Dustproof film, photovoltaic module glass and use method

A photovoltaic glass and photovoltaic module technology, applied in photovoltaic power generation, electrical components, unpacking of objects, etc., to achieve the effect of reducing manufacturing costs, saving transportation costs, and solving contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

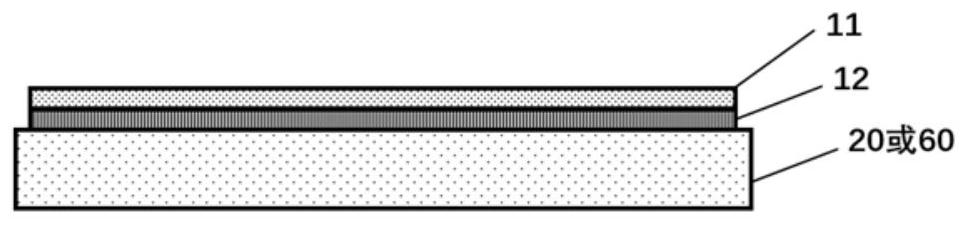

[0070] The dustproof film comprises a PET dustproof layer and a polyurethane elastomer bonding layer, wherein the thickness of the PET dustproof layer is 50 μm, and the thickness of the polyurethane elastomer bonding layer is 20 μm. Both the PET dustproof layer and the polyurethane elastomer bonding layer are made of transparent materials, which will not affect the appearance inspection effect of the photovoltaic module.

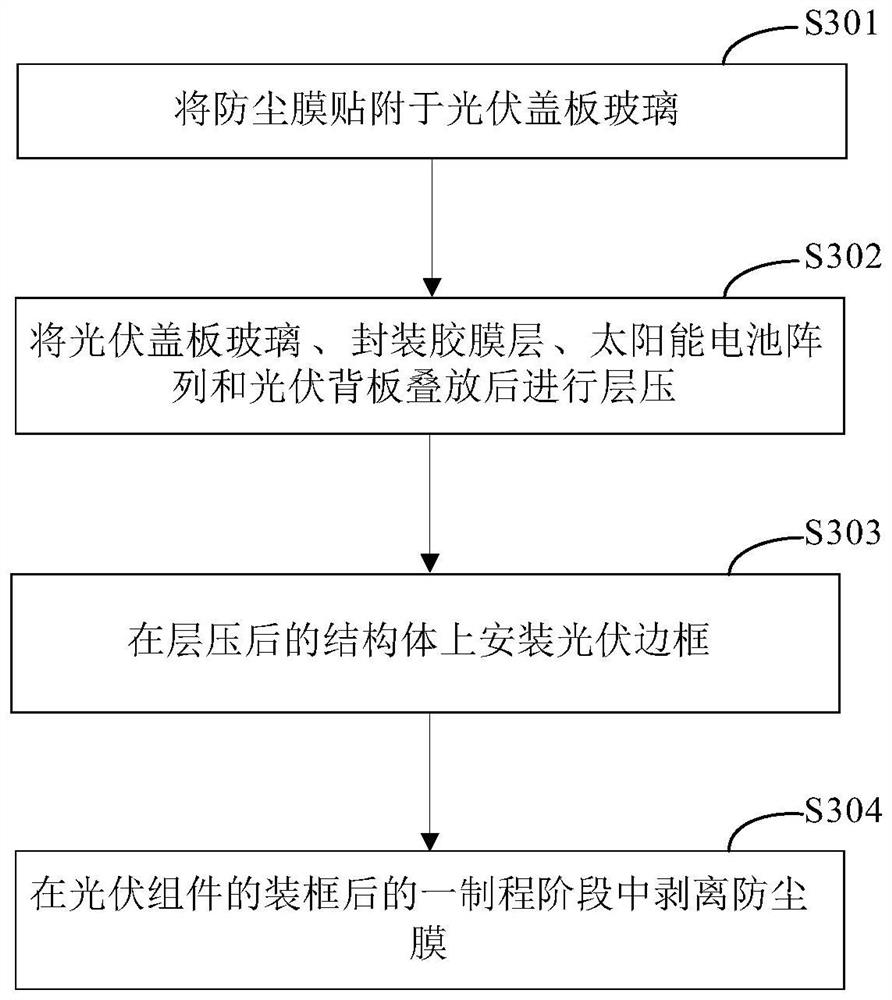

[0071] The use methods of dust film include:

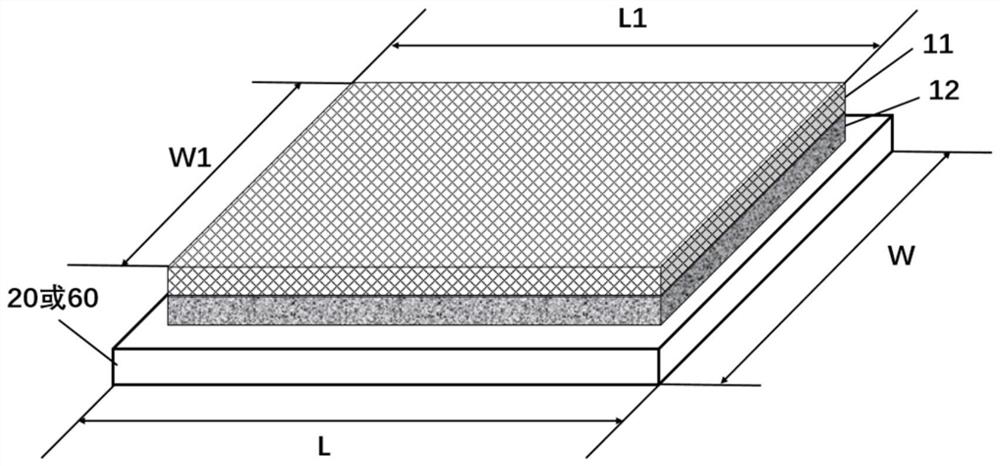

[0072] S1: Attach the dust-proof film 10 to the photovoltaic glass 20 in the center; (L-L1)≥2×H, (W-W1)≥2×H1;

[0073] S2: Laminate the photovoltaic cover glass 20 covered with the dustproof film 10, the encapsulation film layer 30, the solar cell array 40 and the photovoltaic backplane 50, and then install the photovoltaic frame 70;

[0074] S3: The dustproof film 10 is peeled off in the cleaning stage after the I-V test of the photovoltaic module.

[0075]In this embodiment, the area covered by the photovolt...

Embodiment 2

[0077] The dustproof film comprises a PET dustproof layer and a polyurethane elastomer bonding layer, wherein the thickness of the PET dustproof layer is 10 μm, and the thickness of the polyurethane elastomer bonding layer is 10 μm. Both the PET dustproof layer and the polyurethane elastomer bonding layer are made of transparent materials, which will not affect the appearance inspection effect of the photovoltaic module.

[0078] The use methods of dust film include:

[0079] S1: Attach the dustproof film 10 in the center to the photovoltaic glass 20 and the photovoltaic backplane glass 60, (L-L1)≥2×H, (W-W1)≥2×H1;

[0080] S2: Laminate the photovoltaic cover glass 20 covered with the dustproof film 10, the encapsulation film layer 30, the solar cell array 40 and the photovoltaic backplane glass 60, and then install the photovoltaic frame 70;

[0081] S3: The dustproof film 10 is peeled off in the cleaning stage after the I-V test of the photovoltaic module.

[0082] In this...

Embodiment 3

[0084] The dustproof film comprises a PET dustproof layer and a polyurethane elastomer bonding layer, wherein the thickness of the PET dustproof layer is 50 μm, and the thickness of the polyurethane elastomer bonding layer is 20 μm. Both the PET dustproof layer and the polyurethane elastomer bonding layer are made of transparent materials, which will not affect the appearance inspection effect of the photovoltaic module.

[0085] The use methods of dust film include:

[0086] S1: Attach the dust-proof film 10 to the photovoltaic glass 20 in the center, (L-L1)≤2×H, (W-W1)≤2×H1;

[0087] S2: Laminate the photovoltaic cover glass 20 covered with the dustproof film 10, the encapsulation film layer 30, the solar cell array 40 and the photovoltaic backplane 50, and then install the photovoltaic frame 70;

[0088] S3: The dustproof film 10 is peeled off in the cleaning stage after the I-V test of the photovoltaic module.

[0089] In this embodiment, the areas on the surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com