Pneumatic hand control ink supply device

An ink supply device, pneumatic technology, applied in the field of pneumatic manual ink supply device, can solve the problems of high air pressure required, complex structure of the nozzle, dirty ink, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

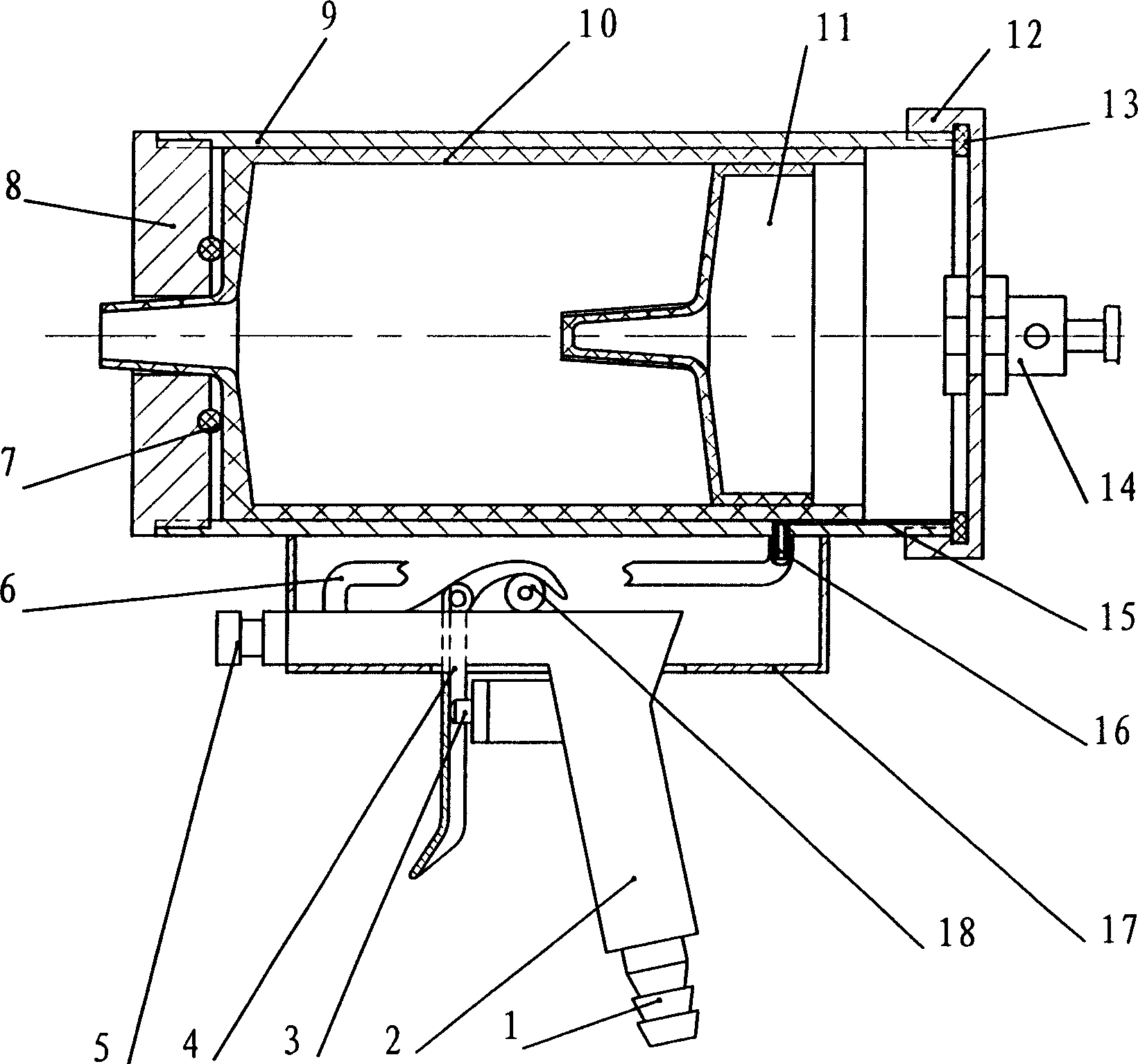

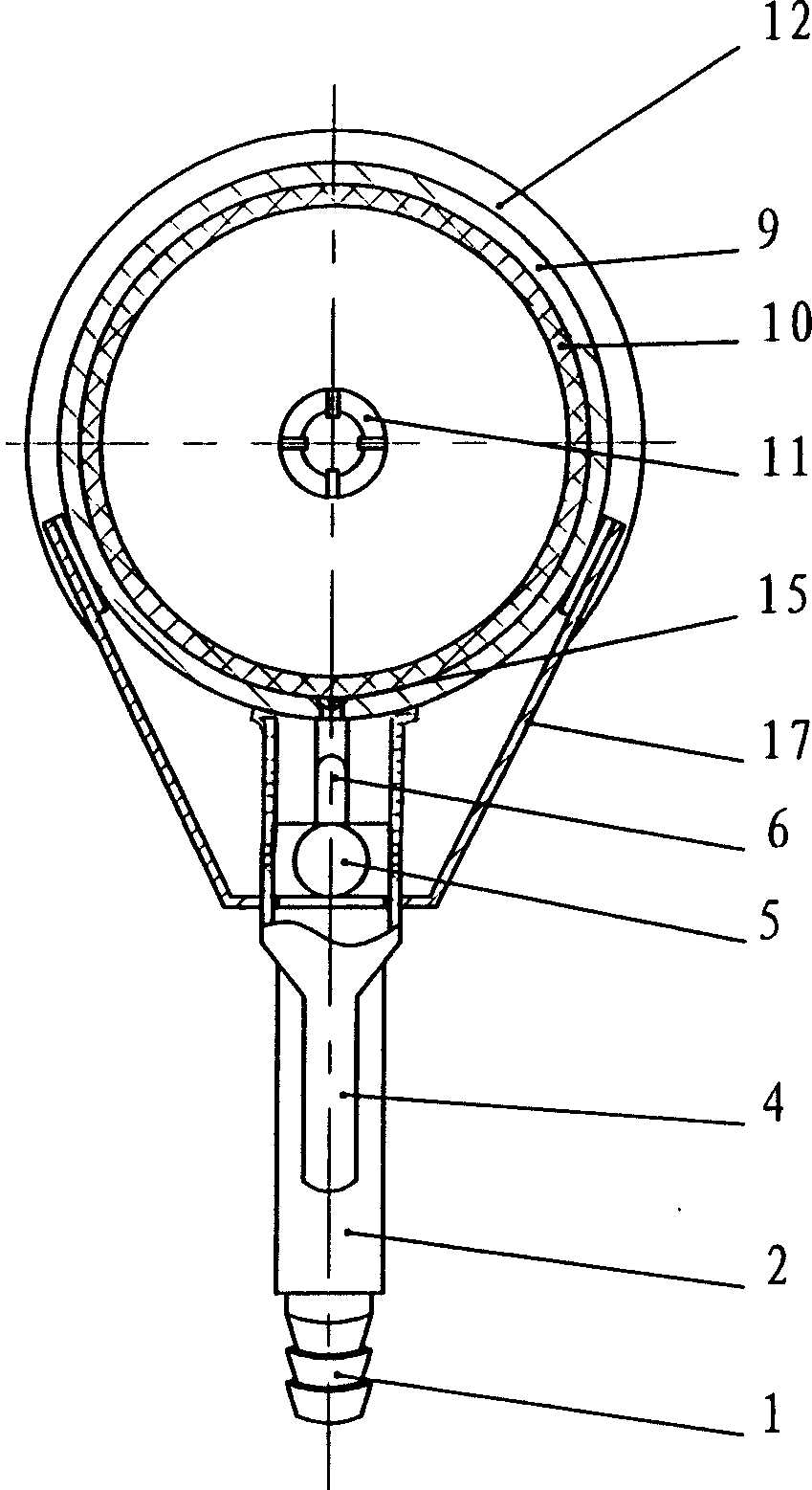

[0017] see figure 1 and figure 2 , the pneumatic manual ink supply device of the present invention includes a cylinder body 9 for placing an ink container, a pneumatic control part is installed on the cylinder body, the air outlet of the pneumatic control part has a gas pipe 6, and the inlet of the pipe and the cylinder body The air hole 16 is connected, and one end of the cylinder body 9 has a back cover 12 which closes the cylinder body to form an air chamber, so as to place the ink container and cover the ink container behind, and the other end has a top plate 8 .

[0018] The back cover 12 can be connected with the cylinder body 9 by threads, or can be connected with the cylinder body by a loose leaf, and fixed with a lock. Described top plate 8 can be fixedly connected with cylindrical shell as a whole, also can adopt threaded connection. A sealing ring 13 is provided at the contact between the rear cover 12 and the end of the barrel 9 to prevent leakage of compressed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com