Patents

Literature

41results about How to "Solve the dirt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

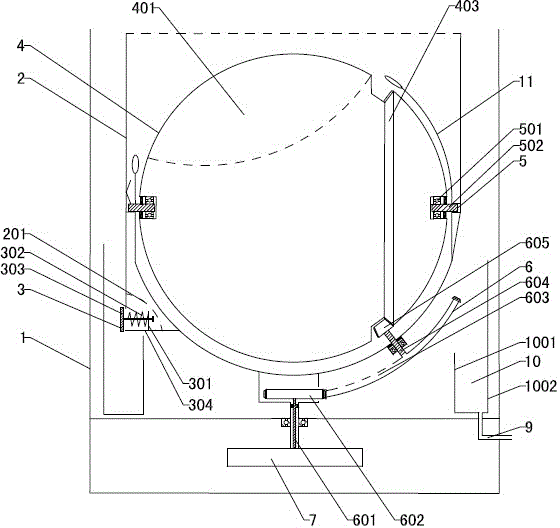

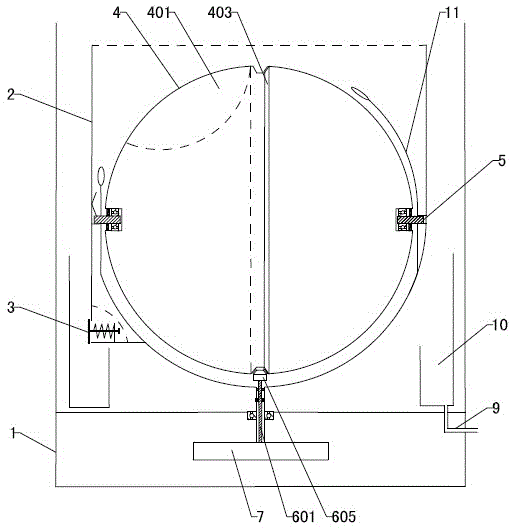

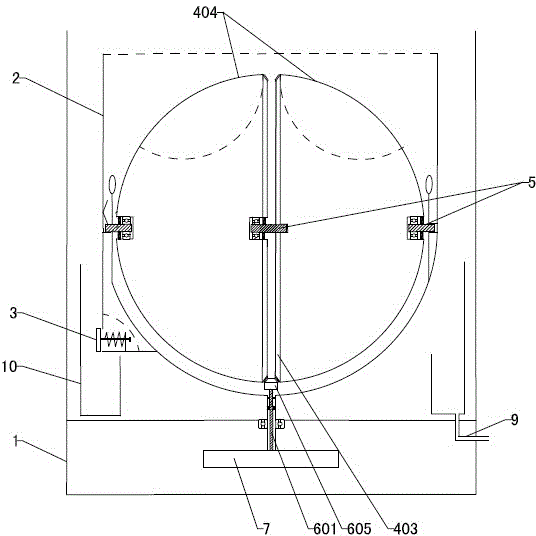

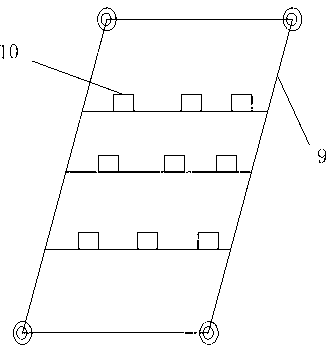

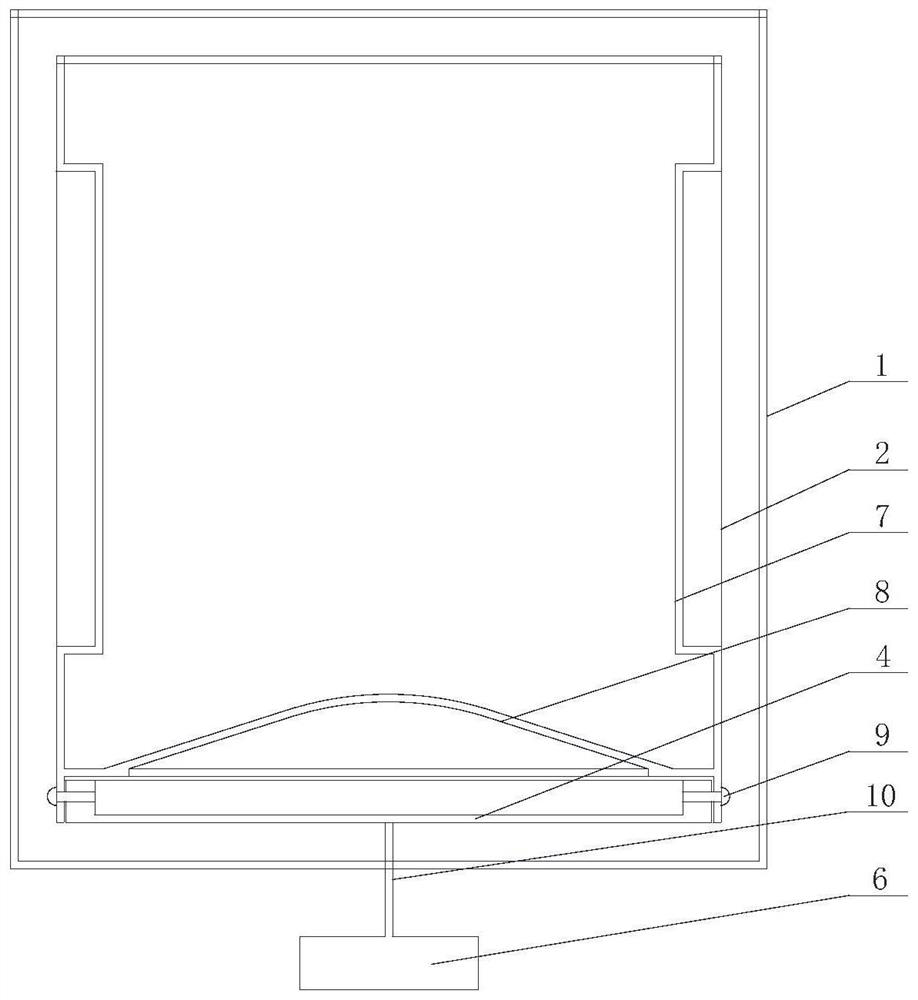

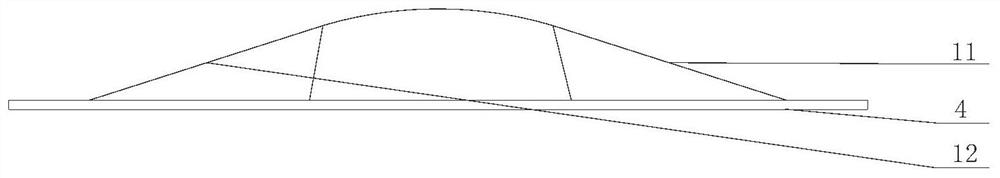

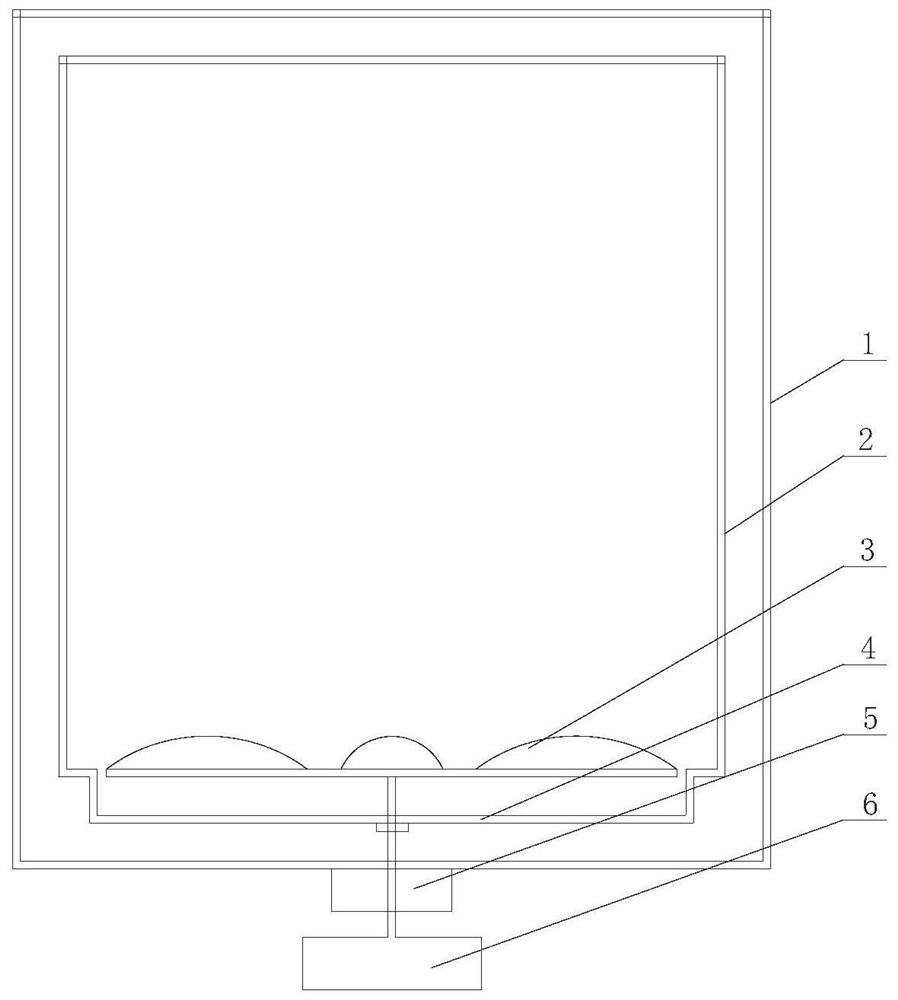

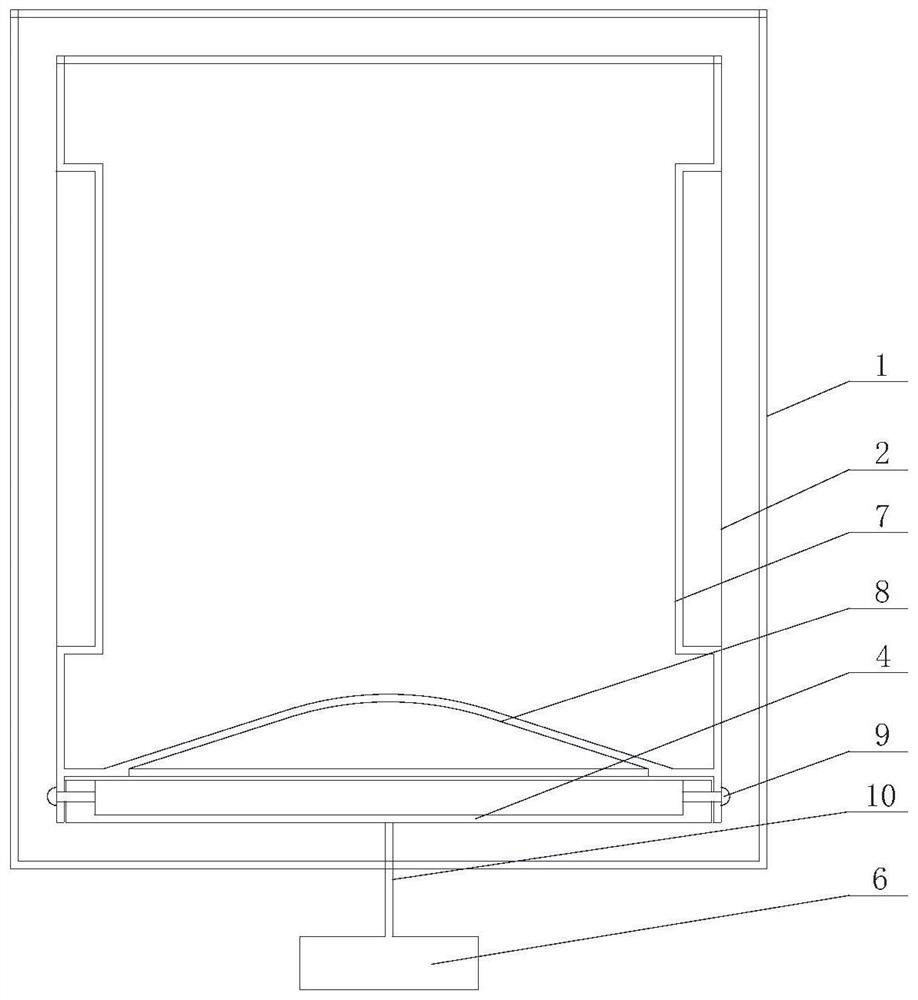

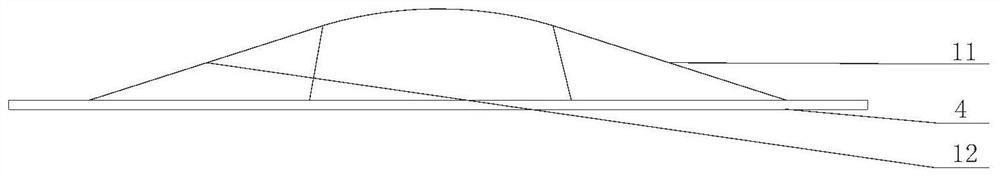

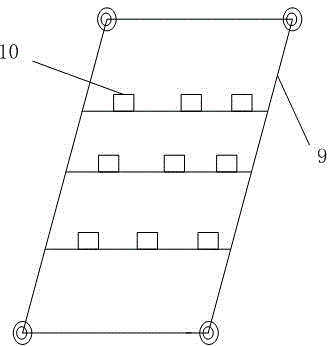

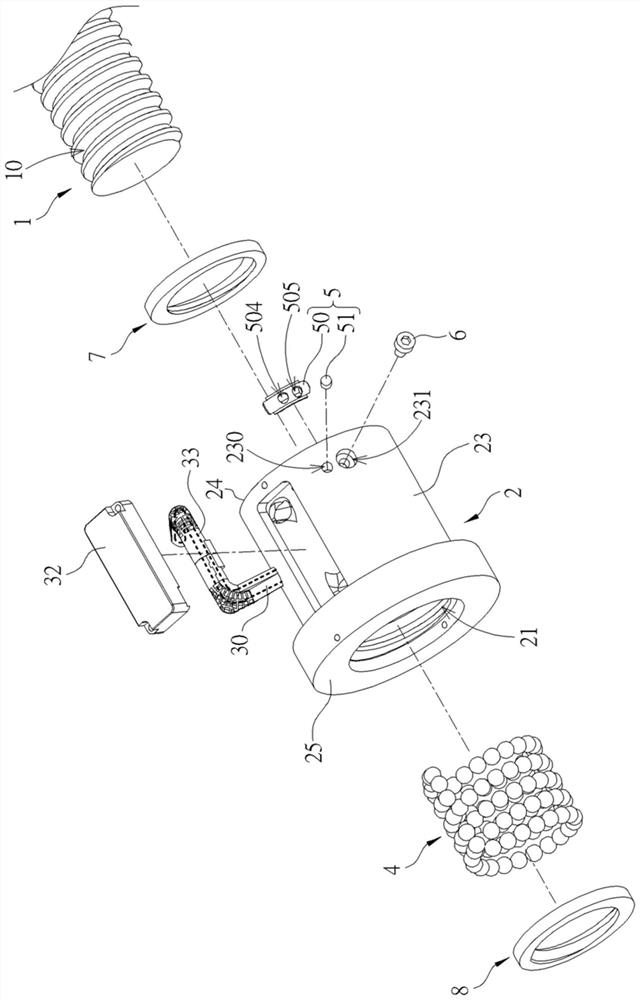

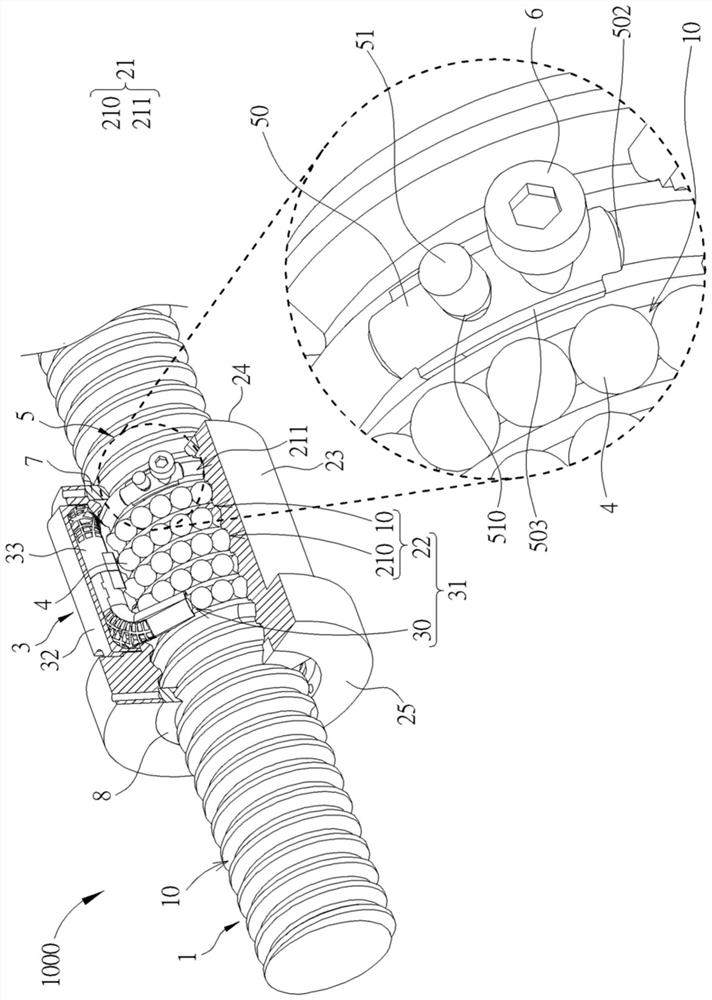

Rolling ball type washing machine

InactiveCN103603168ASolve the problem of inconvenient pick and placeCompact structureOther washing machinesWashing machine with receptaclesImpellerBall type

The invention relates to a rolling ball type washing machine belonging to the field of washing equipment, and particularly relates to a rolling ball type washing machine with a spherical washing drum. A rolling ball (4) is a spherical shell provided with a fetching hole (401) in the top and can rotate in an inner drying cylinder (2) by taking a horizontal central axis as a rotating shaft, and the rolling ball (4) and the inner drying cylinder (2) can synchronously rotate through a power device (7) by taking a central shaft in the vertical direction as a rotating shaft; one side of the lower part of the inner drying cylinder (2) is provided with a water outlet (201) where a centrifugal starting / stopping device (3) is arranged, the circumference below the inner drying cylinder (2) is provided with an annular water receiving tank (10) with an upper opening, and one side of the water receiving tank (10) is connected with a water outlet pipe (9). The rolling ball type washing machine is capable of realizing rolling type washing by using the rolling ball, good in washing effect and capable of saving water and reducing the dosage of detergents; due to the combination of a centrifugal drainage way of the water outlet of the inner drying cylinder, the problem of secondary pollution to clothes is thoroughly solved, and the rolling ball type washing machine can be conveniently changed to work in an impeller washing way.

Owner:张安达

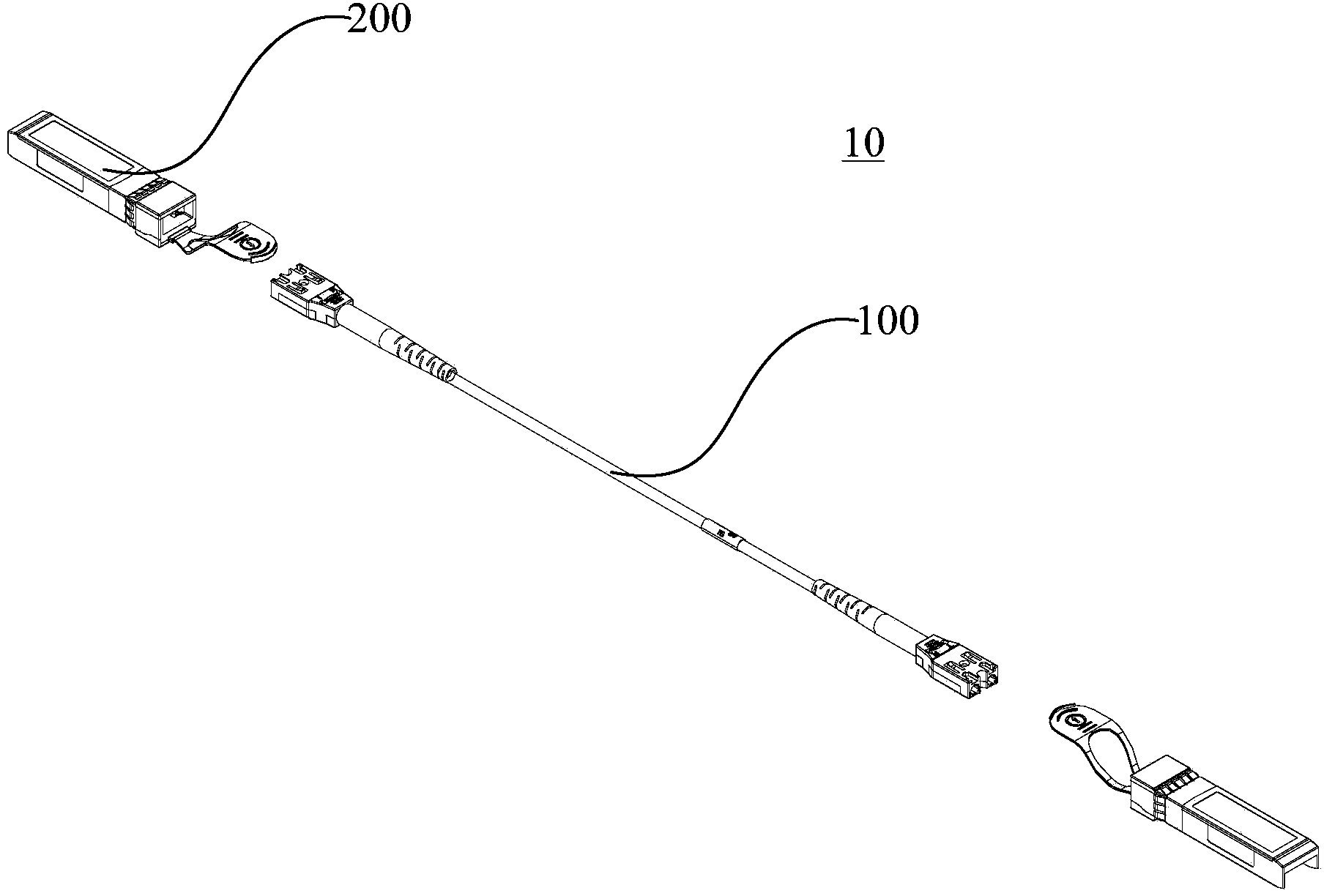

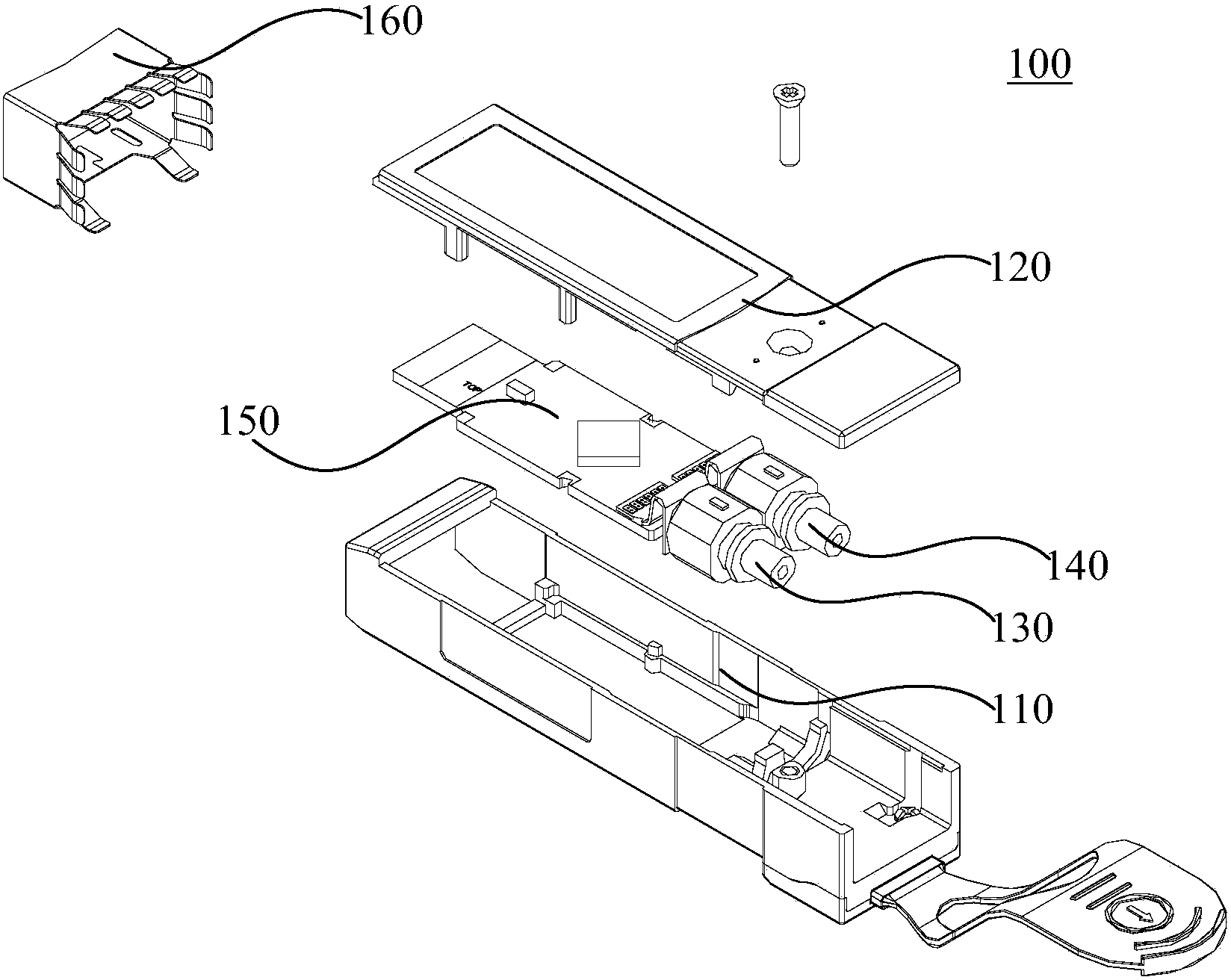

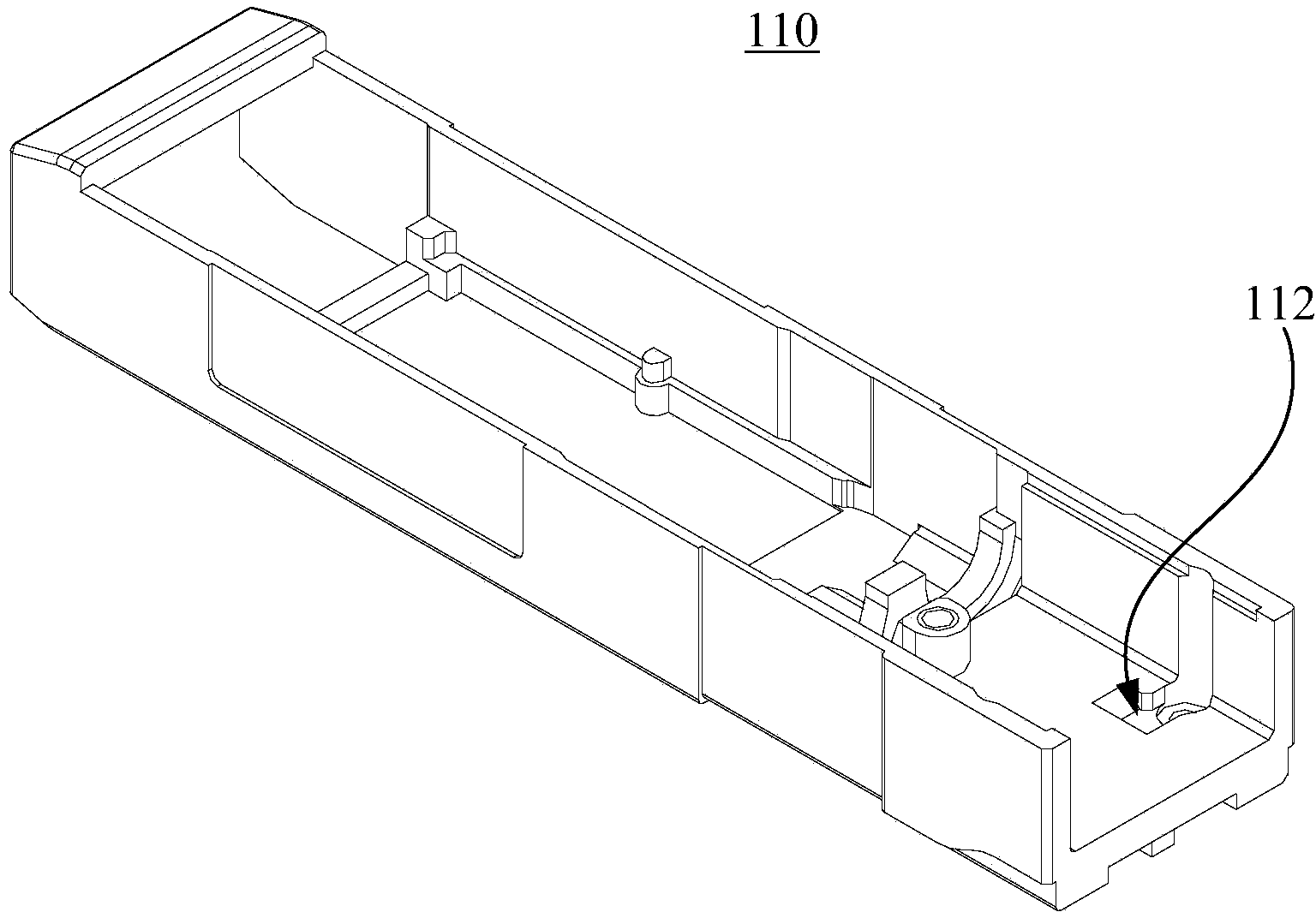

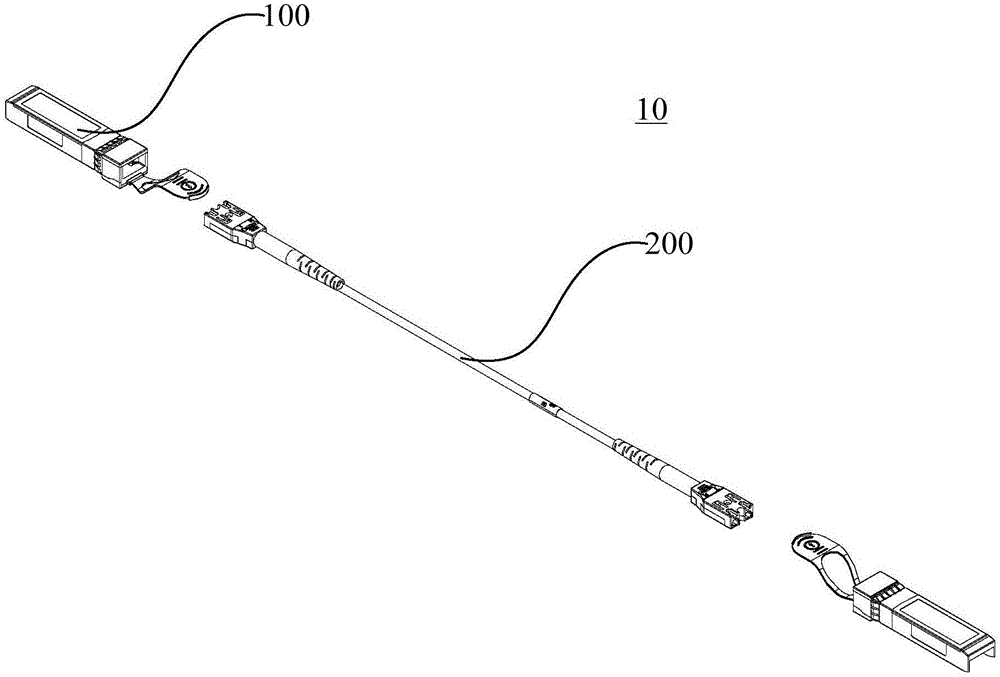

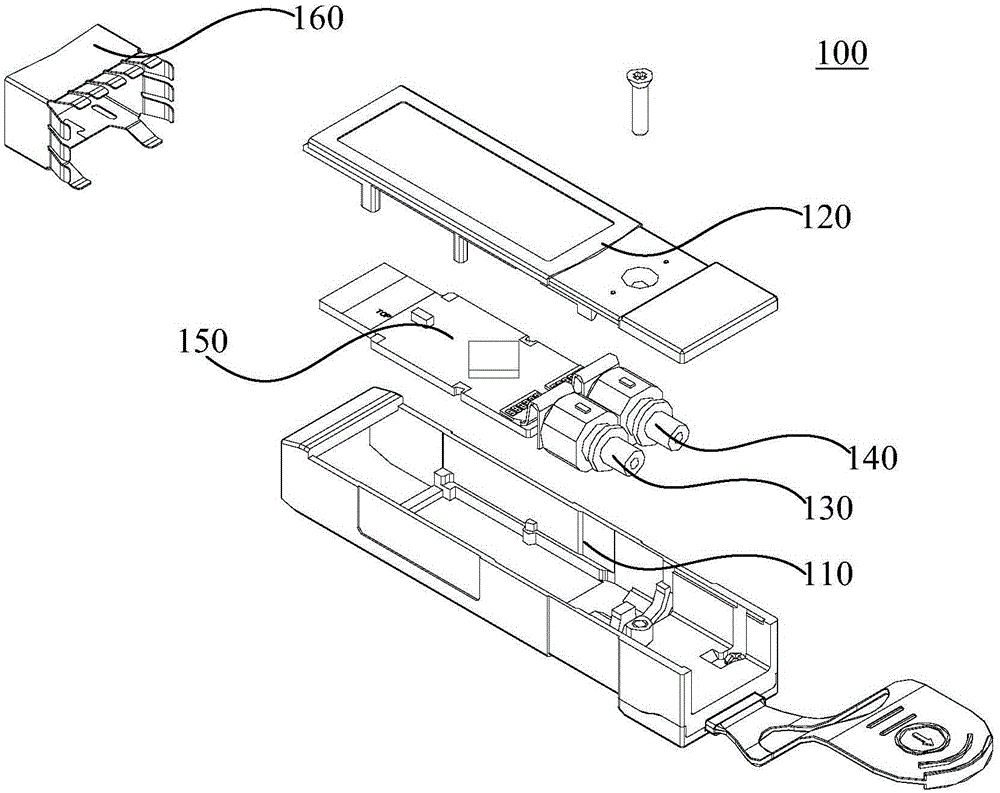

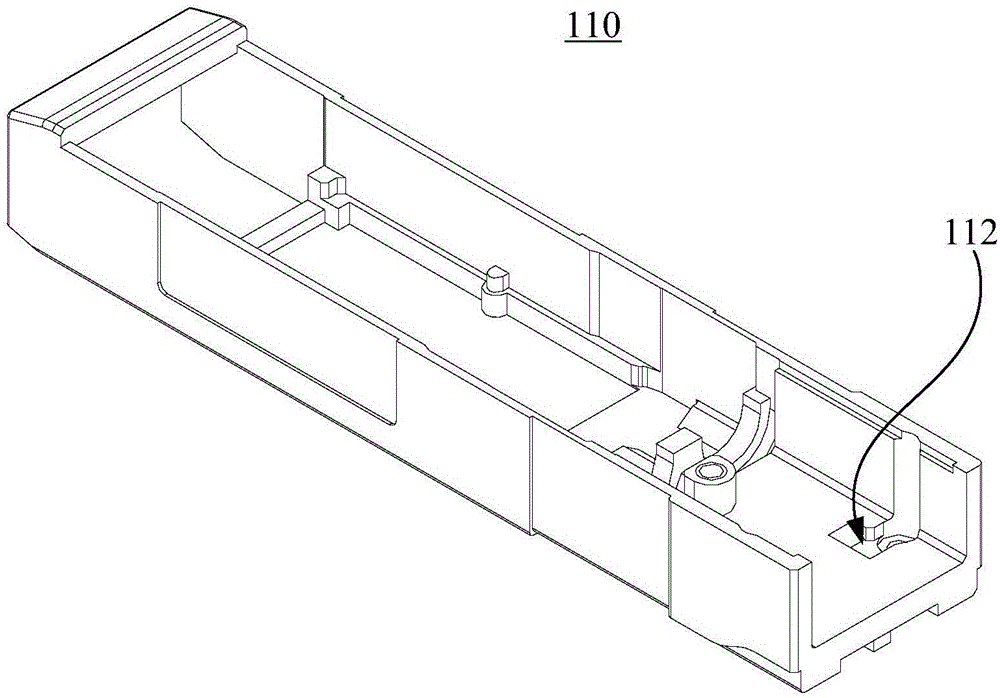

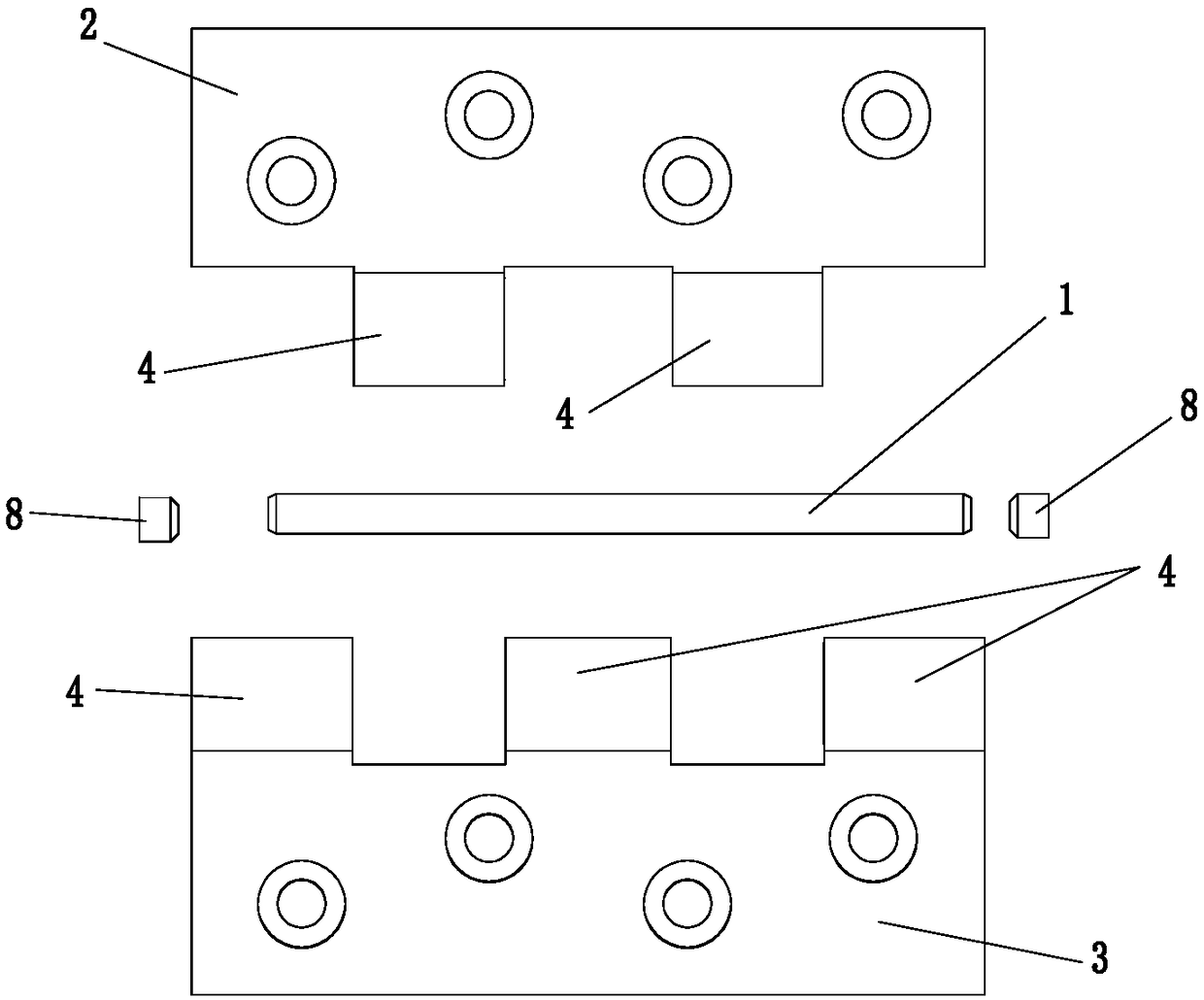

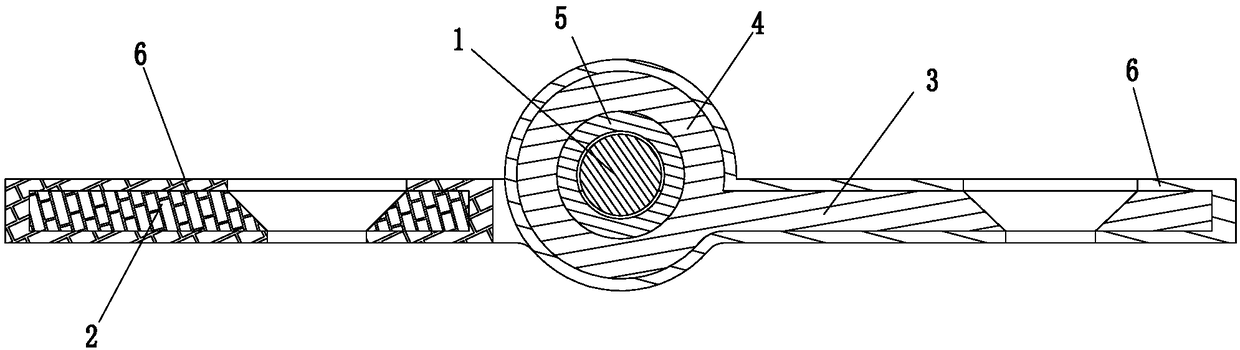

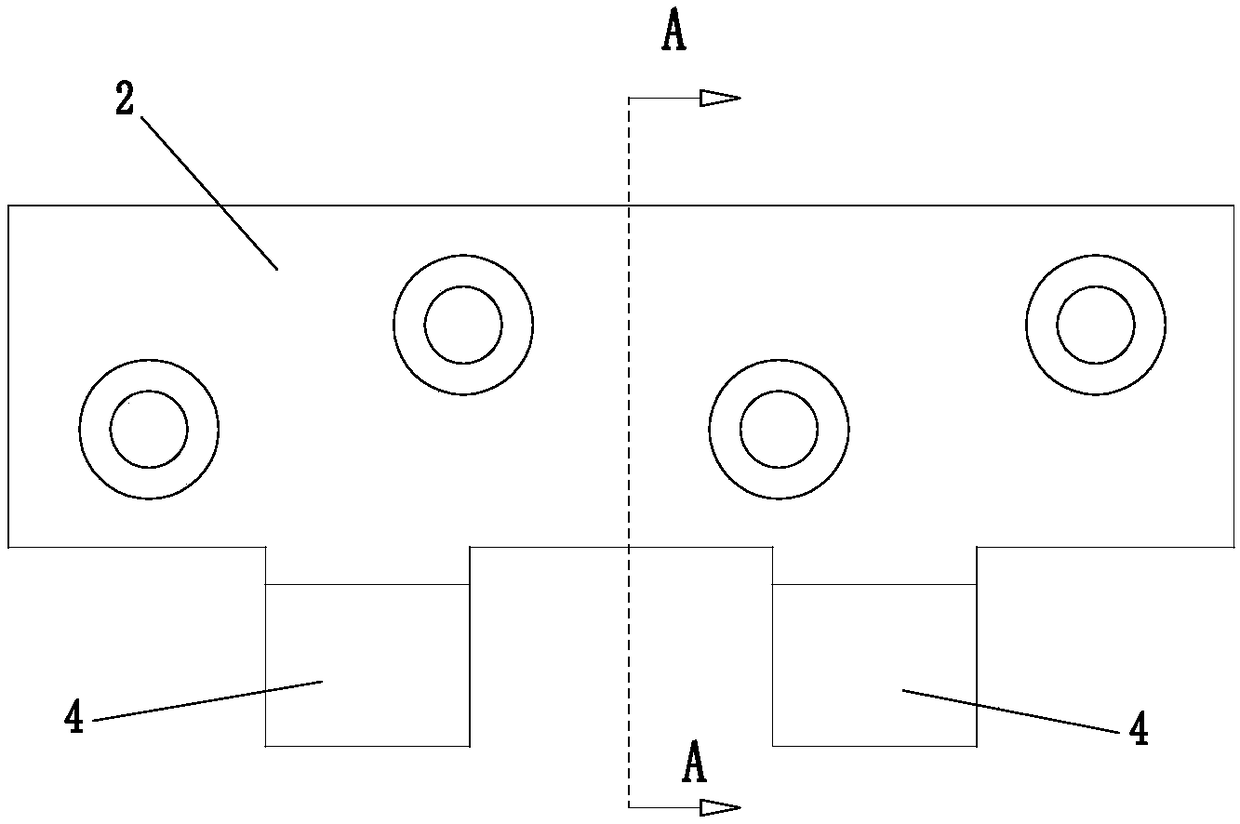

SFP + optical transceiving integrated module interconnection structure

Disclosed is an SFP + optical transceiving integrated module interconnection structure. The SFP + optical transceiving integrated module interconnection structure comprises an optical transceiving integrated module and a fiber connecting line. The optical transceiving integrated module comprises a bottom casing, an upper cover, an optical emission secondary module and an optical receiving secondary module. The upper cover and the bottom casing encloses a narrow and long accommodation cavity together, and an insertion opening communicating with the accommodation cavity is formed at one end of the accommodation cavity; the bottom casing is provided with a first button position groove, and the upper cover is provided with a second button position groove; the fiber connecting line comprises an upper casing, a lower casing and a single-tube double-core optical cable; the outer side surface of the upper casing is provided with a first elastic button position, and the outer side surface of the lower casing is provided with a second elastic button position; and one end of the fiber connecting line passes penetrates the insertion opening, the first elastic button position is clamped with the first button position groove, the second elastic button position is clamped with the second button position groove so as to enable the fiber connecting line to be fixedly connected with the optical transceiving integrated module, and two insertion cores are respectively electrically connected with the optical emission secondary module and the optical receiving secondary module. The SFP + optical transceiving integrated module interconnection structure can effectively solve the problem of a dirty optical end surface.

Owner:SHENZHEN GIGALIGHT TECH

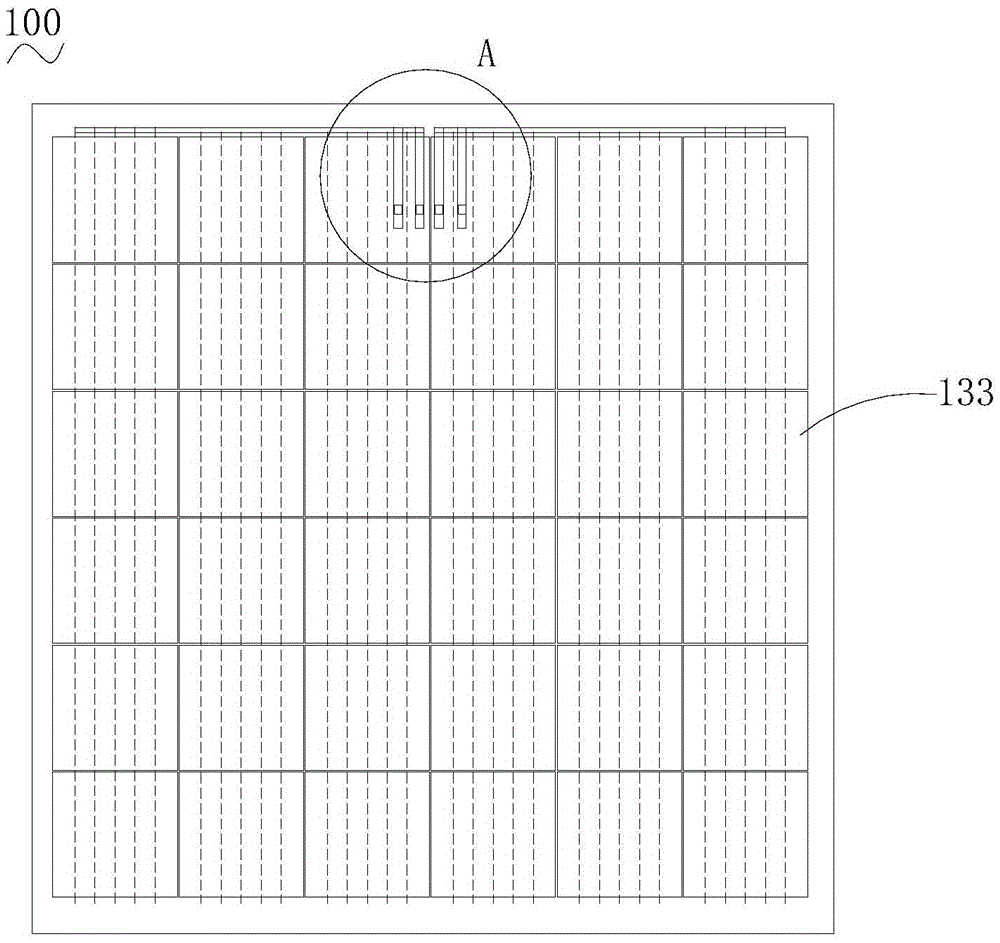

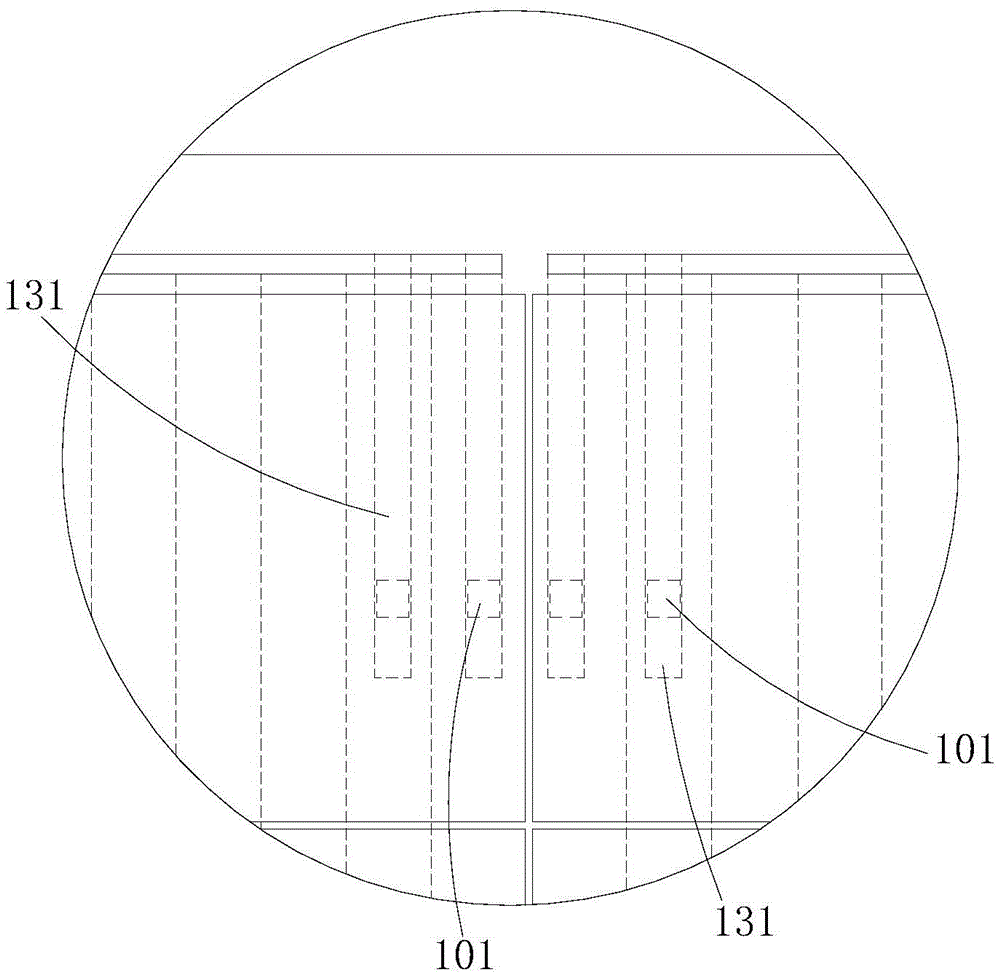

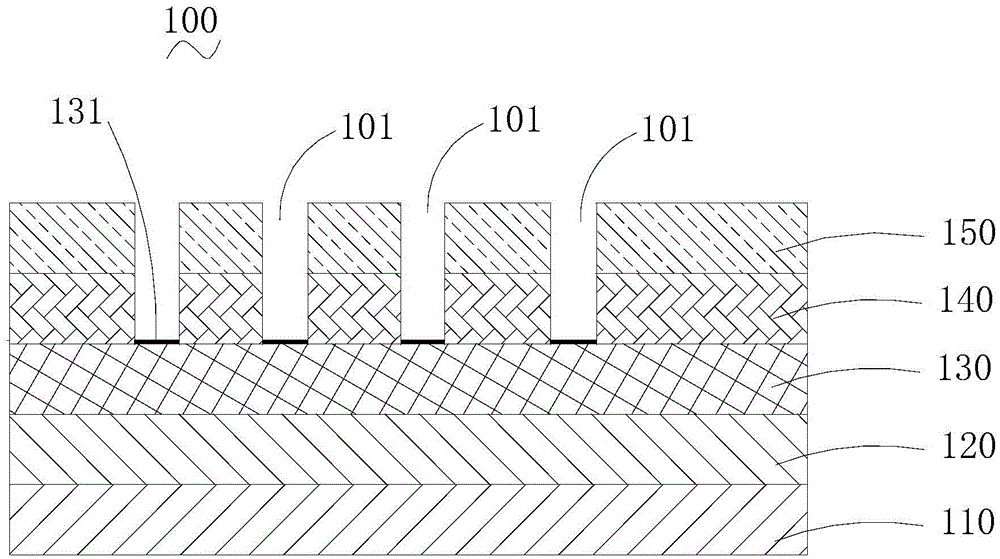

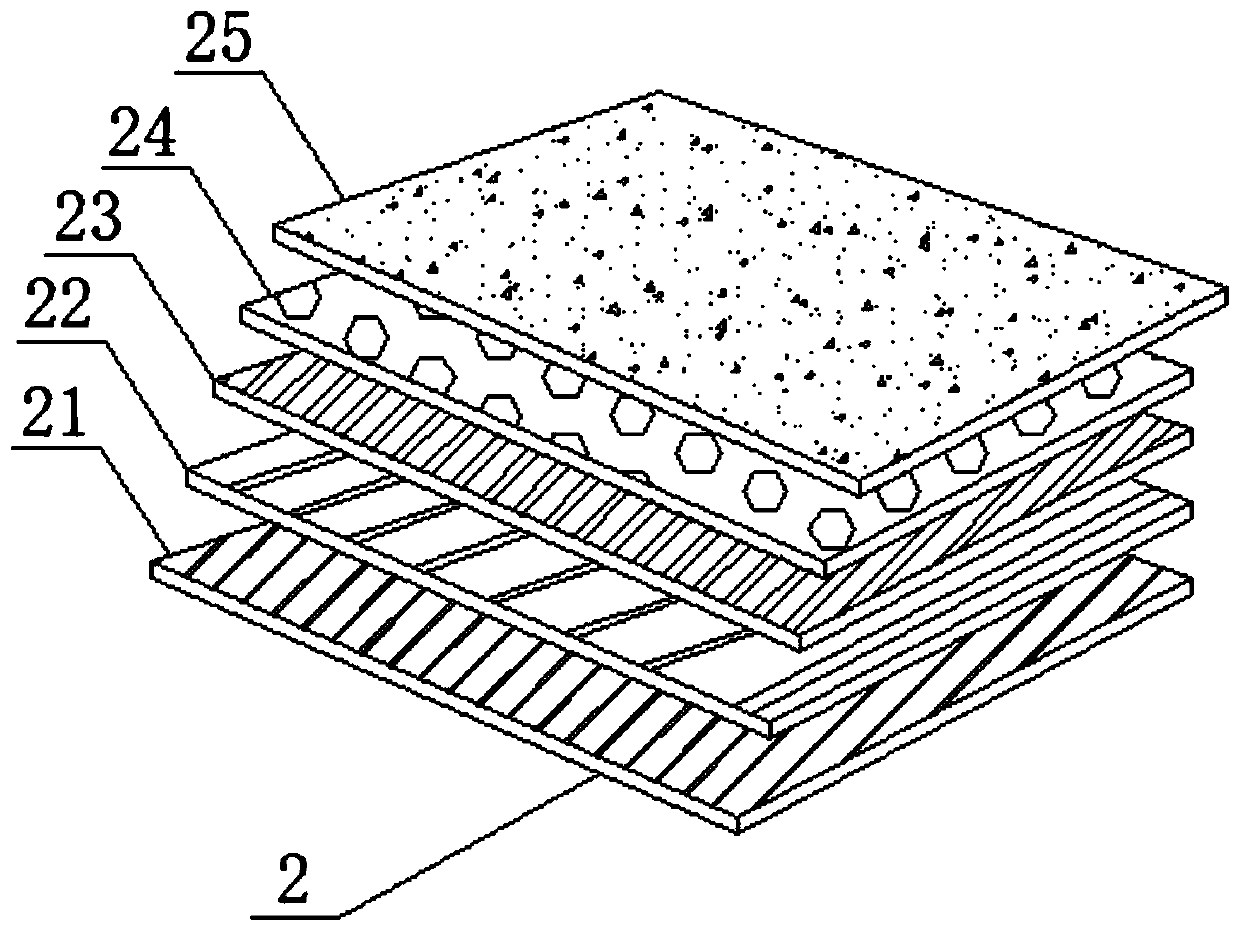

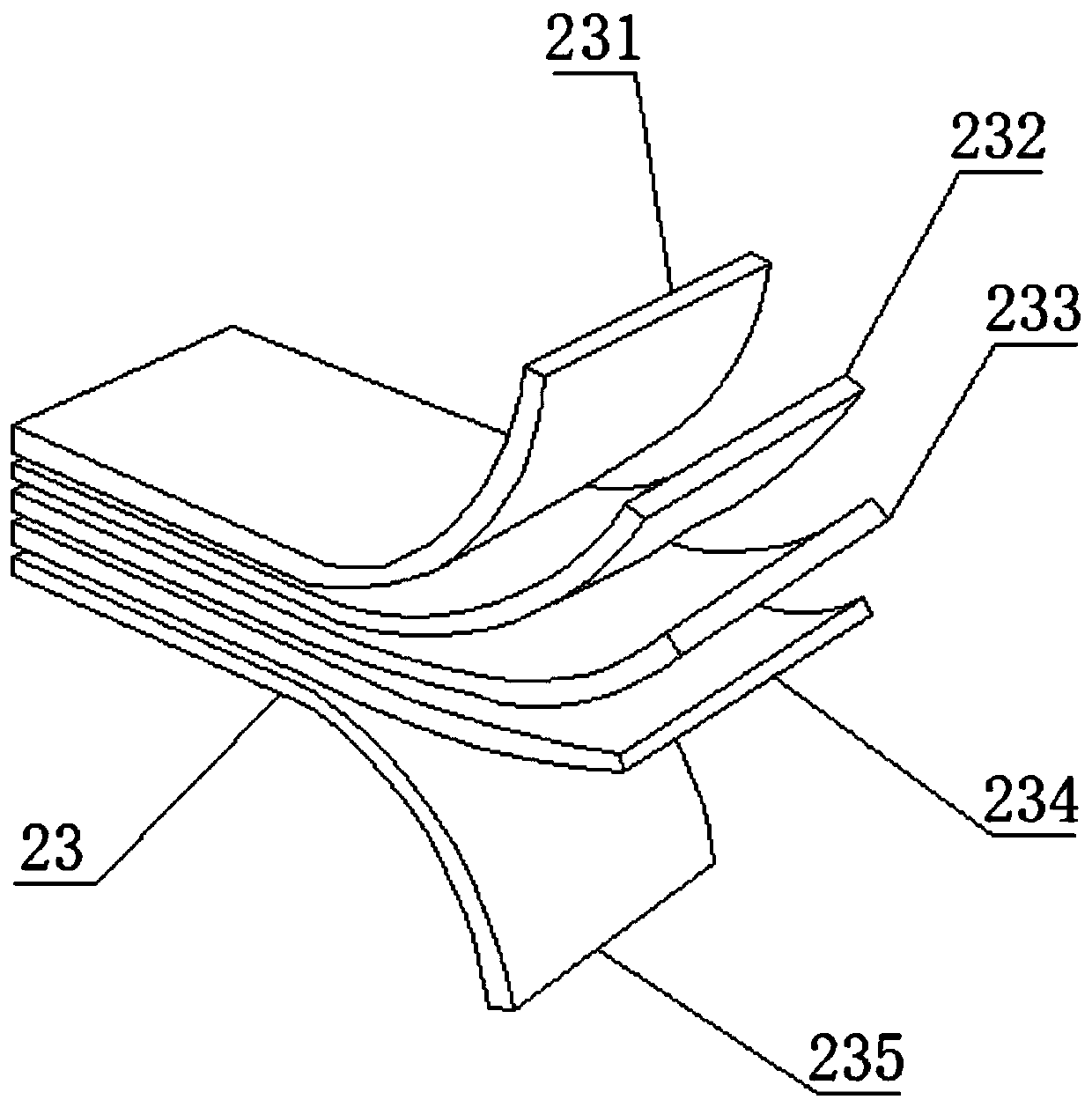

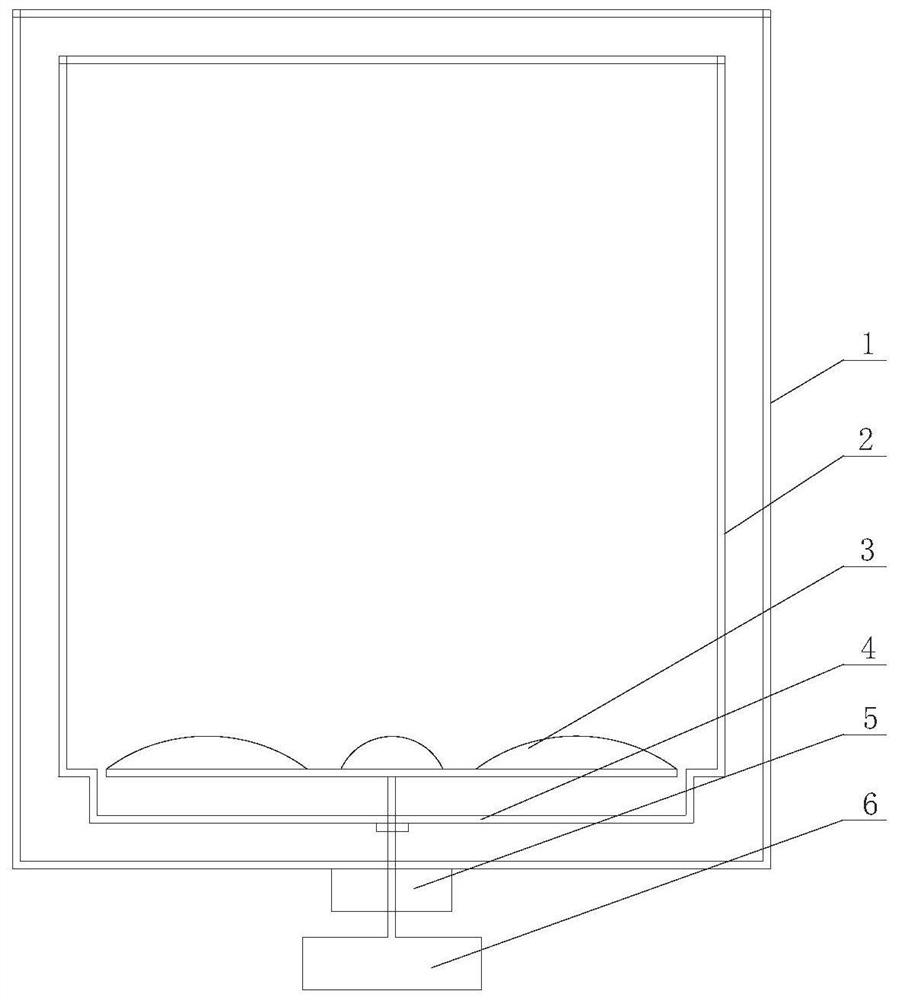

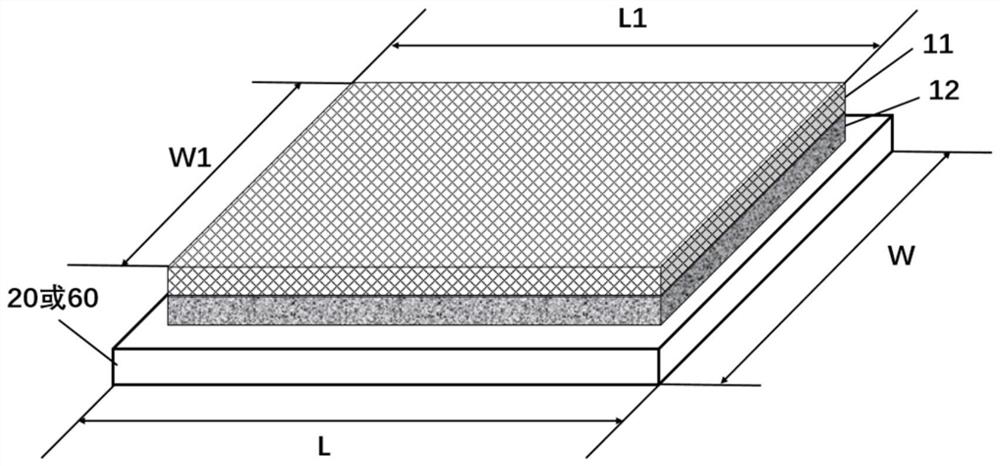

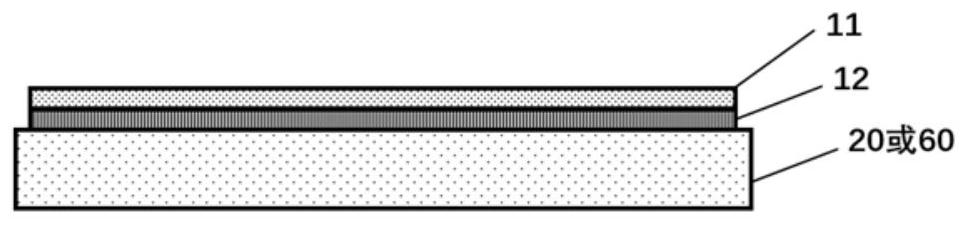

Photovoltaic laminating piece, preparation method thereof and photovoltaic module

InactiveCN105489682AAvoid crackingPrevent spillageFinal product manufacturePhotovoltaic energy generationElectricityElectrical battery

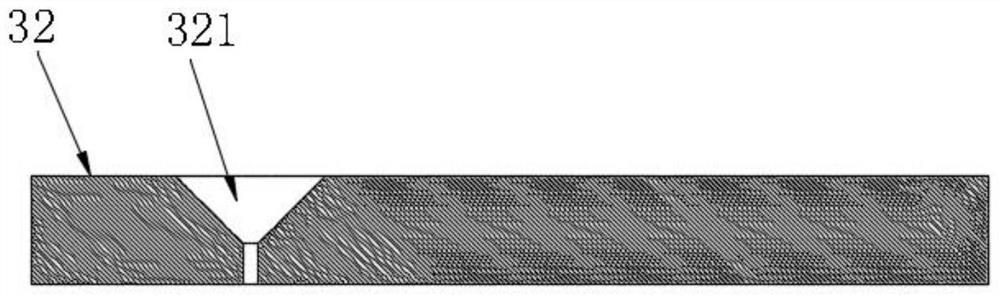

The invention relates to a photovoltaic laminating piece. The photovoltaic laminating piece comprises a transparent cover plate, a first sealing layer, a battery piece layer, a second sealing layer and a back plate which are laminated in sequence, wherein the battery piece layer comprises a plurality of connected battery pieces and a converge belt electrically connected onto the battery pieces; an electrode exposing hole is formed in the back plate, and the electrode exposing hole passes through the back plate and the second sealing layer so that the converge belt is leaked out. According to the photovoltaic laminating piece, the hidden cracking problem of the battery pieces caused by improper outgoing line penetration is avoided; and the manual workload can be greatly reduced. Moreover, the electrical connection quality of the photovoltaic laminating piece and a junction box is improved, the workload of subsequent cleaning stations is reduced, and the cleaning frequency and workload of a laminating machine are reduced. The invention also provides a preparation method of the photovoltaic laminating piece and a photovoltaic module comprising the photovoltaic laminating piece.

Owner:ZHANGJIAGANG GCL INTEGRATION TECH CO LTD

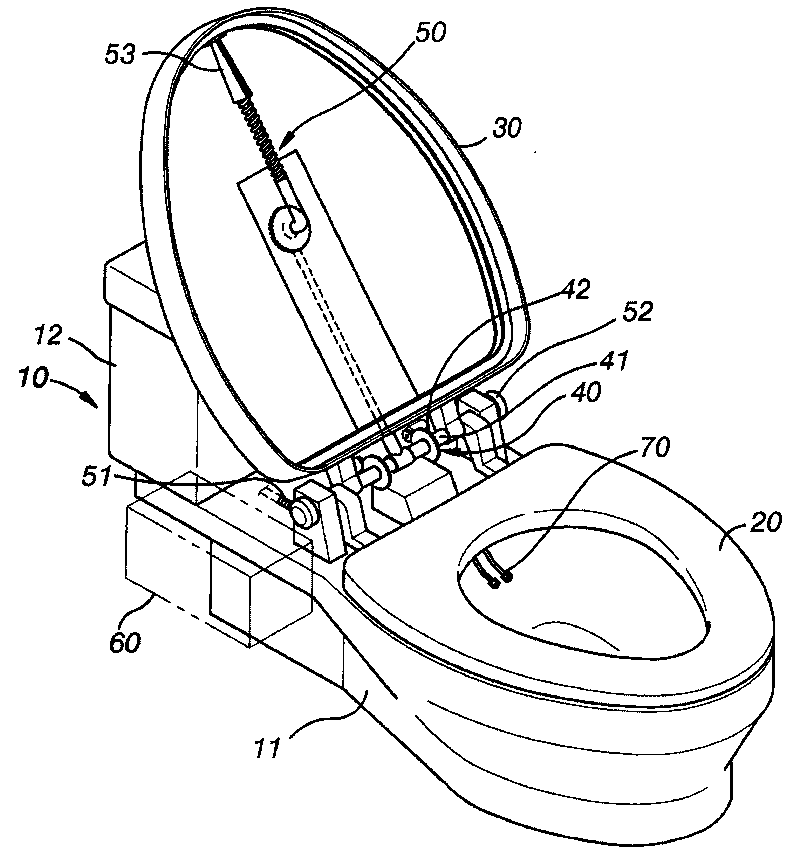

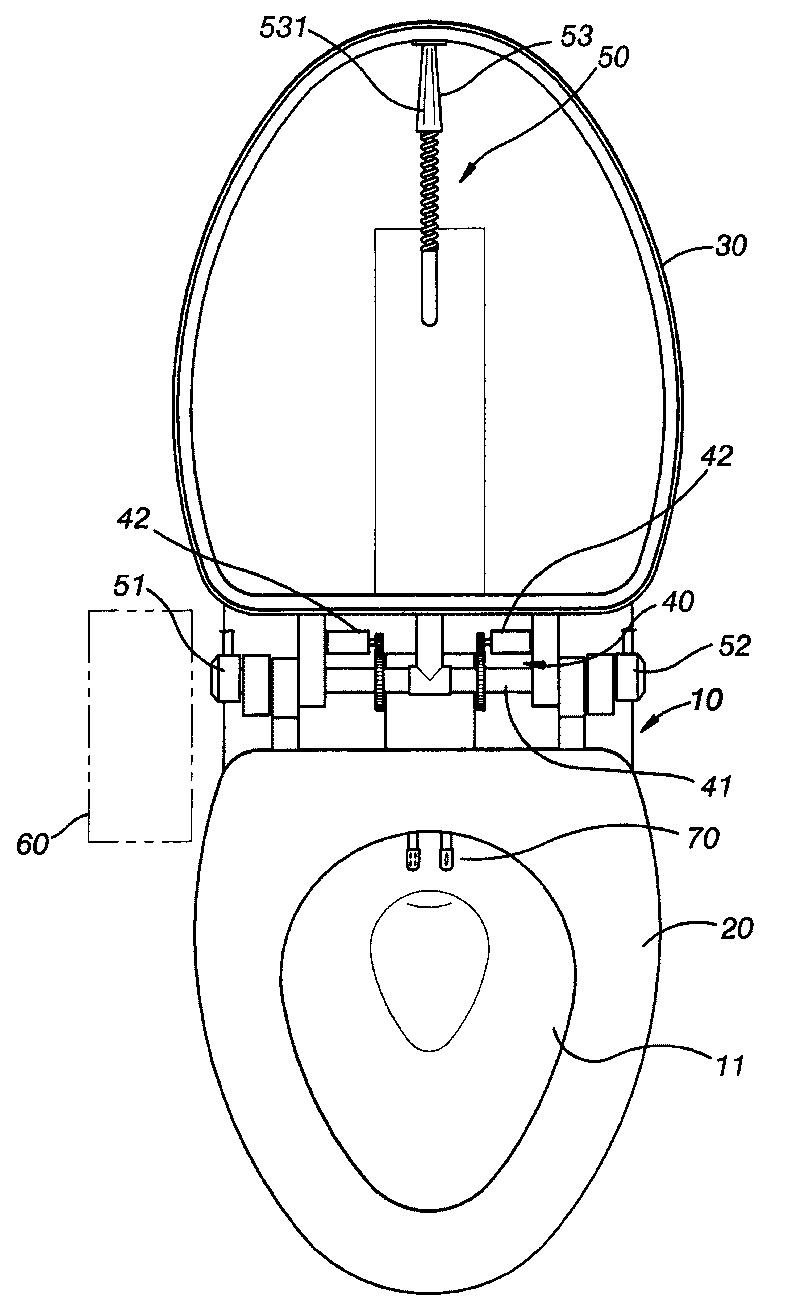

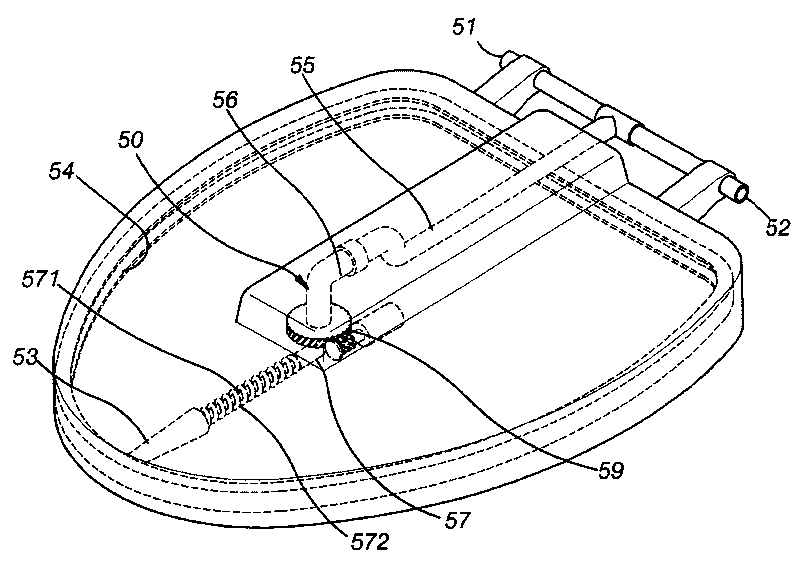

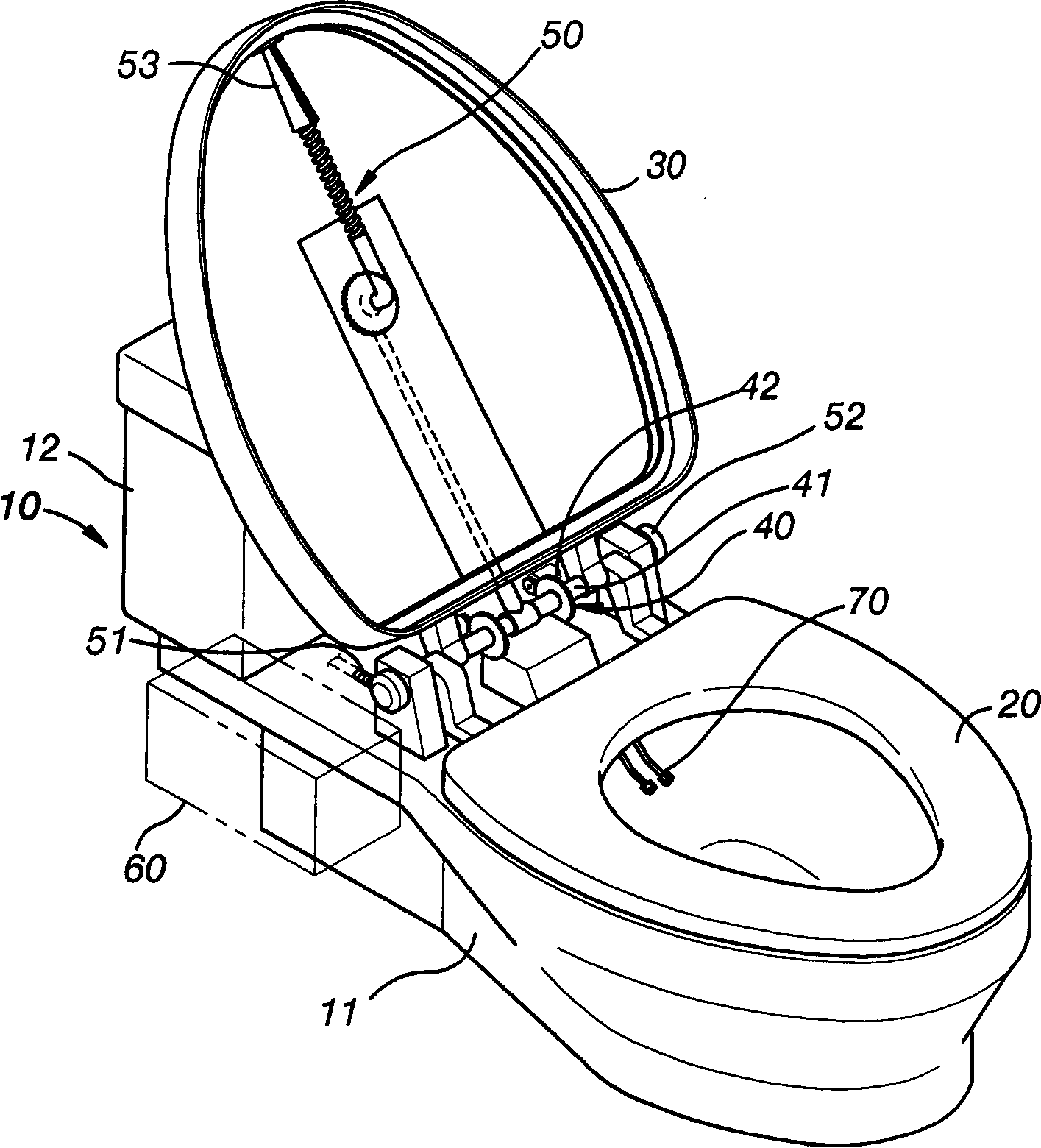

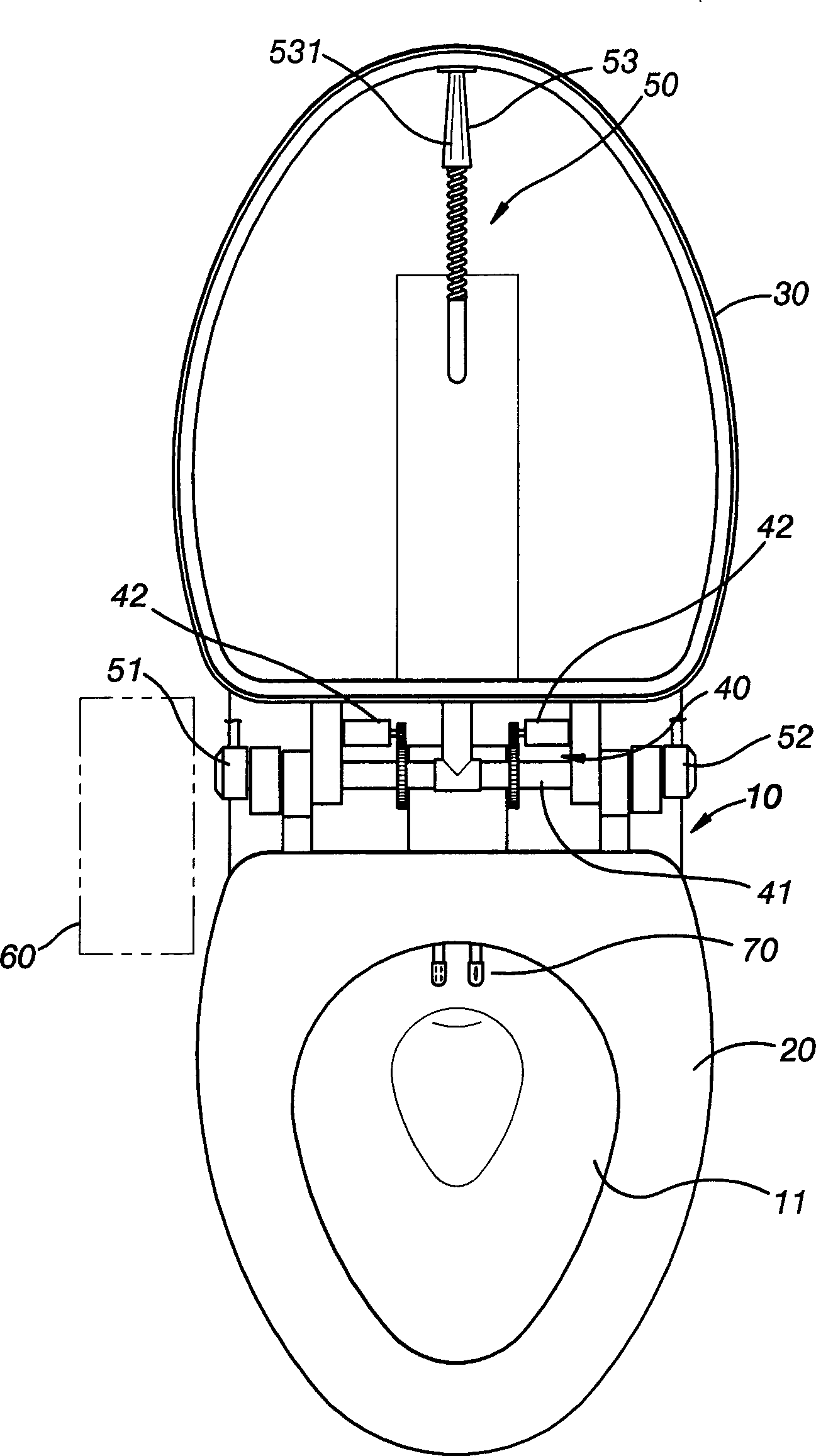

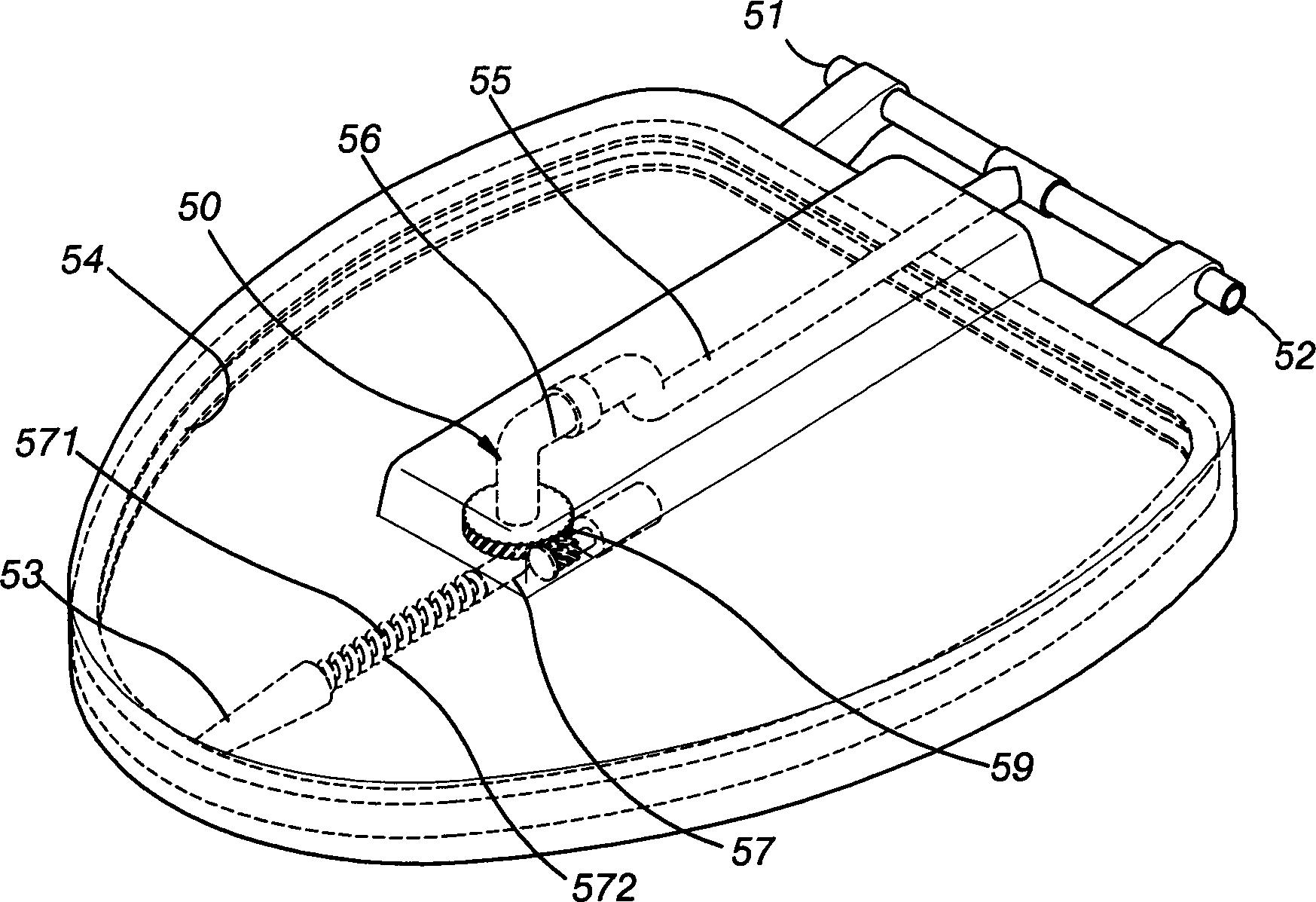

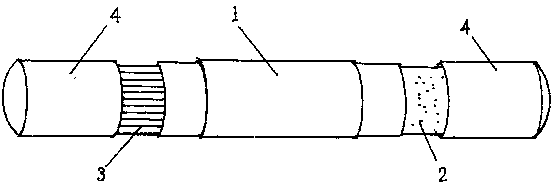

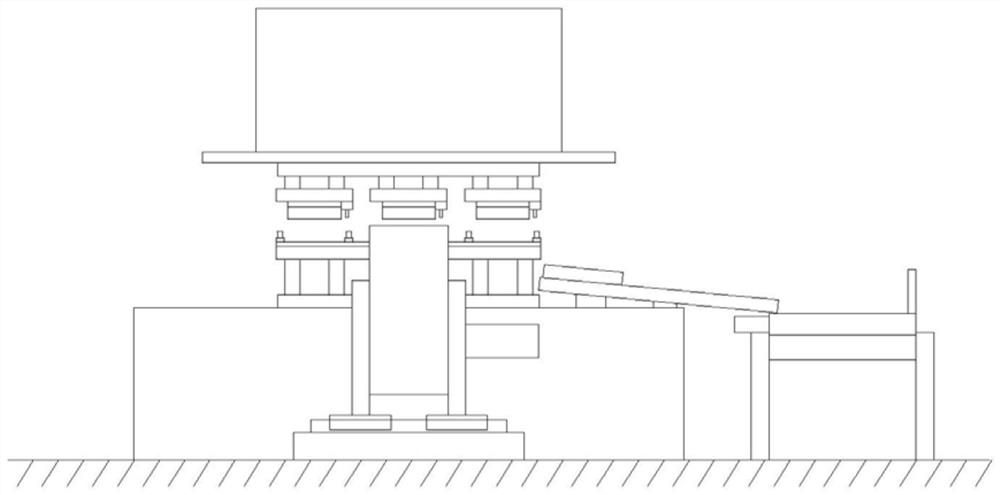

Automatic cleaning device for toilet bowl

ActiveCN101691778ASolve the disturbing problem of manual liftingSolve annoying problemsWater closetsFlushing devicesMechanical engineeringToilet

The invention relates to an automatic cleaning device for a toilet bowl, which is arranged above a toilet bowl body. The toilet bowl body is provided with a urinal and a water tank for supplying water to the urinal; and the toilet bowl comprises a seat board pivoted at the upper edge of the urinal, a cover pivoted and shielded at the upper edge of the urinal to cover the seat board, a cover opening / closing unit connected to the cover to control the opening / closing state of the cover, a seat board cleaning unit arranged on the cover, and a control unit arranged nearby the urinal. The device can utilize the means of infrared induction to enable the cover to be automatically opened when a user is close and automatically closed after being used, can utilize the seat board cleaning unit arranged on the cover to automatically clean the seat board and the inner edge of the toilet bowl, and can also enable the seat board and the toilet bowl to be kept in a cleanest state besides preventing the user from touching the toilet bowl by hands.

Owner:黄海盛

sfp+ optical transceiver integrated module interconnection structure

Disclosed is an SFP + optical transceiving integrated module interconnection structure. The SFP + optical transceiving integrated module interconnection structure comprises an optical transceiving integrated module and a fiber connecting line. The optical transceiving integrated module comprises a bottom casing, an upper cover, an optical emission secondary module and an optical receiving secondary module. The upper cover and the bottom casing encloses a narrow and long accommodation cavity together, and an insertion opening communicating with the accommodation cavity is formed at one end of the accommodation cavity; the bottom casing is provided with a first button position groove, and the upper cover is provided with a second button position groove; the fiber connecting line comprises an upper casing, a lower casing and a single-tube double-core optical cable; the outer side surface of the upper casing is provided with a first elastic button position, and the outer side surface of the lower casing is provided with a second elastic button position; and one end of the fiber connecting line passes penetrates the insertion opening, the first elastic button position is clamped with the first button position groove, the second elastic button position is clamped with the second button position groove so as to enable the fiber connecting line to be fixedly connected with the optical transceiving integrated module, and two insertion cores are respectively electrically connected with the optical emission secondary module and the optical receiving secondary module. The SFP + optical transceiving integrated module interconnection structure can effectively solve the problem of a dirty optical end surface.

Owner:SHENZHEN GIGALIGHT TECH

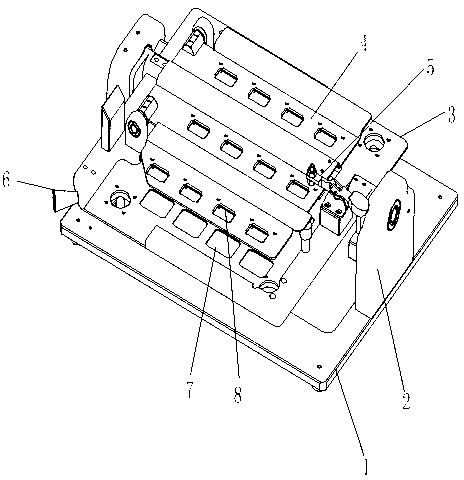

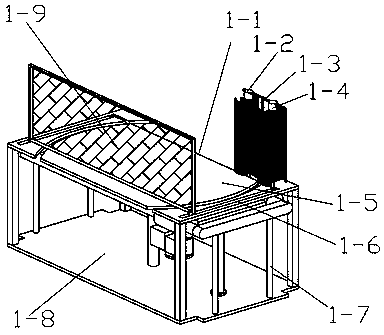

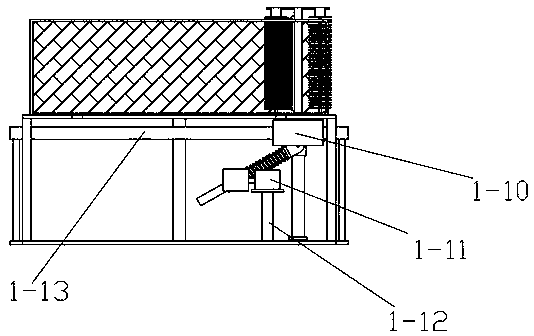

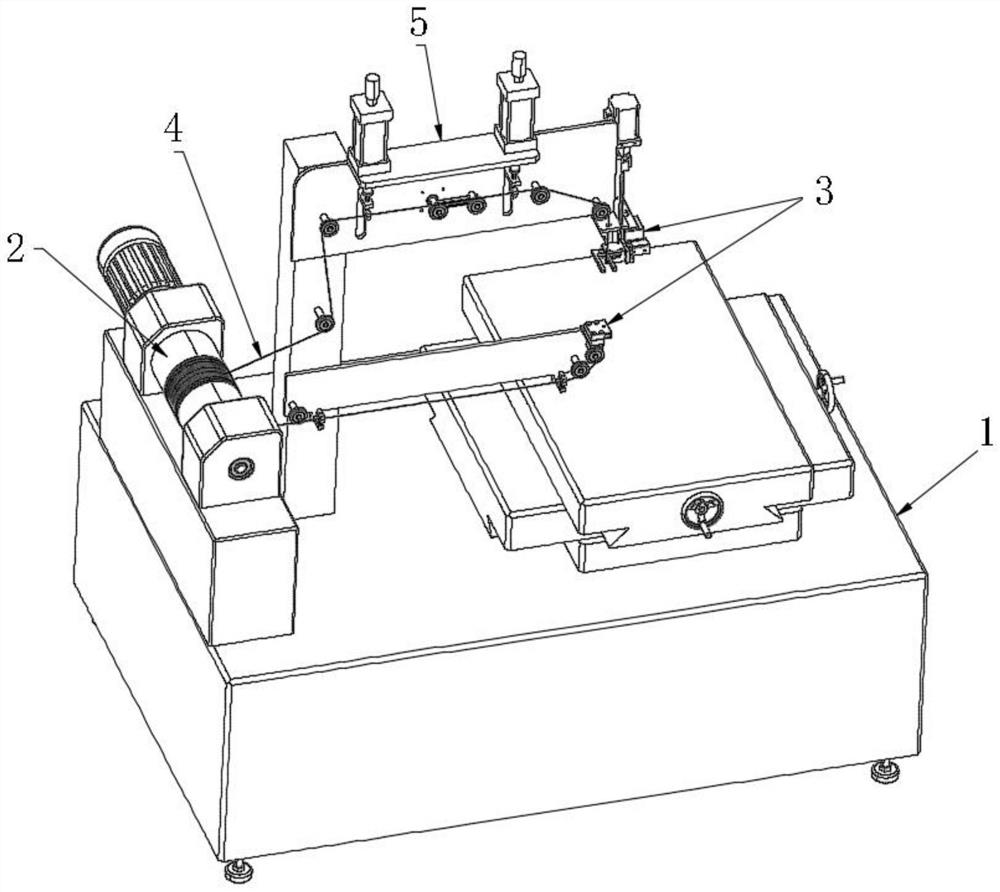

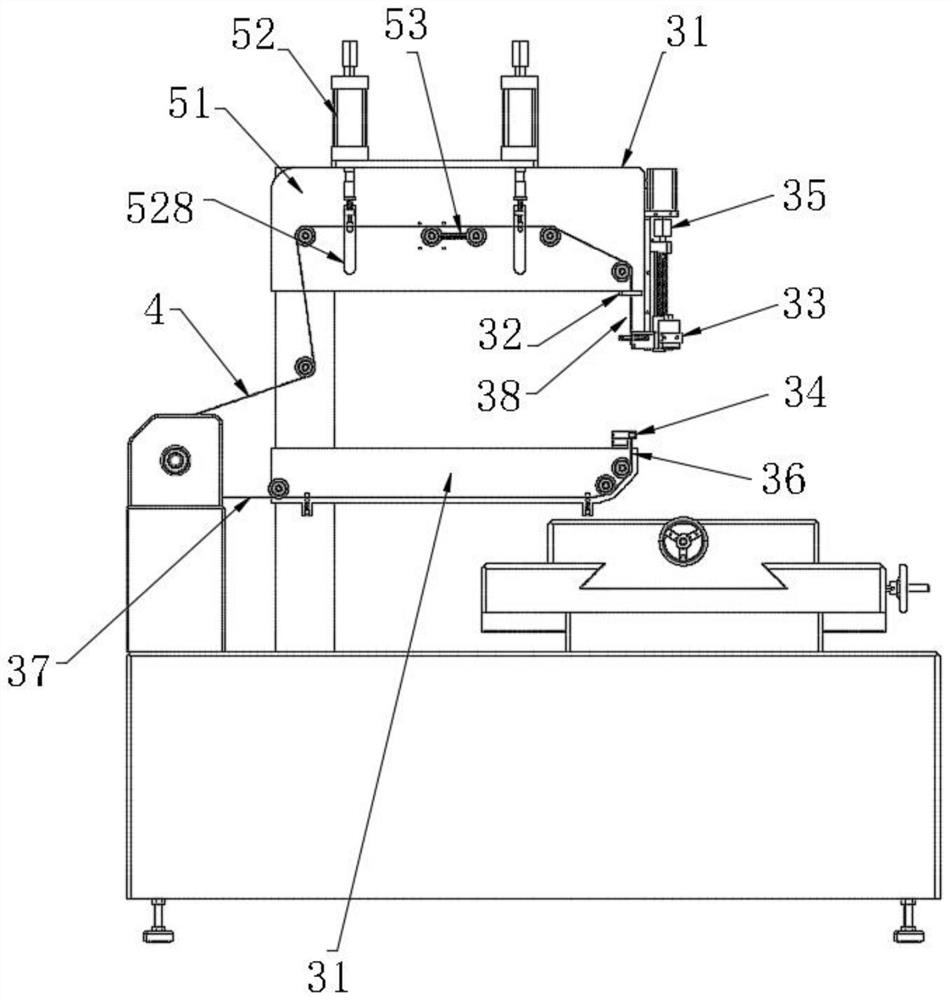

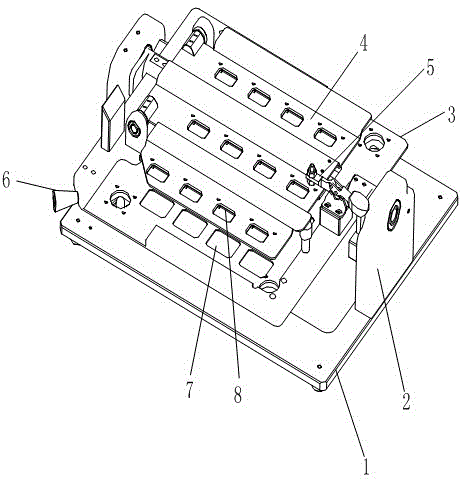

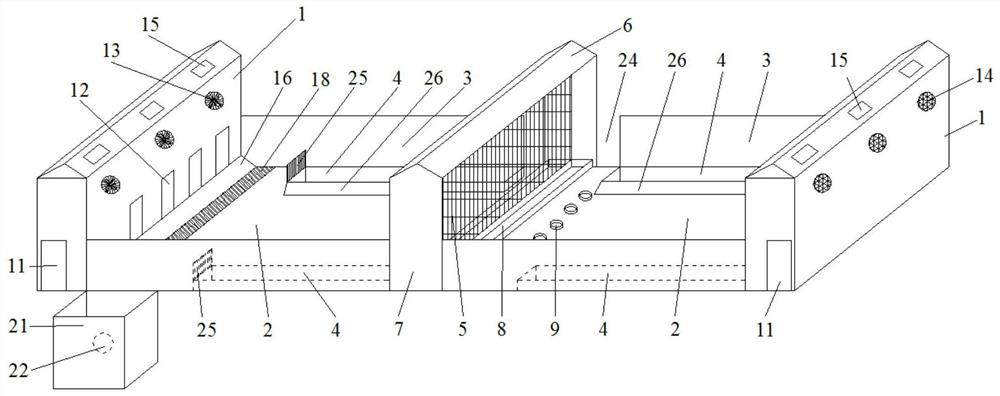

Hard disc magnetic head mounting and dispensing rack

ActiveCN103212522AImprove positioning accuracyImprove work efficiencyLiquid surface applicatorsCoatingsFixed frameEngineering

The invention provides a hard disc magnetic head mounting and dispensing rack. Supporting lug bosses are arranged at the two sides of a base; the supporting lug bosses are provided with rotary discs through vertical central rotary shafts; the centers of the rotary discs are provided with product holes which are uniformly distributed at intervals; a washing frame for fixing products are arranged above the product holes and is provided with product fixing frames with the same quantity as that of the product holes and the product fixing frames are distributed rightly above the product holes; one sides of the rotary lug bosses are provided with a single-phase overturning type protective cover for fixing the washing frame through the lug bosses; the protective cover is provided with working holes with the same quantity as that of the product holes, wherein the working holes are distributed in a manner of penetrating through the product fixing frames; and the other sides of the rotary discs are provided with an elbow clamping device for clamping the protective cover. According to the rotary discs disclosed by the invention, forward and backward work of products can be realized and the working efficiency is accelerated; the washing frame can fix a plurality of the products for one time to operate at the same time and the exchanging time of the product is reduced, so that the working efficiency is accelerated; and meanwhile, only the washing agent needs to be washed so that the hard disc magnetic head mounting and dispensing rack is convenient and fast to wash.

Owner:SUZHOU KAIFA TECH CO LTD

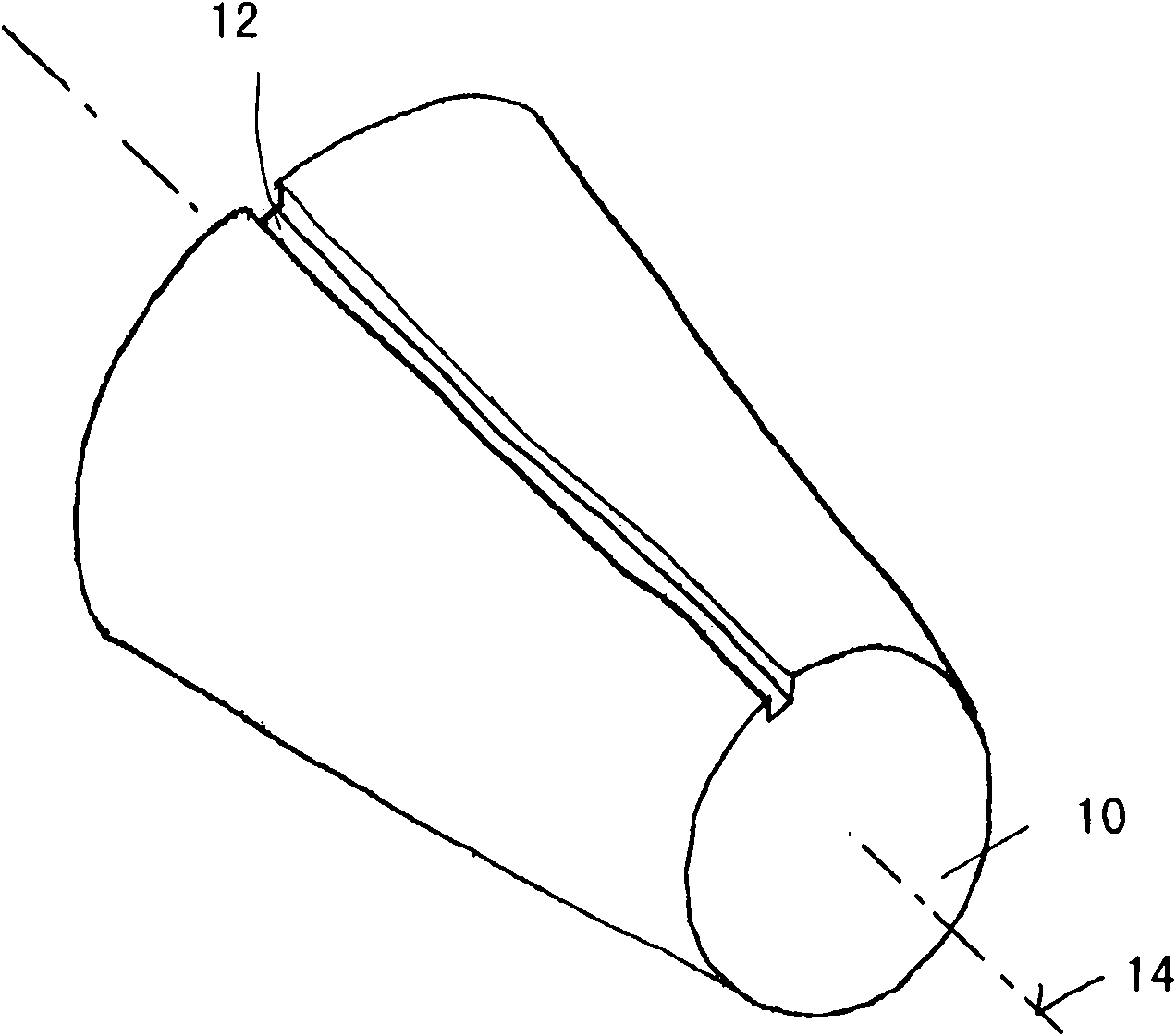

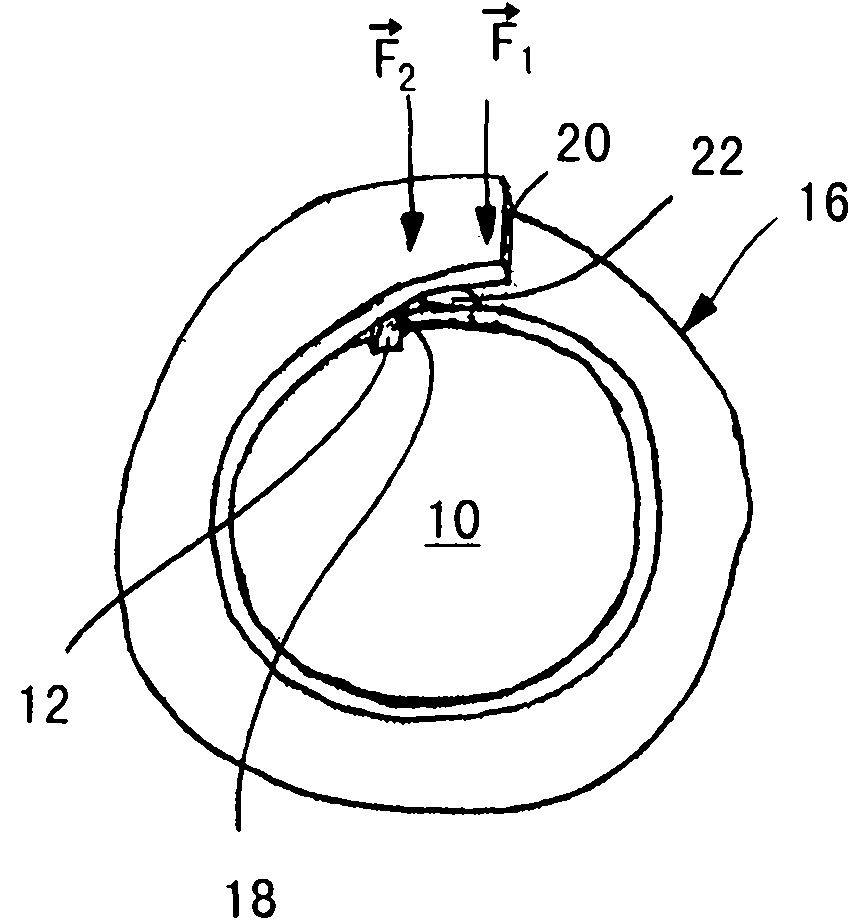

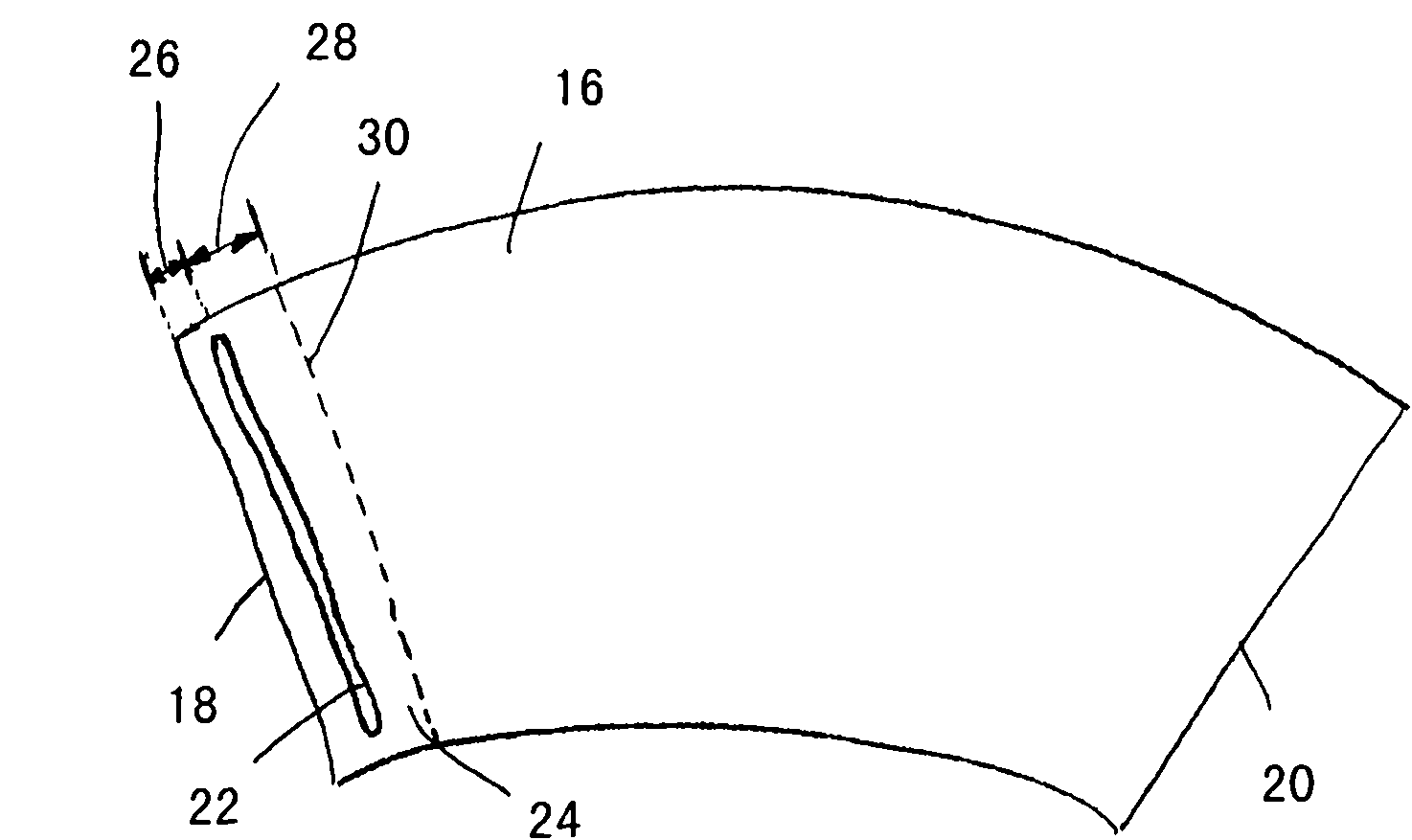

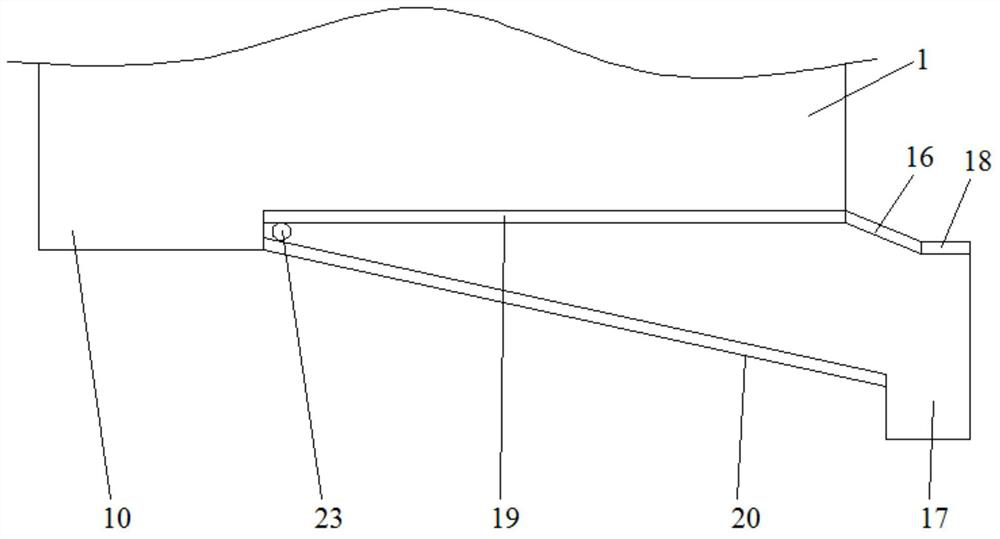

Folding mandrel, device and method for manufacturing glued sleeves

InactiveCN101837661ASolve the dirtAvoid running disturbancesEnvelopes/bags making machineryPaper/cardboard wound articlesAdhesiveEngineering

Folding mandrel, device and method for manufacturing glued sleeves. The invention relates to a folding mandrel for a device for manufacturing glued sleeves, in particular paper sleeves for the manufacture of paper cups, where the folding mandrel is provided for winding of a plane segment and is so dimensioned that in the wound-on state of the segment an overlap containing adhesive is obtained. In accordance with the invention, the folding mandrel is provided with at least one recess for receiving any adhesive escaping from the overlap. Use for example for the manufacture of paper cups.

Owner:MICHAEL HORAUF MASCHFAB

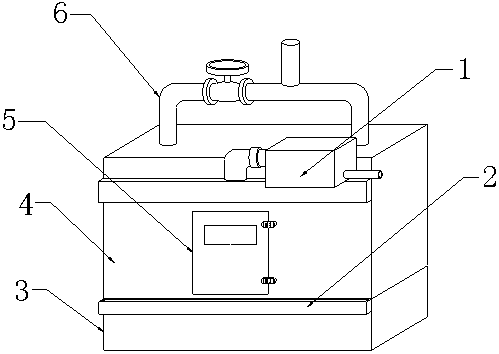

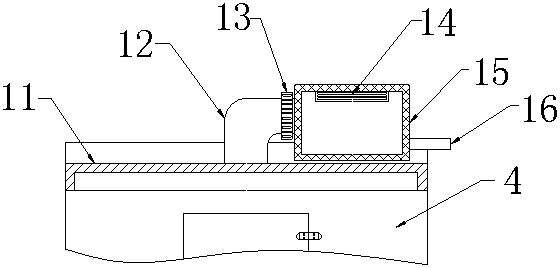

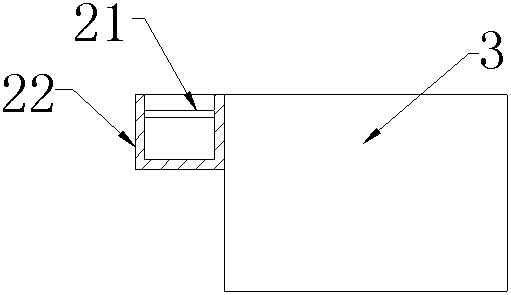

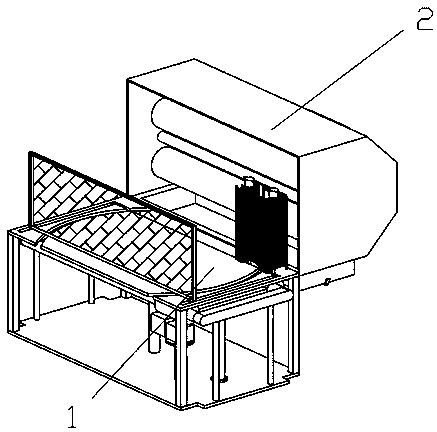

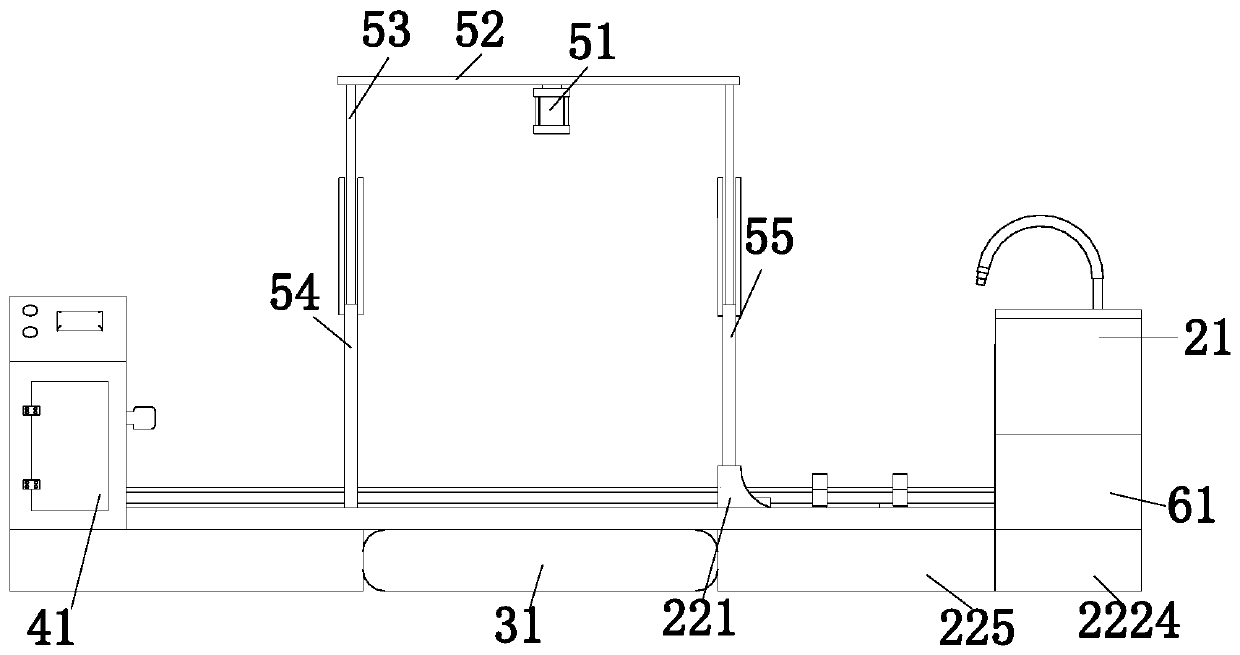

Steam box of continuous tie-dying machine

InactiveCN108049084AAvoid churnSolve wasteTextile treatment containersTextile treatment machine arrangementsEngineeringWater collection

The invention provides a steam box of a continuous tie-dying machine. The steam box comprises a cover body, an air inducing pipe, a fan, a condensing plate, a water collection tank, a water drainage pipe, a grid net and a square box, wherein the cover body is fixedly arranged at the upper part of the front end surface of an oven body; the air inducing pipe is arranged in the middle part of the upper end surface of the cover body, and the upper end of the air inducing pipe is connected with the water collection tank; the fan is arranged on the air inducing pipe; the condensing plate is arrangedat the upper end surface of the interior of the water collection tank; the water collection tank is arranged at the right side of the upper part of the front end surface of the oven body; the water drainage pipe is arranged at the lower part of the right end surface of the water collection tank. By adopting the design, the oven has the advantages that the function of quickly collecting and liquefying excessive steam is realized, and the loss of steam is avoided; the grid net is arranged in the middle part of the interior of the square box, and the square box is fixedly arranged at the upper part of the front end surface of the base, so that the function of collecting the liquefied water on a sealing door is realized, and the condition of the liquefied water dripping onto ground is avoided; the structure is reasonable, the functions are complete, the practicality is strong, the stability is good, and the reliability is high.

Owner:中山市智辉科技服务有限公司

Middle-large double-coated dog hair combing device capable of preventing hair from flying

The invention relates to a middle-large double-coated dog hair combing device capable of preventing hair from flying, and belongs to the technical field of pet devices. The middle-large double-coateddog hair combing device includes a hair combing mechanism and a hair collecting mechanism. By the adoption of the middle-large double-coated dog hair combing device capable of preventing the hair fromflying, the problems are solved that because middle-large double-coated dogs are large in size and have bushy hair which is distributed in two layers, hair combing consumes time and power, and the hair flies when the hair of the middle-large double-coated dogs is combed; because the hair of the middle-large double-coated dogs lacks of care, bacteria breed and dirt is sheltered.

Owner:NANNING FUJIU INFORMATION TECH

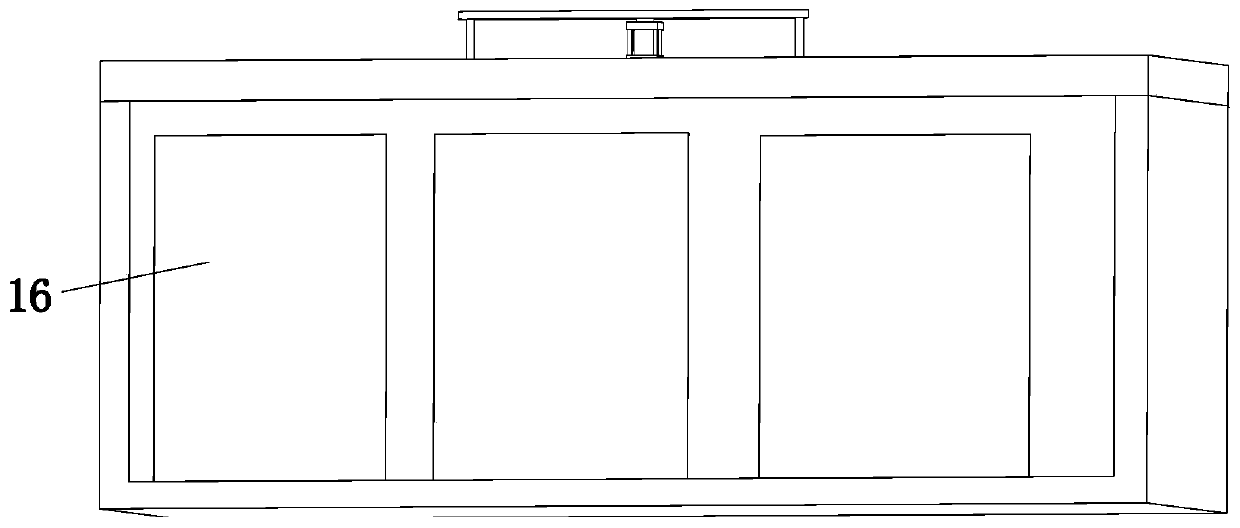

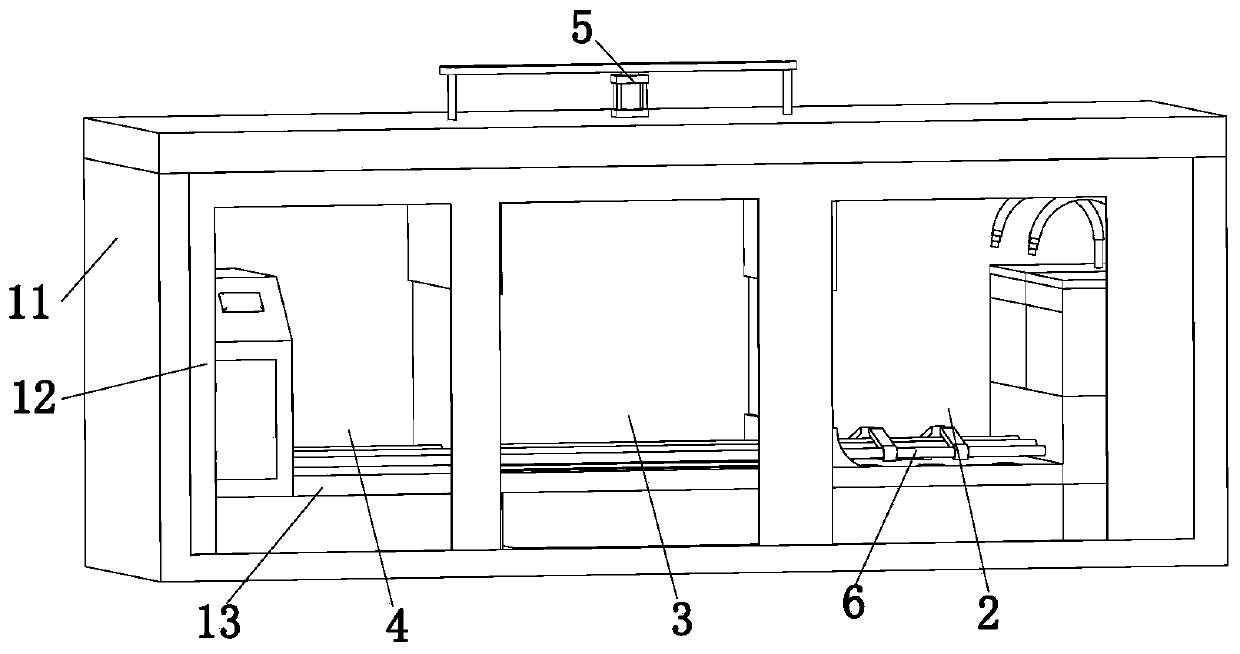

Tire cleaning and rubber spraying integrated machine

InactiveCN111531930AIncrease work rateSolve the dirtTyresDrying chambers/containersAutomotive engineeringAssembly line

The invention relates to the technical field of tire processing, and in particular to a tire cleaning and rubber spraying integrated machine. The tire cleaning and rubber spraying integrated machine comprises a machine case, a washing bin, a drying bin, a rubber spray bin, a closing device and a tire driving device; the machine case is arranged on the ground; the washing bin, the drying bin, the rubber spray bin, the closing device and the tire driving device are arranged inside the machine case; the washing bin, the drying bin and the rubber spray bin are sequentially arranged inside the machine case in the order of the movement direction of a tire; the closing device is connected with the top of the machine case; the tire driving device is arranged inside the machine case after penetrating through the cleaning bin, the drying bin, the rubber spray bin and the tire driving device so as to solve the problems about excessive waste of floor space during actual application of assembly line type tire cleaning and spraying operation as well as dirt on the ground and too much sewage caused by the assembly line type operation that requires frequent manual washing.

Owner:郑云龙

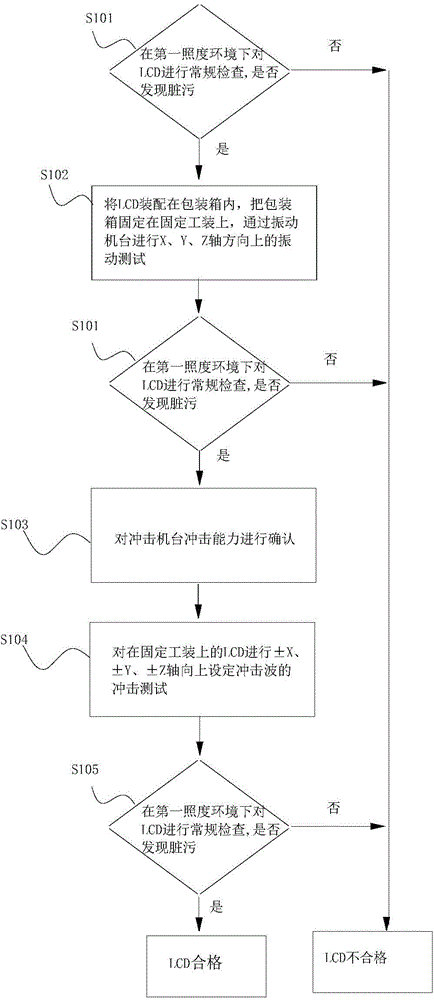

Testing method for finding out dirt and abnormality of LCD

InactiveCN104678599ASolve the dirtQuality assuranceNon-linear opticsImaging qualityMechanical impact

The invention provides a testing method for finding out dirt and abnormality of an LCD. The method comprises the steps of inspecting the general image quality; performing vibration testing, namely, assembling the LCD in a packing box, packing the LCD according to the LCD sealing packing box standard, and then performing the axial vibration testing in the set axial direction; inspecting the general image quality after each axial vibration testing; performing mechanical impact testing, namely, fixing the LCD on a fixed workpiece, fixing the fixed workpiece on an impact stand, and performing the impact stress testing for the set impact wave in the set axial direction; repeating the general image quality inspection after each axial impact stress test; inspecting the general quality image again; determining that the LCD is unqualified in case of dirt or chips, and otherwise, determining that the LCD is qualified. With the adoption of the method, the problems such as dirt and chips of the LCD after long-term transporting and use can be found out.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

Intelligent automatic threading numerical control linear cutting machine tool

PendingCN114393262ASolve the dirtSolve difficultyElectrical-based auxillary apparatusNumerical controlWire cutting

The invention discloses an intelligent automatic wire penetrating numerical control wire cutting machine tool, and relates to the technical field of wire cutting machine tools, the intelligent automatic wire penetrating numerical control wire cutting machine tool comprises a machine tool body, the machine tool body is provided with a wire winding cylinder, a wire pressing mechanism and a wire penetrating mechanism, an electrode wire is wound on the wire winding cylinder, and the wire penetrating mechanism comprises a lower wire frame, a limiting plate, a wire clamping moving chuck, a limiting frame, a first moving device, a wire connector, a needle leading wire and a connecting part. A water nozzle penetrates through the limiting plate, a needle leading wire is clamped through the wire clamping moving chuck, then the wire clamping moving chuck is driven through the first moving device, the needle leading wire can move towards the limiting frame and is finally clamped by the wire connector, and therefore a wire conveying closed loop is formed by the electrode wire, the wire connector, the connecting part and the wire winding barrel. When the needle guide wire is driven to the limiting frame by the wire clamping moving chuck and the first moving device, the needle guide wire correspondingly passes through a hole site in a workpiece, automatic wire threading of the workpiece is achieved, the problems encountered by manual wire threading are effectively avoided, the labor cost is effectively reduced, and the working efficiency is improved.

Owner:朱双全

Environment-friendly waterproof device for building construction project

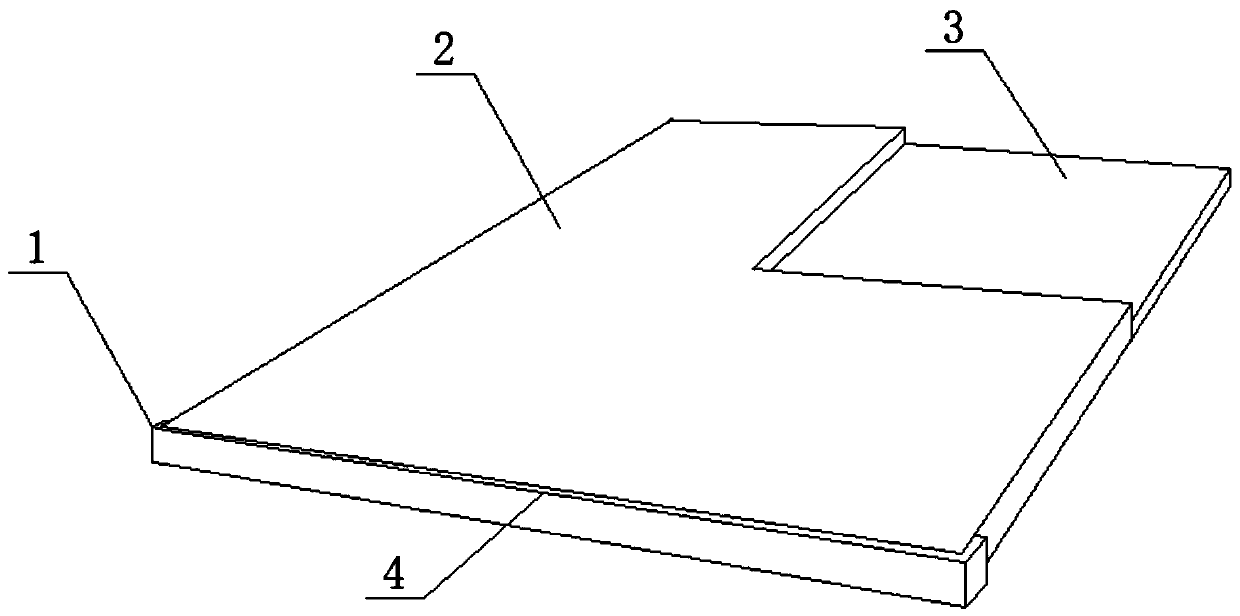

InactiveCN110056133AImprove sturdinessWon't breakRoof covering using flexible materialsRoof covering insulationsArchitectural engineeringHouse building

The invention discloses an environment-friendly waterproof device for a building construction project. The environment-friendly waterproof device for the building construction project comprises a plate body and a flanging, wherein the plate body is of a rectangular structure; the flanging is arranged on one side of the left end of the plate body; the flanging is arranged on one side where a wall surface is arranged; the plate body and the flanging are connected through hot melting; a wall body is arranged on the left side of the flanging; and a paving place is arranged at the lower end of theplate body. A structural plate can have better firmness under the action of a stiffening layer. According to the environment-friendly waterproof device for the building construction project, the surface of the plate body is coated with various coatings, a waterproof layer and an ultraviolet-proof layer are included, so that the function of the coatings on the surface of the plate body can be better promoted, and the surface of the plate body is prevented from being damaged due to the action of water through the waterproof layer, and dirt cannot adhere.

Owner:JIANGSU ZHENGWEI CONSTR

Automatic flushing device for toilet

ActiveCN101691778BSolve the disturbing problem of manual liftingSolve annoying problemsWater closetsFlushing devicesMechanical engineeringToilet

Owner:黄海盛

Portable combined erasing eraser

The invention provides a portable combined erasing eraser. An eraser head and a brush are arranged at the two ends of a portable rod correspondingly, and buckled sealing covers are arranged at the twoends in a matched manner. Therefore, the eraser for erasing pencil words can be conveniently stored and carried without contaminating and damaging the brush.

Owner:ZAOYANG NO 1 EXPERIMENTAL ELEMENTARY SCHOOL

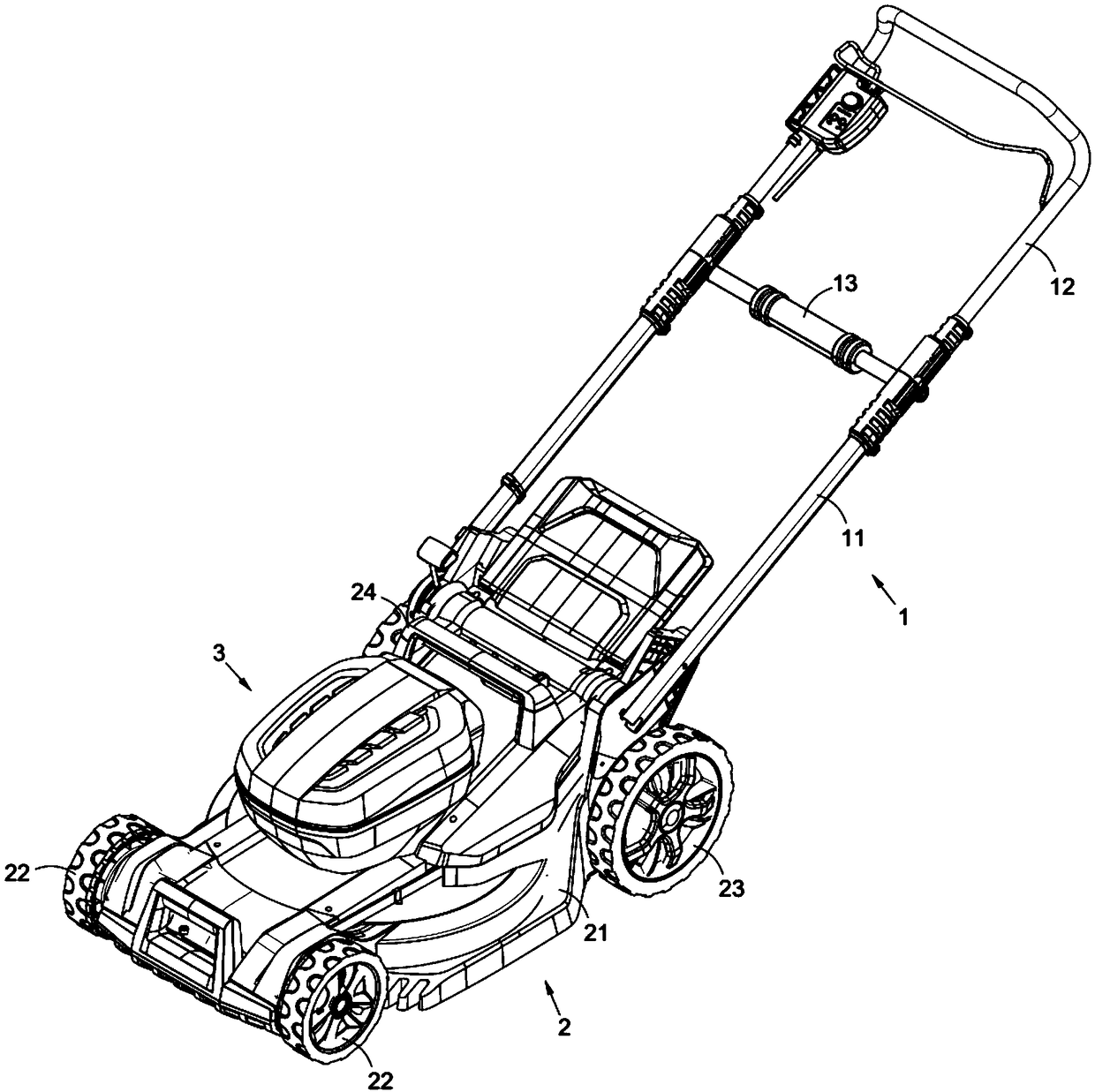

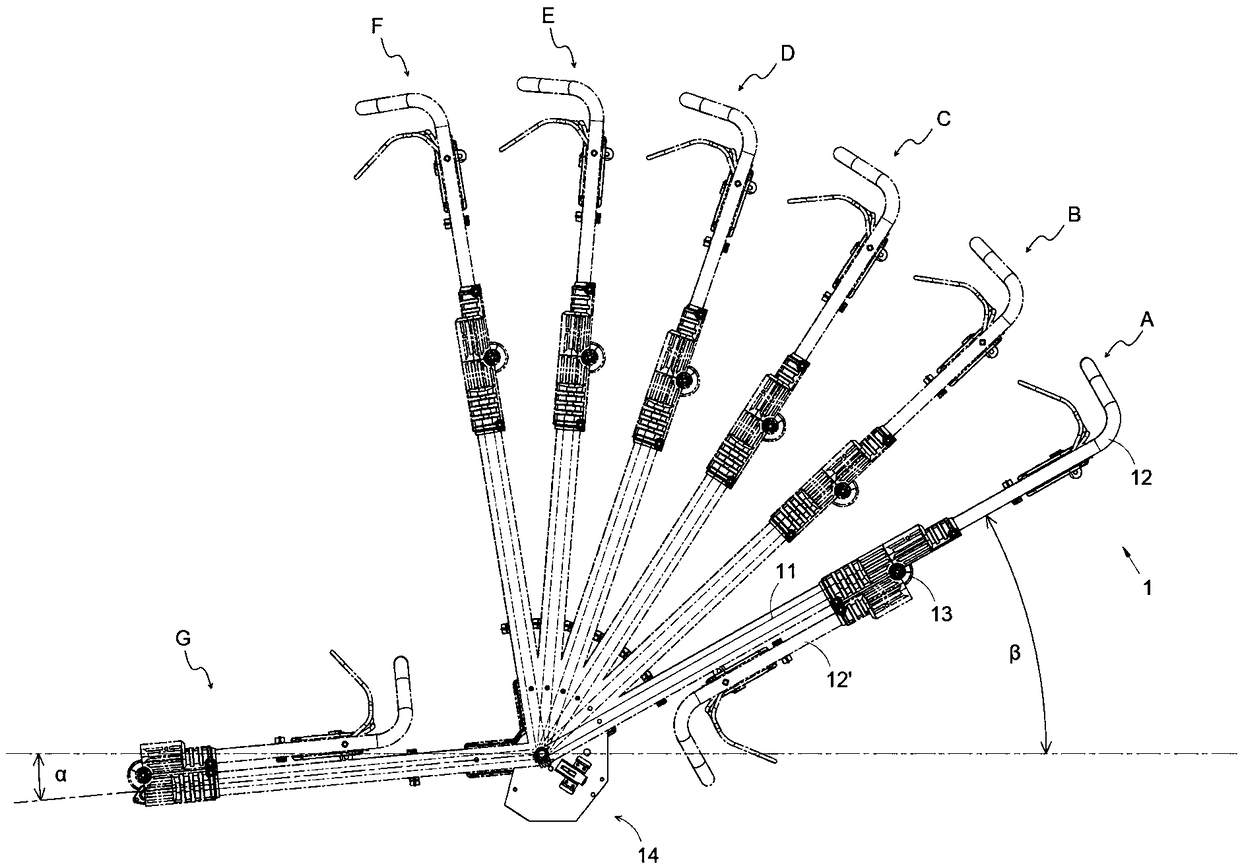

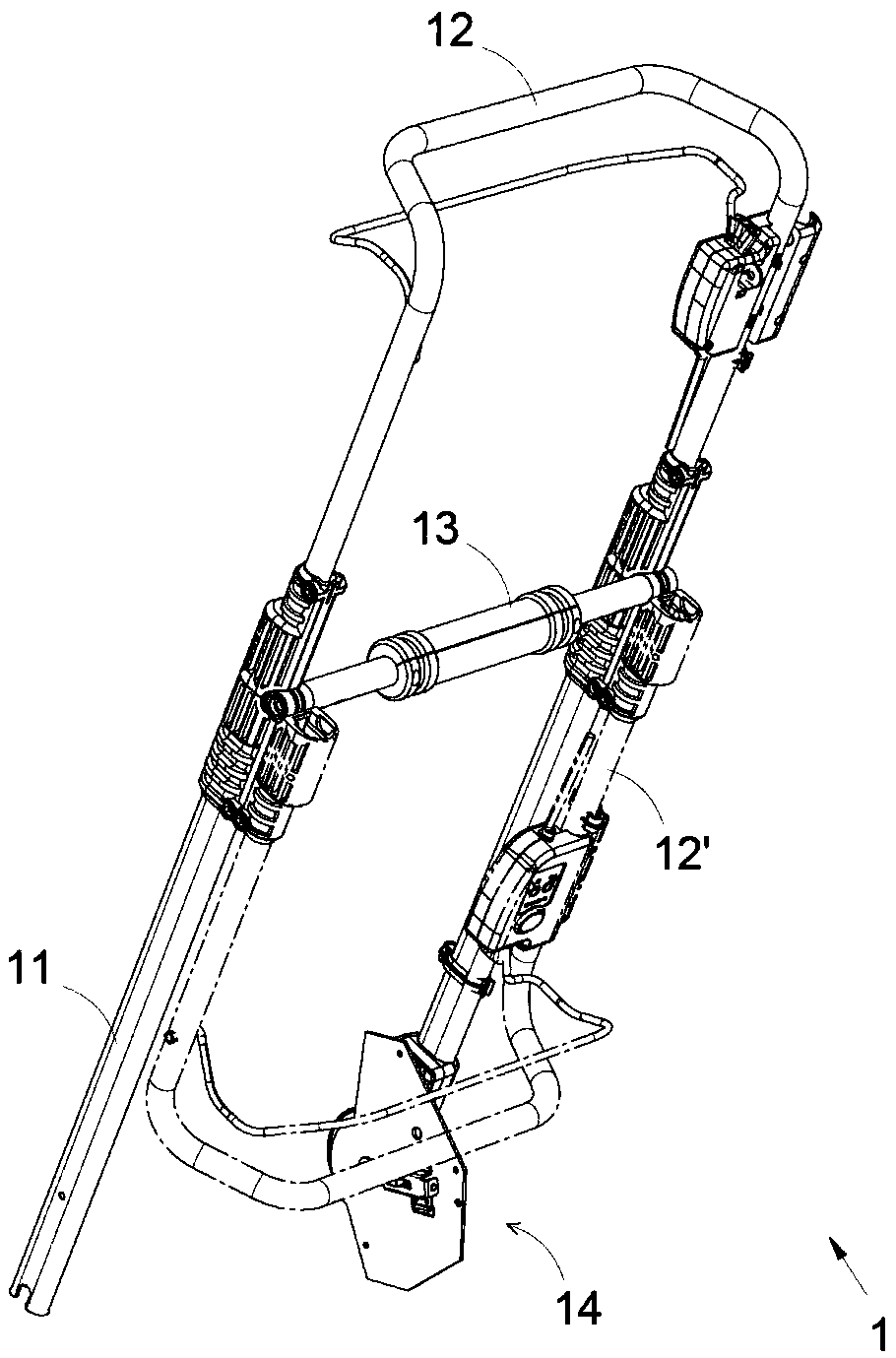

Electric lawn mower with functions of adjusting height and secondarily folding

PendingCN109392415AEnable connectivityAchieve unlockMowersAgricultural undercarriagesRotation - actionLocking mechanism

The invention discloses an electric lawn mower with the functions of adjusting height and secondarily folding, including a machine body, and a secondarily folding push hand rotatablely connected to the rear end of the machine body, wherein the machine body includes a shell, front wheels and back wheels respectively used for supporting the front and rear ends of the shell, a height-adjusting mechanism is arranged in the shell for adjusting the height of the machine body relative to ground, the secondarily folding push hand includes a gesture-locking mechanism fixedly connected with the rear endof the shell, a lower push rod with a root part connected with the gesture-locking mechanism, an upper push rod arranged on the top of the lower push rod, and a cross rod arranged between the upper push rod and the lower push rod, and when the upper push rod carries out reciprocating rotation action relative to the lower push rod and around the cross rod, the bottom of the upper push rod and thetop of the lower push rod are selectively clamped. The electric lawn mower disclosed by the invention is convenient to store by secondarily folding, and also can adjust the height of the machine bodyfrom the ground to adapt to different operational requirements.

Owner:SUZHOU KINGCLEAN PRECISION MACHINERY

Washing machine

PendingCN112127108AAvoid waterSolve the dirtOther washing machinesTextiles and paperLaundry washing machineWater flow

The invention provides a washing machine. The washing machine comprises an inner barrel capable of independently containing washing water in the washing process, and is characterized in that a barrelbottom protruding part protruding towards the interior of the inner barrel is assembled on the inner surface of the barrel bottom of the inner barrel in a sealed mode or integrally formed, and a drainage port is formed in the barrel bottom of the inner barrel; and the washing machine further comprises a drainage sealing device, and the drainage sealing device comprises a sealing mechanism capableof blocking and sealing the drainage port and a driving mechanism for driving the sealing mechanism to open / close the drainage port. According to the washing machine inner barrel, the barrel bottom protruding part protruding towards the interior of the inner barrel is assembled on the inner surface of the barrel bottom in a sealed mode or integrally formed, an impeller is omitted, the problem thatdirt is prone to being hidden between the impeller and the barrel bottom is solved, water flow and clothes are driven by the barrel bottom protruding part to move along with the barrel bottom protruding part to be washed / rinsed, and the clothes washing effect is guaranteed.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

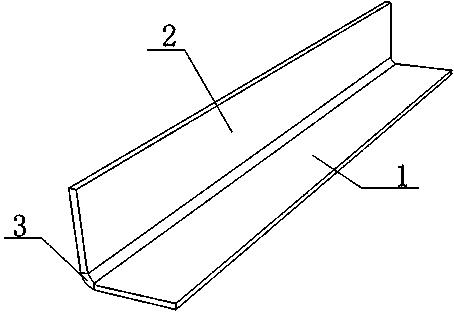

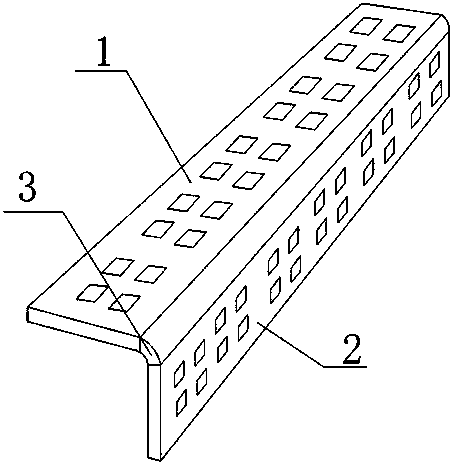

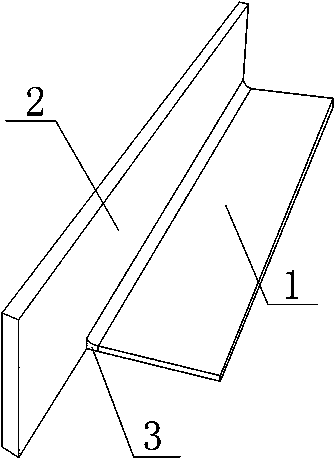

Right-angle foot line brick using method for buildings

InactiveCN104179330AEliminate gapsSolve the problem of water seepageBuilding constructionsBrickArchitectural engineering

The invention discloses a right-angle foot line brick using method for buildings. The right-angle foot line brick using method includes that a horizontal plate is vertically connected with a vertical plate, so that cracks between floor tiles of the ground and interior wall tiles of the wall space are removed in interior decoration, and problems of crack water seepage and dirt shelter are solved; the horizontal plate is connected with the vertical plate through an arc connection portion, and small angles between the horizontal plate and vertical plate are filled, so that cleaning tools can be used for cleaning the small angles optionally; meshes are arranged on the bottom surface, made of ceramic materials, of the horizontal plate and the reverse side of the vertical plate, and the meshes sunken inwards to form grooves, so that contact area of mortar and the plates is increased by the aid of the grooves, and firm connection of a right-angle foot line brick is facilitated; the right-angle foot line brick is simple in structure, convenient and practical and convenient to mount.

Owner:SICHUAN JINFENG CONSTR

Washing machine

PendingCN112127123AAvoid waterSolve the dirtOther washing machinesTextiles and paperLaundry washing machineControlled drainage

The invention provides a washing machine. The washing machine comprises an inner barrel capable of independently containing washing water in the washing process and a drainage sealing device, a drainage port is formed in the barrel bottom of the inner barrel, the drainage sealing device comprises a drainage mechanism and a sealing mechanism, the drainage mechanism is provided with a drainage channel communicating with the drainage port, and the sealing mechanism is installed in the drainage channel in an openable and closable mode. According to the washing machine, the drainage sealing deviceis adopted to achieve sealing and opening control over the drainage port of the non-porous inner barrel, the drainage sealing device comprises the drainage mechanism, water in the inner barrel can beguided into the internal drainage channel through the drainage port, and the sealing mechanism can achieve opening and closing control over the drainage channel, so that the drainage sealing device can serve as an independent module to be installed on the drainage port, sealing assembly of the drainage port does not need to be considered, and installation is easier and more convenient.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Oilless self-lubricating hinge and manufacturing method thereof

InactiveCN108729784AAvoid Dirty ProblemsGood self-lubricating performanceOther manufacturing equipments/toolsHingesEngineeringHardness

The invention discloses an oilless self-lubricating hinge and a manufacturing method thereof. A self-lubricating lining layer is arranged on the inner wall of a bearing of the hinge, and a mandrel penetrates through the self-lubricating lining layer. According to the manufacturing method of the oilless self-lubricating hinge, after a blade blank is manufactured, injection molding is performed on the blade blank on the inner wall of the bearing by adopting plastic with high hardness, high rigidity, high wear resistance and good self-lubricating performance so as to form the self-lubricating lining layer, and finally, a blade of the self-lubricating lining layer after injection molding is assembled with the mandrel so as to form the oilless self-lubricating hinge. According to the oilless self-lubricating hinge which is manufactured by adopting the manufacturing method of the technical scheme, the self-lubricating lining layer is formed in the bearing by injection molding, therefore, themetal mandrel cannot make direct contact with the metal bearing so as not to wear, thus, lubricating oil does not need to be added, so that the problem of dirty caused by oil leakage is avoided, andadditionally, the self-lubricating lining layer has good self-lubricating performance, so that the service life of the hinge is long.

Owner:傅光

Hard disk magnetic head installation dispensing frame

ActiveCN103212522BImprove positioning accuracyImprove work efficiencyLiquid surface applicatorsCoatingsFixed frameEngineering

The invention provides a hard disc magnetic head mounting and dispensing rack. Supporting lug bosses are arranged at the two sides of a base; the supporting lug bosses are provided with rotary discs through vertical central rotary shafts; the centers of the rotary discs are provided with product holes which are uniformly distributed at intervals; a washing frame for fixing products are arranged above the product holes and is provided with product fixing frames with the same quantity as that of the product holes and the product fixing frames are distributed rightly above the product holes; one sides of the rotary lug bosses are provided with a single-phase overturning type protective cover for fixing the washing frame through the lug bosses; the protective cover is provided with working holes with the same quantity as that of the product holes, wherein the working holes are distributed in a manner of penetrating through the product fixing frames; and the other sides of the rotary discs are provided with an elbow clamping device for clamping the protective cover. According to the rotary discs disclosed by the invention, forward and backward work of products can be realized and the working efficiency is accelerated; the washing frame can fix a plurality of the products for one time to operate at the same time and the exchanging time of the product is reduced, so that the working efficiency is accelerated; and meanwhile, only the washing agent needs to be washed so that the hard disc magnetic head mounting and dispensing rack is convenient and fast to wash.

Owner:SUZHOU KAIFA TECH CO LTD

A large-scale dry-raised egg duck farm

The invention provides a large-scale dry-raised duck farm, which belongs to a design of duck house, including a first duck farm, a second duck farm and a feeding and drinking area. The first duck farm and the second duck farm have the same structure. The feeding and drinking area is set between the first duck farm and the second duck farm, and the first duck farm and the second duck farm are symmetrically arranged relative to the feeding and drinking area; the first duck farm includes duck houses and a land sports field, and the land sports field is located at Between the feeding and drinking area and the duck house, one end of the feeding and drinking area and one end of the duck house, and the other end of the feeding and drinking area and the other end of the duck house are connected by walls, and there are water sports fields in the land sports fields adjacent to the walls on both sides. The structure of the duck farm is reasonable, and the feeding, drinking water, and egg-laying areas are divided into partitions, which reduces the humidity in the duck house, reduces the incidence of duck diseases and dirty eggs, improves feed utilization, and prolongs the egg-laying time and egg-laying level of laying ducks. , increase egg production, effectively solve the problem of dirty eggshells, increase the efficiency of duck farming, and save investment in drinking water equipment.

Owner:HENAN UNIV OF ANIMAL HUSBANDRY & ECONOMY

Discharge separation and concentrated transportation device of punching machine

PendingCN113414269AFully automatedSolve the dirtMetal-working feeding devicesStripping-off devicesPunchingStructural engineering

The invention relates to a discharge separation and concentrated transportation device of a punching machine,which comprises a cleaning module and a storage module, the cleaning module comprises a first base and independent task units, the first base is provided with a plurality of long-strip-shaped through holes, each through hole is correspondingly provided with one independent task unit, and each independent task unit is divided into a clamping assembly and a wiping assembly; each clamping assembly comprises power mechanisms and telescopic mechanisms, the front wall and the rear wall in the through hole are each provided with one power mechanism, each power mechanism is provided with one telescopic mechanism, and the telescopic mechanisms are driven by the power mechanisms to do lifting motion in the through holes; the wiping assembly comprises outer box bodies, a support plate, a wiping plate and sliding mechanisms, each through hole corresponds to one outer box body, the sliding mechanisms are arranged in the length direction of the through holes, each outer box body is provided with two sliding mechanisms, and the wiping plate covers the inner wall of the support plate; and the storage module comprises a storage box body which is arranged below the first base.

Owner:青岛瑞利杰金属有限公司

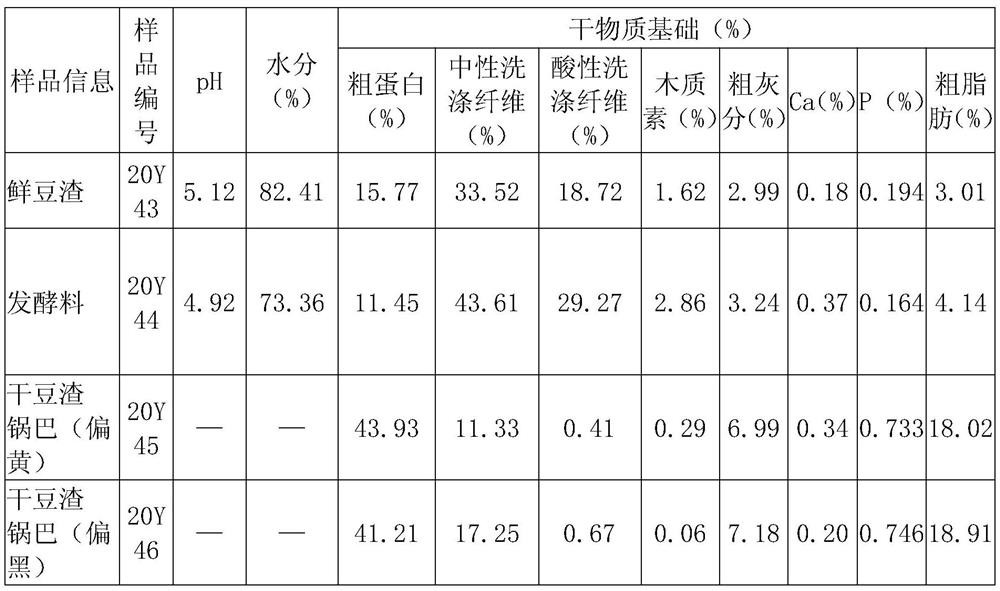

Method for fattening beef cattle by using bean dregs and bagasse

PendingCN114097942ANo longer causes diarrheaReduce inhibitor contentFood processingAnimal feeding stuffFodderFeed additive

A method for fattening beef cattle by using bean dregs and bagasse comprises the following steps: weighing 3-4 parts by weight of bagasse and 6-7 parts by weight of bean dregs, and adding 0.1% by mass of oligosaccharide feed additive for livestock and poultry and 0.1% by mass of gold source microbial additive to obtain a mixture; putting the mixture into a storage tank, rolling and treading, sealing and covering, and carrying out anaerobic fermentation; storing for at least 15 days to obtain a fermented material; laying bagasse padding with the thickness of 80-90 cm on a cattle bed, and burning the bagasse padding into ash after the bagasse padding is used for 3 months to obtain plant ash; and taking out the fermented material, adding 5% of plant ash according to the mass ratio, and uniformly stirring to obtain the beef cattle feed which is used for fattening beef cattle. The bean dregs and the bagasse are fully utilized, the beef cattle fattening cost is low, and the fattening effect is good.

Owner:红河哈尼族彝族自治州畜牧技术推广站

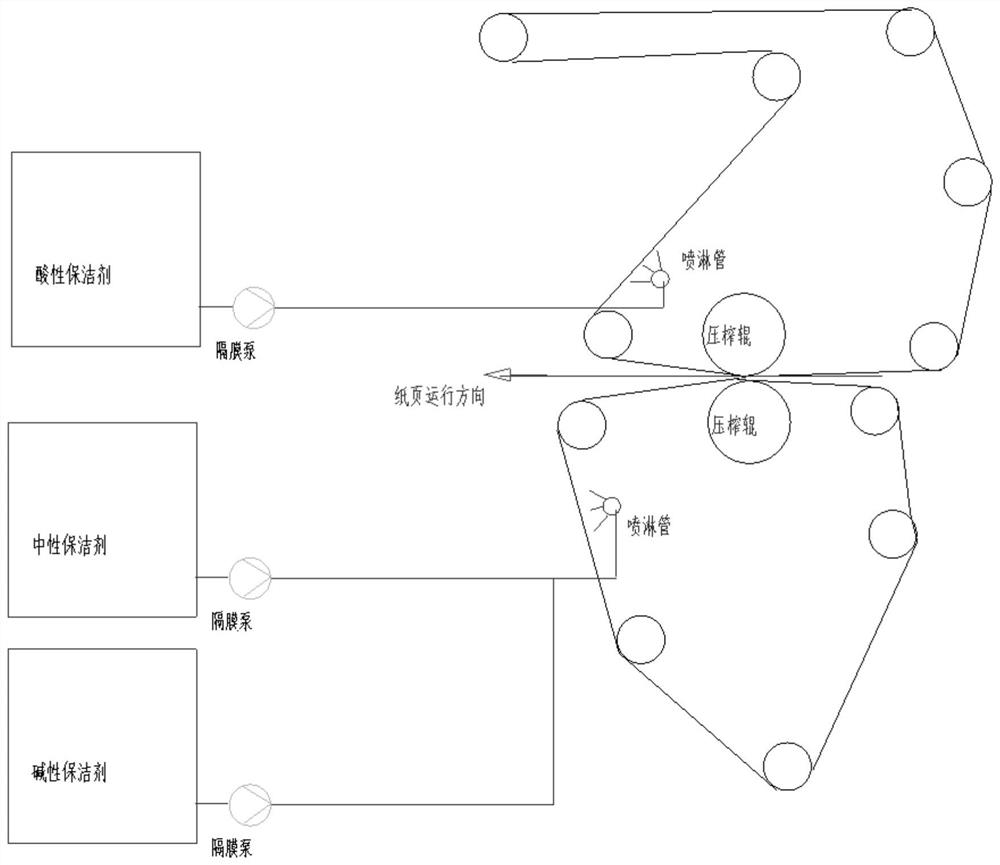

A kind of preparation technology of white flour kraft paperboard

The invention provides a woolen cloth cleaning process for producing white-faced kraft paper. The process is characterized in that a first cleaning agent is used for cleaning upper woolen cloth, a second cleaning agent is used for cleaning lower woolen cloth, and a third cleaning agent is intermittently used for cleaning the lower woolen cloth. The process can effectively solve the contamination problem of the upper and lower woolen cloth, organic and inorganic pollutants accumulated in the woolen cloth are removed, and the porosity and absorbability of the woolen cloth are improved, so that the dewatering performance of the woolen cloth is improved.

Owner:DONGGUAN NINE DRAGONS PAPER IND

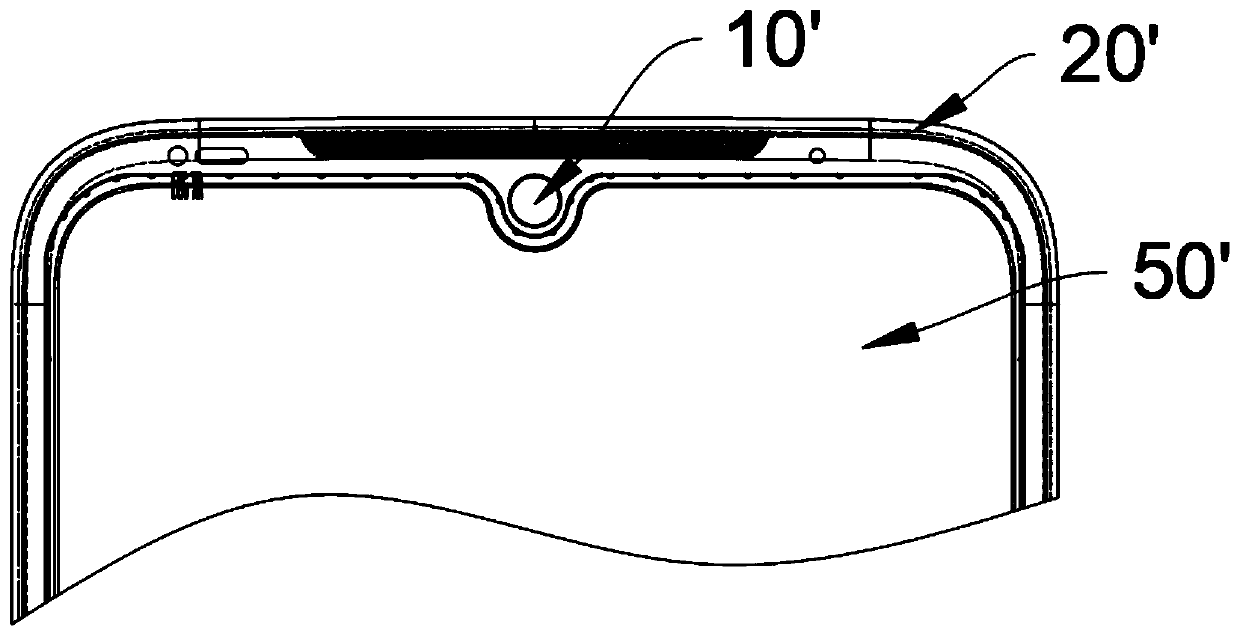

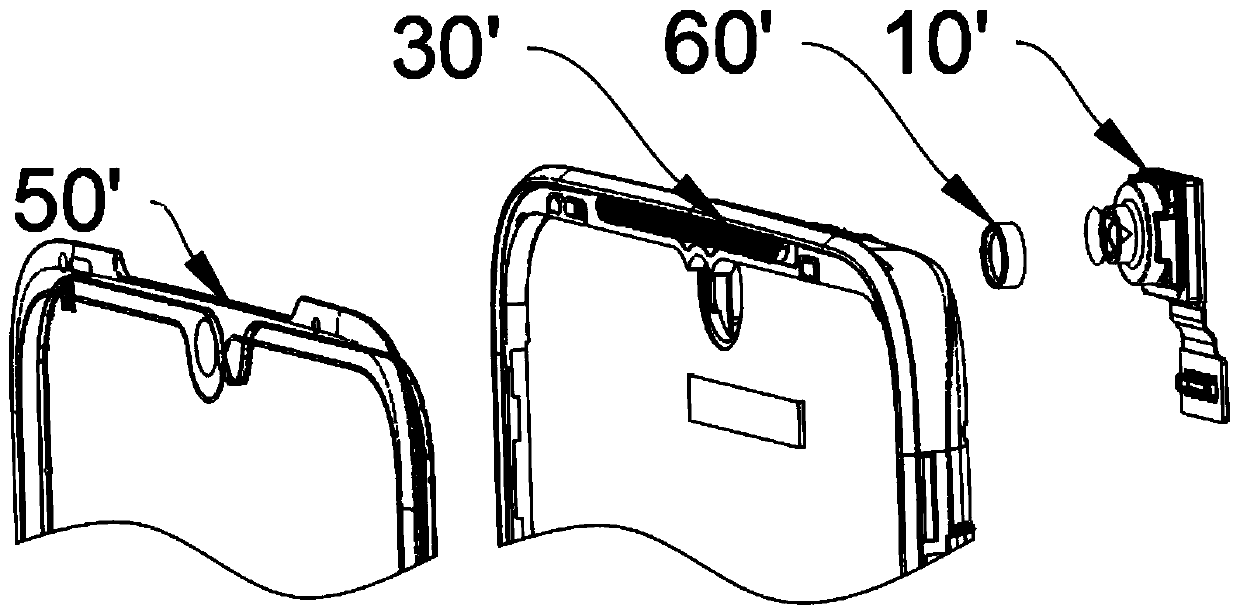

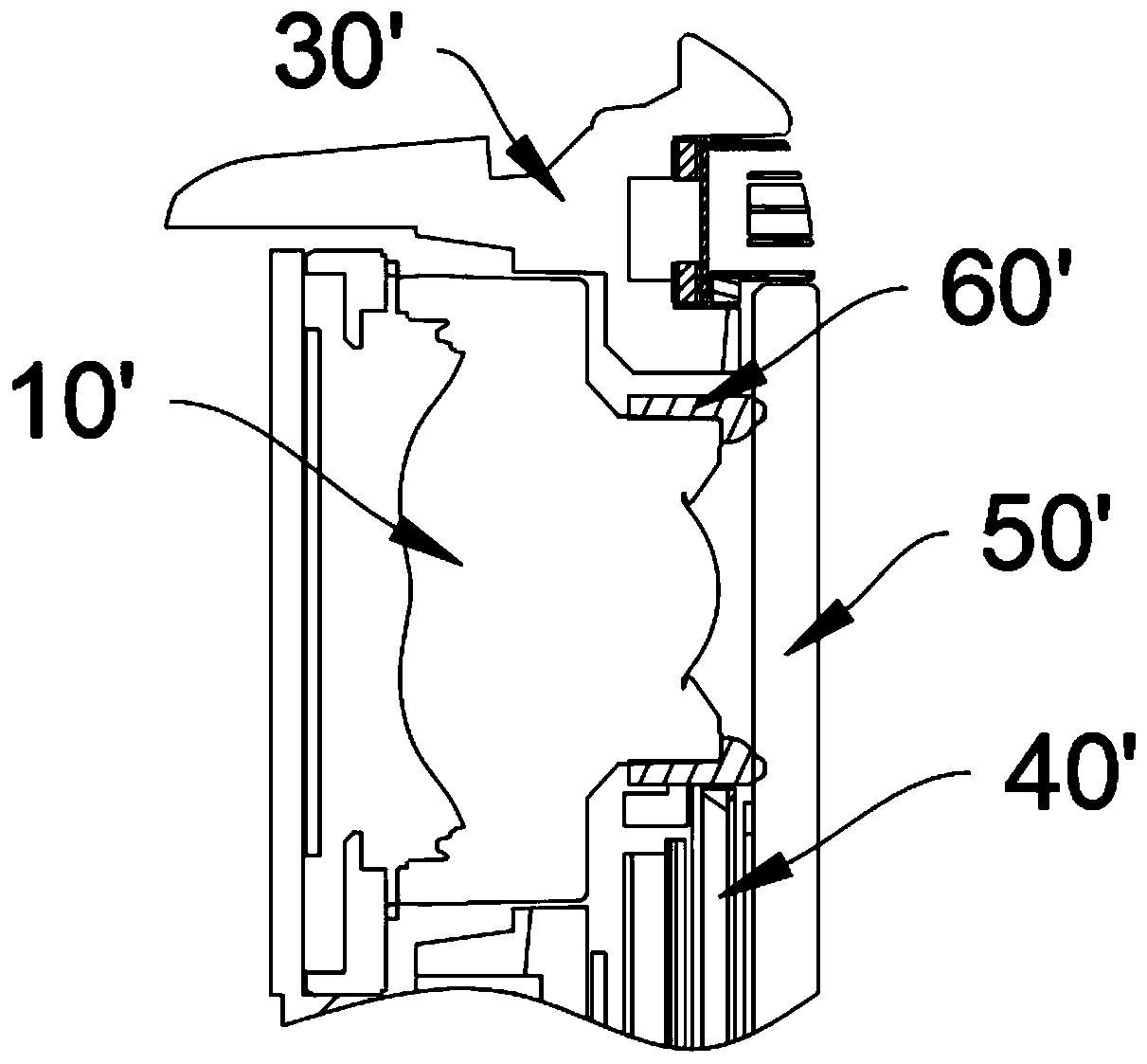

Mobile terminal

ActiveCN110545344ASolve the dirtSolve scrapTelephone set constructionsComputer terminalCamera module

The invention discloses a mobile terminal, which comprises a sealing element, a camera module and a display screen. The sealing element is sleeved at the rear end of the camera module, and the displayscreen is arranged close to the front end of the camera module. According to the mobile terminal provided by the invention, the display screen is arranged close to the front end of the camera modulethrough the rear sealing element, so that the screen-to-body ratio is improved to the maximum extent. Meanwhile, the sealing element avoids the front end of the camera module and correspondingly avoids the display screen, so that the problems of white spots, light leakage, breakage and the like of the display screen caused by deformation of the sealing element are solved.

Owner:HUAQIN TECH CO LTD

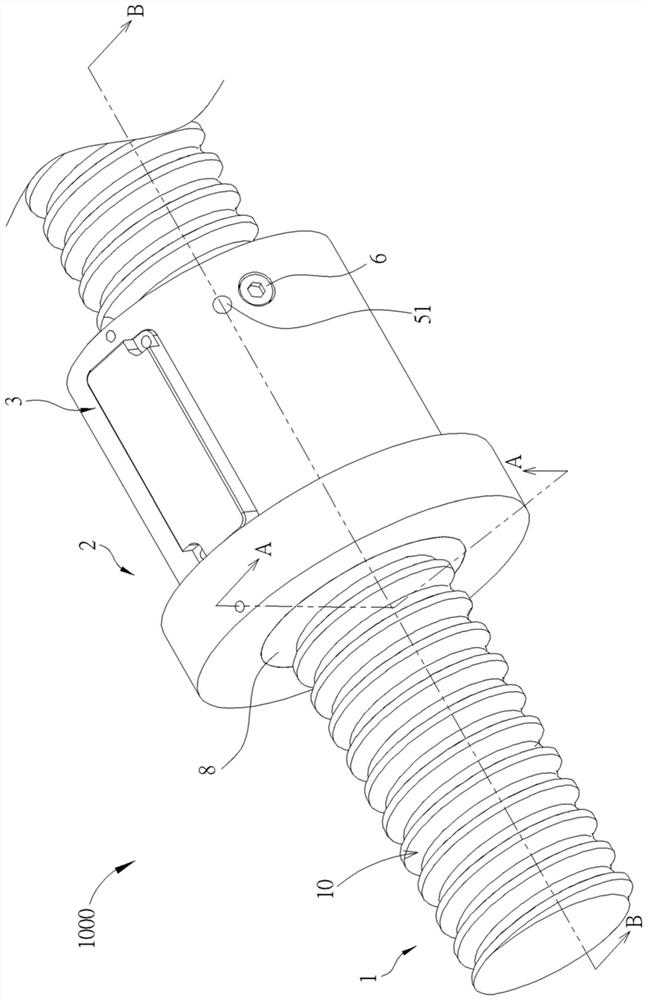

Transmission with monitoring function

ActiveCN113048206BSolve the dirtImprove accuracyGearingGear lubrication/coolingTooth segmentMonitoring features

Owner:HIWIN TECH

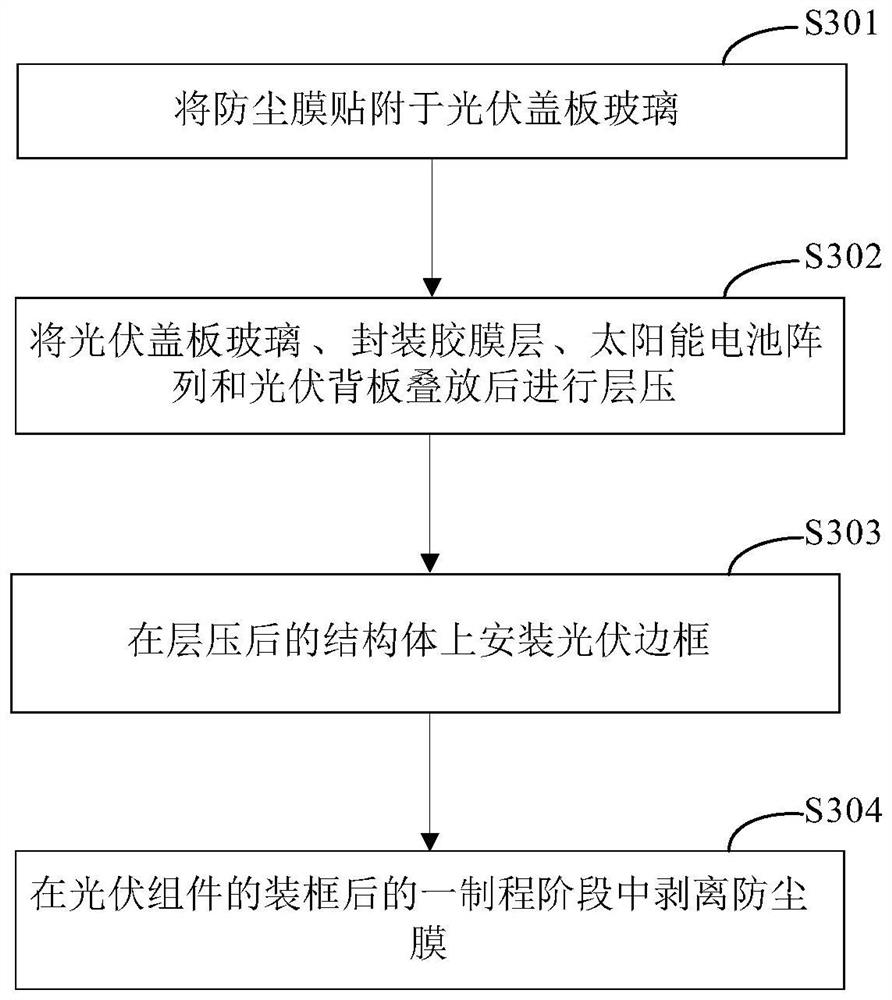

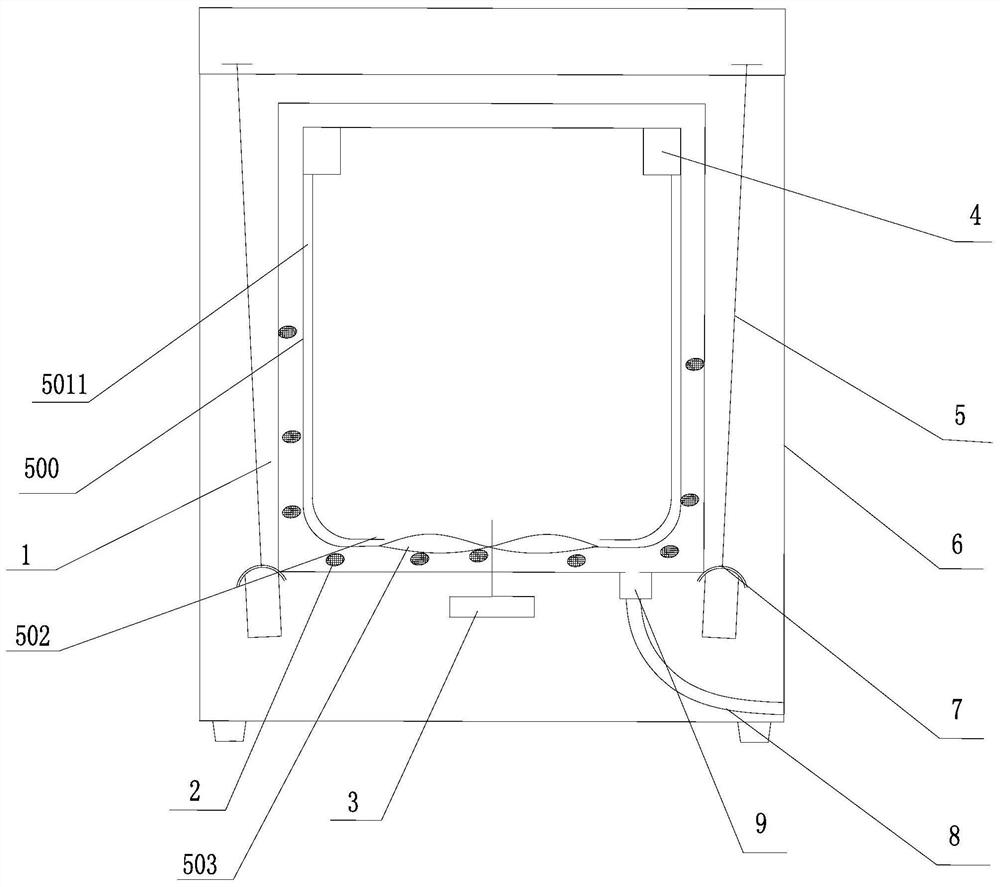

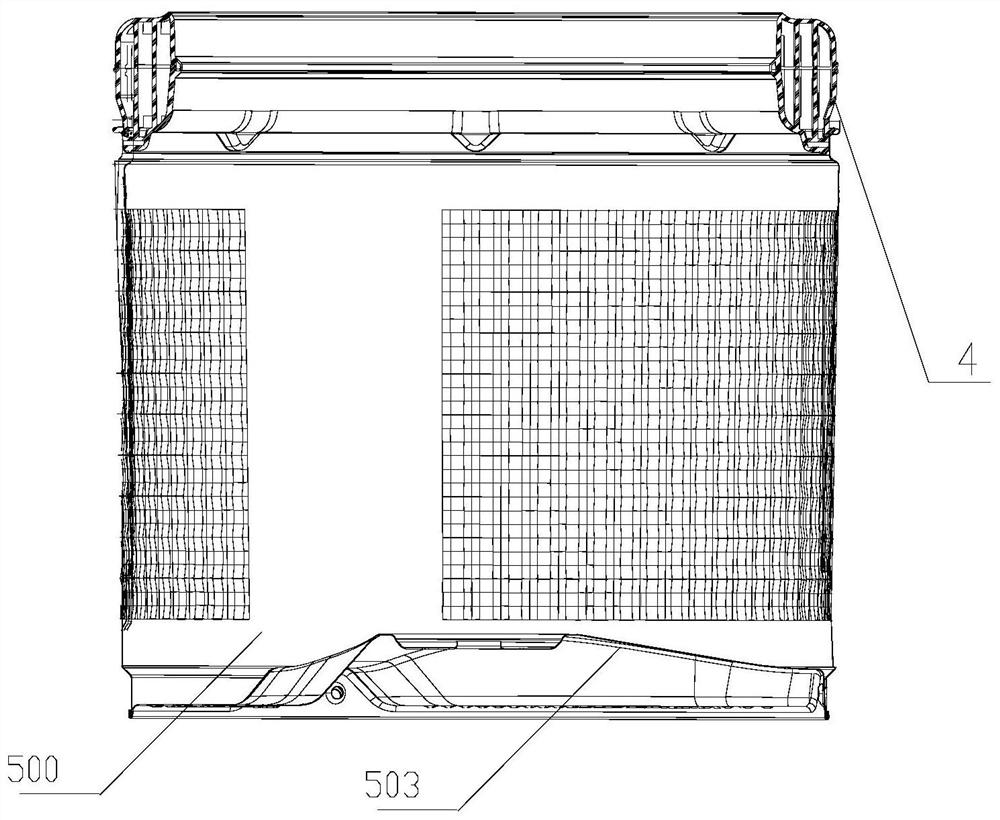

Dustproof film, photovoltaic module glass and use method

PendingCN114335217ASolve the dirtSave time and costArticle unpackingPhotovoltaic energy generationPolyurethane elastomerAssembly line

The invention discloses a dustproof film, photovoltaic module glass and a use method. The dustproof film comprises a dustproof layer and a polyurethane elastomer bonding layer arranged on the dustproof layer. When the dustproof film is applied to the photovoltaic glass transportation process, the problem of smudginess in the photovoltaic glass transportation process can be solved, and the glass feeding time and the transportation cost are saved. When the dustproof film is applied to photovoltaic module manufacturing, the problem of smudginess of photovoltaic module glass in the manufacturing process can be solved, and the product yield is improved; the cleaning period of equipment such as a laminating machine and an assembly line can be prolonged, the cleaning time before the photovoltaic module is delivered is shortened, and the manufacturing cost of the photovoltaic module is further greatly reduced.

Owner:HEFEI & SOLAR TECH +1

Washing machine

PendingCN112127103ASolve the dirtRealize no-cleanOther washing machinesTextiles and paperLaundry washing machineWater flow

The invention belongs to the technical field of washing equipment, and particularly relates to a washing machine. The washing machine comprises an outer barrel, an inner barrel, a water stirring structure and a cleaning device, wherein the water stirring structure is integrally arranged on the inner bottom wall of the inner barrel; and the cleaning device is arranged between the outer barrel and the inner barrel, and the cleaning device acts along with water flow to clean the inner side of the outer barrel or / and the outer side of the inner barrel. According to the washing component of the washing machine, the whole washing component is free of cleaning, manual dismounting is not needed, trouble is saved, convenience is achieved, and cleanliness and sanitation are achieved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

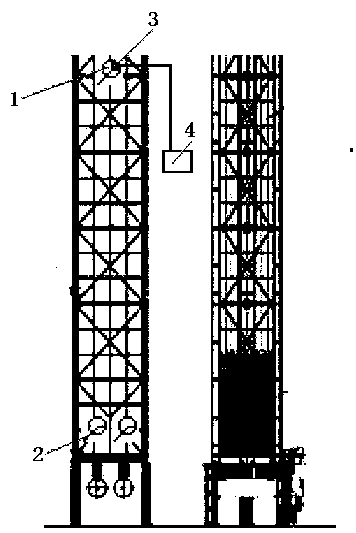

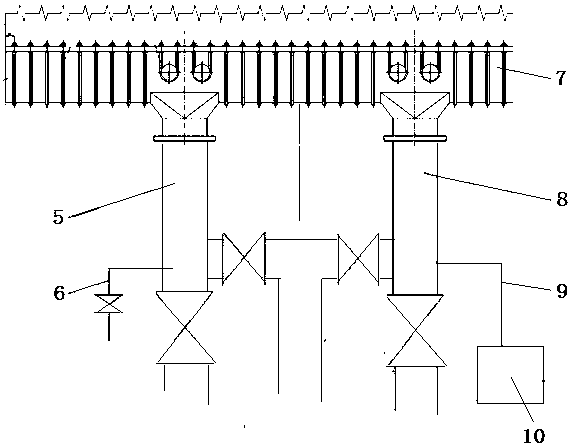

Cleaning device and optimized operation method for monitoring and cleaning the degree of dirt and corrosion inside the cooling triangular heat exchanger of the indirect air-cooled island

ActiveCN106440928BImprove heat transfer efficiencyExtended service lifeFlush cleaningEngineeringPollution

The invention relates to an internal dirt and corrosion degree monitoring and cleaning device for a cooling triangle heat exchanger of an indirect air-cooling island and an optimized running method. At present, problems of large difficulty in monitoring of the corrosion degree and cleaning of internal dirt during long-term running of the cooling triangle heat exchanger of the indirect air-cooling island are difficult to solve. The device comprises a water supply pipe, the cooling triangle heat exchanger of the indirect air-cooling island and a water return pipe and is characterized by further comprising cleaning brushes, a water drainage pipeline, a water inlet pipeline, a pulsed gas-water two-phase flow cleaning device and probes; a squint window is arranged on the cooling triangle heat exchanger of the indirect air-cooling island; the cleaning brushes are connected onto the squint window; the probes are mounted on the cooling triangle heat exchanger of the indirect air-cooling island; the pulsed gas-water two-phase flow cleaning device is connected with the water inlet pipeline; the water inlet pipeline is connected with the water return pipe; and the water supply pipe communicates with the water return pipe through a pipeline. With the device, the problems of large difficulty in monitoring of the corrosion degree and cleaning during long-term running of aluminum pipes and aluminum fins of the cooling triangle heat exchanger of the indirect air-cooling island can be solved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com