Pneumatic circulation air compression pump and air engine combined body

An air engine and air pressure pump technology, applied in the direction of rotating or swinging piston engine, machine/engine, rotating piston engine, etc. and other problems, to achieve the effect of low gas consumption and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

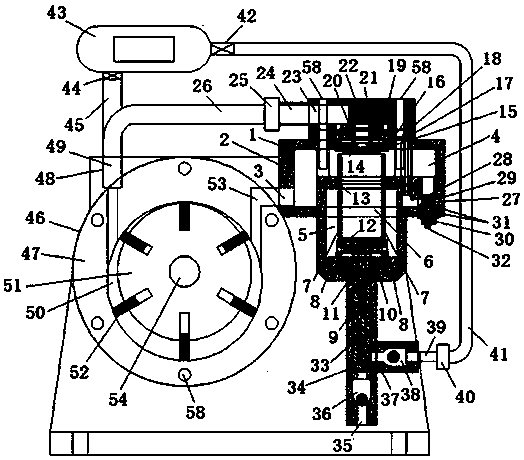

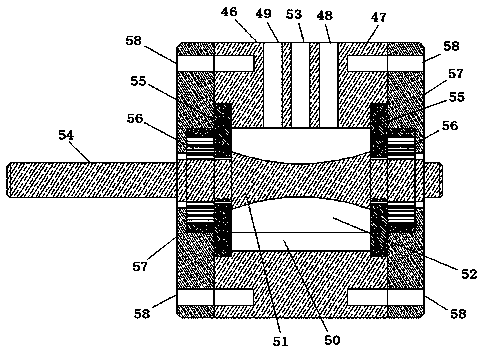

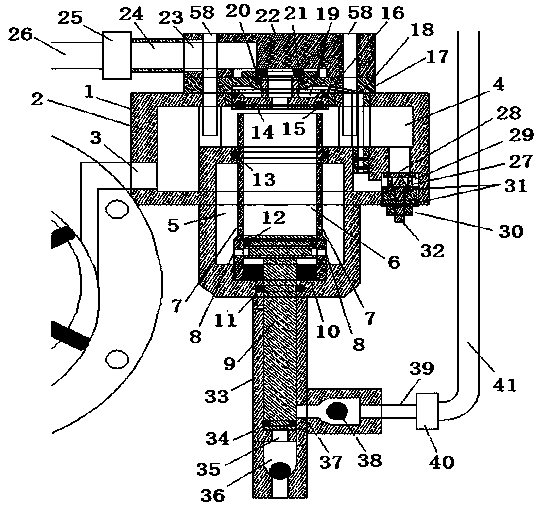

[0025] refer to Figure 1-Figure 4 , a combination 1 of a pneumatic circulating air compressor and an air engine, including a pneumatic circulating air compressor and a vane air engine 6;

[0026] The pneumatic circulating air pump includes a pneumatic circulating air pump housing 2, a pneumatic circulating air pump inlet 3, an intake gas storage chamber 4, a piston return chamber 5, a cylinder I 6, and a cylinder inlet to the piston return chamber. Air outlet 7, piston air return port 8, piston I9, gasket I10, sealing ring I11, sealing ring II12, sealing ring III13, cylinder head piston 14, sealing ring IV15, sealing ring V16, cylinder head 17, air inlet of cylinder head 18. Cylinder head air storage chamber 19, sealing ring Ⅵ20, sealing gasket Ⅱ21, cylinder exhaust cover 22, exhaust cover air outlet 23, joint Ⅰ24, check valve Ⅰ25, return air pipe 26, switch 27, air intake of switch cavity Port 28, switch air cavity outlet 29, switch lock nut 30, seal ring VII31, switch air ...

Embodiment 2

[0031] refer to Figure 4-Figure 5 , a combination 1 of a pneumatic circulating air compressor and an air engine, comprising a pneumatic circulating air compressor and a piston air engine;

[0032] The pneumatic circulating air pump includes a pneumatic circulating air pump housing 2, a pneumatic circulating air pump inlet 3, an intake gas storage chamber 4, a piston return chamber 5, and an air outlet 7 for the cylinder inlet piston return chamber , Piston air return port 8, gasket Ⅰ10, sealing ring Ⅰ11, sealing ring Ⅱ12, sealing ring Ⅲ13, cylinder head piston 14, sealing ring Ⅳ15, sealing ring Ⅴ16, cylinder head 17, cylinder head air inlet 18, cylinder head gas storage Cavity 19, sealing ring Ⅵ20, gasket Ⅱ21, cylinder exhaust cover 22, exhaust cover outlet 23, joint Ⅰ24, check valve Ⅰ25, air return pipe 26, switch 27, switch air cavity inlet 28, switch air cavity Air outlet 29, switch lock nut 30, sealing ring VII 31, switch air rod 32, air compressor air storage tank 43, a...

Embodiment 3

[0035] refer to Figure 4 and Image 6 , a combination 1 of a pneumatic circulating air compressor and an air engine, comprising a pneumatic circulating air compressor and a piston air engine;

[0036] The pneumatic circulating air pump includes a pneumatic circulating air pump housing 2, a pneumatic circulating air pump inlet 3, an intake gas storage chamber 4, a cylinder head piston 14, a sealing ring IV15, a sealing ring V16, and a cylinder head 17 , cylinder head air inlet 18, cylinder head air storage chamber 19, sealing ring Ⅵ20, sealing gasket Ⅱ21, cylinder exhaust cover 22, exhaust cover air outlet 23, joint Ⅰ24, check valve Ⅰ25, air return pipe 26, switch 27 , switch air cavity inlet 28, switch air cavity outlet 29, switch lock nut 30, sealing ring VII 31, switch air rod 32, air compressor air storage tank 43, air compressor exhaust valve 44, air compressor Exhaust pipe 45; the piston air engine includes cylinder II 63, piston II 64, piston connecting rod pin 59, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com