Single-cylinder four-stroke gaseous propellant engine

A gaseous fuel, four-stroke technology, applied to combustion engines, internal combustion piston engines, machines/engines, etc., can solve the problems of engine muffler overheating, high exhaust harmful emissions, high exhaust temperature, etc., to achieve faster combustion speed and comprehensive performance optimization , Improve the effect of calibration power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

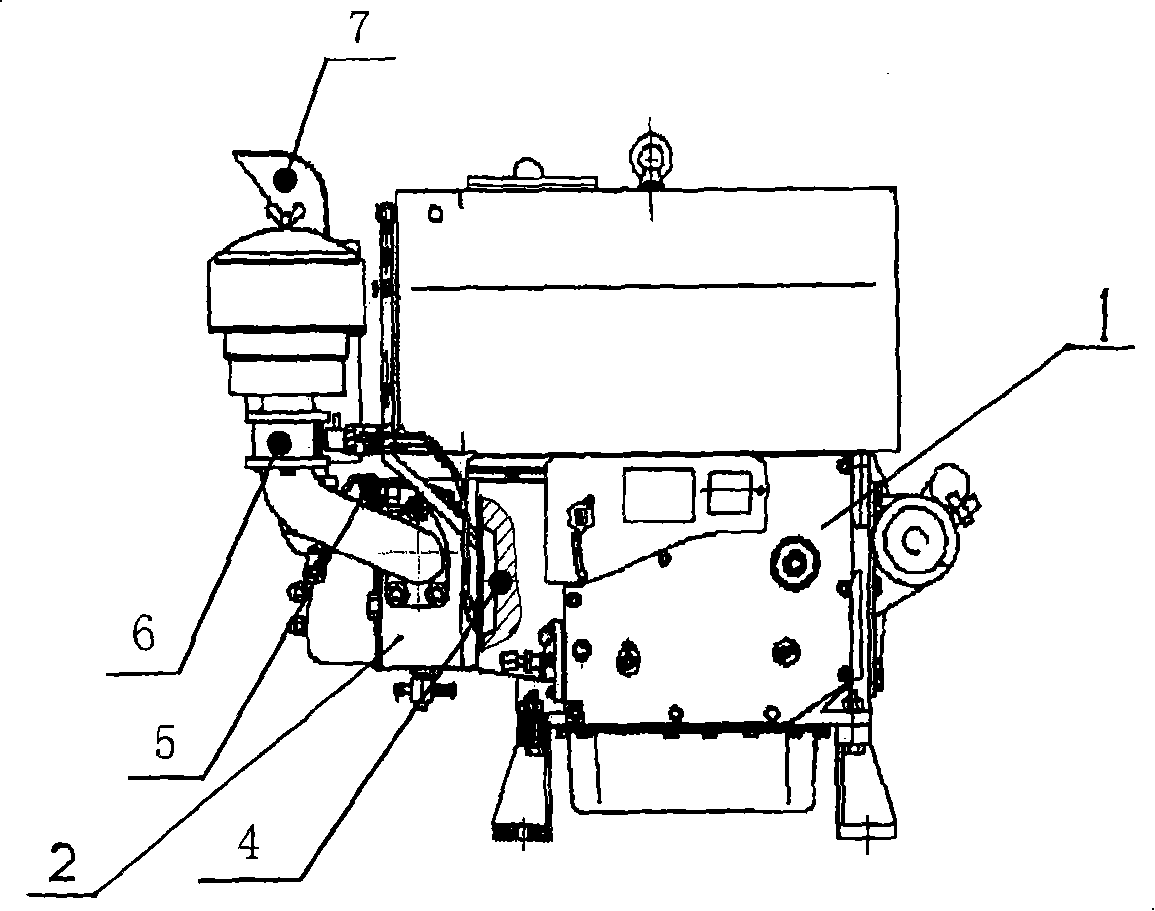

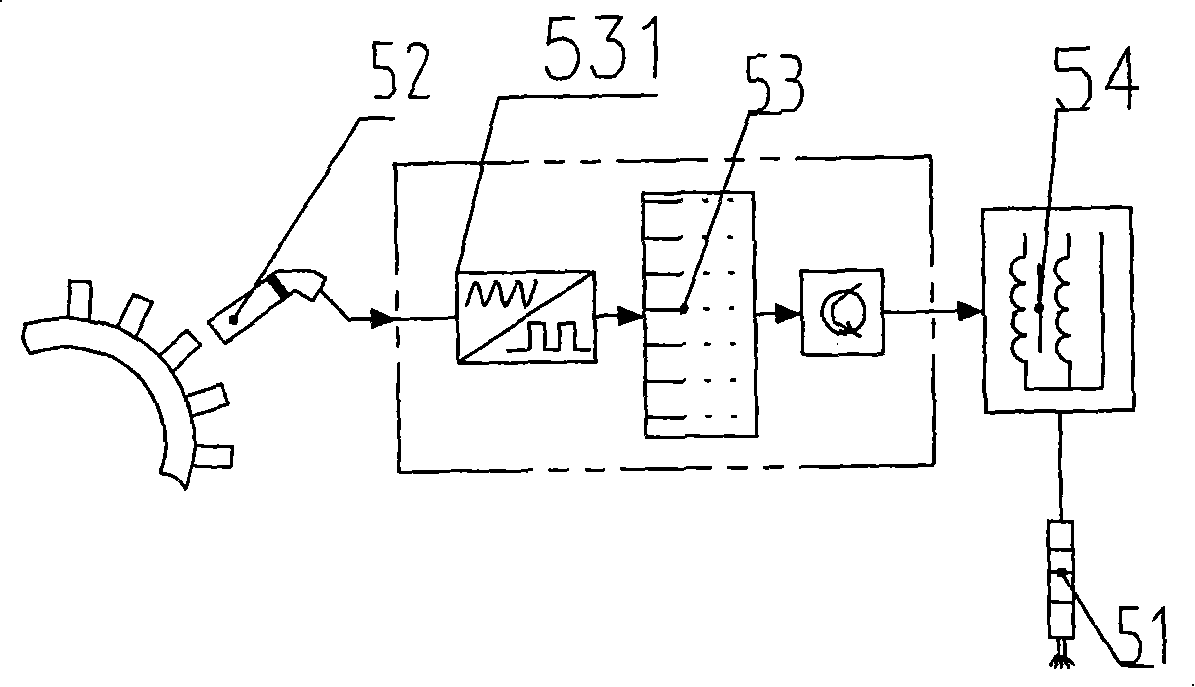

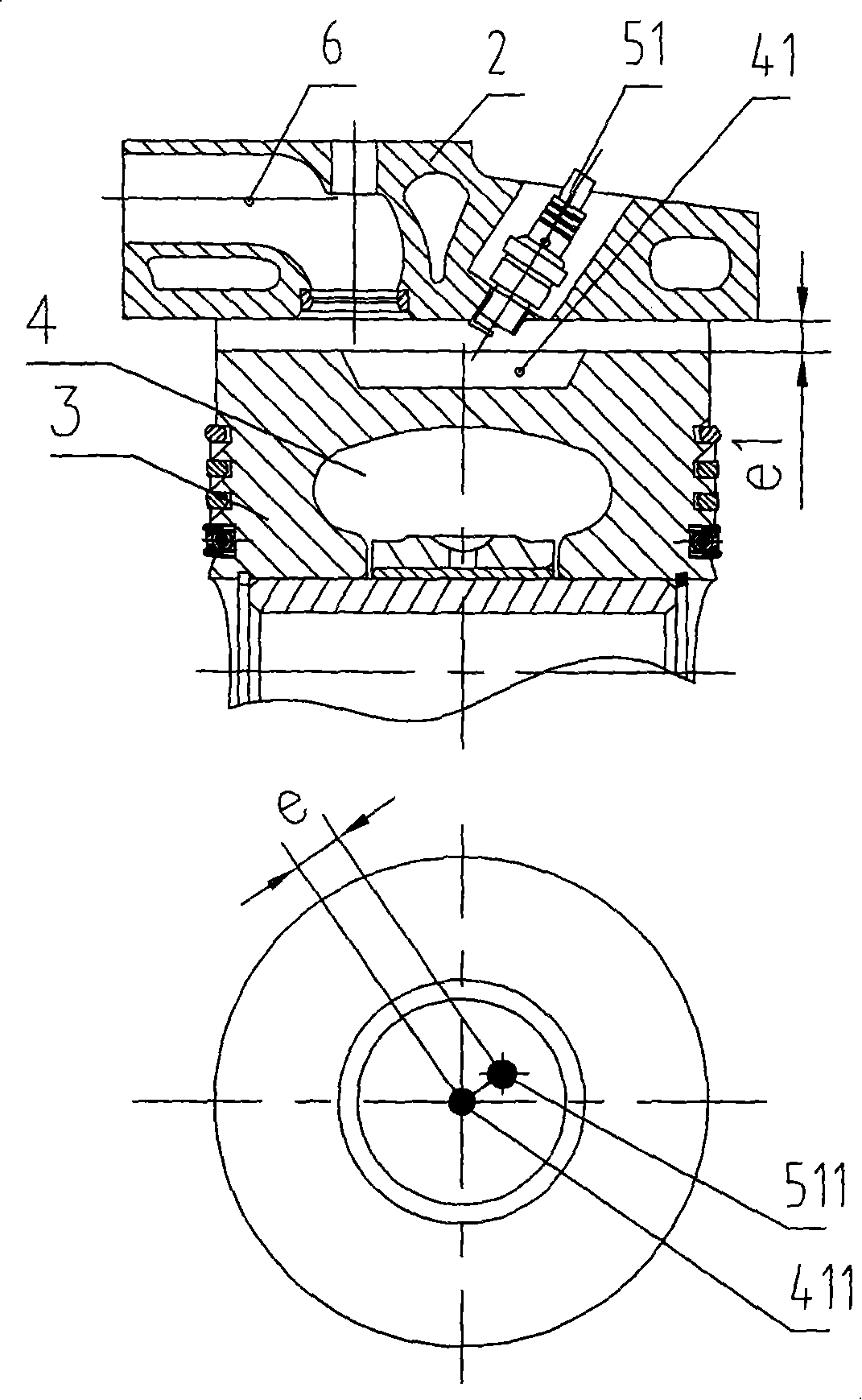

[0020] A single-cylinder four-stroke gas fuel engine has a body 1 provided with a cylinder head 2 and a piston 3. The cylinder head 2 is provided with a spark plug 51 and an intake port 6 of a spiral structure. Below the intake port 6 is a piston 3. The body 1 Between the bottom surface of the cylinder head 2 and the top surface of the piston 3 is a combustion chamber 4, the combustion chamber 4 is below the spark plug 51 and the intake passage 6, the combustion chamber 4 is connected with an ignition device 5, and is connected with the intake passage 6 and the exhaust device respectively. 7 Unicom, the ignition device 5 includes a rotational speed signal generator 52 that can detect the rotational speed and angle of the crankshaft in the body 1, an ignition control circuit 53 that receives the signal from the rotational speed signal generator 52 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com