Blade gear ring rotor air engine and circulating system

An air engine and engine cover technology, applied in the direction of rotary piston engines, rotary or swinging piston engines, engine components, etc., can solve the problems of low speed, large air consumption, and small button force, and achieve high efficiency and low air consumption. Low, high-horsepower effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

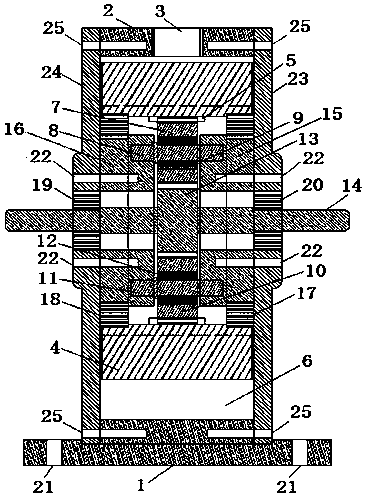

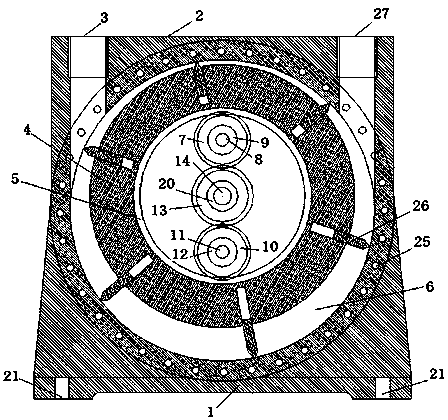

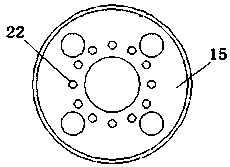

[0034] refer to Figure 1-Figure 4 , a blade ring gear rotor air engine 1, including engine casing 2, engine air inlet 3, blade ring gear rotor 4, ring gear rotor internal gear 5, cylinder 6, transmission gear I7, transmission gear shaft I8, bearing I9 , transmission gear Ⅱ10, transmission gear shaft Ⅱ11, bearing Ⅱ12, output shaft gear 13, output shaft 14, transmission gear bracket Ⅰ15, transmission gear bracket Ⅱ16, bracket bearing Ⅰ17, bracket bearing Ⅱ18, output shaft bearing Ⅰ19, output shaft bearing Ⅱ20, Machine foot screw hole 21, gear bracket screw hole 22, engine cover plate Ⅰ 23, engine cover plate Ⅱ 24, cover plate screw hole 25, blade 26, engine exhaust port 27;

[0035] The outer periphery of the blade ring gear rotor 4 is connected to the blade 26 and installed in the cylinder 6 of the engine casing 2. The transmission gear I7 is connected to the transmission gear shaft I8 through the bearing I9, and the transmission gear II10 is connected to the transmission gear...

Embodiment 2

[0042] refer to Figure 8-Figure 9 , a blade ring gear rotor air engine, the difference from Embodiment 1 is: the transmission crankshaft 30 is used to replace the transmission gear shaft I8 and the transmission gear shaft II11, and the output crankshaft 36 is used to replace the output shaft 14; the transmission crankshaft 30 is installed with Crankshaft transmission gear I28, crankshaft transmission gear II29, one end of the transmission crankshaft 30 is connected with the gear crankshaft bracket I34 through the bearing III31, and the other end is connected with the gear crankshaft bracket II35 through the bearing IV32, the crankshaft transmission gear I28, the crankshaft transmission gear II29 It meshes with the internal gear 5 of the ring gear rotor, and the transmission crankshaft 30 is connected with the output crankshaft 36 through a connecting rod 33 .

[0043] Utilizing the blade ring gear rotor air engine of the present invention can effectively solve the problem of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com