High-blast-temperature combinative heat exchange system of blast furnace

A heat exchange system and air temperature technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of high equipment operating costs, unsatisfactory effects, and high equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

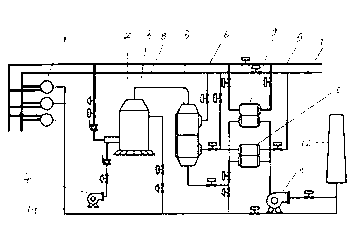

[0005] control figure 1 It can be seen that a blast furnace high air temperature combined heat exchange system includes a hot blast stove 1, a front combustion furnace 2, an air spoiler heat exchanger 3, a blower 4, a cold gas main pipe 5, a hot gas main pipe 6, and a cold air main pipe 7 , hot air main pipe 8, gas heat pipe heat exchanger 9, air heat pipe heat exchanger 10, induced draft fan 11 and chimney 12, said blower 4 and hot gas main pipe 6 are respectively connected to the pre-combustion furnace 2 through the control valve, and the cold gas A control valve is provided between the main pipe 5 and the hot gas main pipe 6, and a control valve is provided between the cold air main pipe 7 and the hot air main pipe 8. The cold gas main pipe 5 is connected to one end of the gas heat pipe heat exchanger 9 through the control valve, and the gas heat pipe is exchanged. The other end of the heater 9 is connected to the hot gas main pipe 6 through the control valve, the cold air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com