sewage collection tank 14 and a sewage pipe 15; Orifice plate 22, the filter material 20 of lightweight expanded particle is placed in the lower part of orifice plate 22; Several communication holes 41 are opened at the lower part of the conical surface of the pool body 10, and the outer conical surface of the pool body 10 is connected by the communication holes 41. A circle of recoil chamber 40 is provided, and an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com