Spectrum detection method and device for dielectric barrier discharge

A technology of dielectric barrier discharge and detection method, applied in the field of instrument analysis, can solve the problems of low plasma temperature, low sensitivity, large gas consumption, etc., and achieve the effects of simple detection part, improved sensitivity and less gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

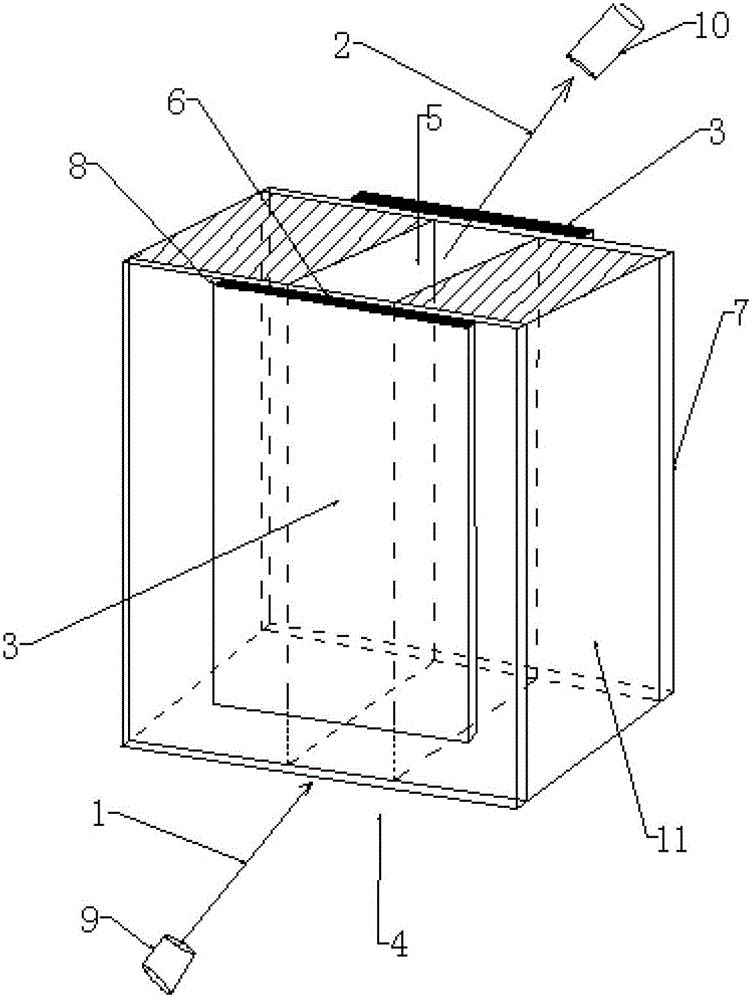

[0027] Example 1: The dielectric barrier discharge device is composed of 2mm glass 11 and 1mm quartz 7 in a cavity of 2mm×6mm×60mm, the distance between the barrier media is 2mm, the outside of quartz 7 is pasted with copper electrode plate 8, and the outside of quartz 7 is silver plated. The silver-plated layer 6 and the quartz 7 form a mirror, and the copper electrode plate 8 is connected to a high-voltage high-frequency power supply through a wire 3, and the voltage is 2000V and the frequency is 30KHZ.

[0028] The standard solution Hg is formed into a hydride, the carrier gas is blown off to form Hg vapor, and the Hg vapor enters the discharge chamber from the carrier gas inlet 4. The helium gas is introduced into the discharge chamber at 300ml / mim, and the high-voltage and high-frequency power supply is turned on to form plasma The carrier gas outlet 5 is discharged, and the illuminator 9 hollow cathode lamp produces incident light 1 from the carrier gas inlet 4 at an angle o...

Embodiment 2

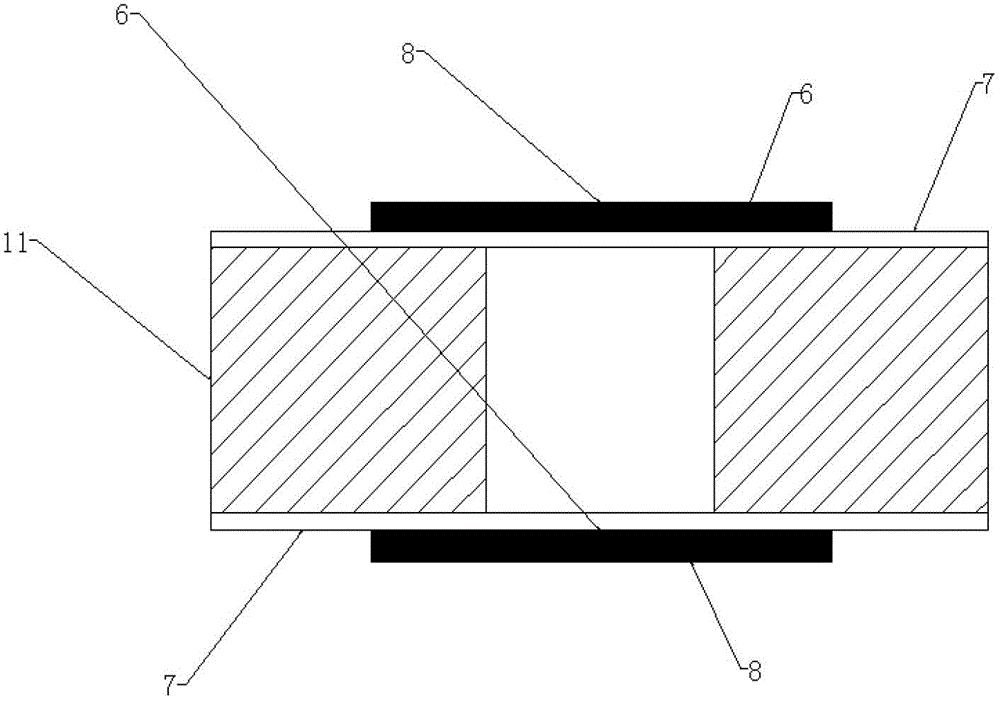

[0031] Example 2: The cavity is composed of 4mm quartz 11 and 1.5mm heat-resistant glass 7 to form a 4mm×5mm×70mm cavity. The distance between the barrier media is 4mm. An aluminum plate 8 is attached to the outside of the heat-resistant glass 7, the surface of the aluminum plate 6 and the barrier The two smooth sides of the medium are combined into a mirror (such as figure 2 As shown), the aluminum electrode plate 8 is connected to a high-voltage and high-frequency power supply through a wire 3, and the voltage is 7000V and the frequency is 3MHZ.

[0032] The standard solution Cr solution is sprayed pneumatically to make the Cr solution form vapor, the vapor enters the discharge chamber from the carrier gas inlet 4, and the nitrogen is introduced into the discharge chamber at a flow rate of 200ml / mim, and the high-voltage and high-frequency power supply is turned on to form plasma and emit light at the same time The laser light in the device 9 produces incident light 1 from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com