Combined steam generation device with preheating water tank and method for generating steam

A technology of steam generating device and preheating tank, which is applied in the field of steam generator and combined steam generating device, which can solve the problems of high operating cost, poor reliability, uneven heating, etc., and achieve high combustion efficiency, low gas consumption, and improved water supply The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

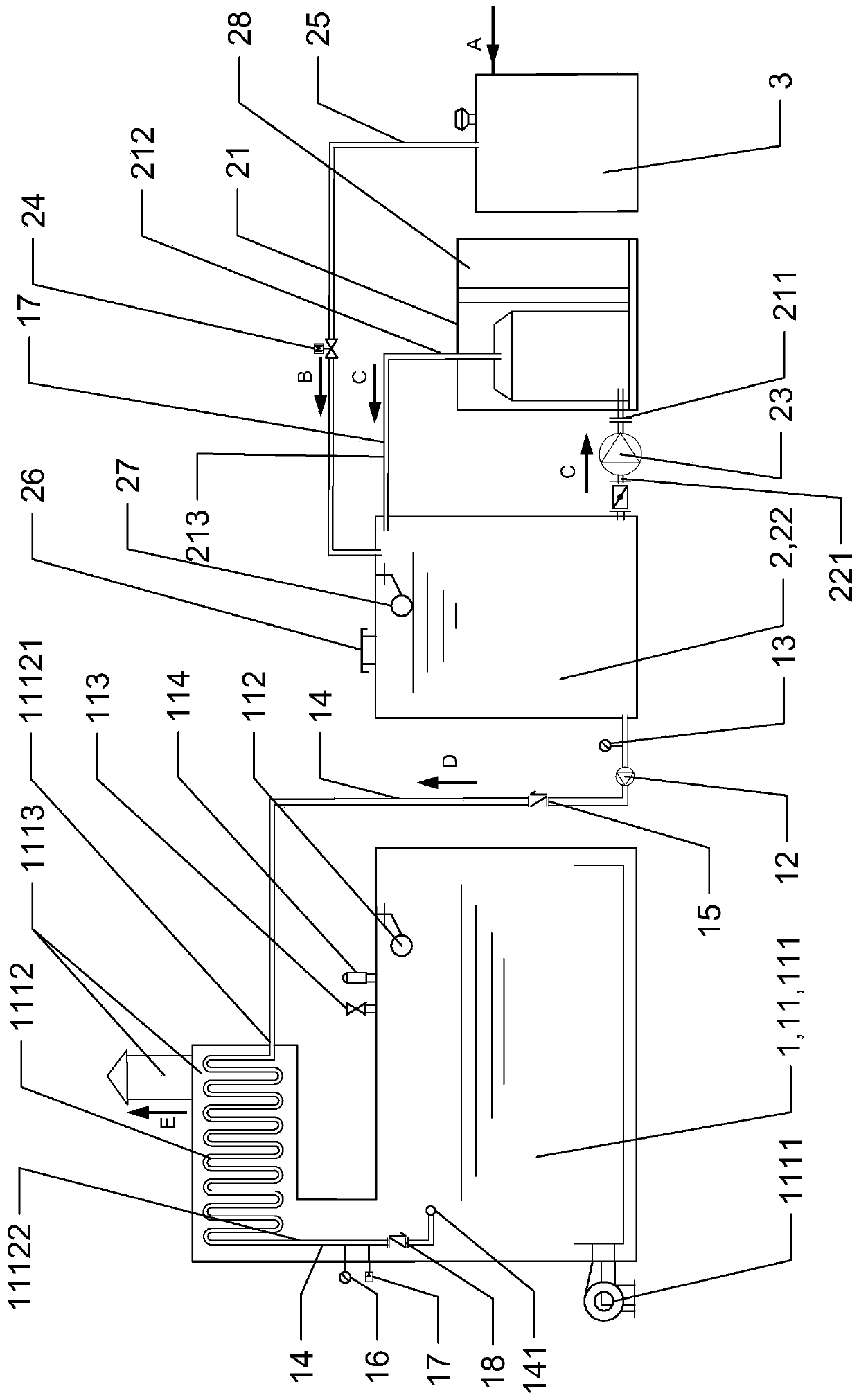

[0035] see figure 1 , a combined steam generating device with a preheating water tank, from tap water inlet to steam outlet, composed of soft water processor 3, normal pressure heating water system 2 and steam production system 1 connected in series through pipelines; the steam The production system 1 includes a steam boiler 11, a frequency conversion feed water pump 12, a check valve 13 and a preheating water inlet pipe 14; the normal pressure heating water system 2 includes a preheating electromagnetic boiler 21, a preheating water tank 22, a circulating water pump 23, Electromagnetic valve 24, cold water pipeline 25. The steam boiler 11 is a gas-fired steam boiler 111 . The preheating electromagnetic boiler 21 adopts a three-phase power frequency induction electromagnetic boiler or a single-phase power frequency induction electromagnetic boiler.

[0036] The outlet of the water softener 3 is connected to the top of the preheating water tank 22 through the cold water pipel...

Embodiment 2

[0050] The difference between the steam generation device of Embodiment 2 and Embodiment 1 is that the steam boiler 11 is a resistance boiler among electric boilers, and there is no waste heat recovery device 1112 in the steam production system 1, and the rest is the same as that of Embodiment 1.

Embodiment 3

[0052] Adopt the method for producing steam of a kind of combined steam generating device with preheating water tank described in embodiment 1 has the following steps:

[0053] Step 1: Input the softened water into the preheating tank 22 through the cold water pipe 25, and the float valve 27 and the solenoid valve 24 work together to keep the preheating tank 22 at a reasonable water level.

[0054] Step 2: Turn on the preheating electromagnetic boiler 21 at night with low electricity, and the circulating water pump 23 circulates the water in the preheating water tank 22 into the preheating electromagnetic boiler 21 for heating.

[0055] Step 3: Turn on the burner 1111 of the gas-fired steam boiler 111 during the day, and the flue gas in the flue 1113 further heats the hot water in the waste heat recovery device 1112, and the hot water enters the gas-fired steam boiler 111 to generate steam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com