Washing device for bulbs

A technology for cleaning devices and light bulbs, which is applied to cleaning hollow objects, cleaning methods and utensils, and cleaning methods using liquids, etc. It can solve the problems of low efficiency and chemical liquids are not easy to clean, and achieve clean, simple and efficient cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

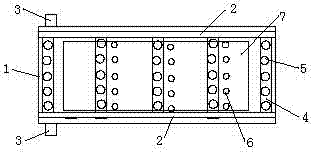

[0013] Combine below figure 1 with figure 2 Specific description embodiment:

[0014] A light bulb cleaning device, comprising a frame 1, the frame 1 is provided with two opposite transmission chains 2, the transmission chain 2 is connected with a stepping motor 3 through a gear, and the two opposite transmission chains 2 are provided with a number of connecting plates 4, and the connecting plates 4 are circularly moved under the action of the conveying chain 2. The connecting plates 4 are provided with a number of lamp holes 5, and the frame 1 is located on the A water spray device 6 is provided below the connecting plate 4 , and the water spray device 6 is arranged correspondingly to the lamp hole 5 , and a water collection tank 7 is provided below the water spray device 6 .

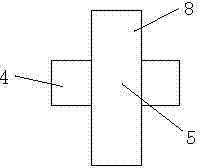

[0015] Preferably, a protective tube 8 is installed in the lamp hole 5 .

[0016] Preferably, the connecting plate 4 is hinged between the two conveyor chains through a hinge.

[0017] The bulb cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com