Board machine

A cardboard machine and pulp technology, applied in paper machine, wet end of paper machine, paper making, etc., can solve problems such as increase in total cost, and achieve the effect of reducing investment and operating cost, low energy consumption and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

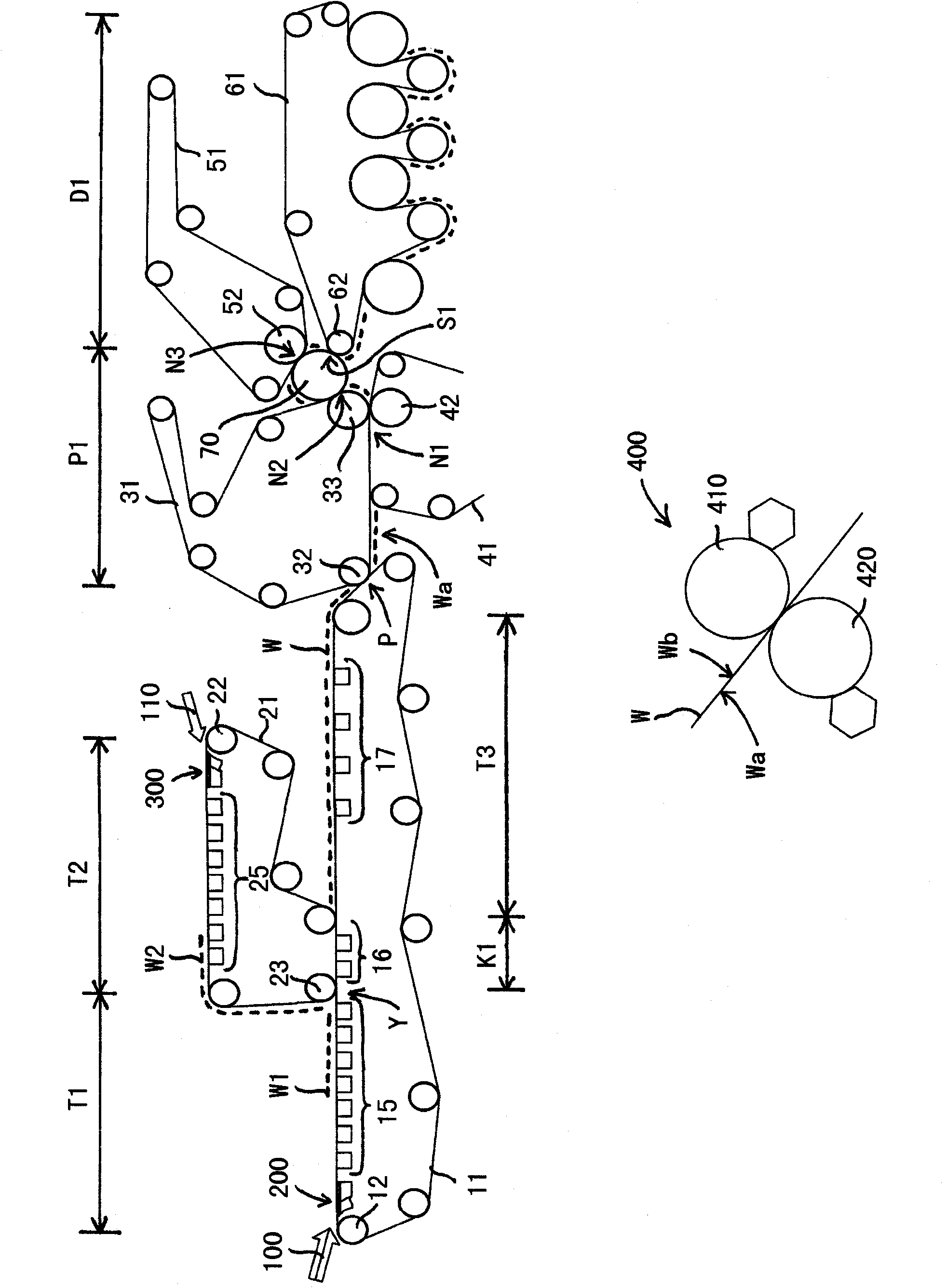

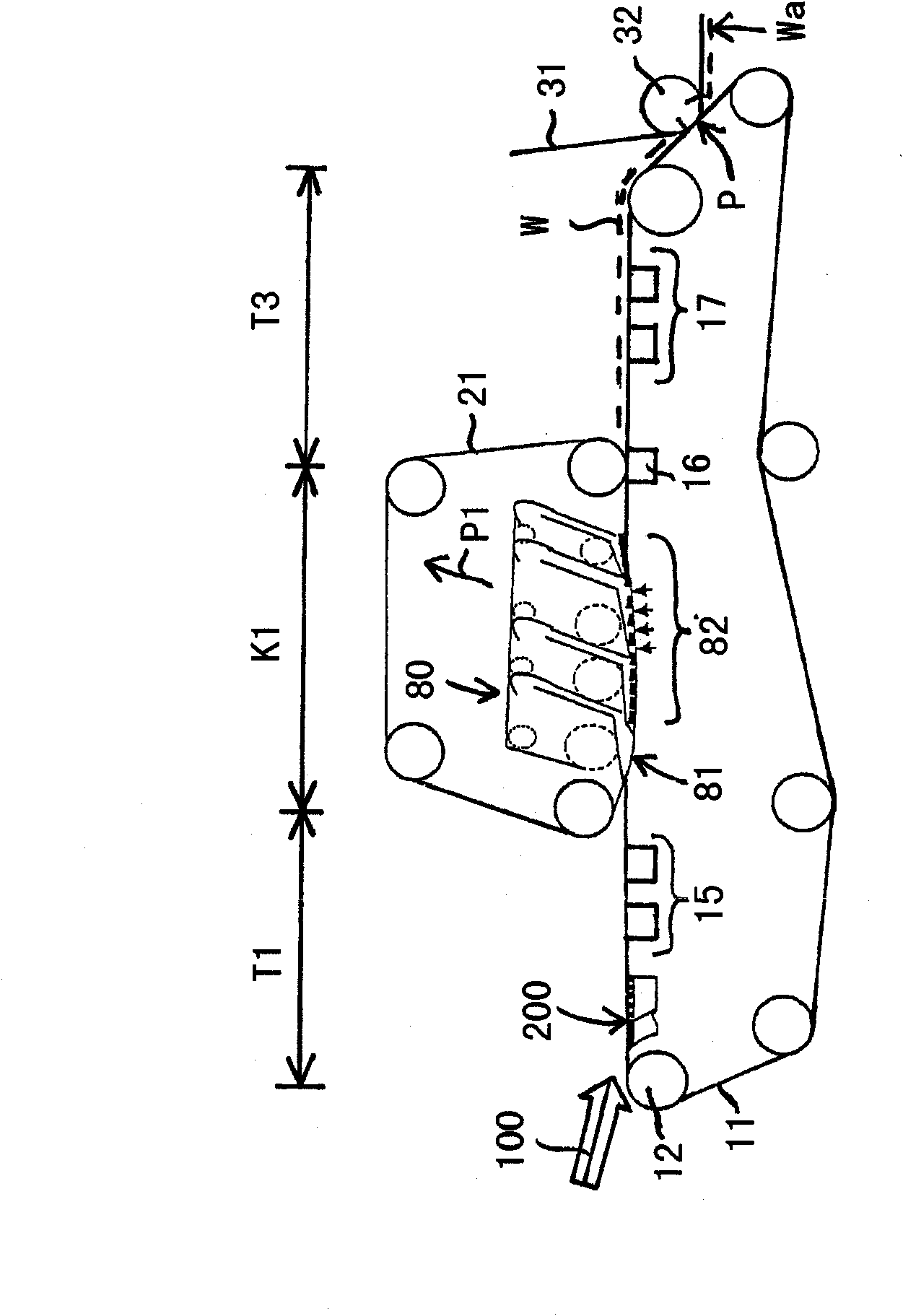

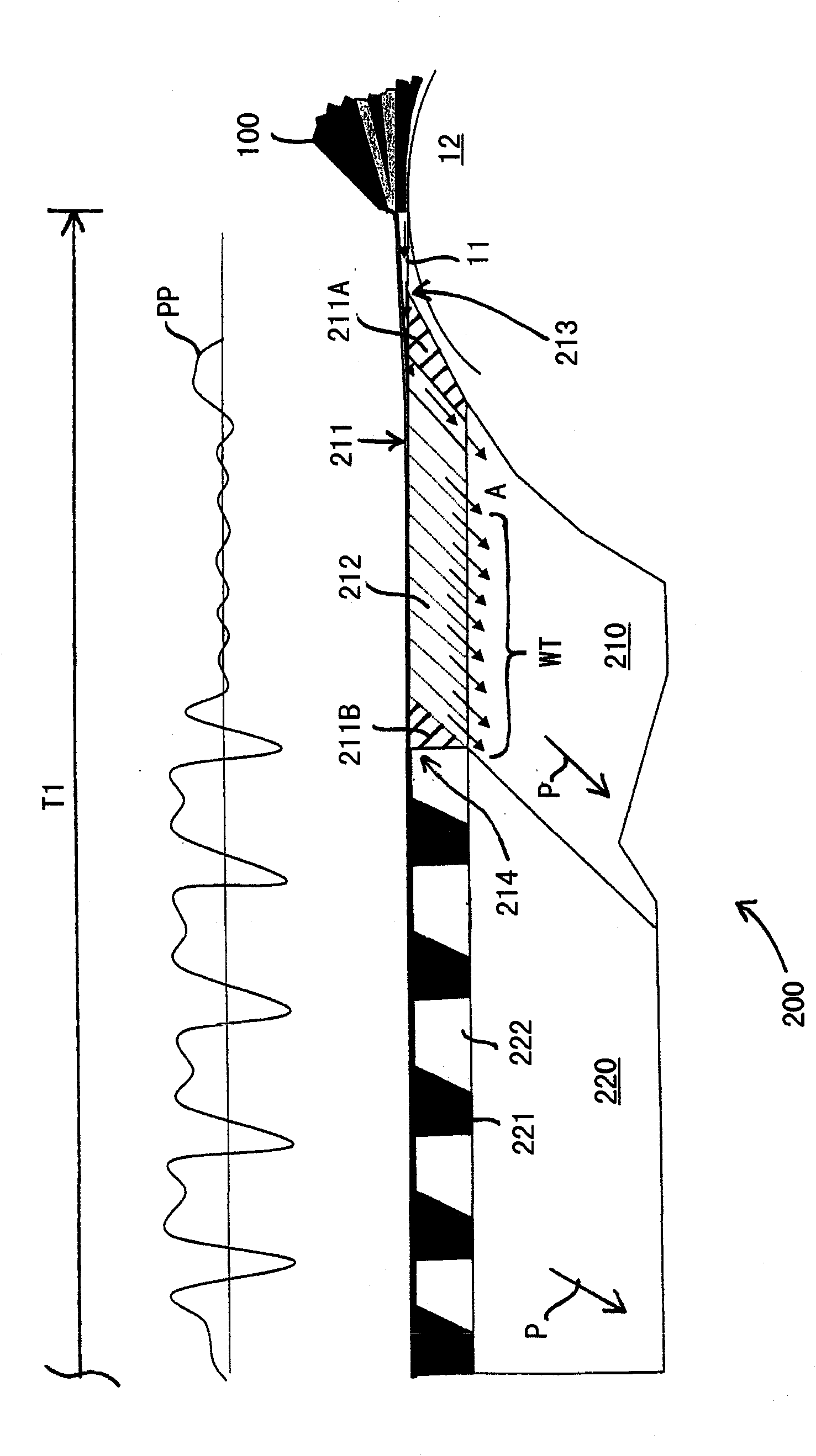

[0034] figure 1 A schematic diagram is shown of a board machine according to the invention with two separate forming sections consisting of partial webs. The first wire unit comprises a lower wire 11 on which a first Fourdrinier section T1 is formed. A first headbox 100 , which is a double-layer headbox, feeds a jet of pulp suspension to a first forming board 200 located behind the first breast roll 12 . Water is uploaded from above the lower wire 11 on the first fourdrinier section T1 traveling along the first forming plate 200 by utilizing the dehydration fitting 15 (it may be a water suction box provided with a strip cover) arranged below the lower wire 11 The delivered web is removed.

[0035] Following the first wire unit is a second wire unit comprising an upper wire 21 on which a second Fourdrinier section T2 is formed. On the upper wire 21 , a second headbox 110 , which is a single-layer headbox, feeds a jet of pulp suspension onto a second forming plate 300 located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com