Small automatic acid preparation device and acid preparation method

An acid dispensing device and automatic technology, which is applied to chemical instruments and methods, transportation and packaging, mixer accessories, etc., can solve the problems of large equipment footprint, complex acid adding process, and inhalation hazards, achieving a small footprint, Improve the efficiency of acid mixing and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the embodiments and accompanying drawings. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

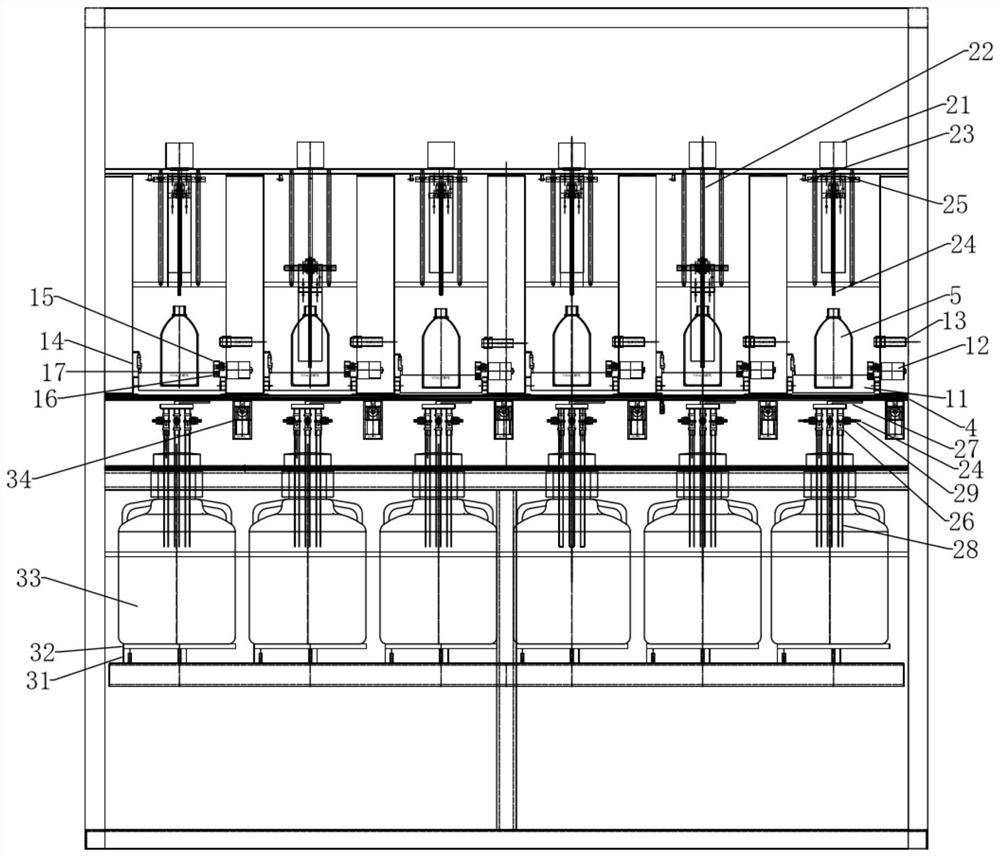

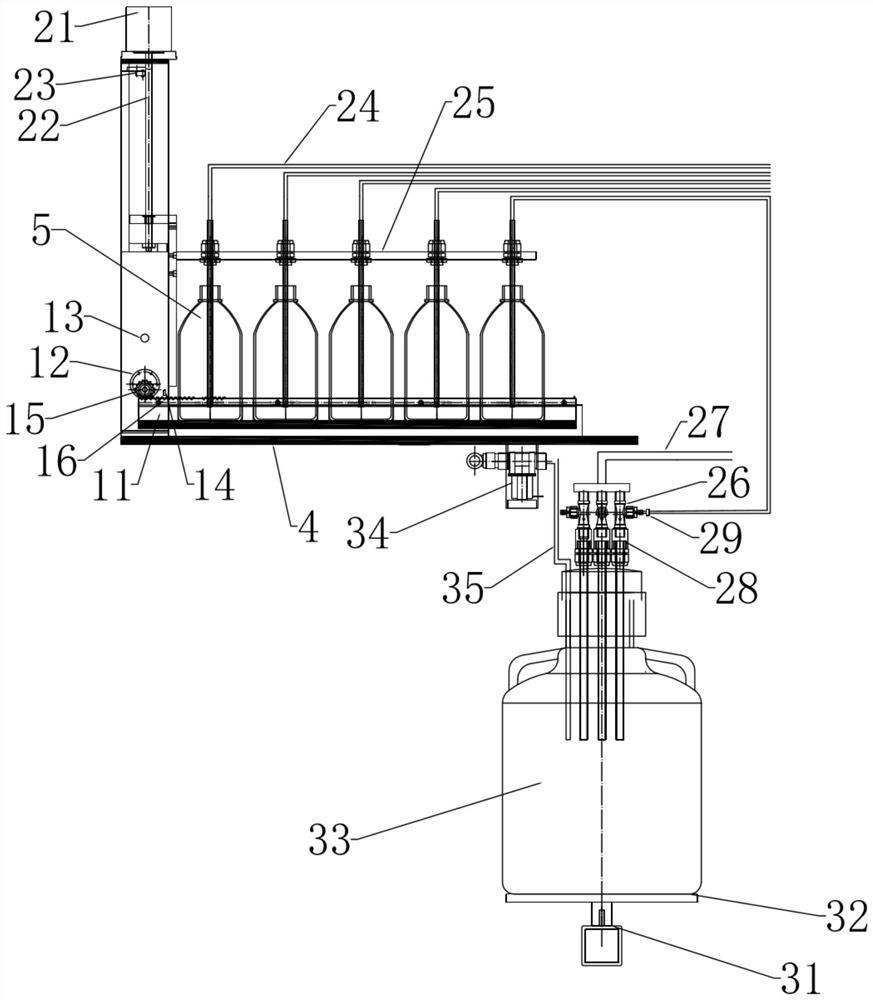

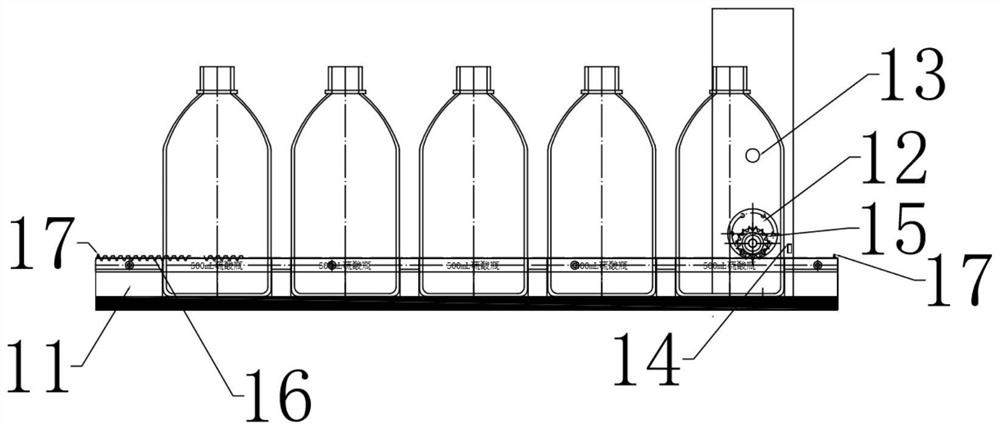

[0040] The invention provides a small automatic acid dispensing device (referred to as the device, see Figure 1-6 ), it is characterized in that the device includes a substrate 4, PLC and several acid units ( figure 1 There are 6 acid dispensing units in the middle); PLC is connected with all acid dispensing units, and can control all acid dispensing units to configure different concentrations and different types of acids at the same time; each acid dispensing unit includes a transmission mechanism 1, a liquid suction mechanism 2 and Weighing mechanism 3;

[0041] The delivery mechanism 1 is used to send the liquid bottle 5 containing the original acid into the device and the empty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com