A device at hatch covers

A hatch cover, closed position technology, applied in ship hatches/hatches, transportation and packaging, ship parts, etc., can solve problems such as oil leakage in pipelines, danger of slippery base surfaces for people on board, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

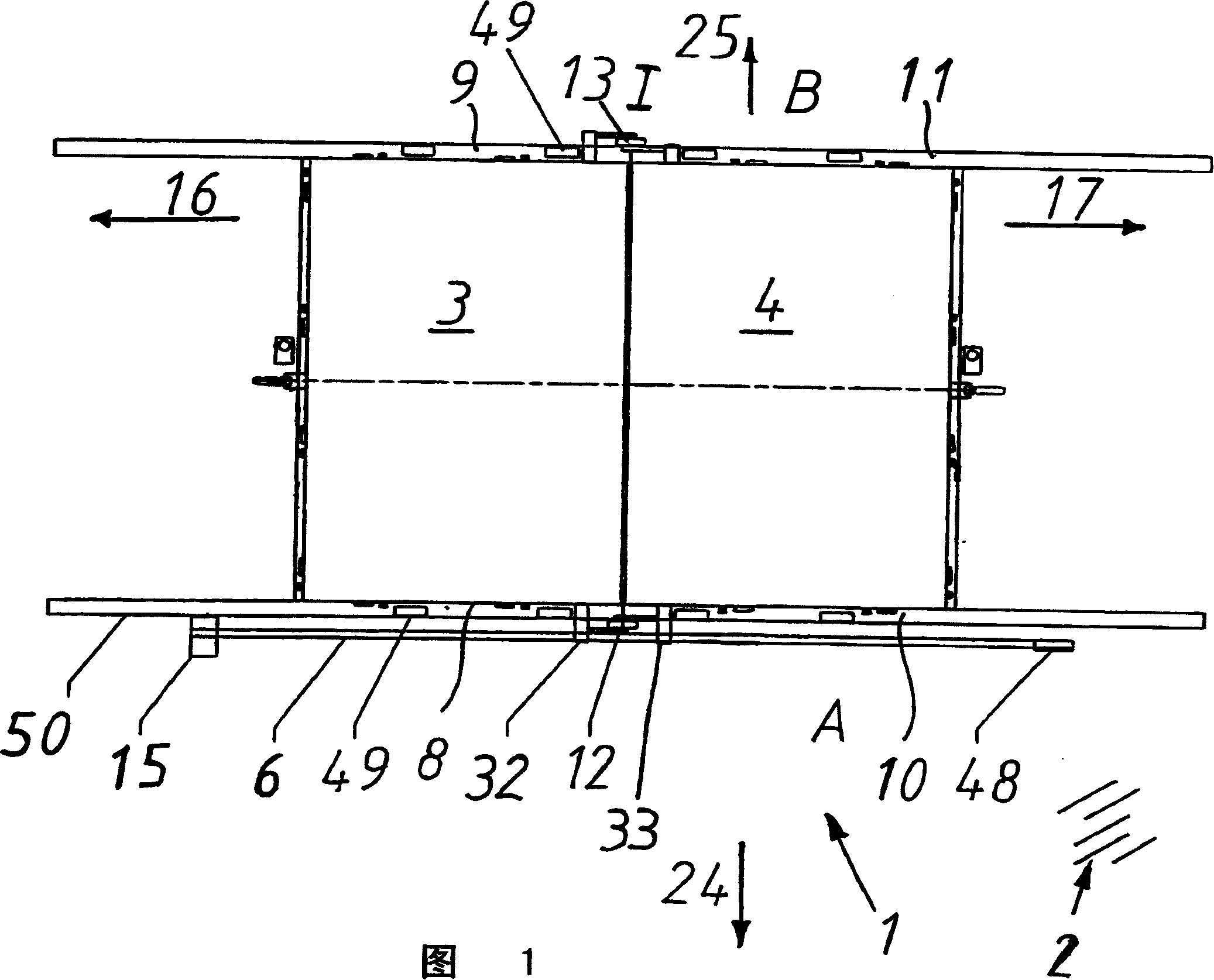

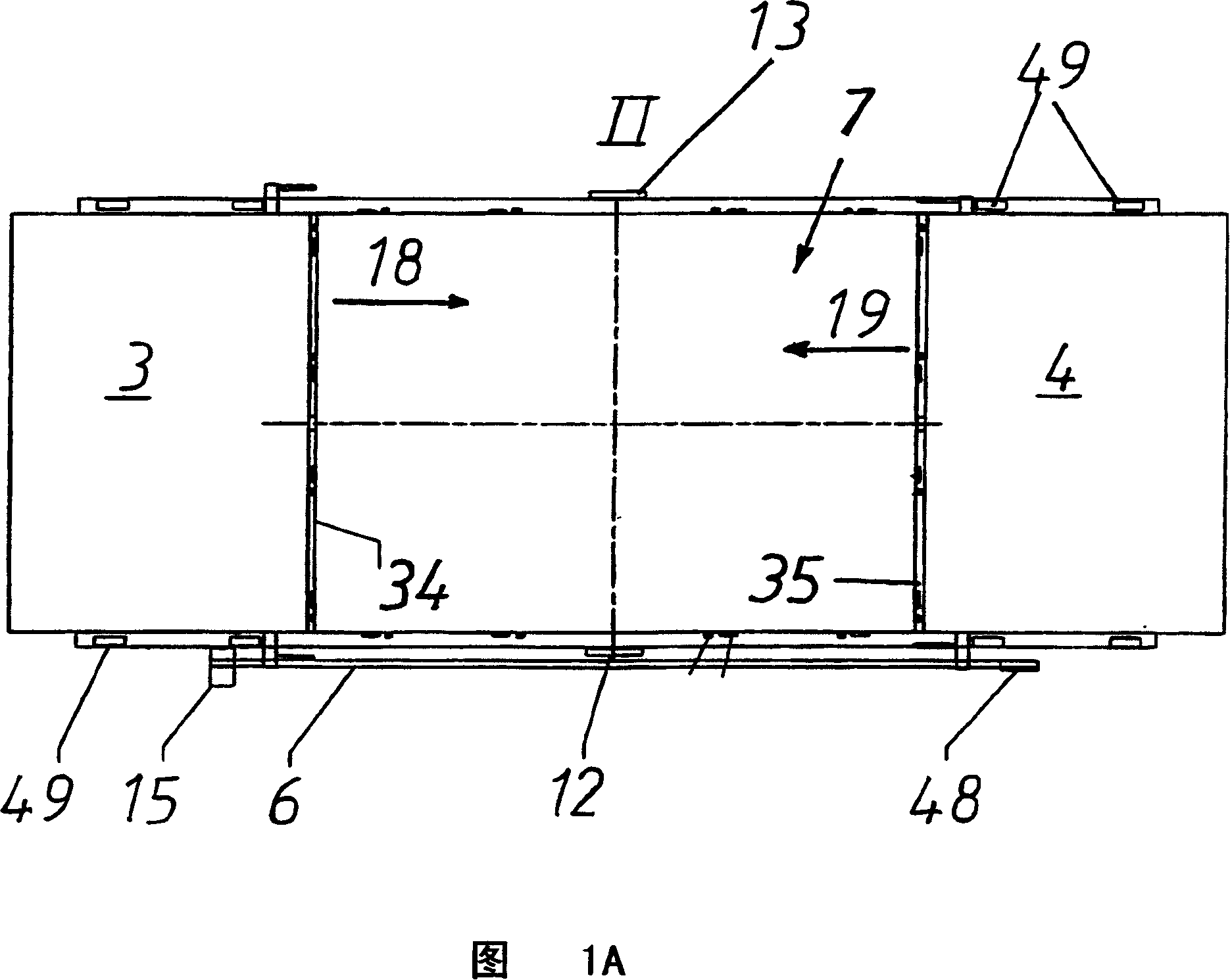

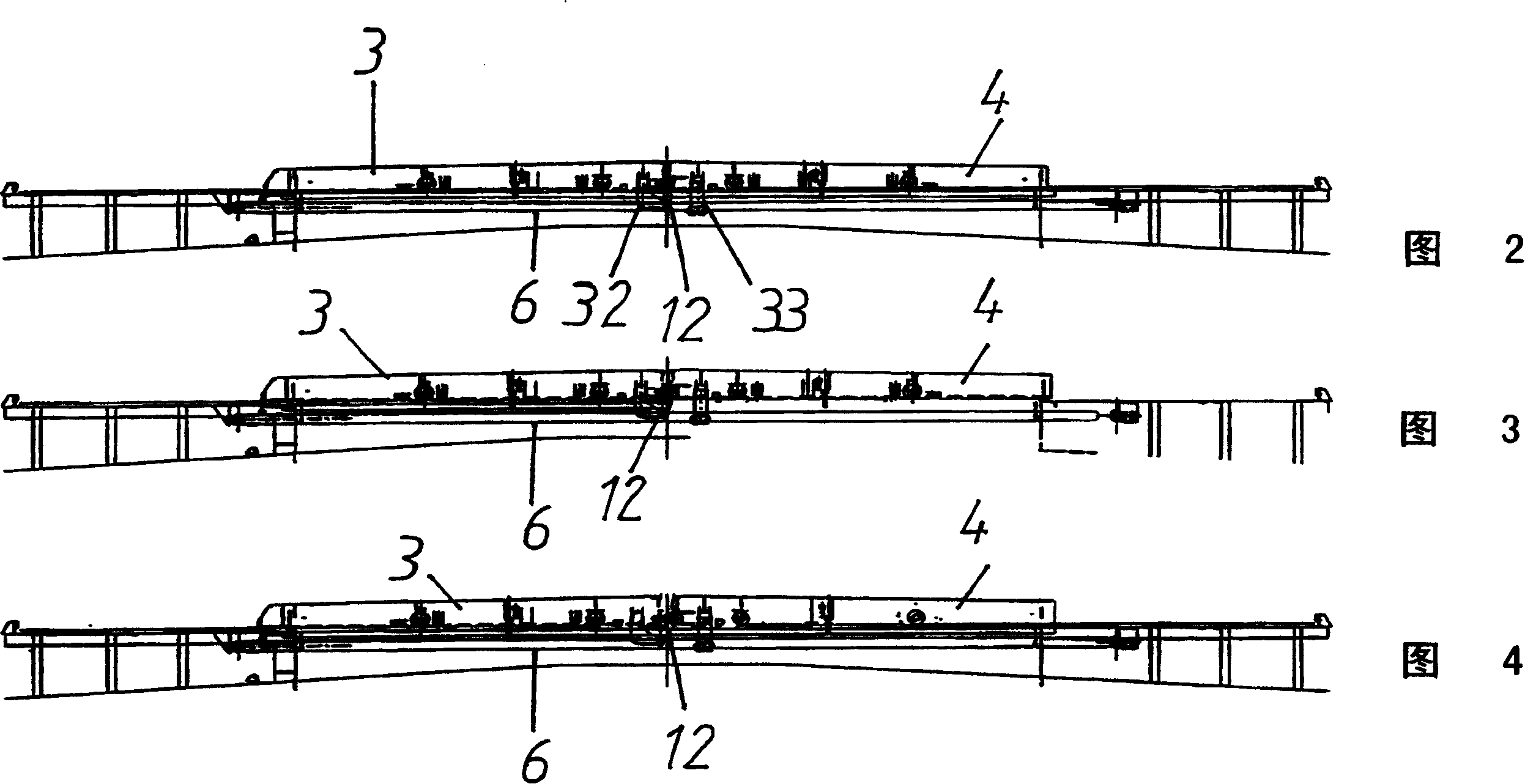

[0030] This new single lift side rolling hatch cover is designed to be a reliable and cost effective hatch cover for bulk carriers. This will apply to all aspects of hatch covers such as design, purchase, manufacture, installation and repair. These aspects affect the cost of all components involved. In design work, it is always desirable to reduce the number of parts and assemblies to be manipulated. This has been a no-compromise solution to the established standards of the equipment.

[0031] A hydraulic cylinder lifting mechanism is fitted in the middle of the longitudinal hatch coamings at the starboard (SB) and port (PS) sides of the ship. This mechanism acts on one of the panels, while a fork linkage acts on the other panel. Release and lift both panels simultaneously to a rolled position. Hydraulic oil is supplied to the hydraulic cylinders by a local small pump unit fitted near the mechanism and connected to two pipes. To reduce the number of parts and avoid electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com