Aluminum liquid turning bag hot air energy-saving heating device and heating method thereof

A heating device and energy-saving technology, which is applied in the field of aluminum casting, can solve the problems of high gas cost and transportation cost, environmental pollution, and aluminum liquid pollution, etc., and achieve the effects of convenient flame intensity, reduction of production cost, and reduction of environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

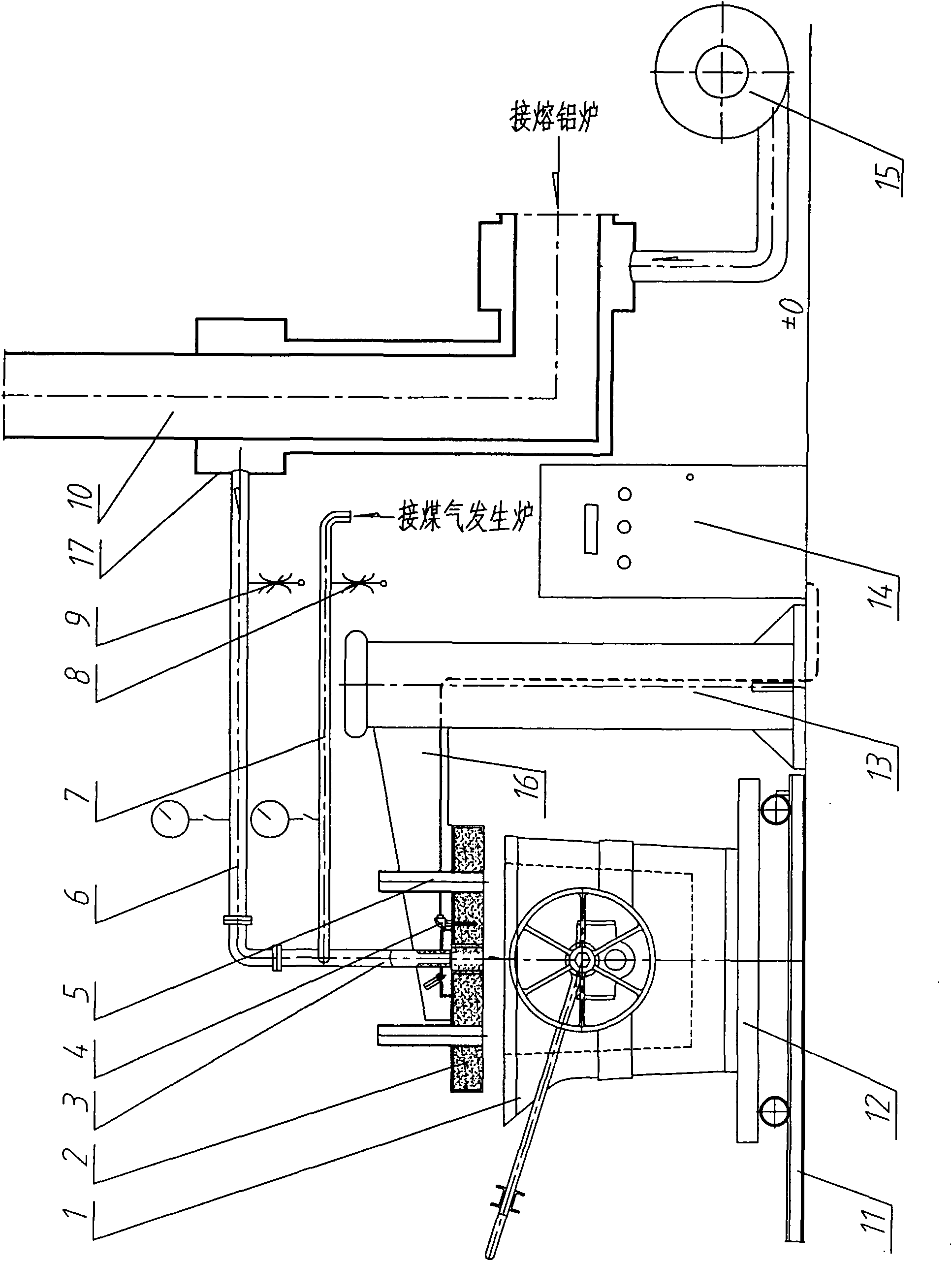

[0030] An aluminum liquid subcontracting hot air energy-saving heating device, the hot air flue liner 10 is connected to the smoke exhaust opening of the aluminum melting furnace, and the connecting part is connected to a blower that can send compressed air to the compartment of the hot air flue liner 10 15; the fire sealing cover 2 is connected with the supporting column 13 through the crossbeam 16, and the fire sealing cover 2 is provided with the flame spray pipe 3; the hot air flue duct bellows 17 of the hot air flue duct 10 is connected with the hot air pipe 6, and the hot air The other end of the pipe 6 is connected to the top of the flame pipe 3, and the middle part of the flame pipe 3 is provided with a lateral opening, on which a gas pipe 7 is connected, and the other end of the gas pipe 7 is connected to the gas outlet of the gas generator; Below is provided with the subpackage 1 that can hold molten aluminum.

[0031] The fire sealing cover 2 is provided with a smok...

Embodiment 2

[0037] A heating method using the hot air energy-saving heating device of the aluminum liquid subcontractor, which is characterized in that it includes the following steps: a) placing the subcontractor 1 on a small flat car 12, and pushing the small flat car 12 to the fire sealing cover through the track 11 2, and make the subpackage 1 located at the center of the lower part of the flame sealing cover 2;

[0038] B) open blower 15, and blower 15 sends compressed air in the interlayer of hot air flue liner 10;

[0039] c) Press the ignition button of the gas stove, and at the same time slowly open the gas flow regulating valve 8 to ignite the gas;

[0040] d) Heat up the subpackage 1, while continuing to open the gas flow regulating valve 8, slowly open the hot air flow regulating valve 9, and adjust the flame intensity by observing the flame color at the mouth of the subpackage 1 so that the flame does not flow from the subpackage 1 It is advisable to overflow the outlet, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com