Numerical control pull rod pipe burr removing machine

A technology for deburring machines and pipes, which is applied to the parts of grinding machine tools, machine tools suitable for grinding the edge of workpieces, grinding machines, etc. Energy saving, fast efficiency, high operational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

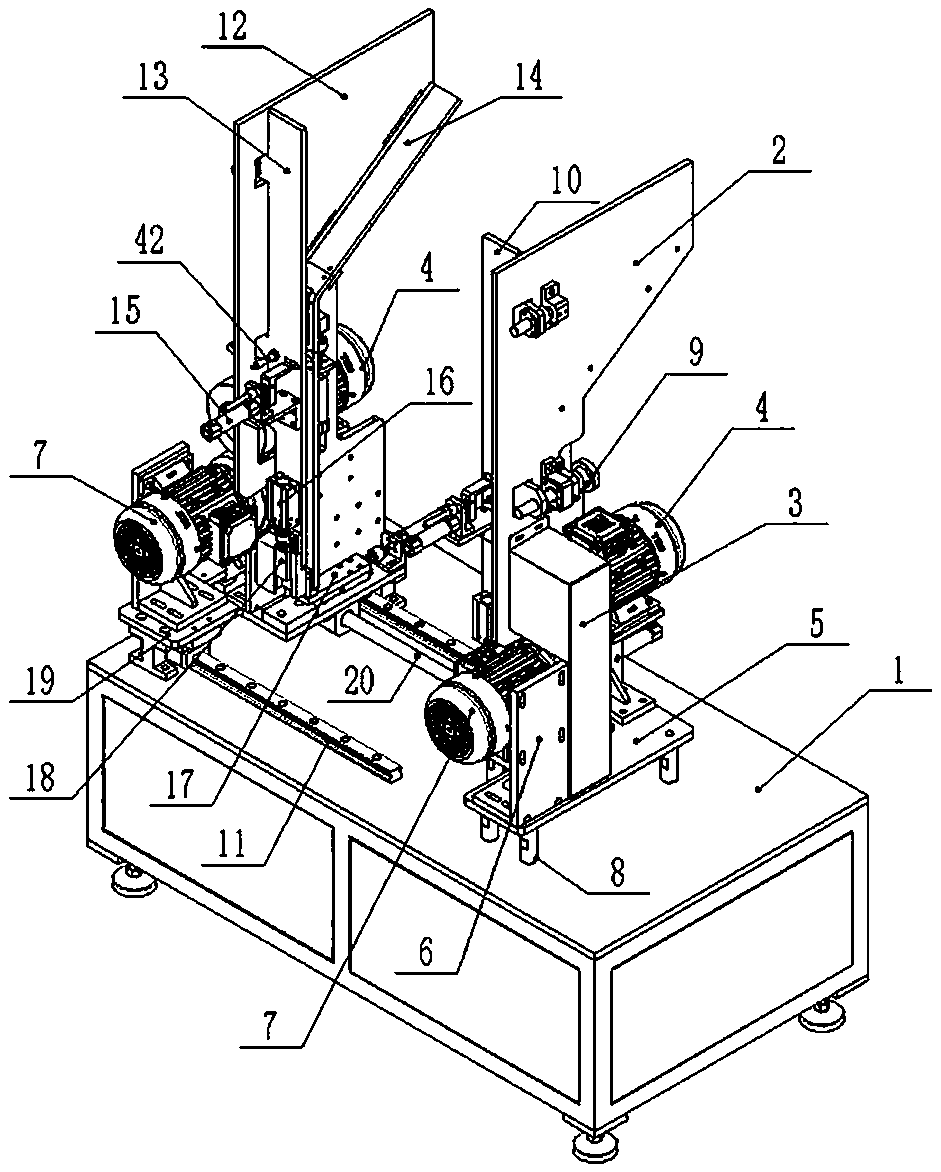

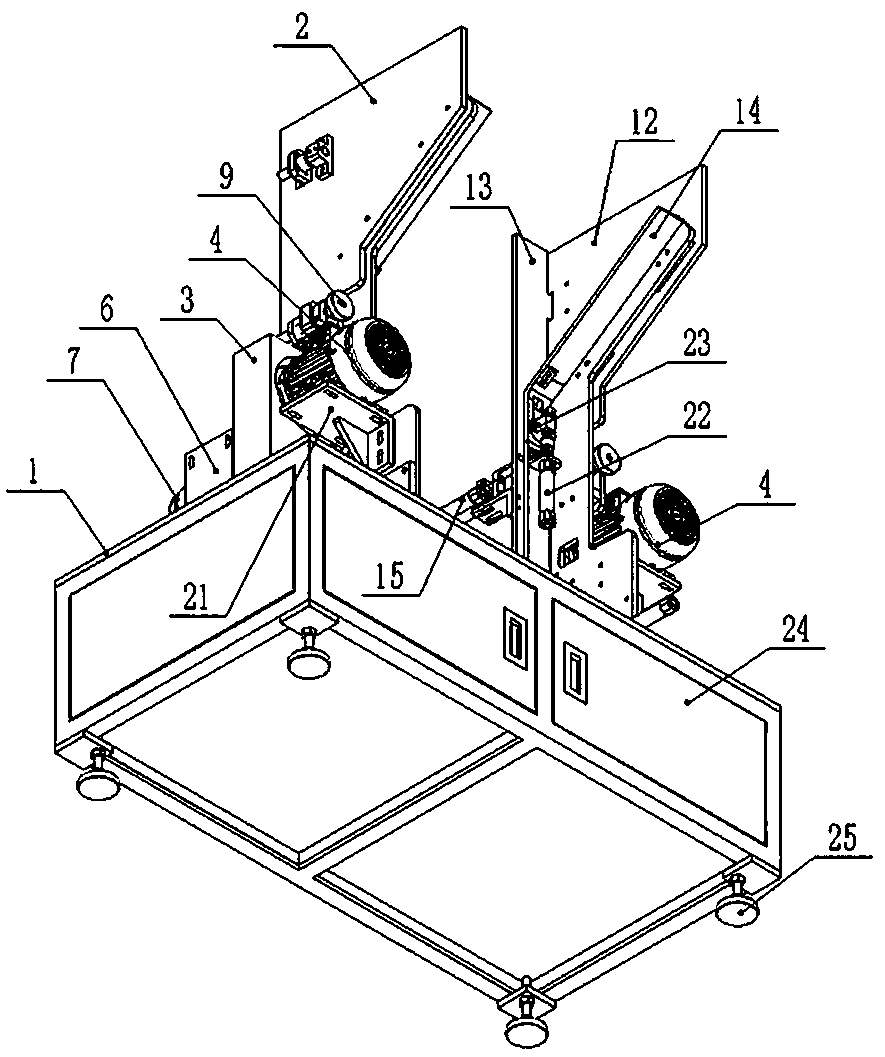

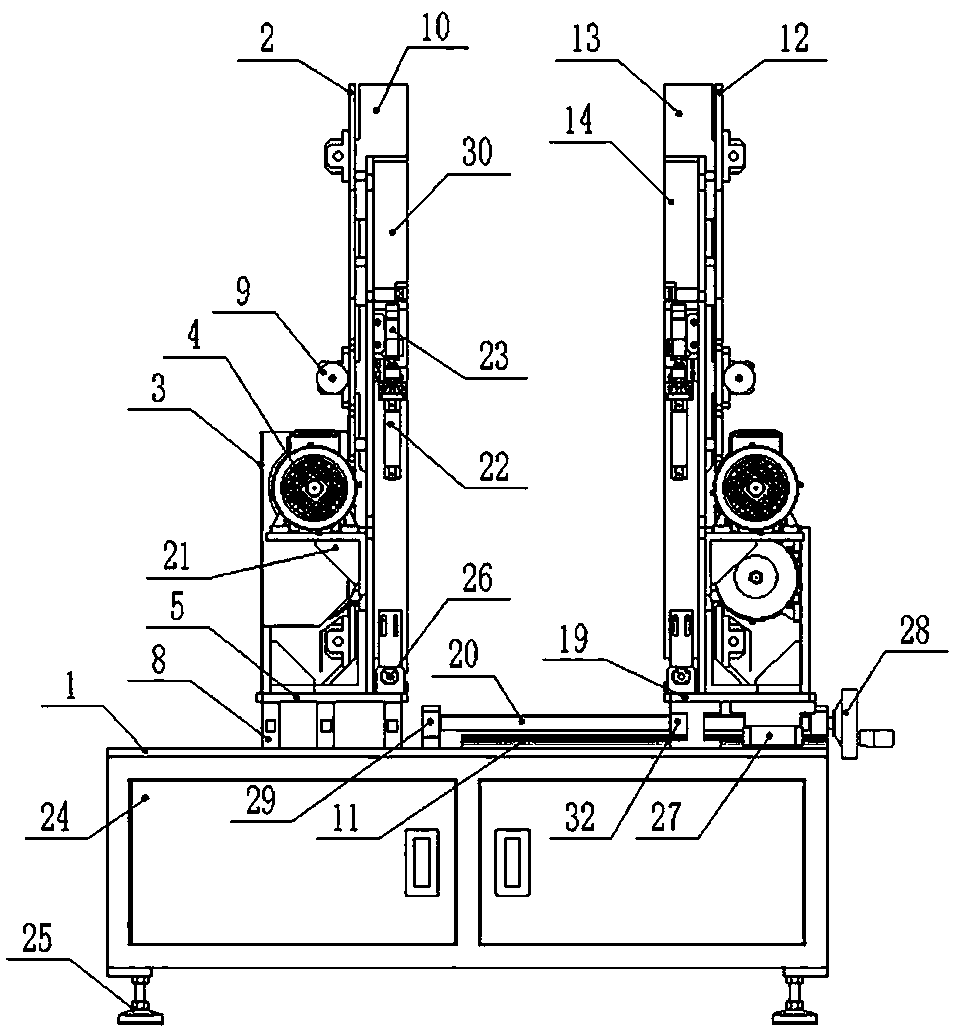

[0026] see Figure 1-10 , a numerically controlled pull rod pipe material deburring machine, comprising a table panel 1, a moving silo base plate 19, a fixed silo base plate 5, a first motor 4, a second motor 7, a self-locking device, a push rod device, and a pipe adjustment device and distance adjuster 9, the bottom of the table panel 1 is provided with a support box 24, and the front side of the support box 24 is provided with a switch door, and articles can be stored in the support box 24, and the bottom of the support box 24 is all arranged There are four sets of support legs 25, the upper end surface left side of the table panel 1 is provided with a fixed silo group, the upper end surface right side of the table panel 1 is provided with a mobile silo group, and the bottom of the fixed hopper base plate 5 is evenly arranged with multiple The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com