A leak-proof liquid dispensing device

A leak-proof and liquid-separating technology, which is applied in liquid bottling, packaging, liquid treatment, etc., can solve the problems of polluting the environment, liquid dripping out, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

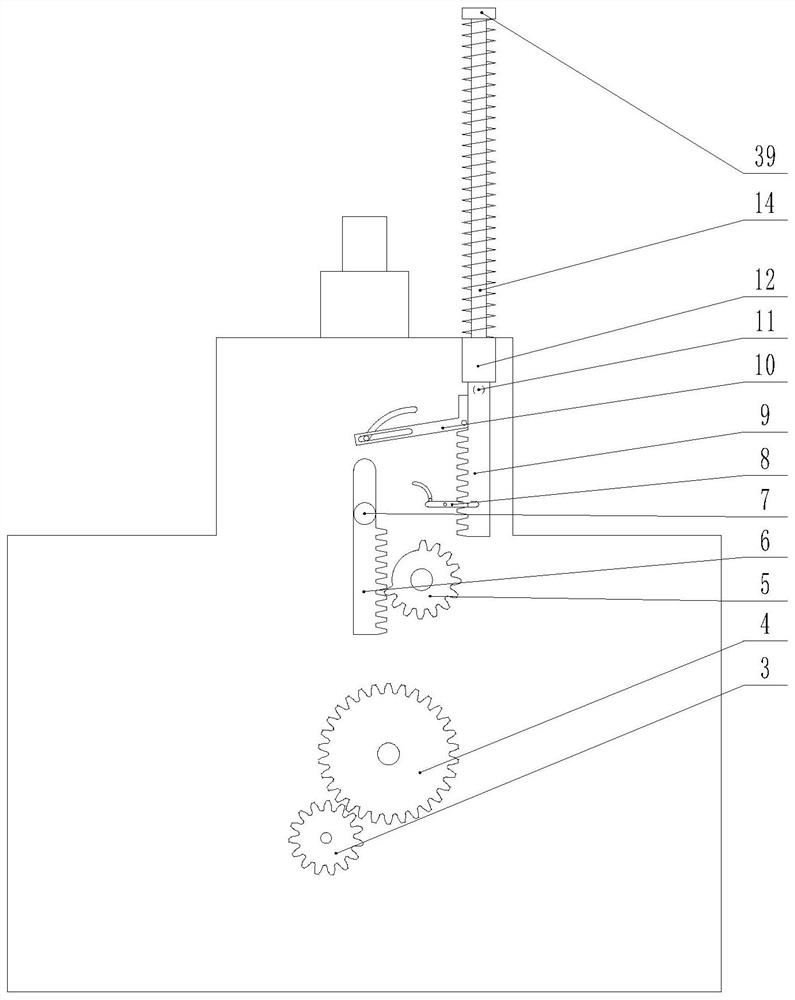

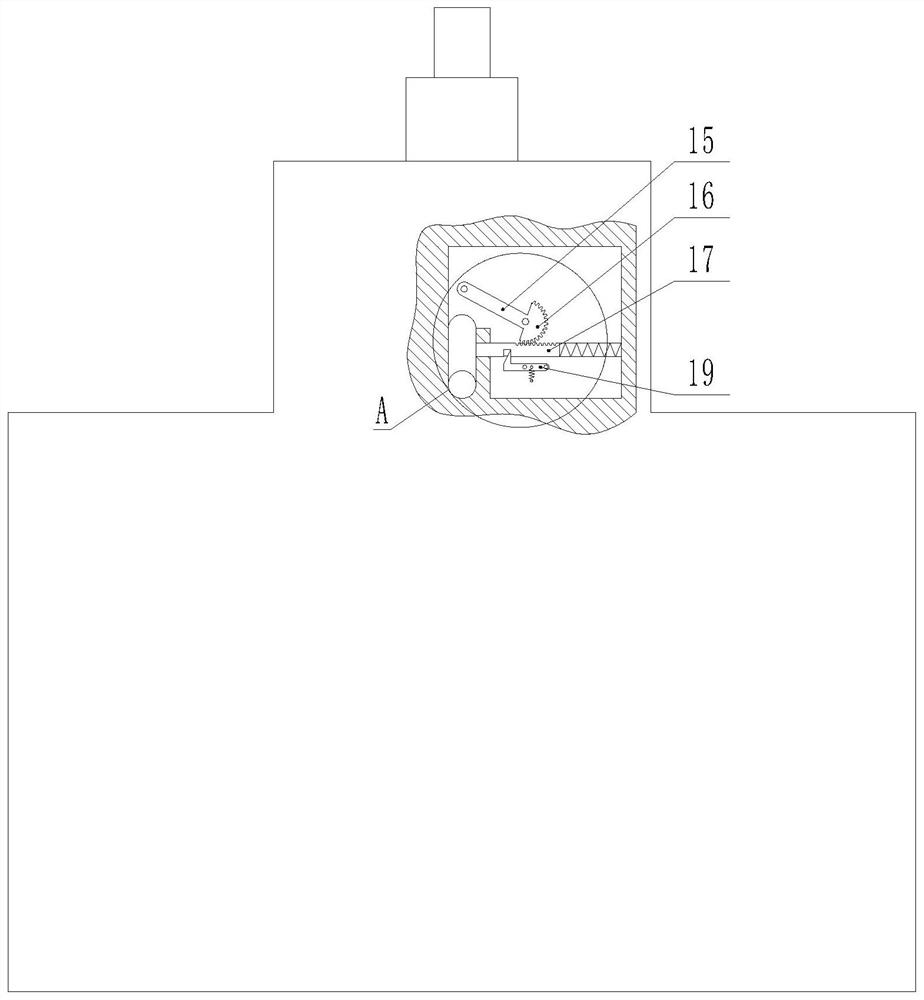

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. For convenience of description, the figure 1 It is a front view, divided into left, right, front and back.

[0018] Such as Figure 1~5 As shown, the present invention includes an outer shell and its internal liquid inlet assembly and bottle changing assembly.

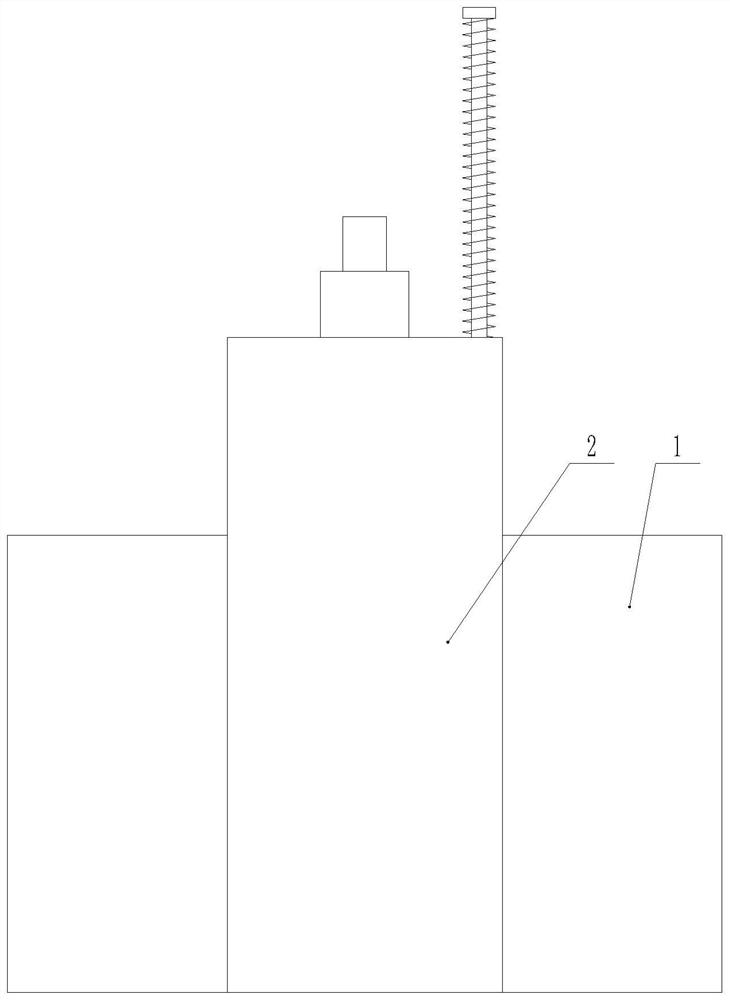

[0019] The outer casing is convex and includes a main cavity 2 and a side cavity 1 , and a through hole is provided in the middle of the upper end wall of the main cavity 2 .

[0020] The liquid inlet assembly includes a liquid inlet tube 37, a catheter and a filling bottle. In order to achieve no leakage of liquid, the pipeline connection of the liquid inlet assembly has an interface sealing function, which can be realized by matching the inner diameter and outer diameter of the pipeline, or the pipe wall or bottle mouth is made of elastic material that can be slightly deformed , suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com