Dust removing sprayer for mine

A technology for spraying machines and mines, which is applied in dust prevention, mining equipment, spraying devices, etc. It can solve problems such as complex control circuits, high fog humidity, and potential safety hazards, and achieve a large diffusion area, fine fog particles, and less water consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

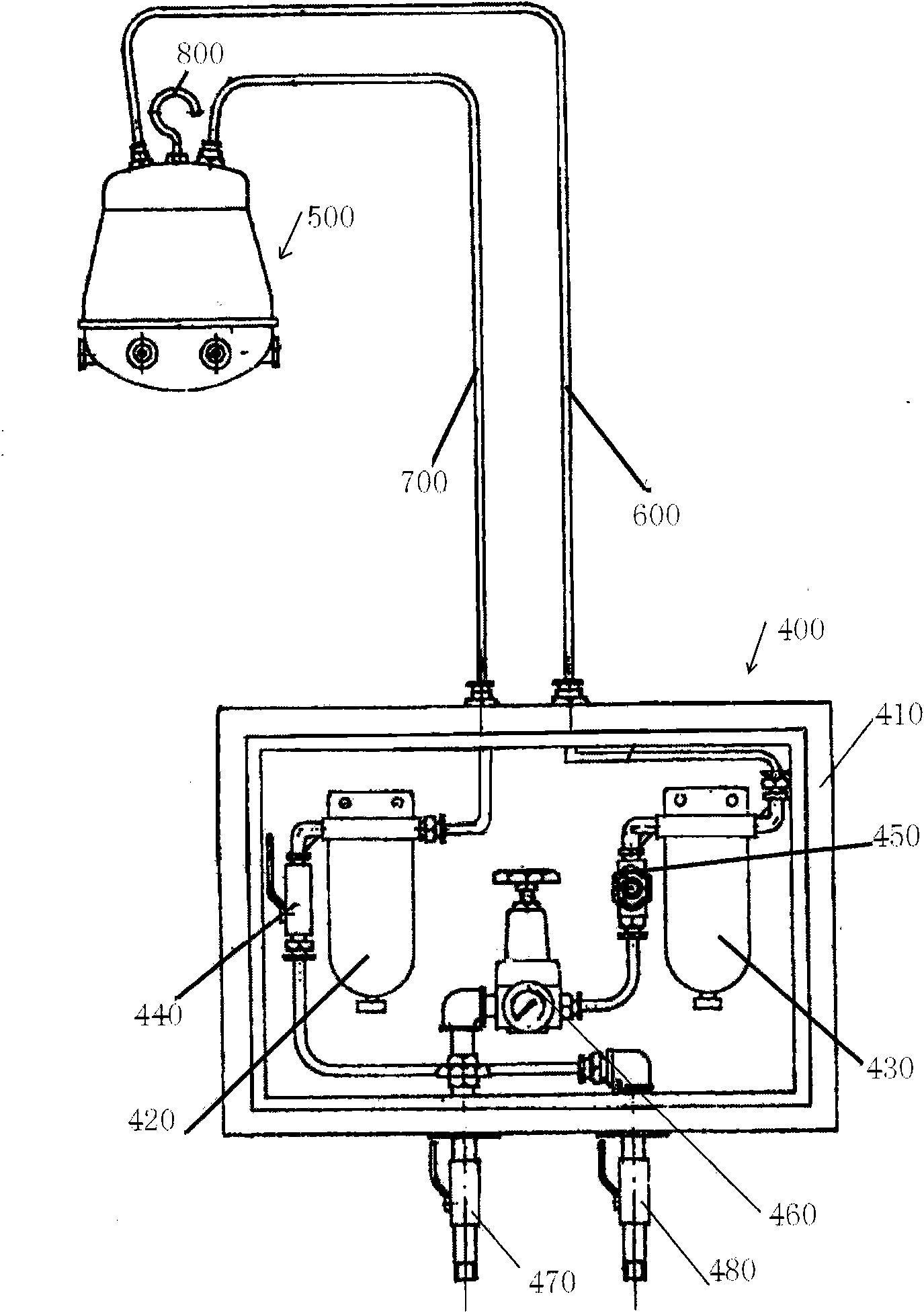

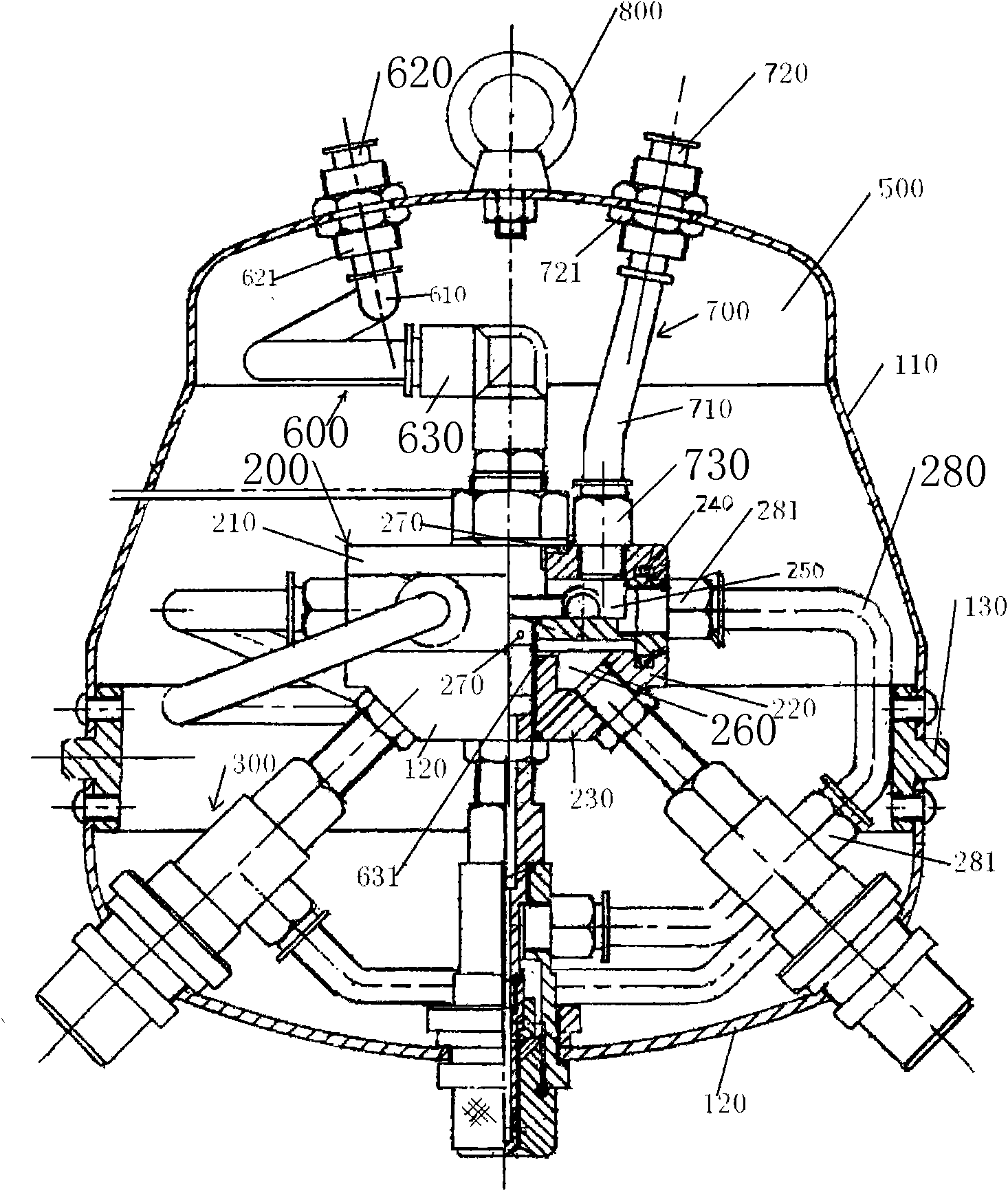

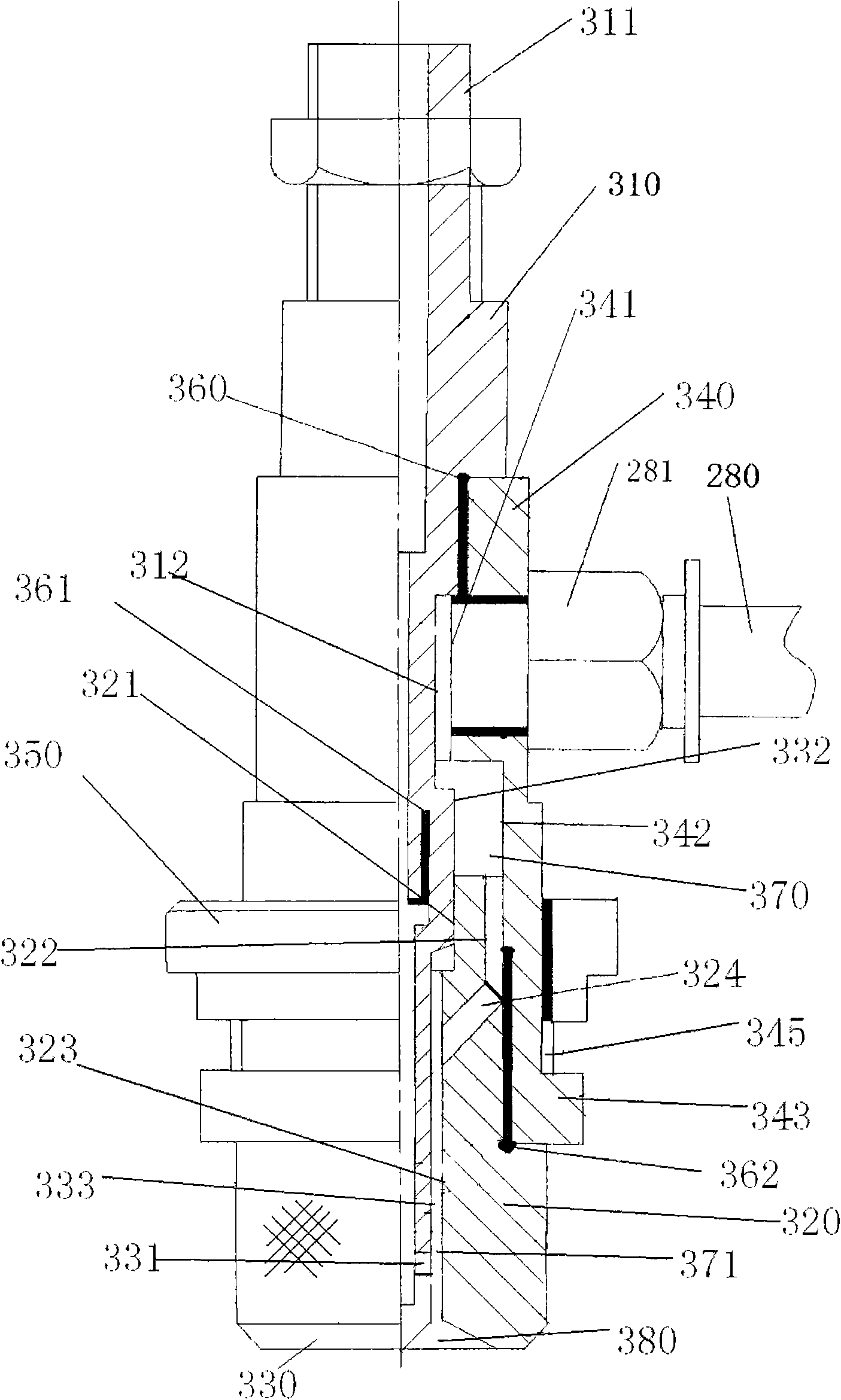

[0028] See figure 1 A kind of mine dedusting sprayer is made up of control box 400 and machine head 500 two parts. The control box 400 includes a box body 410, in which an air filter 420, a water filter 430, an intake trim valve 440, a water intake trim valve 450, a pressure reducing valve 460, an air filter 420 and a water filter are installed. The device 430 is used to purify compressed air and water, and remove impurities in the compressed air and water, so as to improve energy utilization and prolong the service life of the sprayer. The water inlet trim valve 450 and the inlet trim valve 440 are respectively used to adjust the effect of fog making.

[0029] The air inlet of the air filter 420 is connected to the air source of compressed air through the air inlet trim valve 440 , the air inlet valve 480 and the pipeline, and the air outlet of the air filter 420 is connected to the air inlet main pipe 700 . The water inlet end of the water filter 430 is connected to the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com