Oilless self-lubricating hinge and manufacturing method thereof

A manufacturing method and self-lubricating technology, applied in other manufacturing equipment/tools, manufacturing tools, folding boards, etc., can solve the problems of tilting doors and windows, dirty hinges, sagging, etc., to avoid contamination problems and long service life , the effect of good self-lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

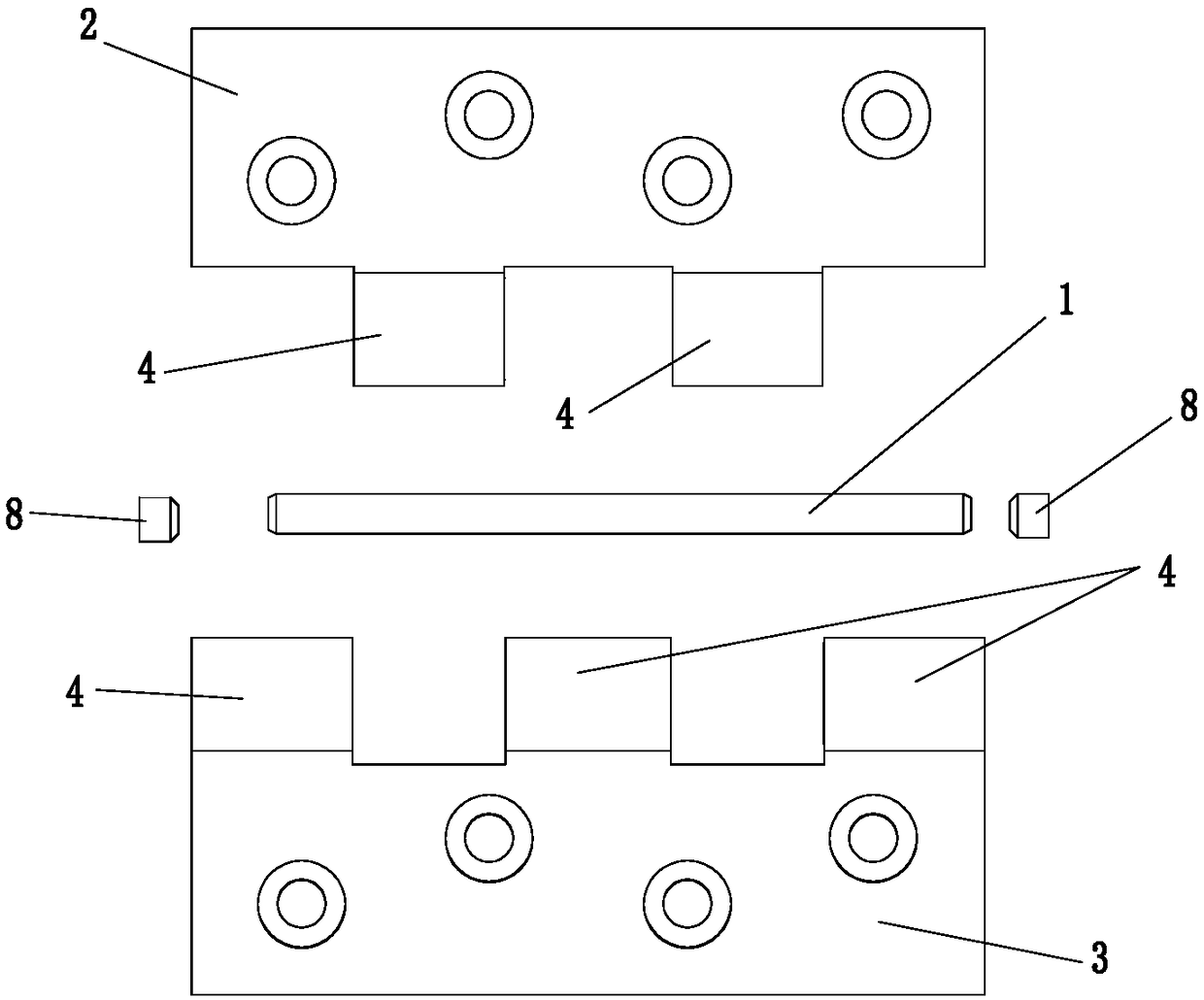

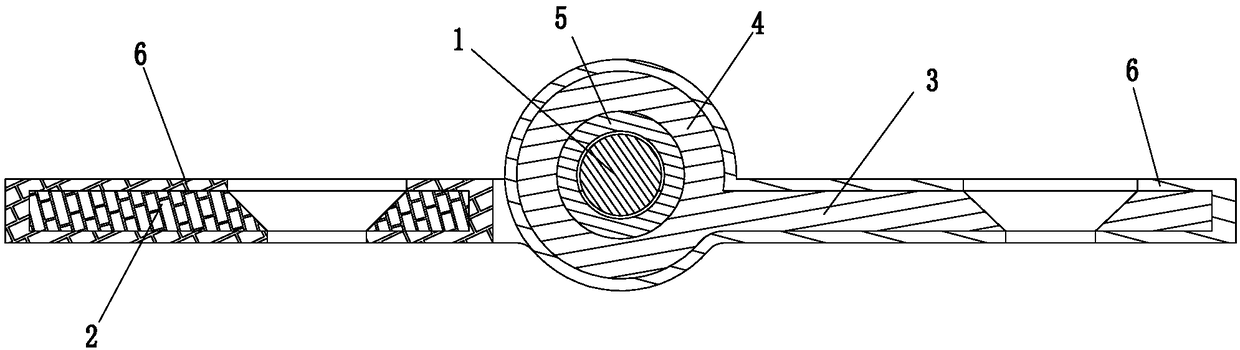

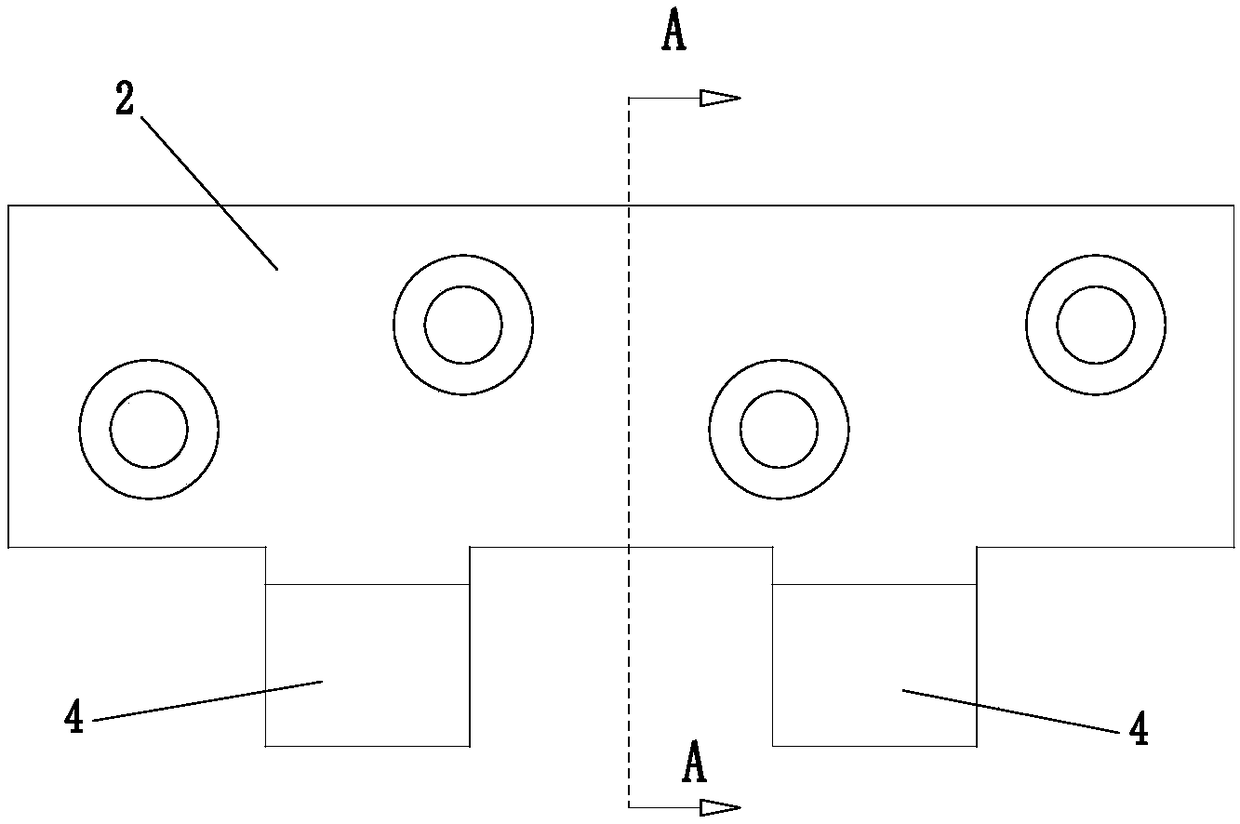

[0038] An oil-free self-lubricating hinge provided in this specific embodiment is as follows: figure 1 As shown, it includes a mandrel 1 and two blades 2, 3, and each of the blades 2, 3 has at least one bearing 4 integrally formed with the blades 2, 3, and the mandrel 1 passes through the bearing 4 In this way, the two blades 2, 3 are rotatably connected. The difference with the prior art is that, as figure 2 As shown, the inner wall of the bearing 4 is also provided with a self-lubricating inner lining layer 5 , and the mandrel 1 is actually penetrated in the self-lubricating inner lining layer 5 .

[0039] This specific embodiment accordingly provides a method for manufacturing an oil-free self-lubricating hinge, which is used to manufacture the aforementioned oil-free self-lubricating hinge. The manufacturing method includes the following steps:

[0040] S1), make the blade blank: manufacture such as with the method for stamping or casting Figures 3 to 6 Shown are blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com