Vegetable garbage treatment device

A technology of garbage disposal device and vegetables, applied in the field of agricultural machinery, can solve problems such as hidden dangers of soil, water, air pollution, random disposal, etc., and achieve the effect of being conducive to stacking and collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

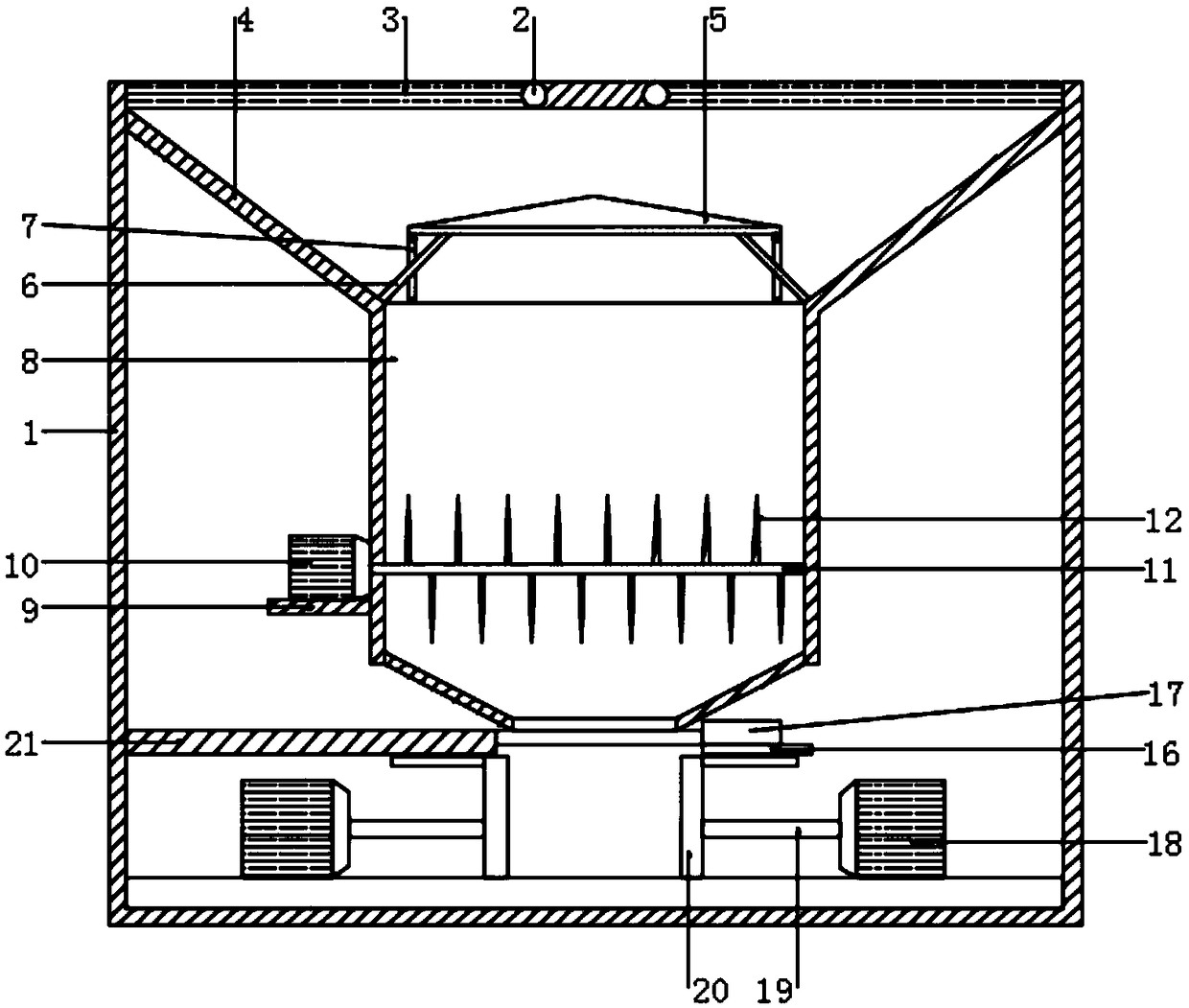

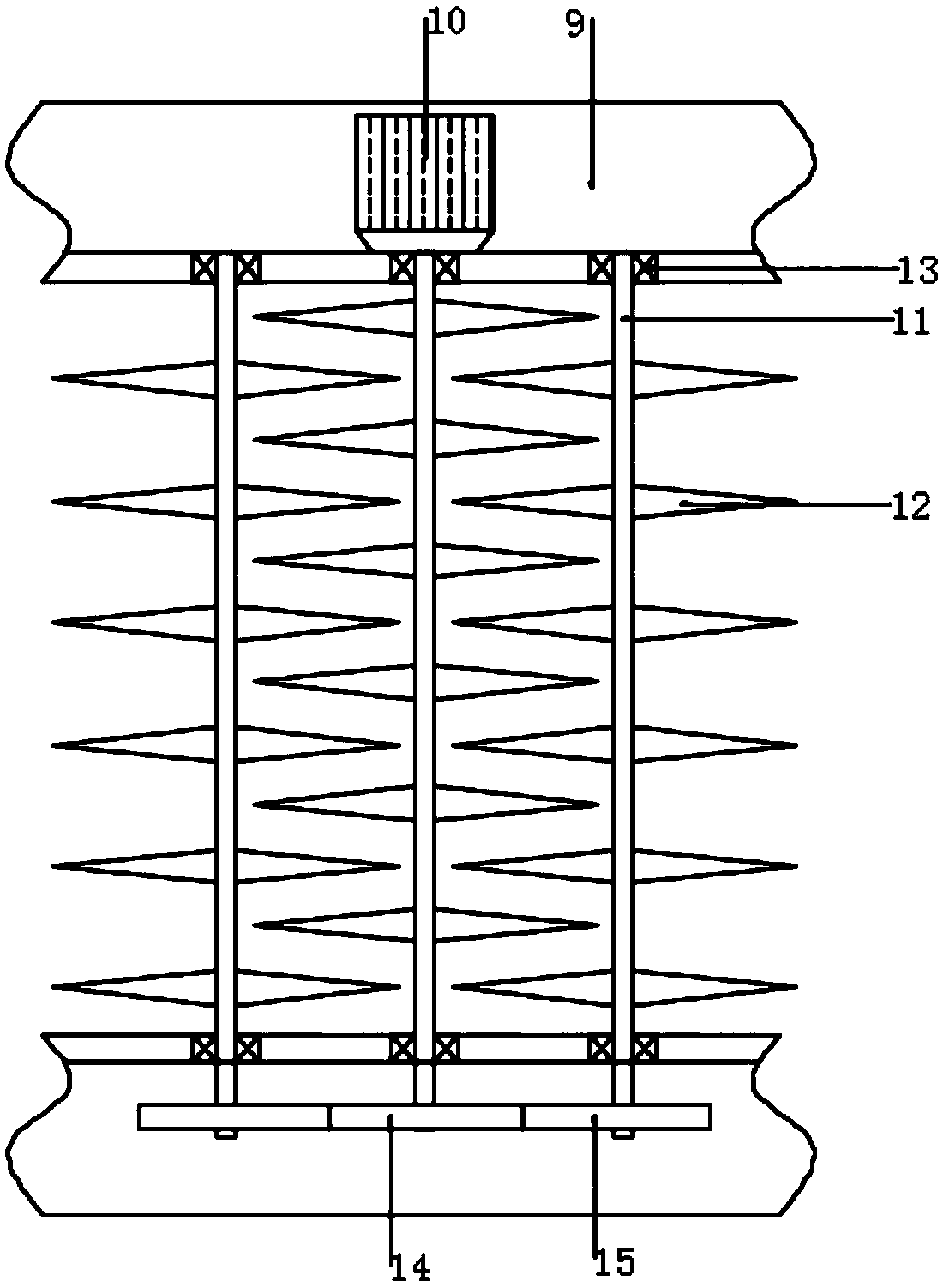

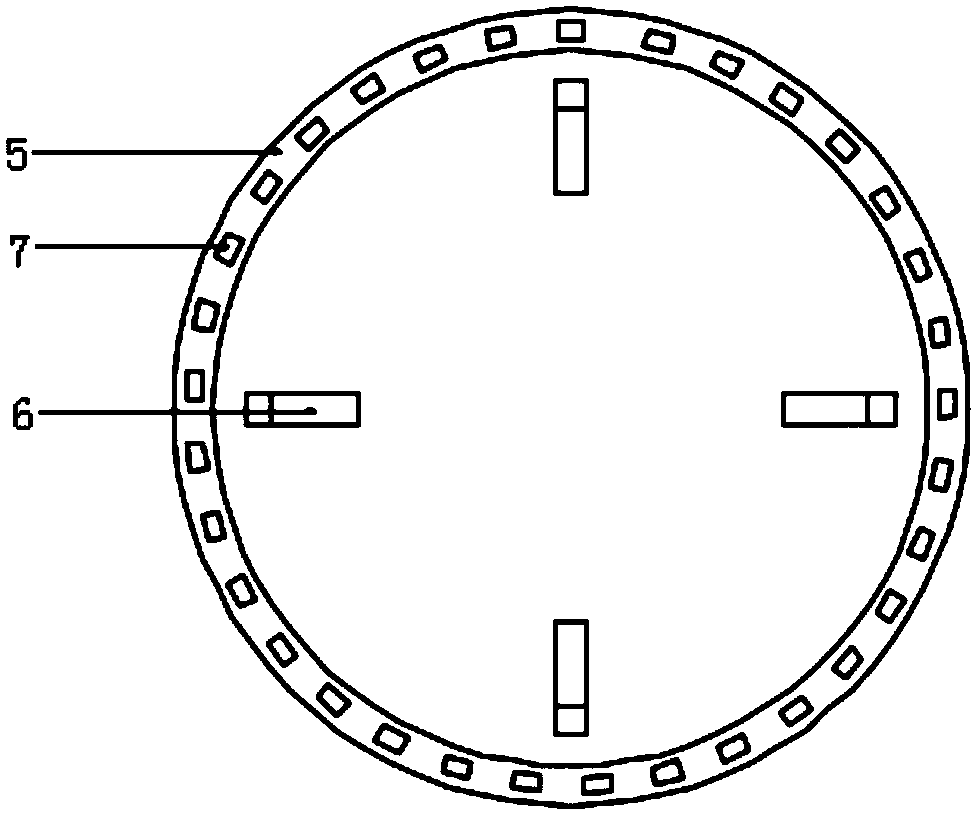

[0027] see figure 1 , 2 , 3 and 5, in the embodiment of the present invention, a kind of vegetable waste treatment device, comprises box body 1, mounting seat 2, cover plate 3, feeding hopper 4, top cover 5, support rod 6, barrier strip 7, crushing chamber 8. Support plate one 9, drive motor one 10, rotating shaft one 11, blade 12, bearing 13, driving wheel 14, driven wheel 15, support plate two 16, automatic valve 17, telescopic motor 18, push rod 19, push plate one 20. Support plate three 21, driving motor two 23, rotating rod 24, connecting rod one 25, connecting rod two 26, sleeve 27, controller 28, push plate two 29 and baffle plate 30; the upper end of the box body 1 is set There is a mounting base 2, a cover plate 3 is movable on the mounting base 2, a feed hopper 4 is arranged under the cover plate 3, and an anti-splash device is installed at the lower end of the feed hopper 4, and the anti-splash device includes a top cover 5 and a support rod 6 and the blocking str...

Embodiment 2

[0029] see Figure 1~4 , in an embodiment of the present invention, a vegetable waste treatment device includes a box body 1, a mounting base 2, a cover plate 3, a feed hopper 4, a top cover 5, a support rod 6, a barrier strip 7, a crushing chamber 8, and a support plate 19. Drive motor 10, rotating shaft 11, blade 12, bearing 13, driving wheel 14, driven wheel 15, support plate 2 16, automatic valve 17, telescopic motor 18, push rod 19, push plate 120, support plate Three 21, storage hopper 22, driving motor two 23, rotating rod 24, connecting rod one 25, connecting rod two 26, sleeve 27, controller 28, push plate two 29 and baffle plate 30; the upper end of the box body 1 is provided There is a mounting base 2, a cover plate 3 is movable on the mounting base 2, a feed hopper 4 is arranged under the cover plate 3, and an anti-splash device is installed at the lower end of the feed hopper 4, and the anti-splash device includes a top cover 5 and a support rod 6 and the blockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com