Water electrolysis system

a water electrolysis and water adsorption technology, applied in the field of water electrolysis system, can solve the problems of large amount of adsorbent becoming considerably large in size, inability to adsorb water well, and inability to supply economical, etc., to achieve the effect of efficiently supplying desired dry hydrogen, simple structure and reliably preventing water from being contained in hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

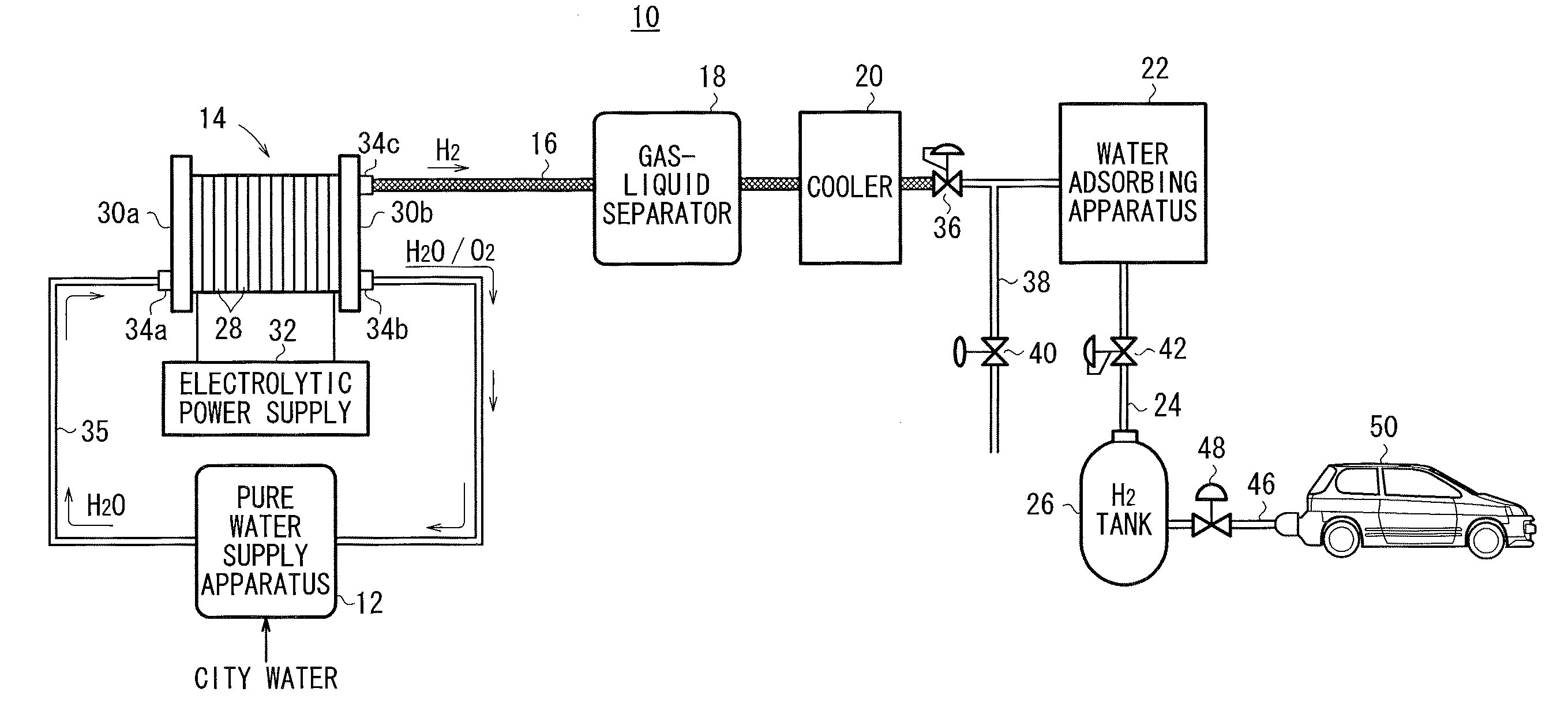

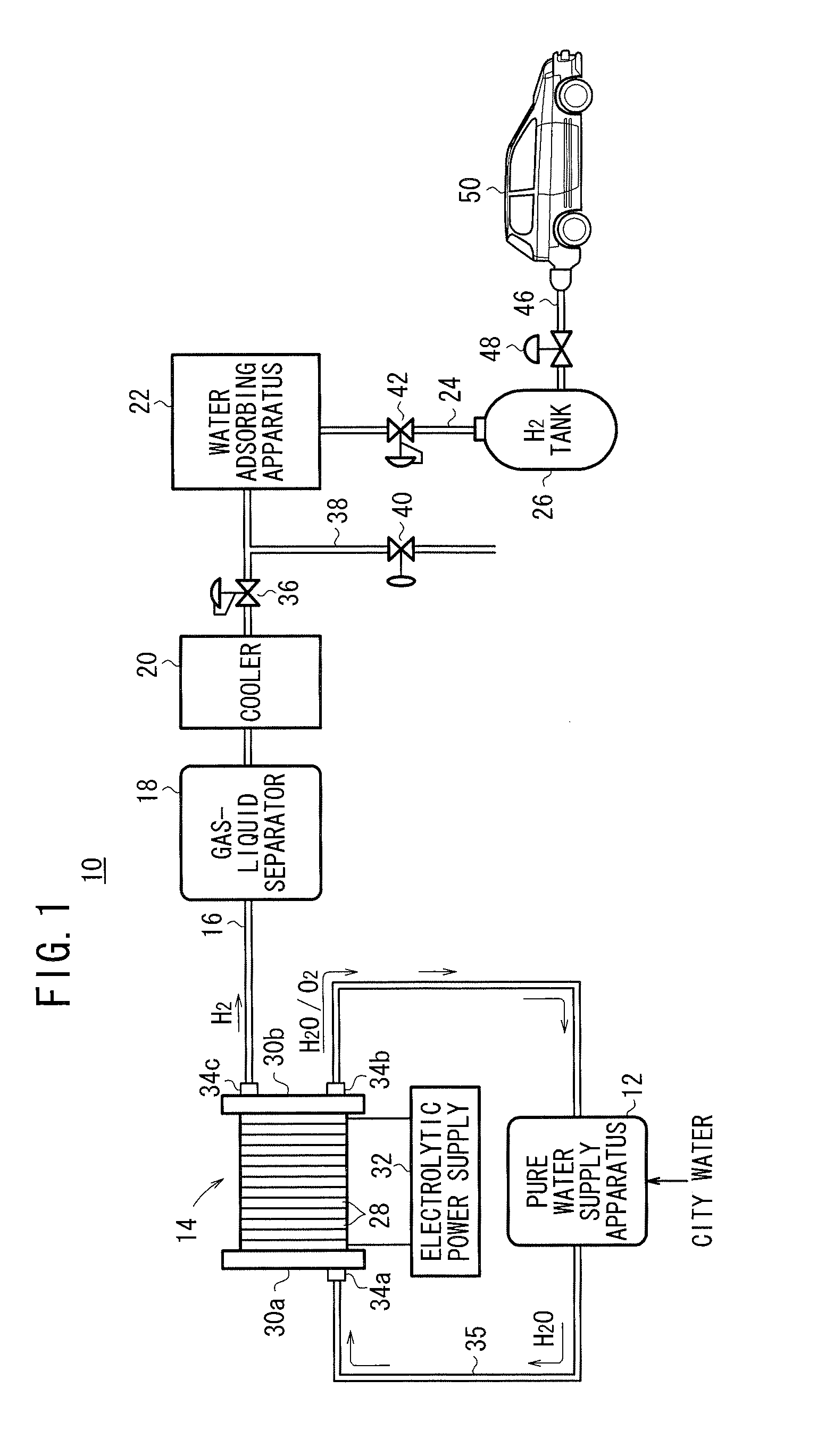

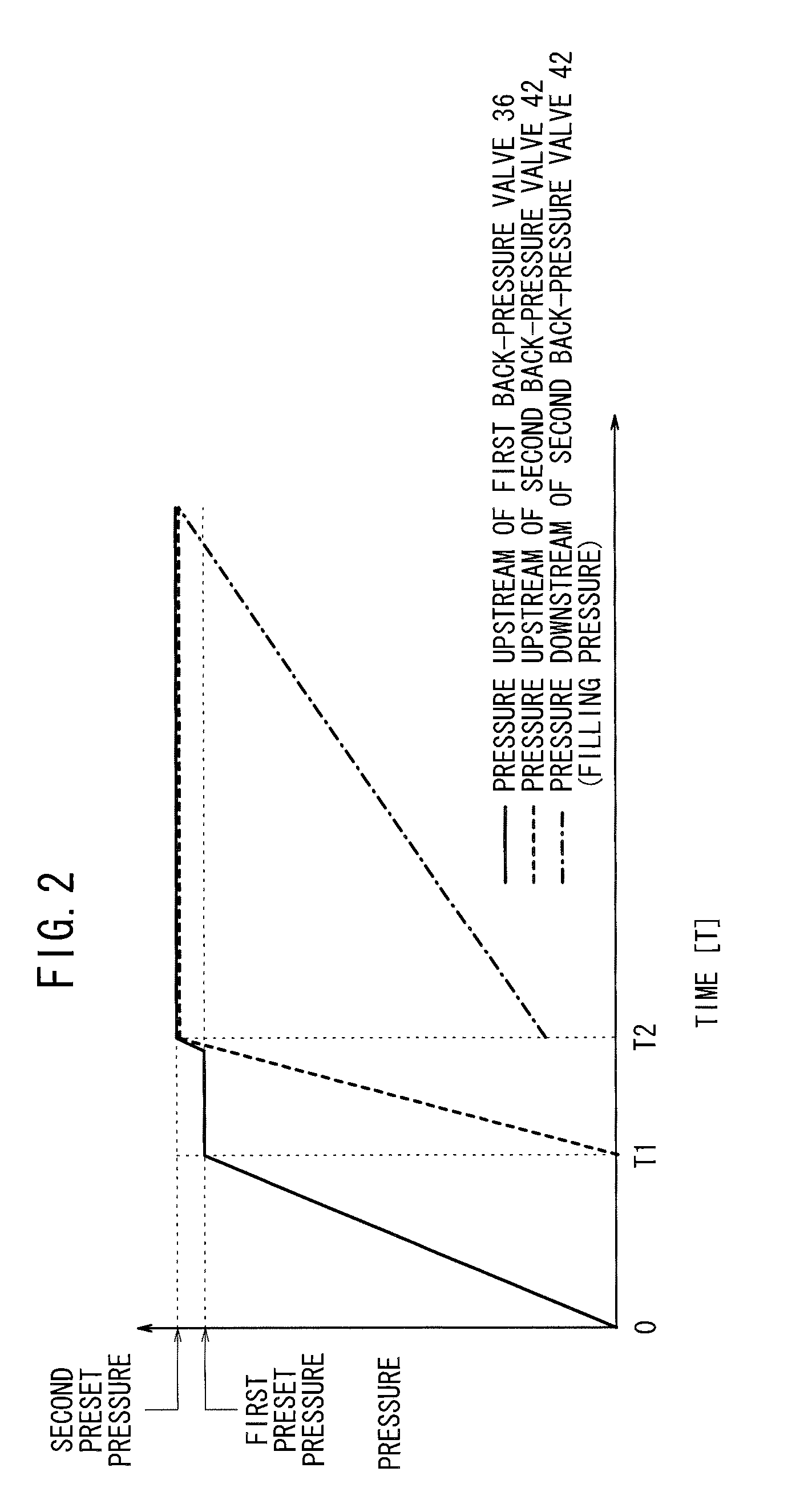

[0027]As shown in FIG. 1, a water electrolysis system 10 according to an embodiment of the present invention comprises a water electrolysis apparatus 14 for being supplied with pure water that has been generated from city water from a pure water supply apparatus 12 and electrolyzing the pure water to produce high-pressure hydrogen (whose pressure is higher than a normal pressure), a gas-liquid separator 18 for removing water contained in the high-pressure hydrogen which is delivered from the water electrolysis apparatus 14 into a hydrogen outlet passage 16, a cooler 20 for cooling the hydrogen discharged from the gas-liquid separator 18, a water adsorbing apparatus 22 for adsorbing away water contained in the cooled hydrogen discharged from the cooler 20, and a hydrogen tank 26 for storing the hydrogen (dry hydrogen) delivered from the water adsorbing apparatus 22 into a dry hydrogen supply passage 24. The hydrogen tank 26 is optional, and may be added when necessary or may be dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com