Flexible cleaning article

a cleaning article and flexible technology, applied in the field of flexible cleaning articles, can solve the problems of rusty metal filaments over time, unfavorable cleaning effect, and affecting the cleaning process, and achieve the effect of convenient and efficient cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

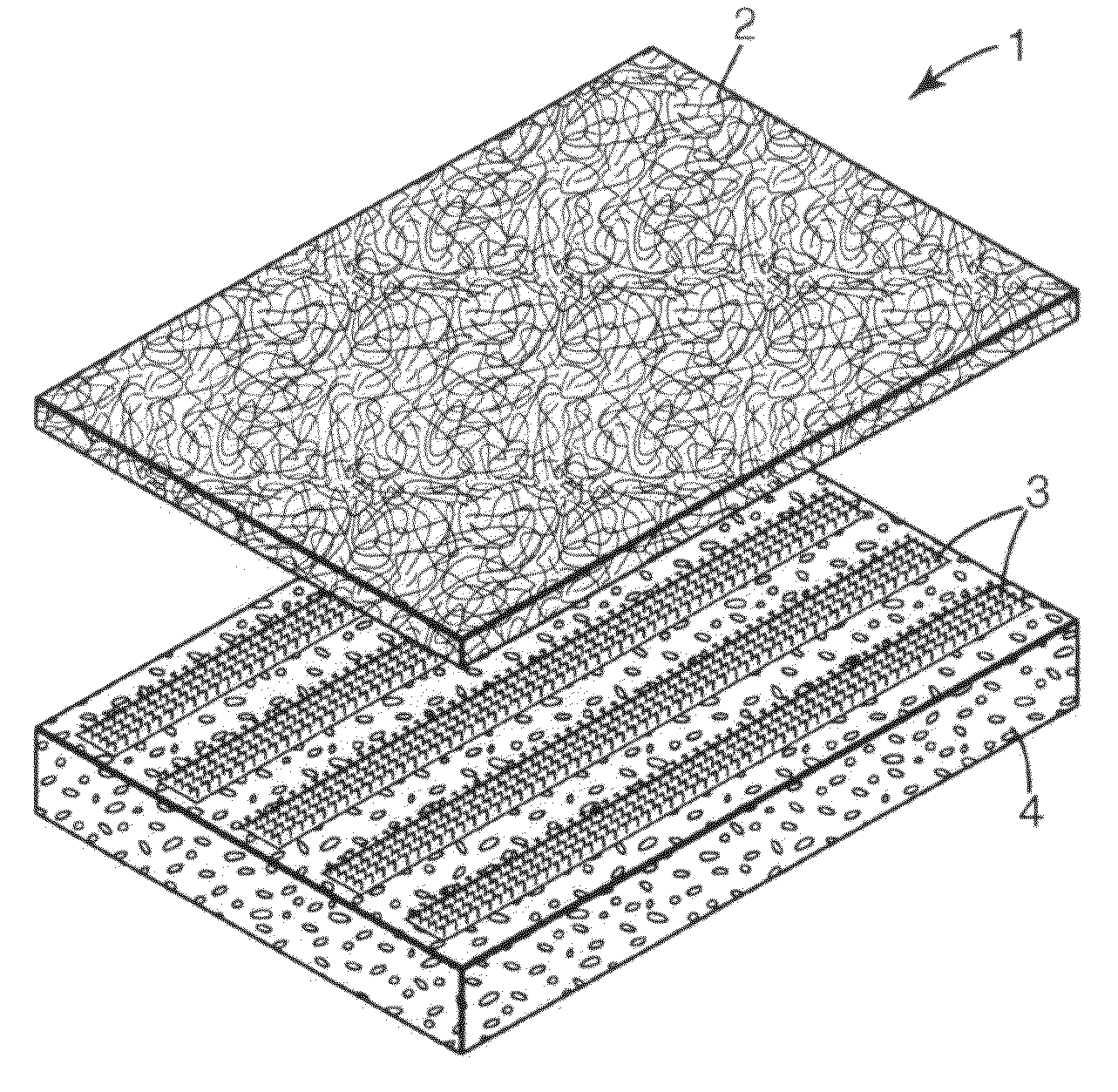

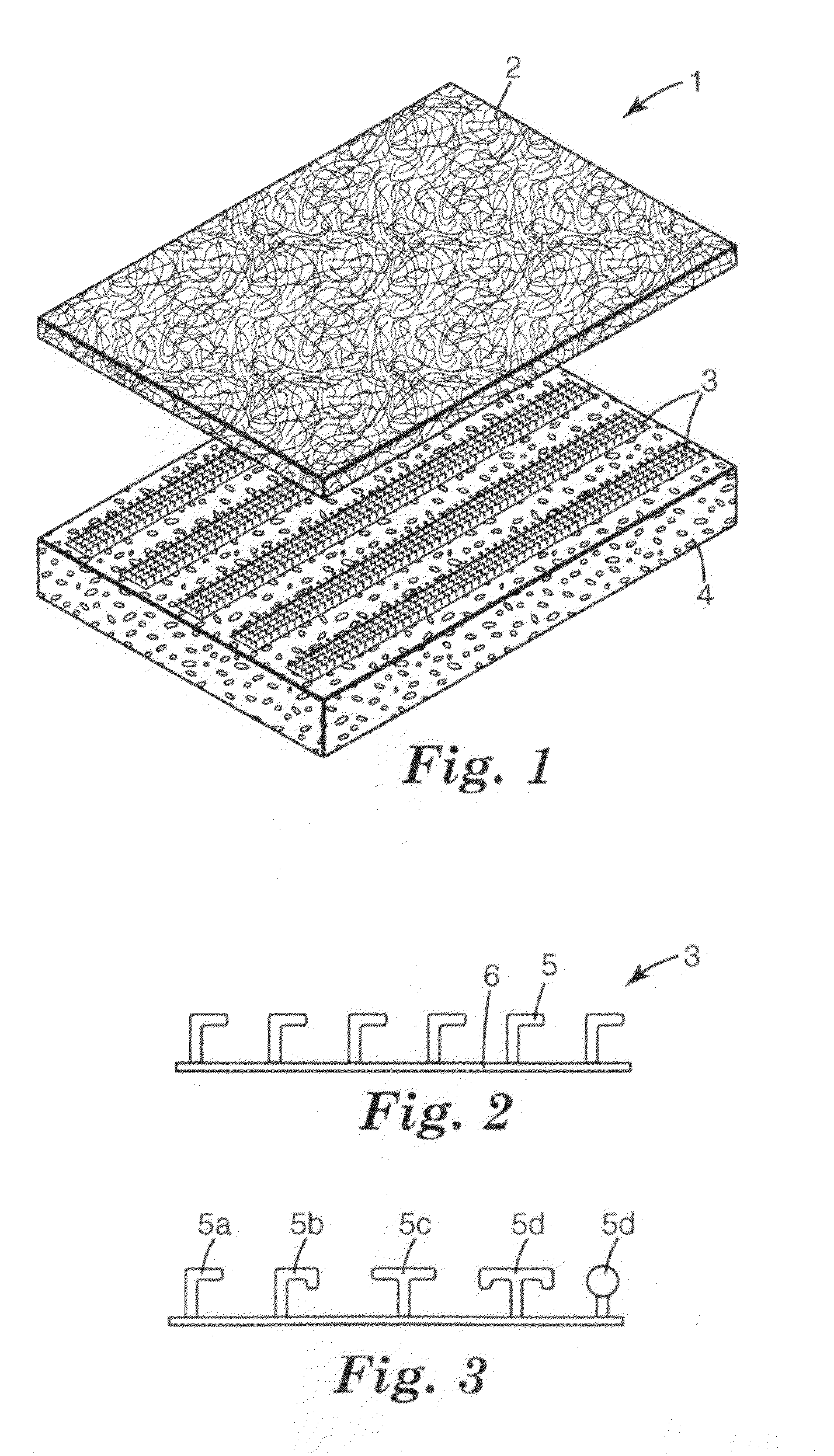

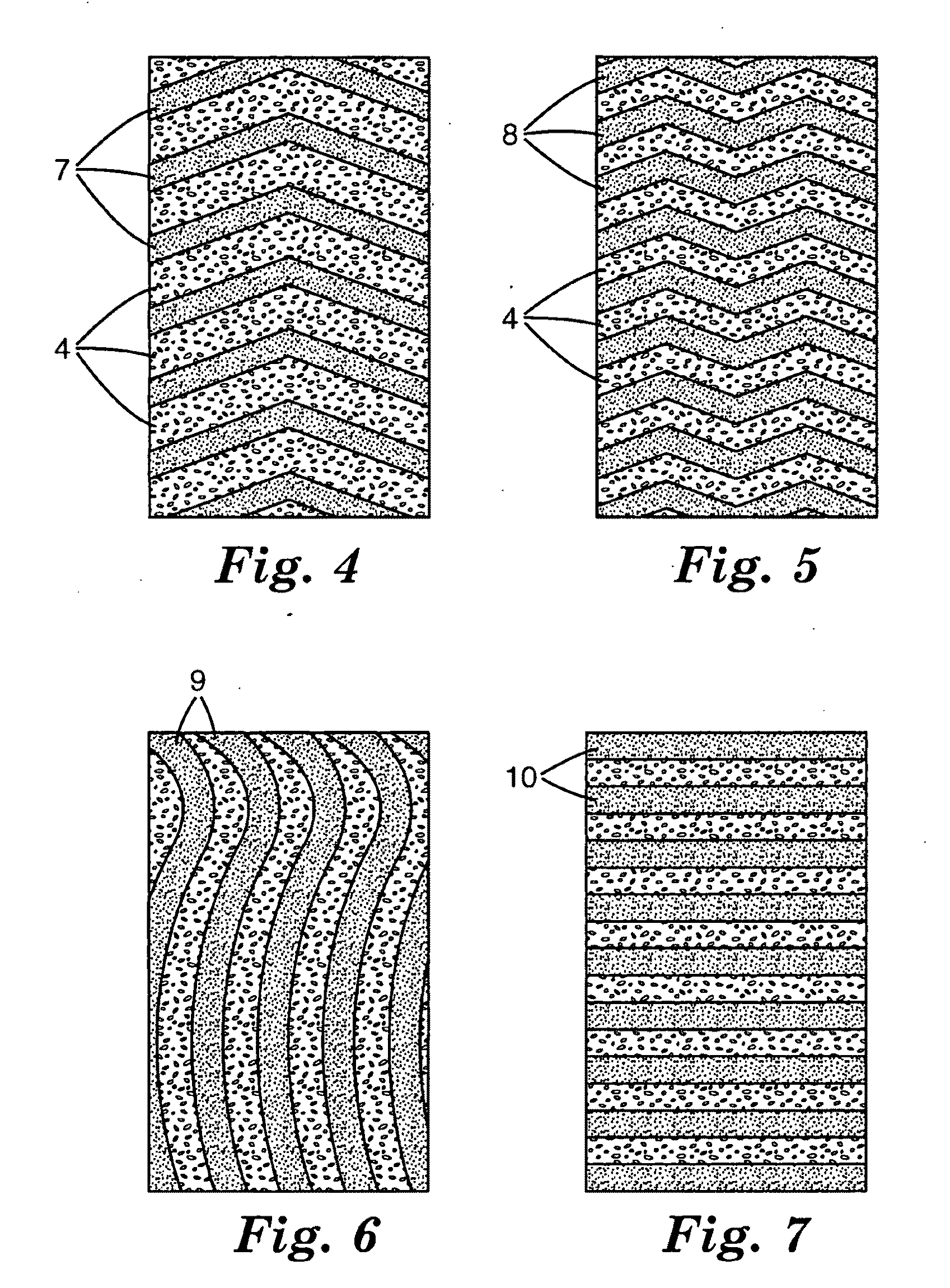

[0042]A hook-like mechanical system 3 composed of approximately 0.25 mm diameter interwoven polyamide filaments (available from Tecelagem Lady Ltda, São Paulo, Brazil, under the tradename VELOK™) was cut into strips of about 2 mm thick, about 4 mm wide and about 110 mm in length. Two strips were applied to one surface of the foam 4 (available from Aunde Coplatex do Brasil S / A, Sao Paulo, Brazil and from Soft-Spuma Indústria e Comércio Ltda., Sao Paulo, Brazil) of 8 mm in thickness by means of a polyurethane adhesive (available from Huntsman ICI Chemicals, LLC, Utah, US, under the tradename RUBINATE™ 9272 MDI) vertically disposed along the flexible article's (5b) length. Approximately 11 mm spacing between the strips was maintained. Samples were pressed to promote adhesion and the adhesive was allowed to set for 24 hours. The area of foam covered by said mechanical system was of about 26%.

example 2

[0043]A hook-type mechanical system composed of approximately 0.25 mm diameter interwoven polyamide filaments (available from Tecelagem Lady Ltda., São Paulo, Brazil, under the tradename VELOK™) was cut into strips of about 2 mm thick, about 7 mm wide and about 110 mm in length. Said strips were applied to one surface of a polyurethane foam 4 (available from Aunde Coplatex do Brasil S / A, Sao Paulo, Brazil and from Soft-Spuma Indústria e Comércio Ltda., Sao Paulo, Brazil) of 8 mm in thickness by means of a polyurethane adhesive (available from Ariston Polimeros Indústria e Comércio Ltda., Sao Paulo, Brazil, under the tradename RESITHANE SL 3000) vertically disposed along the flexible article's (5b) length. Approximately 12 mm spacing between the strips was maintained. Samples were pressed to promote adhesion and the adhesive was allowed to set for 24 hours. The area of foam 4 covered by the mechanical system 3 was of about 37%.

example 3

[0044]A hook-type mechanical system composed of approximately 0.25 mm diameter interwoven polyamide filaments (available from Tecelagem Lady Ltda., São Paulo, Brazil, under the tradename VELOK™) was cut into strips of about 2 mm thick, about 10 mm wide and about 110 mm in length. Said strips were applied to one surface of a polyurethane foam 4 (available from Aunde Coplatex do Brasil S / A, Sao Paulo, Brazil and from Soft-Spuma Indústria e Comércio Ltda., São Paulo, Brazil) of 8 mm in thickness by means of a bi-component polyurethane adhesive (available from Ariston Polimeros Indústria e Comércio Ltda, São Paulo, SP, Brasil, under the tradename RESITHANE 9020; available from Reichold under the tradename RESADUR 19-401) vertically disposed along the flexible article's (5b) length. Approximately 9 mm spacing between the strips was maintained. Samples were pressed to promote adhesion and the adhesive was allowed to set for 24 hours. Area of foam covered by the mechanical system was of ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com