A kind of preparation technology of white flour kraft paperboard

A kraft paperboard and process technology, applied in the field of papermaking, can solve the problems of poor dirt removal effect of calcium carbonate, affecting the dehydration effect of paper, and high content of sticky matter, so as to reduce steam consumption, improve porosity and absorption The effect of improving dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

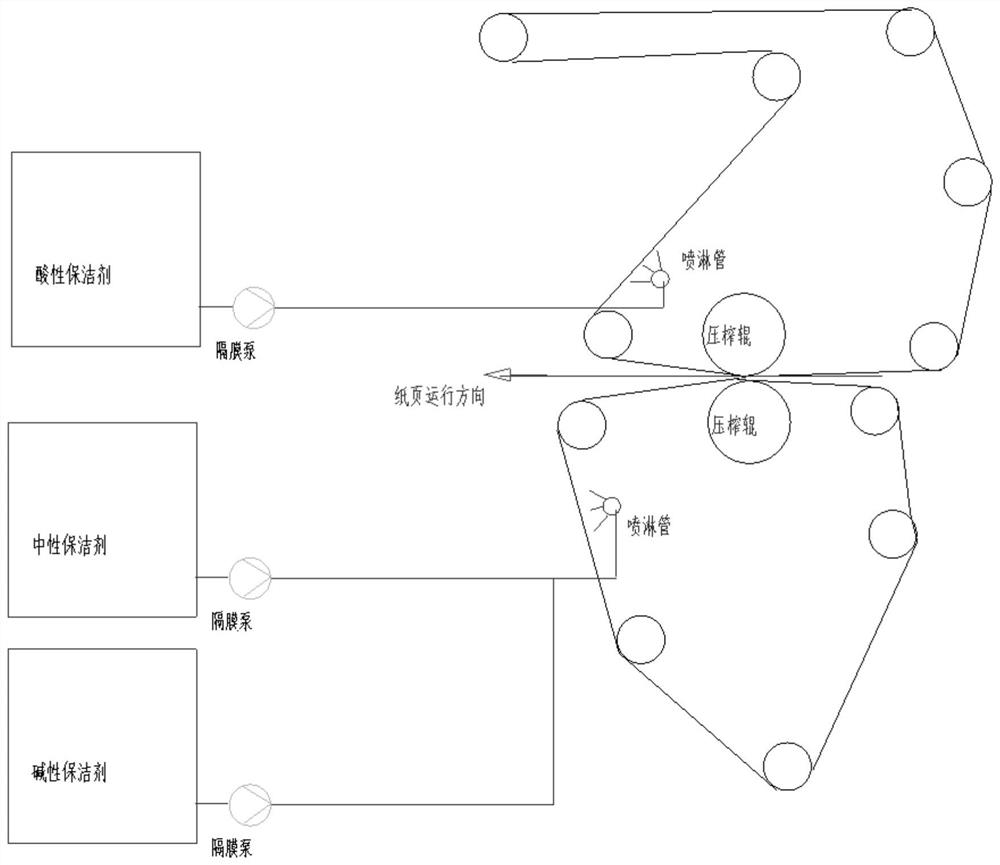

[0032] The present embodiment provides a felt cleaning process for producing white-faced kraft cardboard, the process is:

[0033] Clean the upper felt with an acidic cleaner at a rate of 30mL / min, and clean the lower felt with a neutral cleaner at a rate of 25mL / min, and intermittently use an alkaline cleaner at a rate of 40mL / min amount, every 2 hours, and wash the lower felt for 2 hours each time.

Embodiment 2

[0035] The present embodiment provides a felt cleaning process for producing white-faced kraft cardboard, the process is:

[0036] Clean the upper felt with an acidic cleaner at a rate of 50mL / min, and clean the lower felt with a neutral cleaner at a rate of 35mL / min, and intermittently use an alkaline cleaner at a rate of 60mL / min amount, every 5 hours, and wash the lower felt for 2 hours each time.

Embodiment 3

[0038] The present embodiment provides a felt cleaning process for producing white-faced kraft cardboard, the process is:

[0039] Clean the upper felt with an acidic cleaner at a rate of 40mL / min, and at the same time use a neutral cleaner at a rate of 30mL / min to clean the lower felt, and intermittently use an alkaline cleaner at a rate of 50mL / min amount, every 3 hours, and wash the lower felt for 1 hour each time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com