Gas egg-sausage machine

An egg sausage and gas technology, applied in multi-unit cooking utensils, heating devices, etc., can solve the problems of long heating time, inconvenient movement, fast power consumption, etc., and achieve the effect of rapid temperature increase, cost saving and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

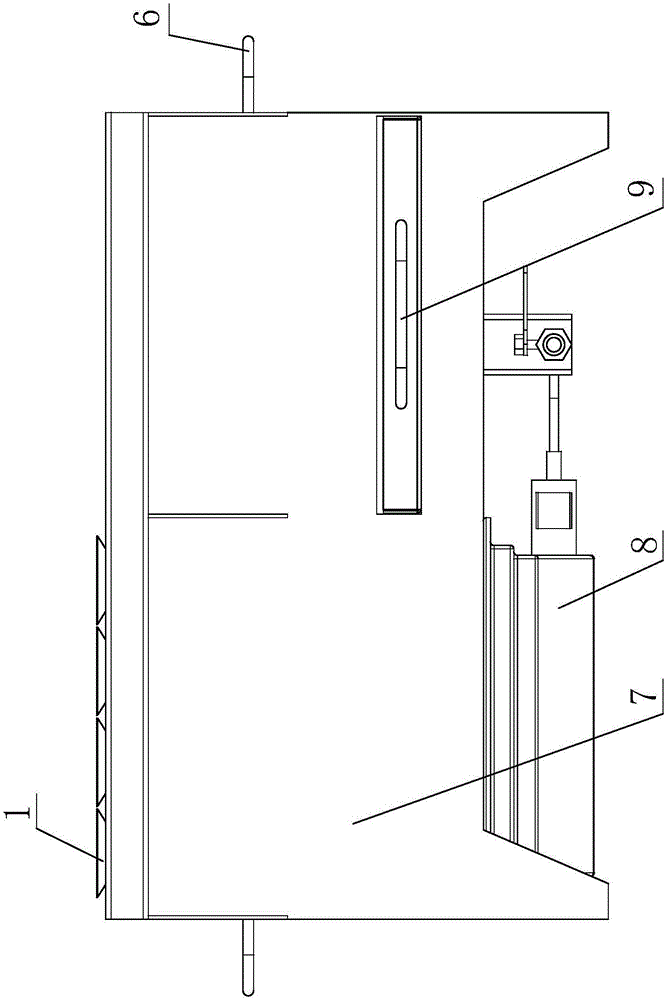

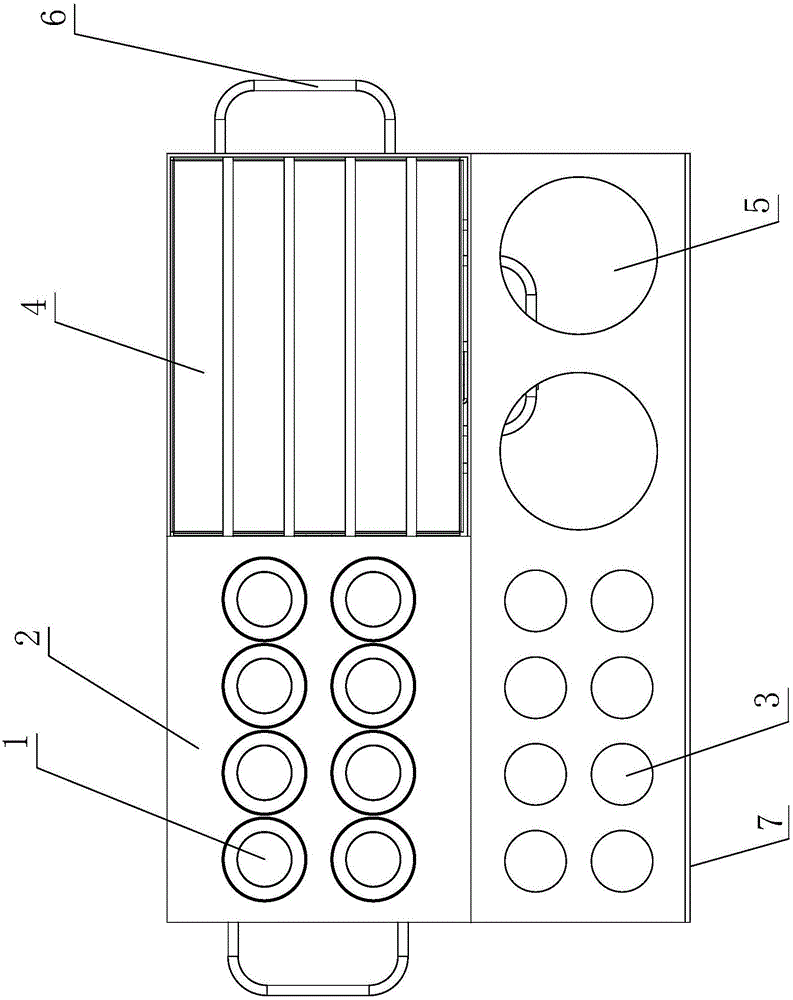

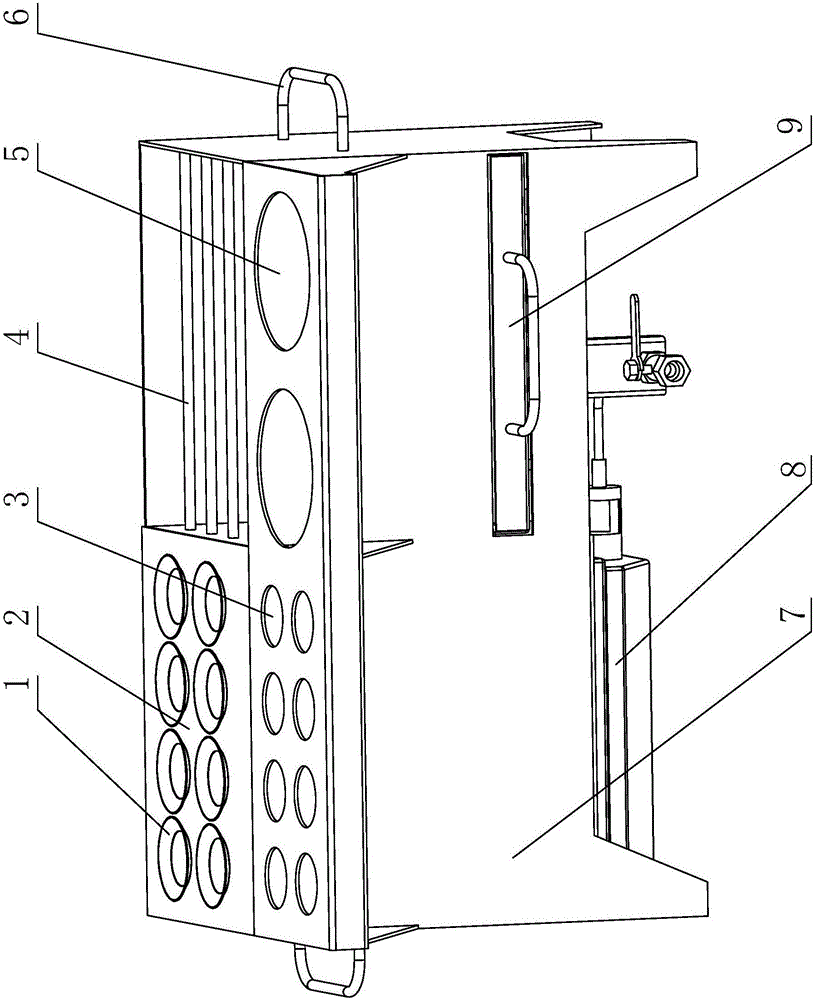

[0013] Such as Figure 1-4 As shown, the gas-fired egg sausage machine includes a box body 7 and a material receiving tray 9. A layer of thermal insulation material 10 is provided on the inner wall of the box body 1. The upper surface of the box body 1 is divided into an egg sausage processing area 2 and an egg sausage reserved storage area 3. , egg sausage heat preservation area 4, flavor cup placement area 5, where the seasoning cup can be placed in the taste cup placement area 5 so as to season the processed egg sausage; The pipe 1 is provided with a gas stove 8 located in the box body 1, the outer end of the gas stove 8 is provided with a gas stove connecting piece, and the box below the egg sausage heat preservation area 4 is provided with a drawable receiving tray 9. When the sausage is seasoned, the condiment can be caught to prevent the condiment and oil stains from falling on the table, which is convenient for cleaning; the two sides of the box body 1 are also provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com