Production technology of hatch coaming and hatch cover

A manufacturing process and hatch coaming technology, which is applied to the manufacturing process of hatch coamings and hatch covers, can solve the problems of difficult control of manufacturing precision, inconvenient manufacturing, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

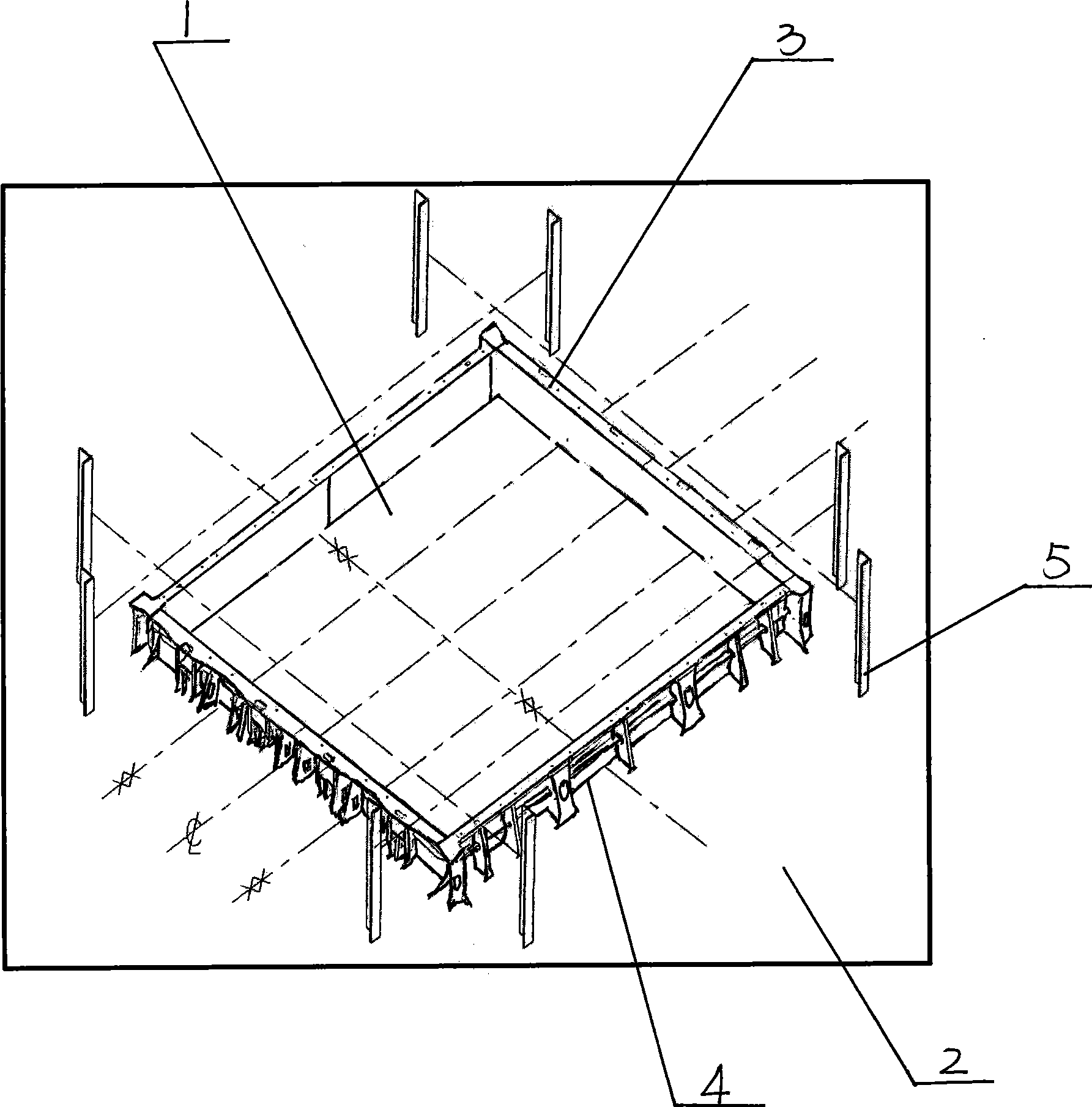

[0013] Such as figure 1 As shown, first copy the actual main deck linetype of the dock where the hatch cover 1 is located to the platform 2, and then position the positioning line above the platform 2 according to the shape and height of the hatch enclosure 3, and then place the hatch enclosures one by one. The wall 4 is positioned and welded, and the precision inspection is carried out to remove the margin; then the feet 5 at the four corners of the hatch enclosure 3 are evenly numbered and symmetrically welded.

[0014] Assembling hydraulic equipment, piping and electrics etc. on the welded hatch coaming 3, and then hoisting the hatch cover 1, installation, and commissioning, this assembly is a conventional process, and will not be repeated here.

[0015] Finally, the whole hatch coaming 3 and the hatch cover 1 that have been made are hoisted onto the dock at one time, and are fixedly connected with the dock.

specific Embodiment 2

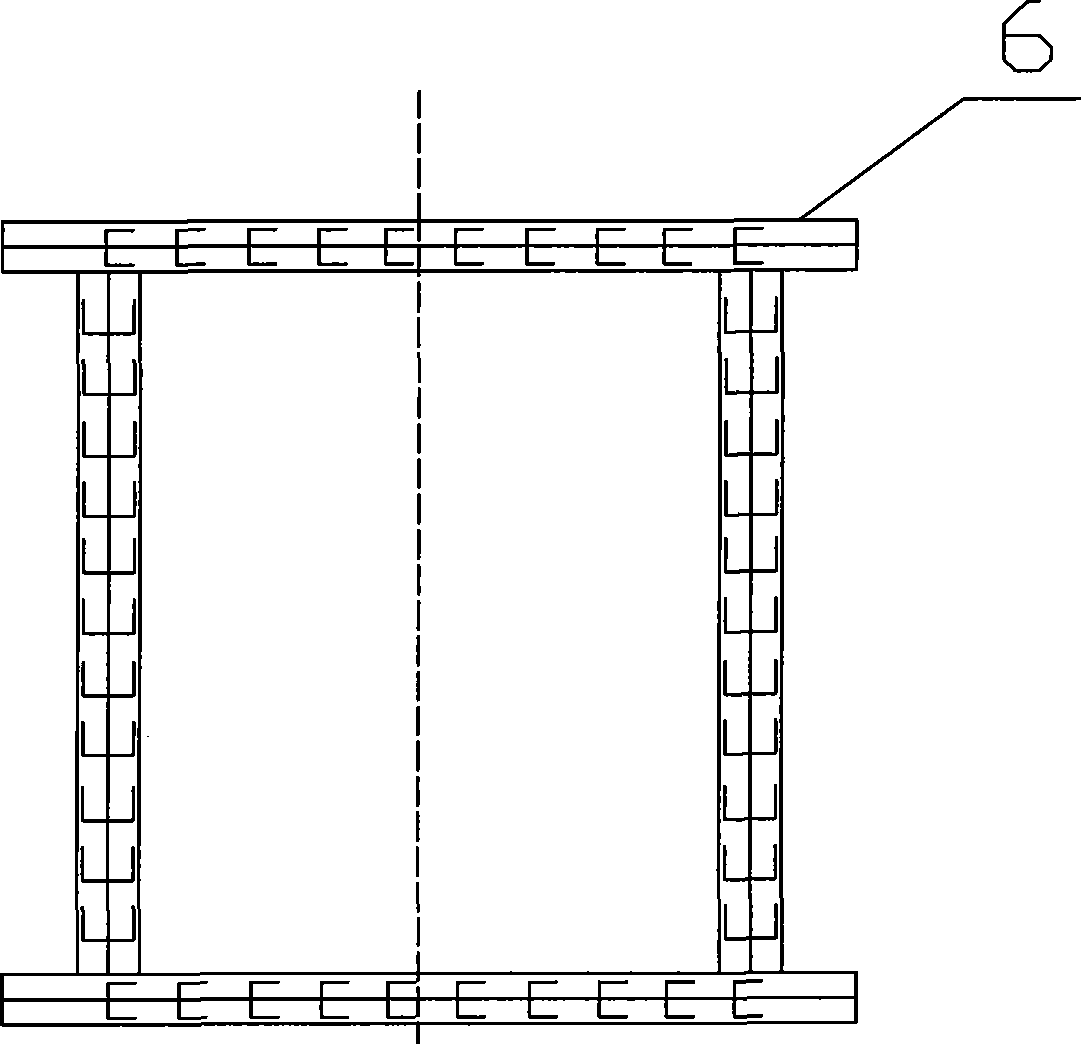

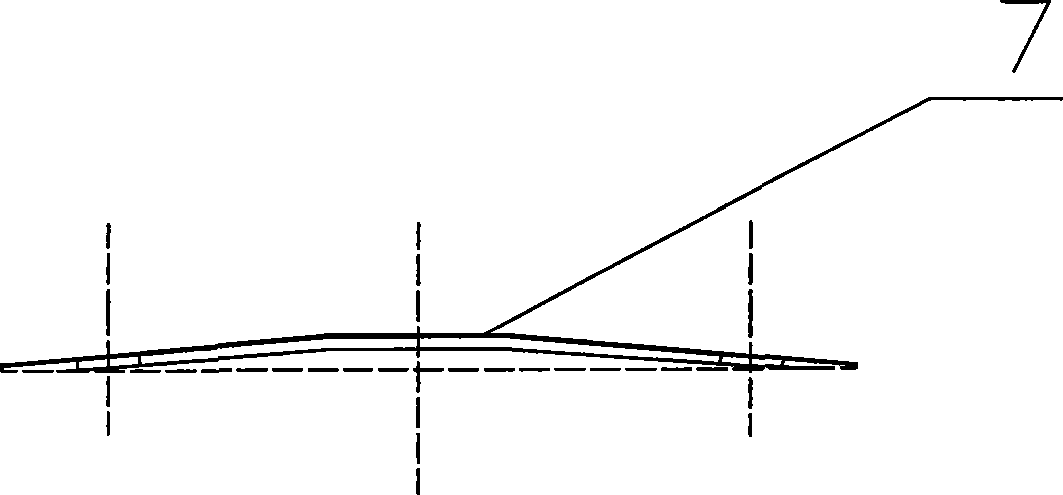

[0016] Such as figure 2 , 3 As shown, the other steps are the same as those in Example 1. In the positioning of the hatch coaming 3, tire frame 6 and tire frame beam arch 7 are made on platform 2 according to the shape of main deck and main deck beam arch. 6. It is made of C20 channel steel and supported by vertical and horizontal diagonal braces. After the tire frame 6 and the tire frame beam arch 7 are manufactured, the accuracy is tested, the margin is removed, and the hatch circumference 3 is positioned and welded on its periphery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com