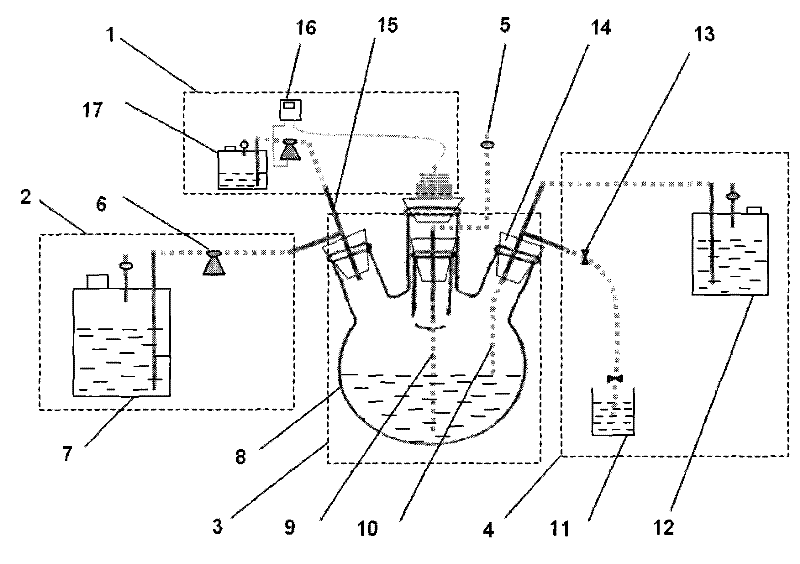

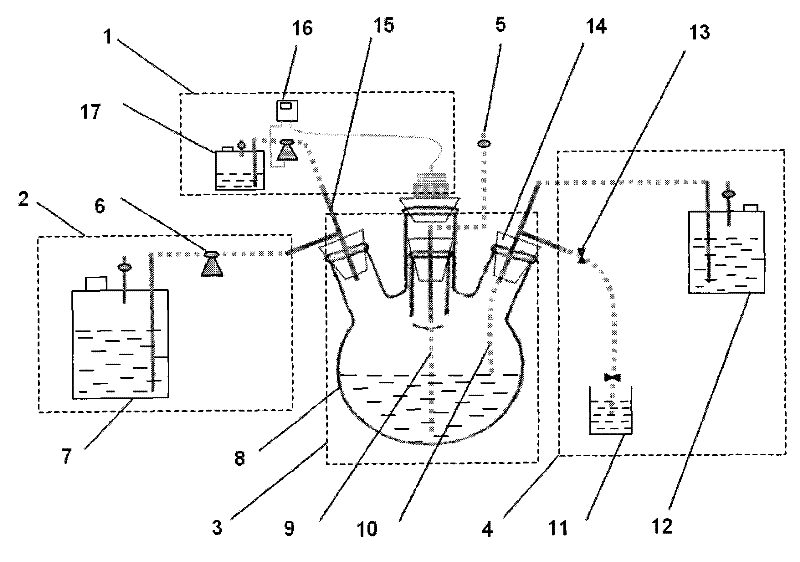

Chemostat continuous cultivation device

A cultivation device and chemostat technology, which is applied in the field of continuous chemostat cultivation devices, can solve the problems of hindering the further development and application of technology, long equipment occupation period, easy to be contaminated by operation, etc. Reduced chance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

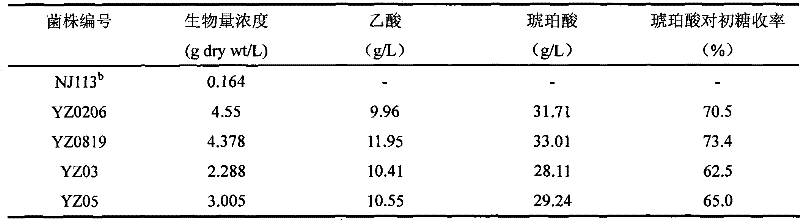

[0042] In this embodiment, Actinobacillus succinogenes (Actinobacillus succinogenes) NJ113, preservation number CGMCC 1716 is used as the starting strain, and the mutant bacteria that are tolerant to high-concentration ammonium ions are continuously cultured and screened in the chemostat of the present invention as an example:

[0043] Medium A (g / L): Glucose 10, K 2 HPO 4 ·3H 2 O 15.5, NaH 2 PO 4 2H 2 O 9.6, NaHCO 3 10, yeast extract 5, corn steep liquor 5, pH 7.2.

[0044] Medium B (g / L): Glucose 20 (growth limiting factor), sodium acetate 1.36, NaCl 1, CaCl 2 0.2, MgCl 2 0.2, Na 2 HPO 4 0.31, NaH 2 PO 4 1.6,K 2 HPO 4 3, yeast paste 10, NH 4 HCO 3 4, 8, 16, 24, 28, C 4 h 4 o 4 Na 2 0,CH 3 COONa·3H 2 O 0, pH 9.0.

[0045] Medium C (solid plate medium) (g / L): glucose 10, K 2 HPO 4 ·3H 2 O 15.5, NaH 2 PO 4 2H 2 O 9.6, NaCl 1.0, corn steep liquor 5, yeast extract 5, NH 4 HCO 3 24. Agar powder 20, bromothymol blue 0.1 (pH 6.0-7.6 yellow to blu...

Embodiment 2

[0053] The implementation steps of the present embodiment are the same as in Example 1, changing the relevant parameter conditions, taking Actinobacillus succinogenes (Actinobacillus succinogenes) CGMCC 1716 as the starting strain, continuous culture and screening in the chemostat of the present invention can utilize inorganic nitrogen Source mutants as an example:

[0054] Medium A: Glucose 20g / L, K 2 HPO 4 ·3H 2 O 31g / L, NaH 2 PO 4 2H 2 O 19.2g / L, NaHCO 3 20g / L, yeast extract 10g / L, corn steep liquor 10g / L, pH 6.5;

[0055] Medium B: glucose 10g / L, sodium acetate 2.72g / L, NaCl 2g / L, CaCl 2 0.4g / L, MgCl 2 0.4g / L, Na 2 HPO 4 0.62g / L, NaH 2 PO 4 3.2g / L, K 2 HPO 4 6g / L, yeast extract 5, 2.5, 0g / L, NH 4 HCO 3 4. 8g / L, C 4 h 4 o 4 Na 2 100,CH 3 COONa·3H 2 O 80, pH 7.0;

[0056] Medium C: Glucose 20g / L, K 2 HPO 4 ·3H 2 O 31g / L, NaH 2 PO 4 2H 2 O 19.2g / L, NaCl 2g / L, corn steep liquor 10g / L, yeast extract 10g / L, NH 4 HCO 3 16g / L, agar powder 20g / ...

Embodiment 3

[0064] In this embodiment, E.coli NZN111 (F-Δpfl::Cam, ldhA::Kan) / pTrc99a-sfcA is used as the starting strain, and the mutant bacteria resistant to organic acids are continuously cultured and screened in the chemostat of the present invention. example:

[0065] Medium A (g / L): Glucose 15, K 2 HPO 4 ·3H 2 O 23.5, NaH 2 PO 4 2H 2 O 14.6, NaHCO 3 15, yeast extract 8, corn steep liquor 7, pH 6.8.

[0066] Medium B (g / L): Glucose 15 (growth limiting factor), sodium acetate 2.13, NaCl 1.5, CaCl 2 0.3, MgCl 2 0.3, Na 2 HPO 4 0.45, NaH 2 PO 4 2.8,K 2 HPO 4 5, yeast paste 5, NH 4 HCO 3 8,C 4 h 4 o 4 Na 2 200,CH 3 COONa·3H 2 O 180, pH 8.0.

[0067] Medium C (solid plate medium) (g / L): glucose 15, K 2 HPO 4 ·3H 2 O 23.2, NaH 2 PO 4 2H 2 O14.6, NaCl 1.5, corn steep liquor 7, yeast extract 8, NH 4 HCO 3 20, agar powder 20, bromothymol blue 0.15 (pH 6.0-7.6 yellow to blue), pH 7.1.

[0068] Using the device of the present invention, continuously cult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dilution degree | aaaaa | aaaaa |

| Dilution degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com