Testing method for finding out dirt and abnormality of LCD

A technology for abnormal testing and contamination, applied in nonlinear optics, instruments, optics, etc., it can solve the problem of no testing method that can find LCD contamination and debris, and achieve the effect of meeting the requirements of use and ensuring the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0019] Embodiment of the test method for finding abnormal LCD dirt

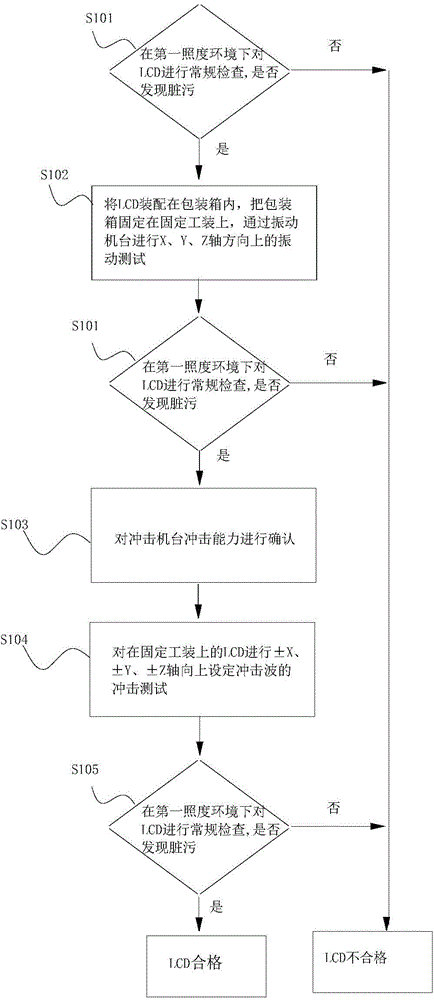

[0020] see figure 1 , a kind of method of testing that finds that LCD is dirty abnormally, it comprises the steps:

[0021] Step S101 : routine image quality inspection: put the LCD to be tested under the environment of the first illuminance, and detect whether there are any abnormalities such as dirt and debris. If dirt or debris is found, it is judged that the LCD is unqualified, otherwise, the LCD is judged to be a qualified product, and the inspection status is recorded. In this embodiment, the first illuminance is 200 lux. The purpose of designing this step is to confirm the status before the LCD test and ensure the validity of the test.

[0022] Step S102: Vibration test: Assemble th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com